Aeromax KHP0041 Manual

Air Source Heat Pump

Installation Manual

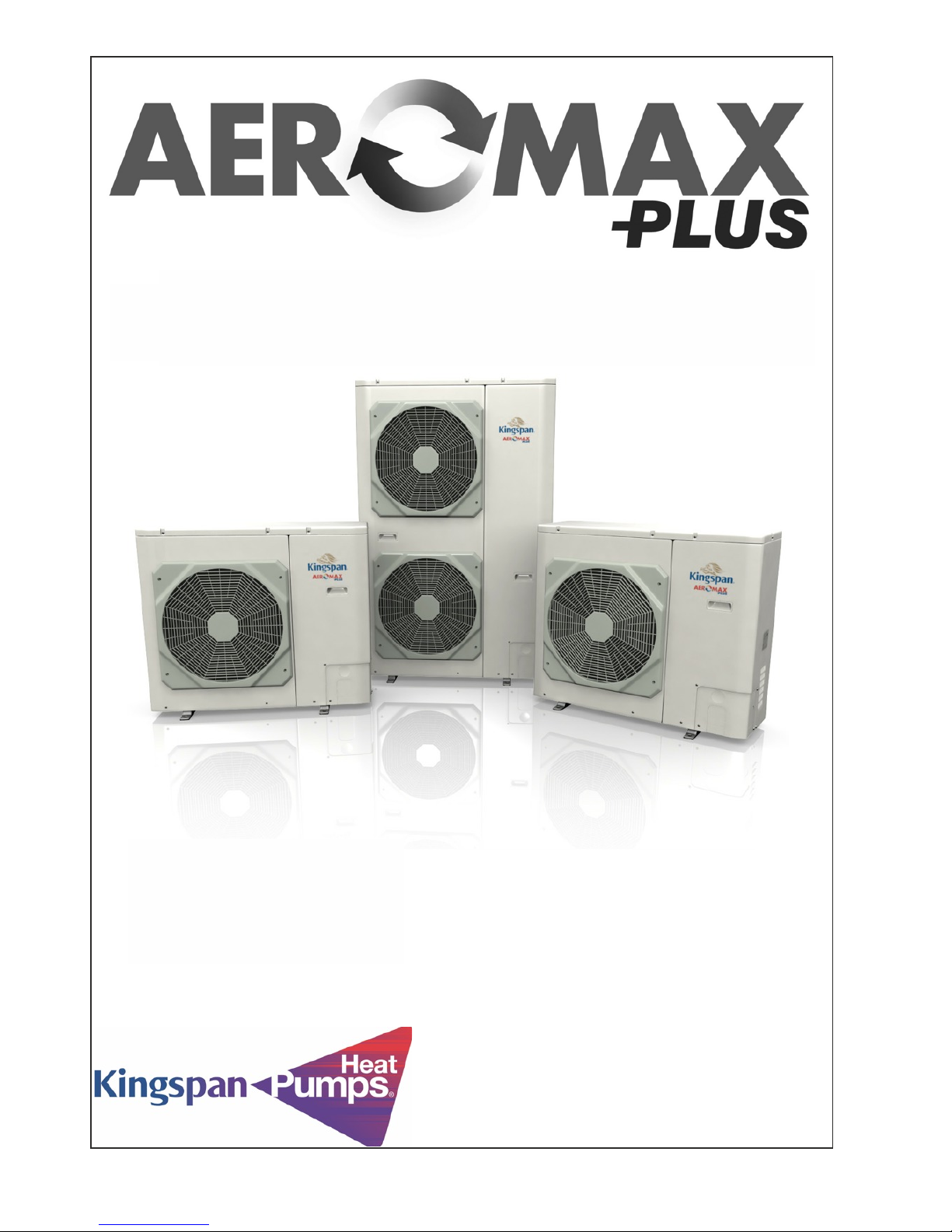

Model numers:

KHP0038: 6kw Heat Pump

KHP0039: 8kw Heat Pump

KHP0040: 12kw Heat Pump

Model numbers:

KHP0041: 4kW Heat Pump

KHP0038: 6kW Heat Pump

KHP0039: 8kW Heat Pump

KHP0040: 12kW Heat Pump

KHP0042: 15kW Heat Pump

A9317D

Air Source heat Pump

Installation and Maintenance Manual

2

2

3

SITING THE UNIT

WATER CONNECTIONS

ELECTRICAL CONNECTIONS

CONTROL WIRING (OPTIONAL)

