Aerodyne Beechcraft Baron G58 User manual

1

2

TABLE OF CONTENTS

Additionalitemsrequired…………….

Adhesivesandbuildingsupplies…..

Optionalsuppliesandtools………….

Wingassembly…………………………….

Installingthelandinggear…………..

Fixedgearinstallation…………………

Nosegearinstallation………….........

Retractablelandinggear……………..

Mainlandinggeardoors……………..

Nosegeardoors………………………….

Empennageassembly…………………

Installingtheelectronics…………….

Wingattachment………………………..

Motorinstallation……………...........

Nitroengineinstallation………………

Nacelleinstallation………………………

Doorsandinteriorinstallation……

CGandFlyingcharacteristics………

1

1

1

2

5

5

6

6

7

8

9

11

11

13

14

14

15

16

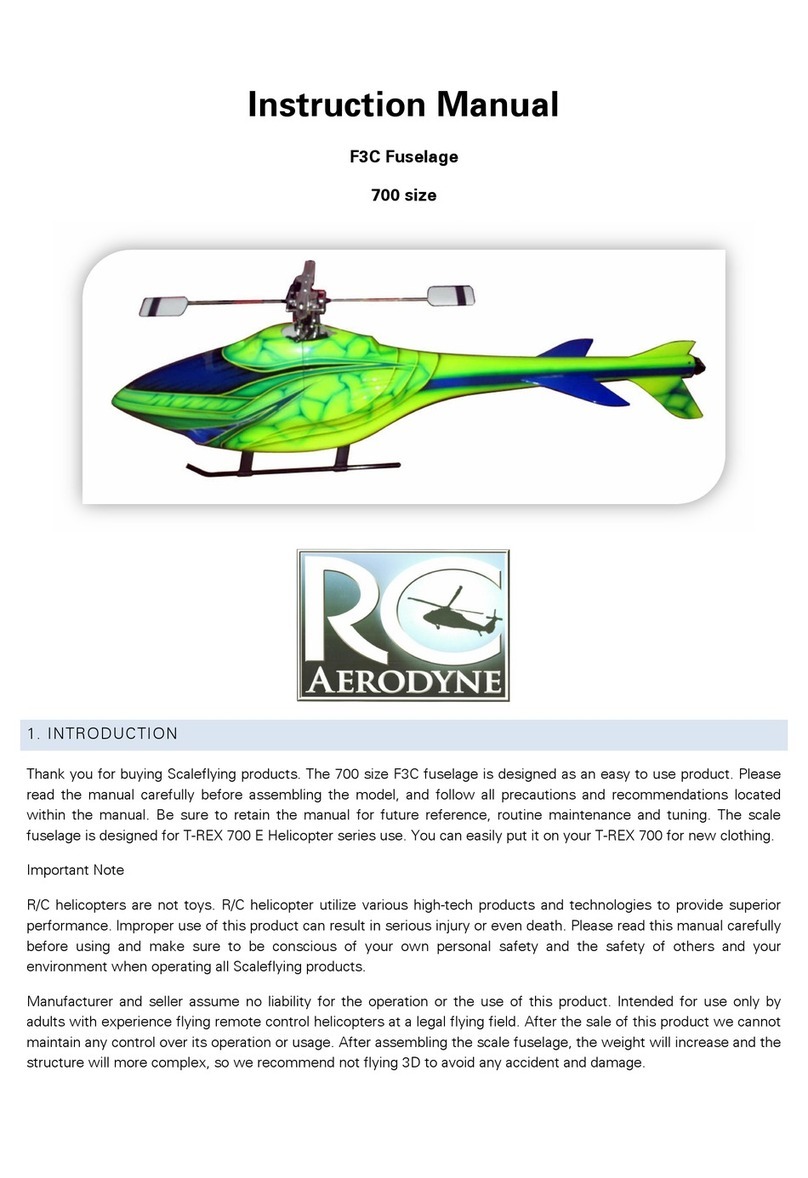

Introduction:

From all of us at RC aerodyne thank you

for your purchase of our Beechcraft G58

Baron. This is one of our finest models

that we have developed and produced.

The aircraft is made up of composite

fiber and balsa wood construction. The

ARF comes fully detailed in every

aspect and is sure to bring the owner

much joy in building and flying this

aircraft. So from all of us here at RC

aerodyne, enjoy your Beechraft G58

Baron.

Additional items required

(2) 2 ½ inch spinners

(2) 11x8 3 bladed props (or)

12x6 2 bladed props

(6) 50 oz/in servos 2-flaps, 2-ailerons

1-elevator, 1-rudder

(1) 35 oz/in servo for the retracts

(optional)

(2) 45 oz/in servos for throttle (if using

nitro engines)

(2) .32-.46 electric motors or

equivalent. Or .32-.46 nitro

engines.