POWER WIRING

FLUSHING WATER AND AIR

CHECKING FOR WATER LEAKS

CONFIGURING & CHECKING THE SYSTEM

Code Description

KHP0041 AEROMAX PLUS 4KW

KHP0038 AEROMAX PLUS 6KW

KHP0039 AEROMAX PLUS 8KW

KHP0040 AEROMAX PLUS 12KW

KHP0042 AEROMAX PLUS 15KW

INSTALLATION

Air / Water Cycle Heat Pump

Contents Page

R-410A - General info 4

Safety procedures 6

Dimensions and clearances 8

Installation & Technical data 10

Water connections 12

Electrical connections 20

Connection ofAuxiliary Accessories 22

System test 24

Unit protection devices 26

Additional System Diagrams 29

Installation Pack 36

Optional Installation Accessories 41

7day hot water programmer 43

Programmable room stat 55

Spare Part List 71

Rating Tables 75

Maintenance. 80

3

4

Introduction

The information in this manual is to provide general

assistance in the selection ofequipment. The

responsibility for the specification ofthe equipment must

however remain that ofthe installer and any consultants

or designers concerned with the installation, specification

or design.

Any water distribution and central heating installation

must comply with the relevant recommendation ofthe

current version ofthe Regulations and British Standards

listed below:

Building Regulations

I.E.E. Requirements for Electrical Installations (BS7671)

Water Regulations Manual Handling Operations

Regulations

British Standards BS6798, BS5449, BS5546,

BS5440:1, BS5440:2, CP331:3, BS6700, BS7593 and

BS7671. Health and Safety Document No 635.

When installing unvented hot water systems section G3 of

the Building Regulations should be adhered to. An

annual inspection would also be required to ensure safe,

long term operation.

Please note: Kingspan Renewables do not accept any

responsibility for matters ofspecification, design or

selection or for the effectiveness ofan installation

containing one ofour products unless we have been

specifically requested to do so.

Important Note - Included in the Aeromax Plus

introduction pack is the Kingspan Renewables 2-year

extended warranty registration card. Please use this card

to register within 30 days of commissioning/occupation if

new build, and ensure the homeowner benefits from the

extended warranty. This needs to be completed by both

the Approved Installer and the current homeowner (or a

signature ofdeveloper is required ifnew build). The

registration card is free post and is logged by our warranty

department.

In the unlikely event of failure ofthe Aeromax Plus heat

pump, return ofthe card ensures that the homeowner’s

warranty claim is dealt with efficiently.

All goods are sold subject to our Conditions ofSale (see

Web site for details).

• This heat pump adopts the new HFC refrigerant

(R410A) which does not destroy ozone layer.

• R-410A refrigerant operates at 50%-70% higher

pressures than R-22. Be sure that servicing equipment

and replacement components are designed to operate

with R-410A.

• R-410A refrigerant cylinders have a dip tube which

allows liquid to flow out with the cylinder in a vertical

position with the valve at the top.

• R-410A systems should be charged with liquid

refrigerant. Use a commercial type metering device in

the manifold hose in order to vaporize the liquid

refrigerant before it enters in the unit.

• As for other HFC, R-410A refrigerant is only

compatible with oils recommended by the compressor

manufacturer.

R-410A - General info

• A vacuum pump is not enough to remove moisture

from oil.

• Oils absorb moisture rapidly. Do not expose oil to

atmosphere.

• Never open system to atmosphere while it is under

vacuum.

• When the system must be opened for service, break

vacuum with dry nitrogen and replace filter driers.

• Do not vent R-410A into the atmosphere.

Use this unit only for factory approved applications.

The capacity and unit code are stated on the nameplate

data.

CAUTION:

• Do not leave the heat pump casing open to atmosphere any

longer than the minimum required for installation.

• Oil in the compressor is extremely susceptible to moisture

absorption.

• The maximum residual quantity of oil used for tubing is 40

mg/10m.

5

Unit protection devices

Check List

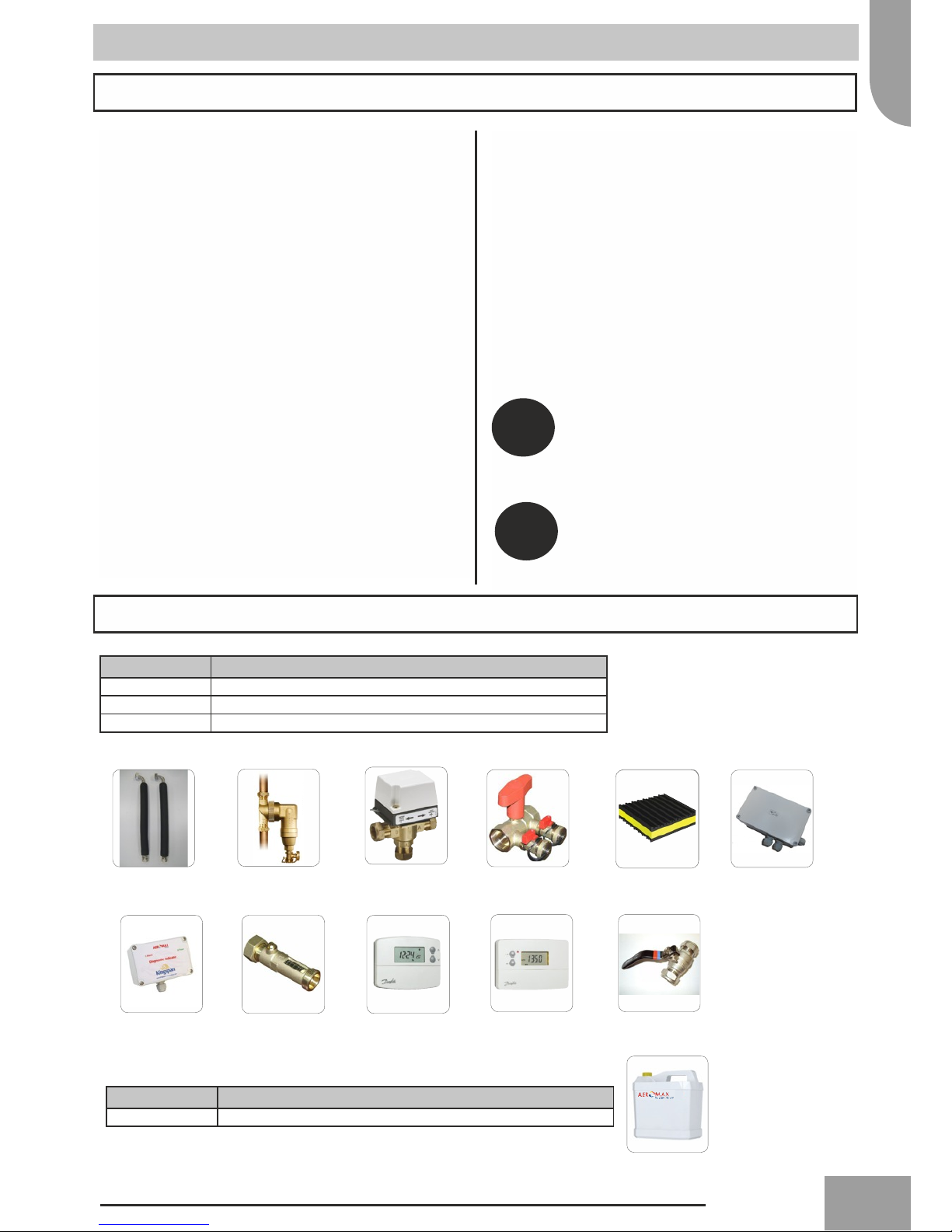

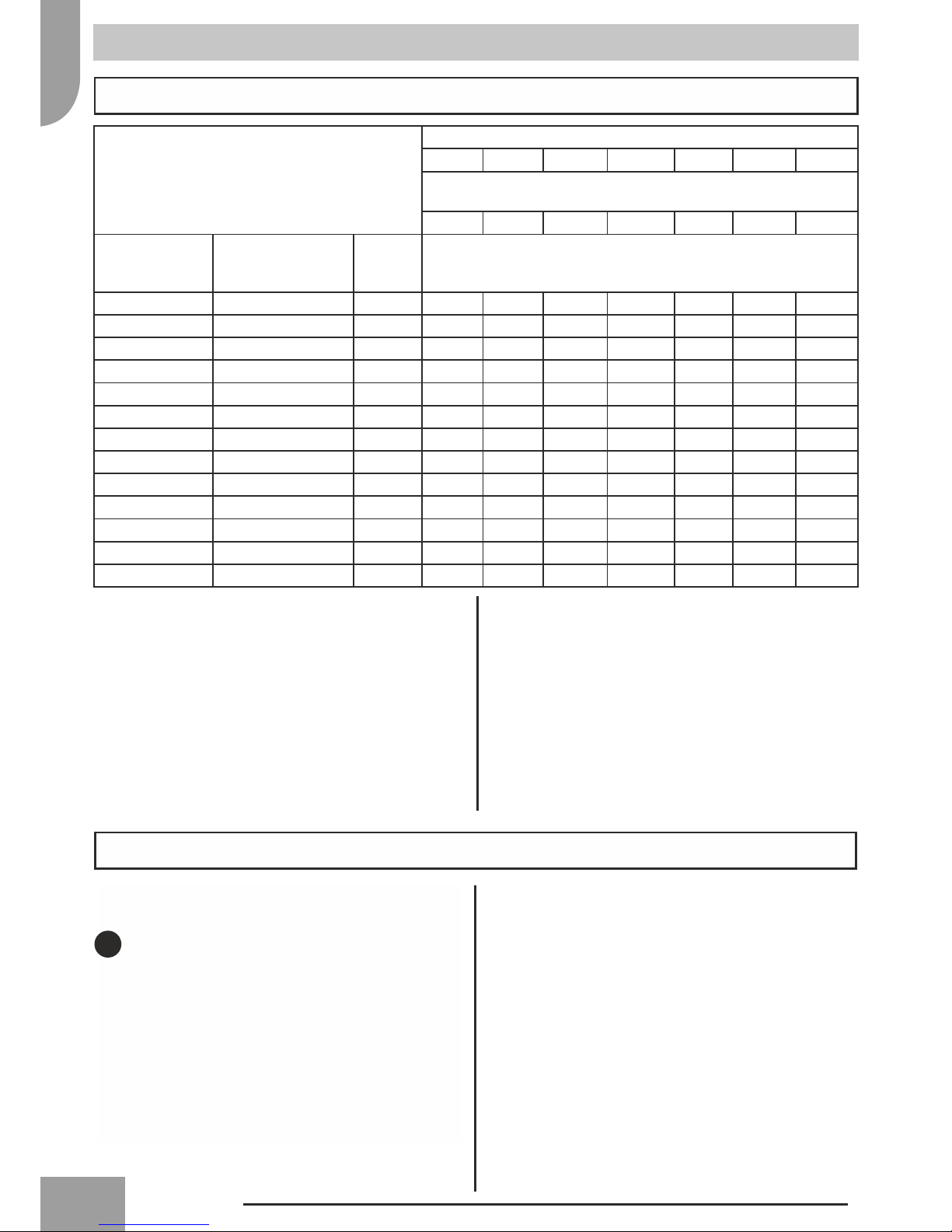

The following items are required for the installation ofthe Aeromax Plus Air Source Heat Pump

Product Code Description

KHP0029 4kW, 6kW & 8kW Installation Pack

KHP0030 12kW Installation Pack

KHP0026 15kW Installation Pack

Pack Contents

2 x 750mm flexible

hoses including 90°

elbow, pre-insulated.

W Plan diverter valve

(heat pump specific) Anti vibration padsFlush & fill ports

(except 15kW)

Diagnostic indicator 2x Full bore isolating

valve with lever arm

System Antifreeze / Inhibitor - Clear

Product Code Description

KHP0023 1 x 25 litre system antifreeze inhibitor - Clear

Introduction

The following check list has been prepared to assist you in

understanding the differences from other types ofheating

systems you may have installed and help to understand

and comply with all ofthe technical details contained

within this document to ensure a successful installation.

System cleaning and Water Characteristics

• In the case ofa new installation, or cleaning the circuit,

it is necessary to perform a preventive cleaning ofthe

system. In order to guarantee the good operation of the

product, each time you clean the system, replace the

water or add glycol, check that the liquid appears clear,

without visible impurities and that the hardness is less

than 20°f

• To help protect the heat pump from any heating system

contamination; the system filter should be fitted

internally on the return pipe.

Recommended system cleansers and inhibitors are listed

below.

Fernox F3 System Cleanser

Fernox HP-15c combined antifreeze and inhibitor

Sentinel

All external connecting pipe work should be suitably

insulated using Armaflex or similar.

Radiator System Circuit

• As the Aeromax Plus generates lower temperatures

than a conventional boiler the radiators should have

been designed to suit the lower mean temperature.

• The basic controls within the standard installers pack

and the parameters on the heat pump are optimised

for use on radiator systems.