(2) 60-75 amp ESC ( if using electric

motors)

(1) external BEC or receiver battery

(M) Miscellaneous servo extensions,

switches, 12ga. wire, and connectors

(2) 5 Cell 4000mah lipo batteries

Adhesives and building supplies

-1 oz bottle of Med CA

-1/2 oz bottle of Slow cure CA

-5 min epoxy

-Canopy glue

-CA accelerator

-CA applicator tips

-Hobby iron

-Rotary tool

-Marker pen

-Razor blade knife

-Petroleum jelly

3

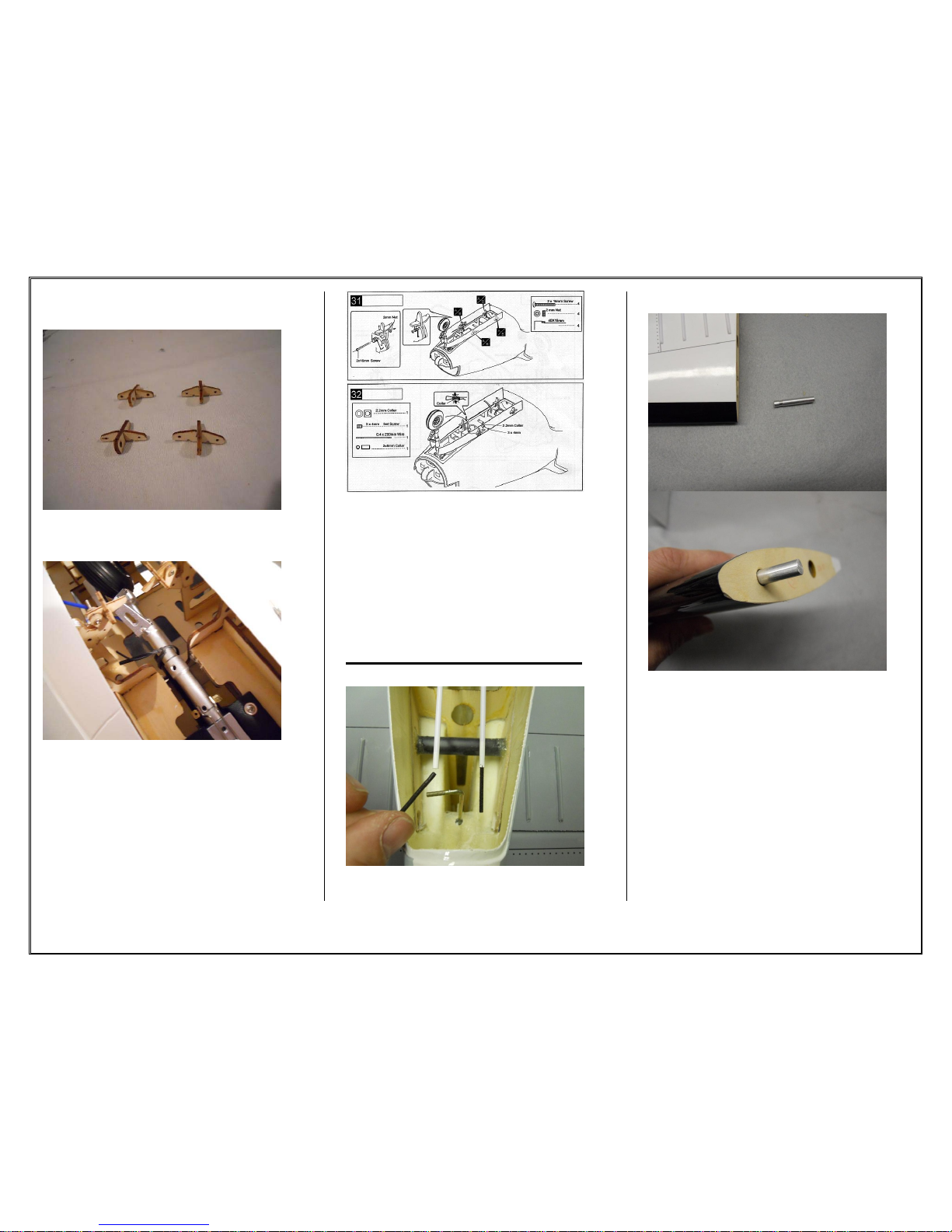

WING ASSEMBLY

1. Remove the flap from the main wing

and remove the wooden dowels and place

them aside.

2. Locate the 4 metal hinges from the parts

bag and insert them into the pre-drilled hole

in the wing.

3. Locate the aileron bell-crank from the

aircraft parts and insert the rod through

the main wing and through the holes in the

flap hinges . It may be necessary to

move the flap back and forth to get the

aileron rod to slide through. After the rod is

in place lightly pull on the hinges to ensure

that the rod has passed through the hinges.

4. Insert the flap and ensure that there is

smooth movement of the flap surface. After

you are satisfied with the placement remove

the flap and apply epoxy to the hinges and

replace the flap into the wing. After the

epoxy is dry pull lightly on the flap to

ensure proper fitting.

4

5. Cut out the covering on the top and

bottom surface of the wing as shown here.

Press down lightly on the center of the

cutout area to get a defined line to cut.

Ensure that you have a sharp razor blade to

give you a clean cut.

6. Assemble the collar as shown above and

place on the aileron bell-crank. Secure the

collar to the bell-crank from both the upper

hole with the 3x25mm screw and the bottom

hole with the 3mm set screw. Attach the

control connector to the flap control rod.

7. Detach the aileron from the wing and

remove the dowels from the hinge holes.

8. Insert the nylon pipe hinges into the

aileron. Cut 2 ridges off 4 pipe hinges for

the 2 outboard hinges on either aileron.