Retrofit Situations

• The heat exchanger should be protected from

particulate contaminates in the water circuit. The

existing radiator circuit must be chemically cleaned

and thoroughly flushed before installation when fitting

in a retrofit situation.

Installation Pack

1 x 25 litre clear - system

antifreeze inhibitor

25L Heat Pump

Anti Freeze

Concentrate

For systems using under floor heating, boiler

back up or clients wishing to alter the

operating parameters of the unit; we

recommend the purchase ofour advanced

controller. See manual for product code

KHP0008.

It is the installer’s responsibility to ensure

correct sizing and provision ofboth the

domestic circulating pump & any associated

central heating expansion vessel

NOTE

NOTE

1 x System filter

Programmable room stat 7 day hot water

programmer

Flow setter

Immersion Heater

Controller

6

Safety procedures

Important safety information is displayed on the product and in this Manual. Please read this

installation manual carefully before installing the unit. It contains further important

instructions for proper installation.

Explanation of illustrated marks

Indicates prohibited items. Indicates mandatory items. Indicates cautions (including danger/warnings).

Explanation of indications

DANGER

WARNING CAUTION

Indicates contents will cause death

or serious injury ifused incorrectly. Indicates contents could cause

death or serious injury ifused

incorrectly.

Indicates contents could cause an

injury or damage to property,

furniture or pets ifthe instructions

are not followed carefully.

General notes

• Please ensure this manual is read thoroughly and kept

for future reference.

• Before any repairs or maintenance are carried out an

assessment ofthe potential risks must be undertaken,

and appropriate measures taken to ensure the safety of

all personnel.

• Do not attempt to repair, move, modify or re-install the

unit on your own.

• Ideally a fully qualified competent MCS installer (such

as those registered under the micro certification scheme)

with prior knowledge ofair to water heat pumps should

be used to install and/or commission the unit.

• All of the manufacturing and packaging materials used

for your new appliance are environmentally friendlyand

can be recycled.

LIABILITY The manufacturer declines any liability

and invalidate the unit warranty for damage resulting

from:

• Improper installation; including failure to follow

instructions in the manuals.

• Modifications or errors in the electrical or

refrigerant or water connections.

• Unapproved units coupling; including other

manufacturers units.

• Use of the unit under condition other than those

indicated.

Units handling

!!

Ensure adequate personal protective equipment is used.

Inspect equipment for damage due to improper transportation or handling: file an immediate claim with

the shipping company.

Dispose ofthe packaging material in accordance with local requirements.

When lifting the unit, absolutely do not use hooks inserted in the side handles, use special equipment

(e.g. lifting devices, trolleys etc.).

Do not step or put anything on the indoor/outdoor unit. It may cause an injury or damage the unit.

Do not place containers filled with liquids or other objects onto the unit.

!

!

!

!

This appliance must not be used by persons (and children) with reduced physical, emotional or

mental faculties or by persons with no experience or knowledge if they are not under the control of

a person responsible for their safety, or if not instructed to the use of this appliance. Make sure

that children do not play with the appliance.

7

Safety procedures

Unit installation

Electrical connections

The installation must be carried out by a qualified

installer.

DO NOT INSTALL IN A PLACE...

• Difficult to access for installation and maintenance.

• Too close to heat sources.

• That might increase the vibration of the unit.

• Which cannot bear the weight of the unit.

• Subject to a risk of exposure to a combustible gas.

• Exposed to oils and vapours.

• With particular environmental conditions ie windy

location.

CHOOSE A PLACE...

• Where noise and discharged air do not disturb neighbours.

• Protected from strong winds.

• That allows for the clearances required.

• Which will not obstruct passageways or doors.

• With floor structure adequately strong to support unit

weight and minimize vibration transmission.

Note...

Fix the unit with locally purchased bolts buried in the block.

If the unit is installed in areas where heavy snowfalls may

occur, it is necessary to raise its level at least 200mm above

the usual snow level or alternatively to use the outdoor unit

wall mounting bracket kit. See Kingspan optional extras

such as the “snow feet”(Anti vibration foot KHP0044 )

recommended for exposed areas to help create an air gap

under the unit.

CAUTION

!

!

All field electrical connections are the responsibility of

the installer.

DANGER

Electrical shock can cause severe personal injury

or death. These operations are to be carried out by

qualified personnel only.