After satisfied with the placement of the

5

hinges remove the hinges from the aileron

and apply epoxy to the hinges and allow

drying. Check to ensure proper fitting.

9. Apply epoxy to the tip of each hinge.

Apply petroleum jelly to the pivoting part of

the hinge to allow the epoxy to move around

the hinge. Insert the aileron to the wing and

allow drying. After dry, apply light tension

to the aileron to ensure a secure fit.

10. Locate 2 out of the 4 wing guides.

Using 5 min epoxy, glue the wing guides

into place on the trailing edge of the outer

wings. Leave ½ in of the guide protruding

from the wing. Let sit and allow to dry.

11. Locate the wing locks and using 5 min

epoxy glue them into place on the outer

wings. Ensure that the cut out portion of the

wing lock is facing the bottom of the wing.

12. Glue in the 4 plastic rings into the 4

holes on the top side of the wing.

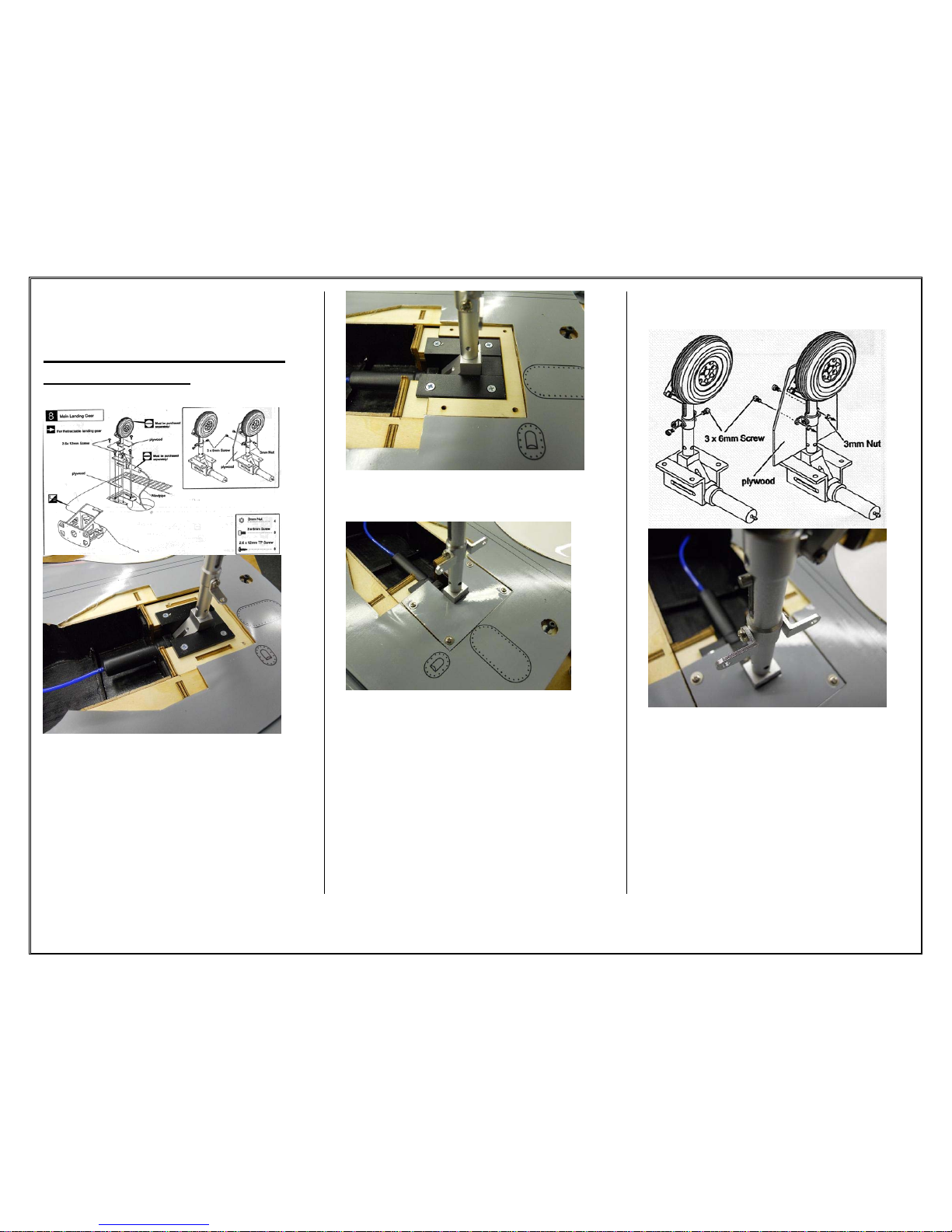

INSTALLING THE

LANDING GEAR

13. Using a razor blades cut out the

landing gear holes in the bottom of the

plane. (If using the fixed gear do not cut out

the black portion of the picture).

6

FIXED GEAR

INSTALLATION

14. Insert the main landing gear into the

landing gear blocks.

15. Epoxy the landing gear blocks into

place.

16. Locate the landing gear cover spacer

and put in place. There is no need to glue

the spacer.

17. Screw the landing gear cover in place.

NOSE GEAR INSTALLATION

18. Assemble the nose gear as shown in

the diagrams above. Epoxy the nose gear

plate to the nose gear block. Secure the

7

nose gear to the fuselage using the 4 screws

as shown above.

RETRACTABLE LANDING

INSTALLATION

19. Install the main landing gear using the

2.6x12mm screws.

20. Place the landing gear cover spacer

into place. There is no need to glue down.

21. Place the landing gear cover into place

and using 2.6x12mm screws to secure into

place.

LANDING GEAR DOORS

22. Attach the gear door mounts to the

landing gear.

8

23. Manually close the landing gear and

hold down with your hand. Place the

landing gear door in place on the wing and

make a mark on the landing gear for where

the door needs to mount.

24. Place the landing gear door in the

proper place and mark the holes for the door

mounts. Drill a hole and place the bolt and

nut in place to mount the door.

25. Route the airline through the punch-

out hole and through the access holes in the

wing.

26. Attach the airline “T” to the 2 airlines

from each landing gear. Ensure that there is

no “kinking” of the airline at the access

holes. Leave plenty of slack in the hose.

27. Install the nose gear into place using

the 2.6x12mm screws. Attach the hose line

and route the line along the outer side of the

fuselage. Install the rudder servo and glue

the bracket into place using epoxy.

9

NOSE GEAR DOORS

28. Assemble the nose gear door hinges

using CA.

29. Use a twist tie to lock the nose landing

gear in the up position to assemble the gear

doors.

30. Attach the landing gear doors as

shown using the hinges provided. Use CA

to tac glue the hinges to the doors. Open

and close the doors to ensure proper fit and

function. After satisfied glue the hinges into

place with epoxy. Use the wire and collar as

shown to close the landing gear doors when

the gear is up.

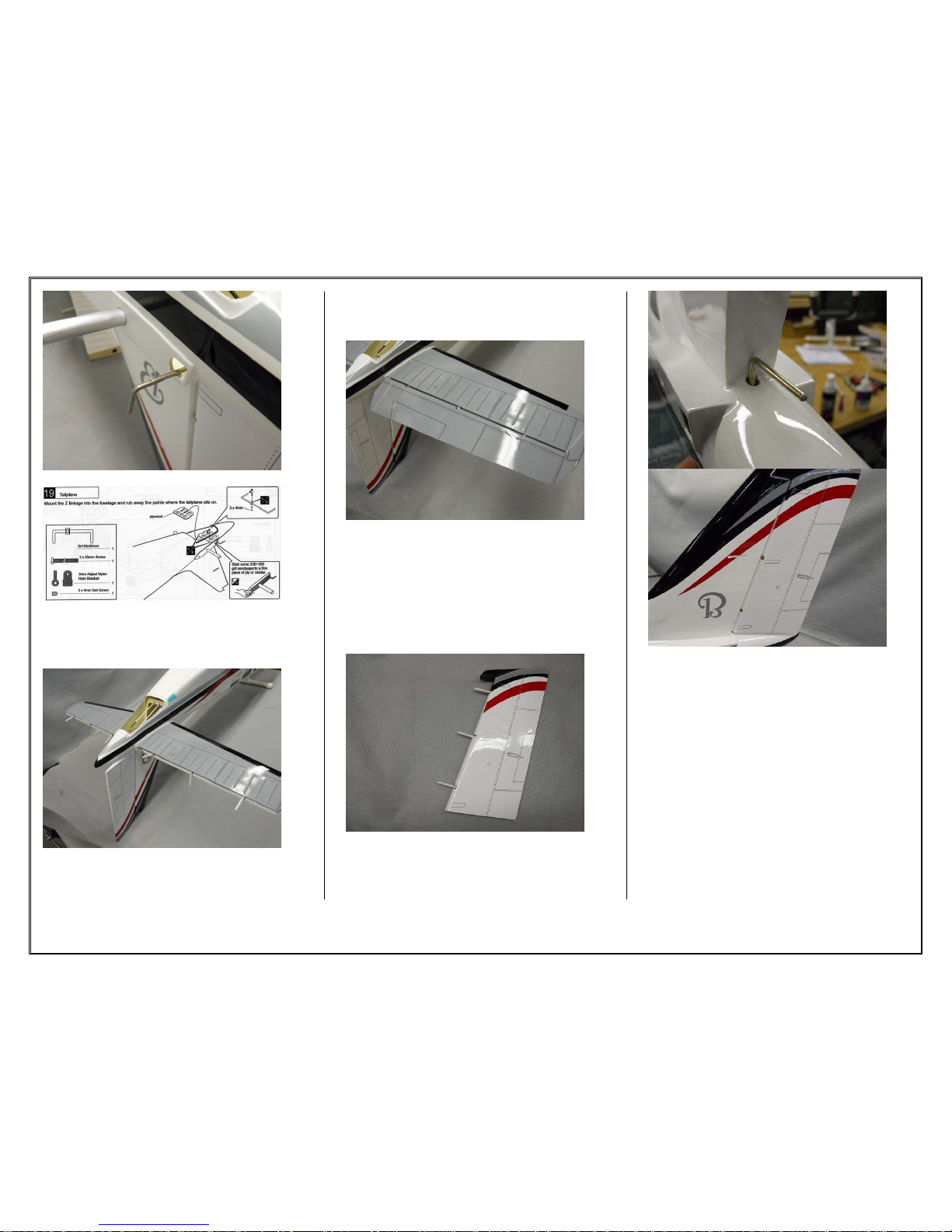

EMPANNAGE ASSEMBLY

31. Insert the threaded rod into each of the

control rods for the tail section.