!WARNING

• This unit complies with Machinery Directive

(2006/42/EC), electromagnetic compatibility

(2004/108/EC) and pressure equipment (EEC/97/23)

Directives.

• To avoid electric shock or fire make sure these

operations are carried out by qualified personnel only.

• Ensure that national safety code requirements have been

followed for the main supply circuit.

• Follow all current national safety code requirements.

• Ensure that a properly sized and connected ground wire

is in place.

• Check that voltage and frequency of the mains power

supply are those required; the available power must be

adequate to operate any other possible appliances

connected to the same line.

• Check that the impedance of the mains power supply is

in conformance with the unit power input indicated in

the rating plate ofthe unit.

• Make sure that properly sized disconnecting and safety

switches are installed.

• The disconnection devices from the mains supply must

allow full disconnection under the conditions provided

for by overvoltage class III.

• Connect the connecting cable correctly. If the

connecting cable is connected in a wrong way, electric

parts may be damaged.

• Connection to the mains supply is of the Y type;

therefore, the cable must only be replaced by a

qualified technician in order to prevent any risk.

• Use the specified cables for wiring and connect them

firmly to the terminals.

• Be sure to provide grounding; inappropriate grounding

may cause electric shock.

• Do not connect ground wires to gas pipes, water pipes,

lightning rods or ground wires for telephone cables.

DANGER:

Do not modify this unit by removing any ofthe safety

guards or by by-passing any ofthe safety interlock

switches.

FINAL CHECK

• If refrigerant gas leaks out during the installation work,

ventilate the room immediately.

• If refrigerant gas leaks into the room and flows near a

fire source, such as a cooking range, poisonous gas is

generated.

Contact the manufacturer ifone ofthe following

events takes place:

• hot or damaged power supply cable;

• unusual noise during operation;

• frequent operation of the protection devices;

• unusual smell (such as smell of burning).

WARNING

!WARNING

!