32. Locate the final 2 wing guides and

glue them into place on the horizontal

stabilizers. Use epoxy to glue into place for

a secure bond.

10

33. Insert the elevator control connector

into place along with the horizontal

stabilizer pipe.

34. Epoxy the horizontal stabilizers and

the elevator hinges into place. Use tape to

ensure the gap between the horizontal

stabilizer and fuselage is tight. Let the

epoxy dry before moving on to the next step.

35. Glue the elevators into place using

epoxy and ensure that there is smooth

movement of the elevator before the glue

cures. Use petroleum jelly on the pivoting

part of the hinge to ensure you don’t lock up

the hinge.

36. Insert the rudder control horn into the

slot in the fuselage. Glue the rudder hinges

into the rudder. Use epoxy to glue the

hinges to the rudder and the to the vertical

stabilizer.

11

37. Assemble the ball link and quick

connect to the control rods. Assemble the

control link to the elevator and rudder

control rods.

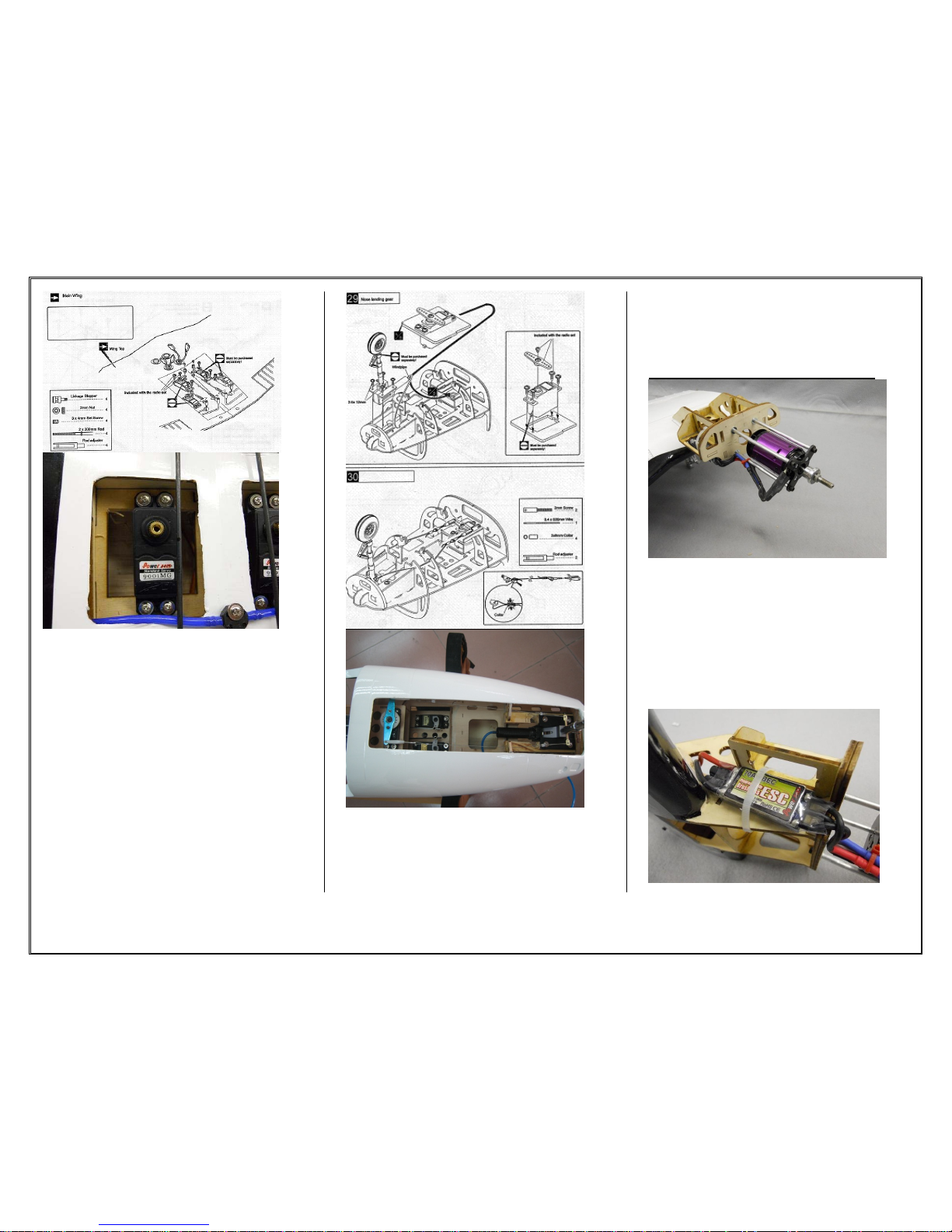

WING ATTACHMENT

38. Center the wing onto the fuselage and

mark the 2 holes in the leading edge of the

wing. Using a ¼ inch drill bit drill the holes

out and place 2 ¼ inch dowels into the

holes. Leave ½ inch of the dowel protruding

from the wing.

INSTALLING THE

ELECTRONICS

39. Install the rudder and elevator servo

into the servo bay on the fuselage. Mount

with the servo head towards the front of the

fuselage.

40. Disconnect the control links from the

control horns and pull out the push rods out

from their sleeves. Attach a threaded rod

into the nylon pushrod and cut to proper

length. Insert the rod back into place and

attach to the servo horn.

12

41. Insert the flap and aileron servos into

the servo bay on the wing. Use the threaded

pushrods and link the servos to their control

horns. Mark and cut the control rods to the

proper length needed.

42. Install the nose gear steering servo and

slide into servo bay. Glue the servo tray into

place using epoxy and let dry. Use the wire

and the connectors supplied to attach the

servo to the nose gear. Attach the wire to

the nose gear and make sure that the wire is

tight. When satisfies crimp the wire tight

and cut off the excess.

MOTOR INSTALLATION

43. Cut and tap 8 aluminum 3/16 pipes and

tap with a 6/32 tap. For a Hacker type

motor the pipes are 98mm long but the

distance may vary depending on the motors

used. Place the motor mount against the fire

wall and center the motor mount on the hole.

Mark and drill all 4 holes for each side. Bolt

the pipes into place and install the motor.

13

44. Install the ESC on the side of the

firewall and route the wires to the center of

the wing.

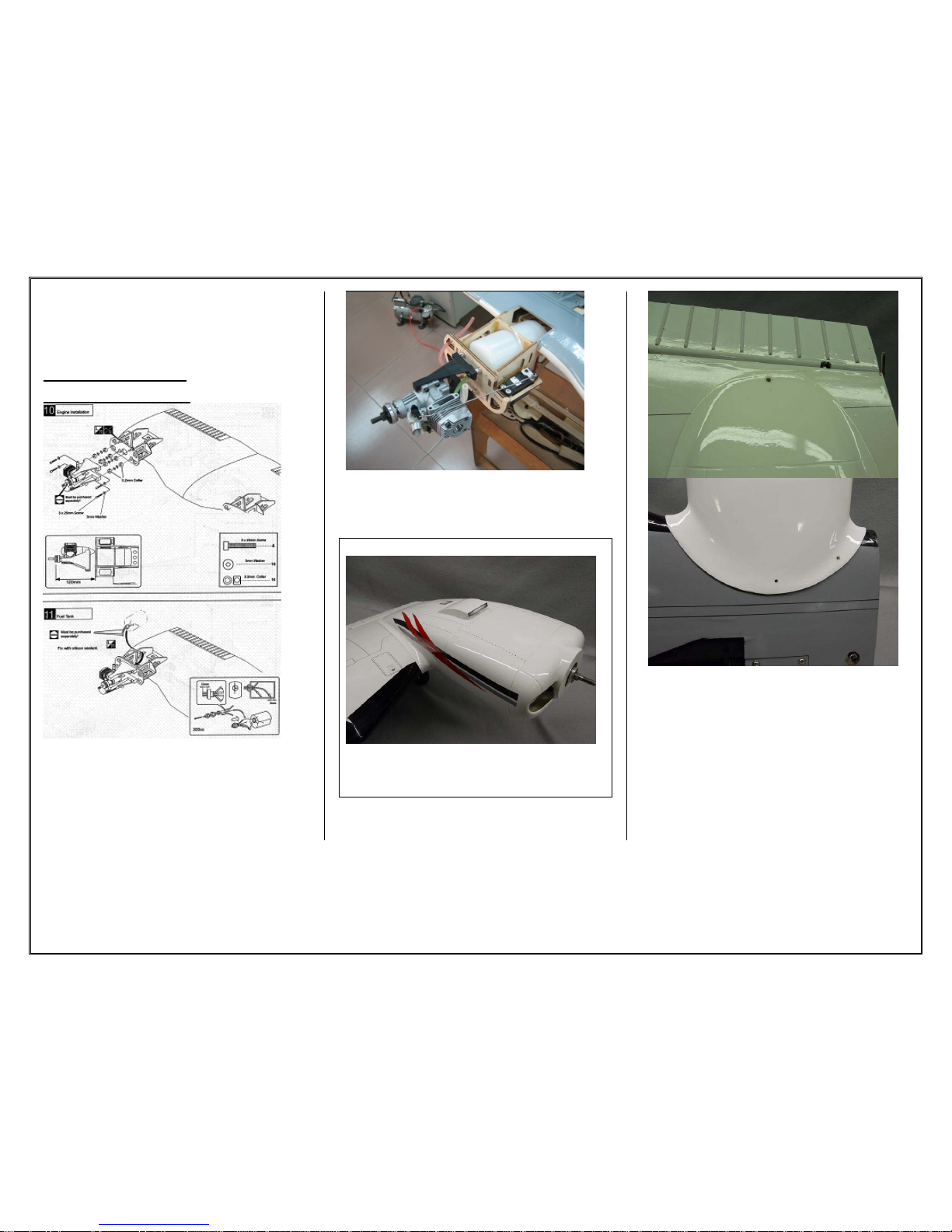

NITRO ENGINE

INSTALLATION

45. Install the engine mounts using the

proper spacers for your motor. You may

need to trial fit the engine mount to

determine the proper spacing. Install the

fuel tank and route all necessary fuel lines

into place on the engines.

46. Install the throttle servo and route the

servo wire toward the center of the wing.

NACELLE INSTALLATION

47. Install the nacelles on each wing.

Ensure that the motor shaft is centered on

the nacelle center hole.

48. Drill one hole on the top of the nacelle

and 2 on the bottom and use the 2.6x12mm

wood screws to mount the nacelle to the

wing.

14

49. Drill 1 hole on either side of the

nacelle cover and using the 2.6x12mm

screws secure into place.

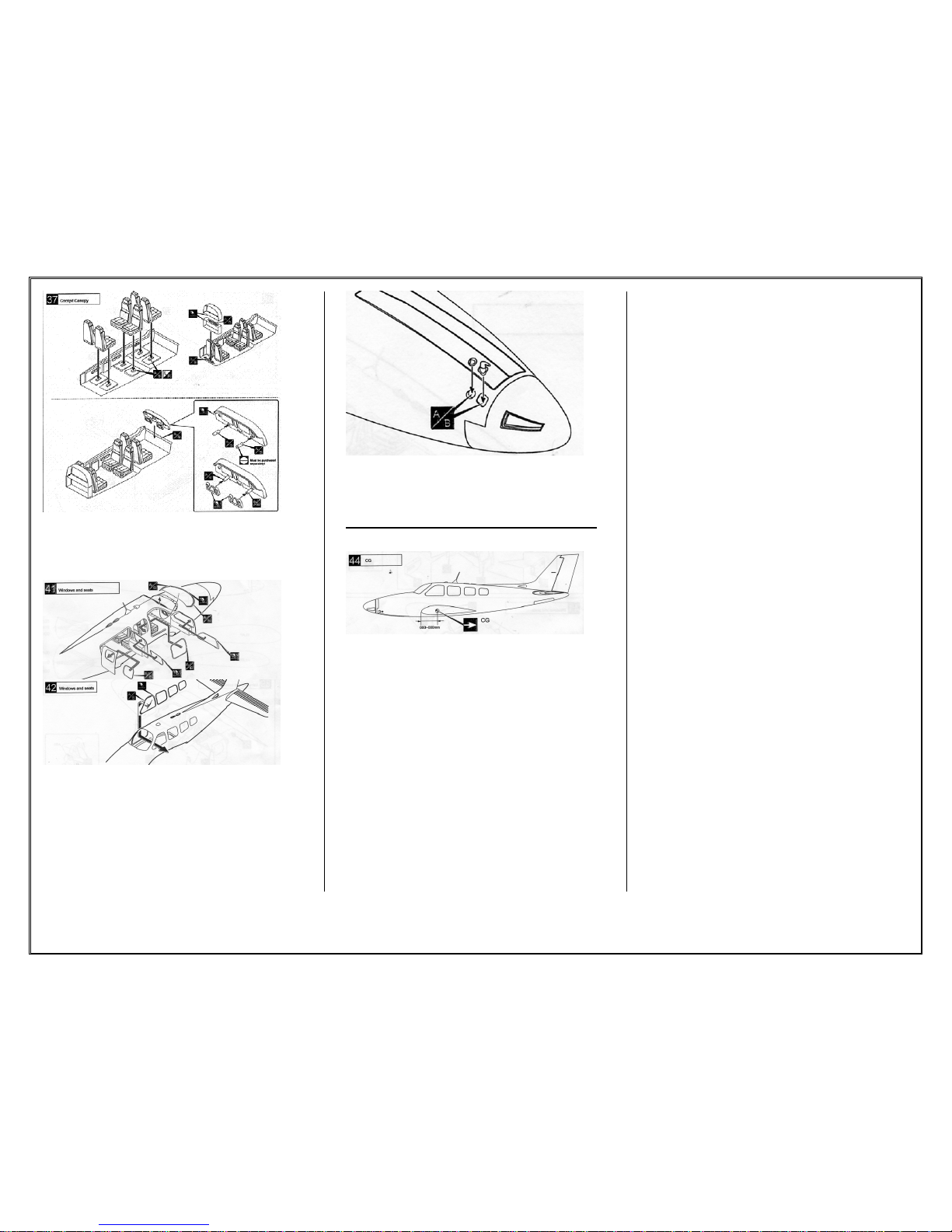

DOORS AND INTERIOR

INSTALLATION

50. Install the upper and lower interior kit.

Assemble the seats and paint as desired.

51. Assemble the hinges for the doors and

install the rear and front doors.

15

52. Install the interior pieces to the

cockpit. Paint as desired. Use med CA for

assembly.

53. Assemble the windows into place and

glue in using canopy glue.

54. Install the final scale details to the

fuselage.

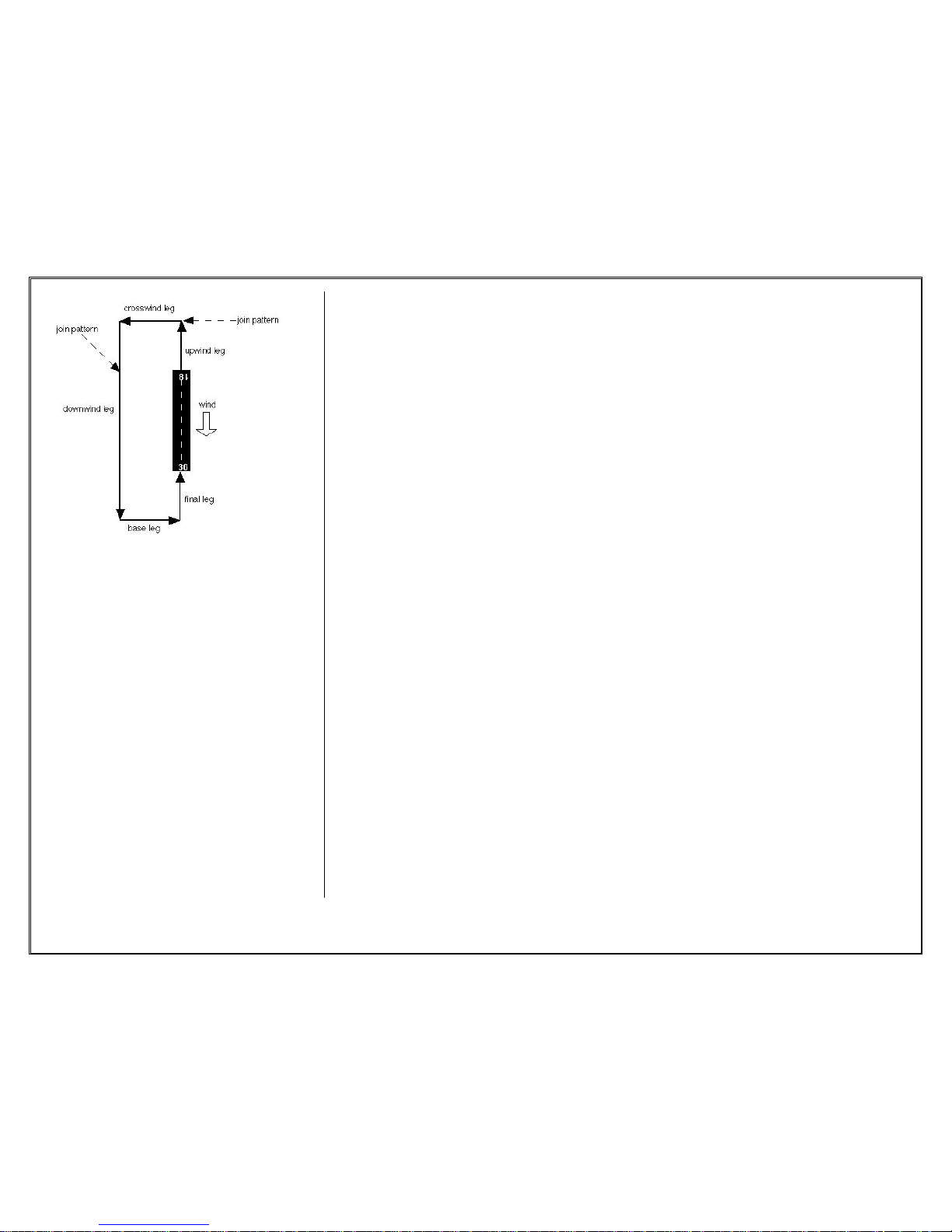

CG and Flying characteristics

The CG location is 3 .25 inch from the

leading edge of the wing.

Wind direction

Pilots prefer to take off and land facing

into the wind. This has the effect of

reducing aircraft speed over ground and

hence reducing the distance required to

perform either maneuver.

Runway orientation is determined from

historical data of the prevailing winds in

the area. This is especially important for

single-runway airports that don't have

the option of a second runway pointed in

an alternative direction. Almost all

runways are reversible, and aircraft use

whichever runway in whichever

direction is best suited to the wind. In

light and variable wind conditions, the

direction of the runway in use might

change several times during the day.

Takeoff:

On takeoff allow the plane track straight

down the runway and get the speed up

on the airplane. The airplane will almost

lift itself off the runway. If not apply a

small amount of up elevator and climb

out at a steady shallow angle. Do not

force the plane up if it is not ready.

Make sure you have the proper length

runway for take-off.

Flying:

The plane is very stable throughout

flight. All throughout slow and fast

flight the plane remains in positive

control and is very easy to handle.

16

Landing:

It is very important to always have

power thru the entire landing procedure.

NEVER CUT THE THROTTLE ON

LANDING!!

This is typical for twins. They do not fly

well with power shut off, especially on

final approach. If you are unfamiliar

with flying twins, they will loose air

speed quickly without proper throttle

management.

* Tip:

If landing is not your strong point, try

thinking of a low pass. For beginners,

landing such a large plane can be a bit

intimidating at first.

After take-off quickly trim the plane,

and immediately set up for

some approaches. Get a feel for how

much room on final you need to give

yourself. Make some low and slow

passes. When landing always keep

power on. Think of your landing as just

another low and slow pass.

If you are unfamiliar with flying a

typical pattern, please refer to diagram

above. This will help with your

approaches.

When turning base to final, it is very hard to

see the speed of your aircraft due to the

orientation of your location and

the position the aircraft is pointed in. Its

critical to make sure you have enough

speed on final until you are able to see

the aircraft at a better angle.

These are the recommended control surface

throws:

High Rate / Low Rate

ELEVATOR

3/4" up 1/2" up

3/4" down 1/2" down

RUDDER

1-1/4" right 3/4" right

1" left 1/2" left

AILERONS:

3/4" up 1/2" up

1/2" down 1/4" down

FLAPS: 1-1/4" down

Table of contents

Other Aerodyne Toy manuals