8

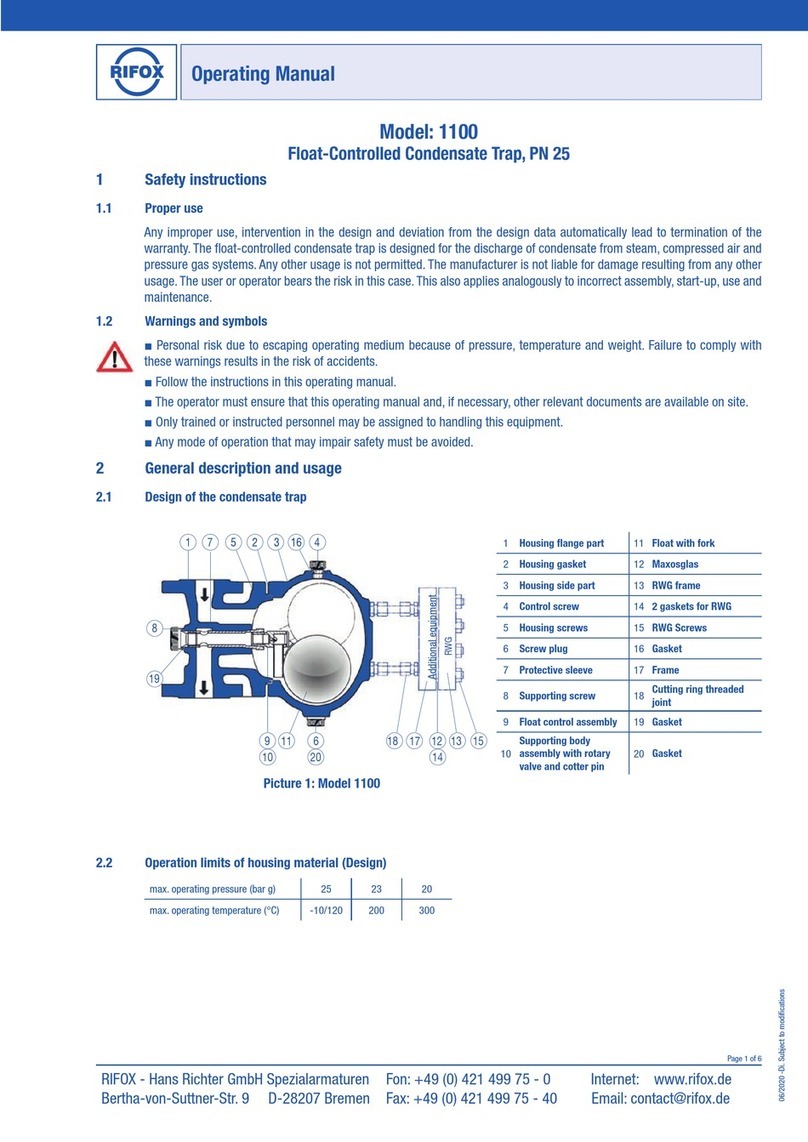

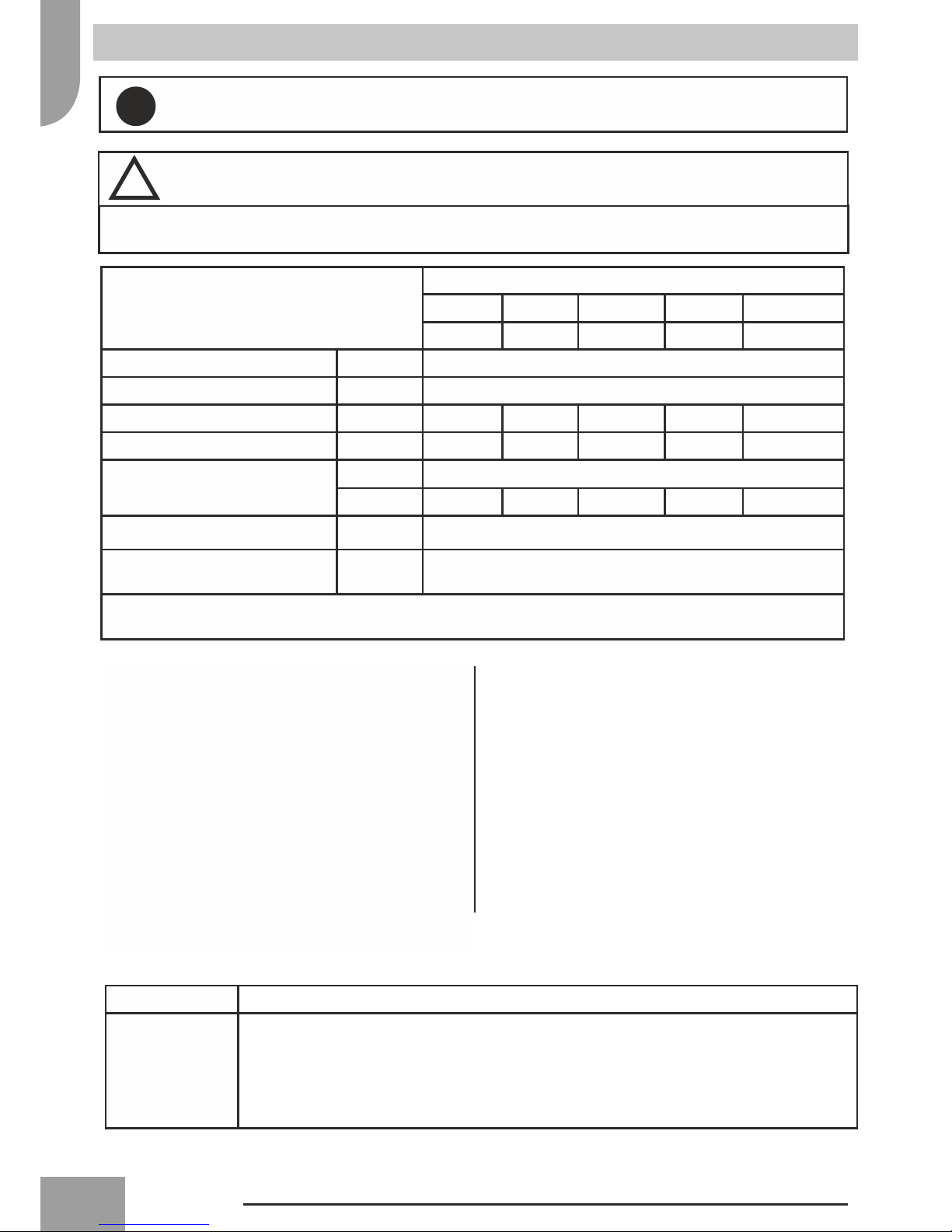

Minimum installation clearances in mm are shown in fig. 2 (single installation) and fig. 3 (serial installation)

Note: The height ofthe obstacle at both front and rear side should be lower than the height ofthe outdoor unit.

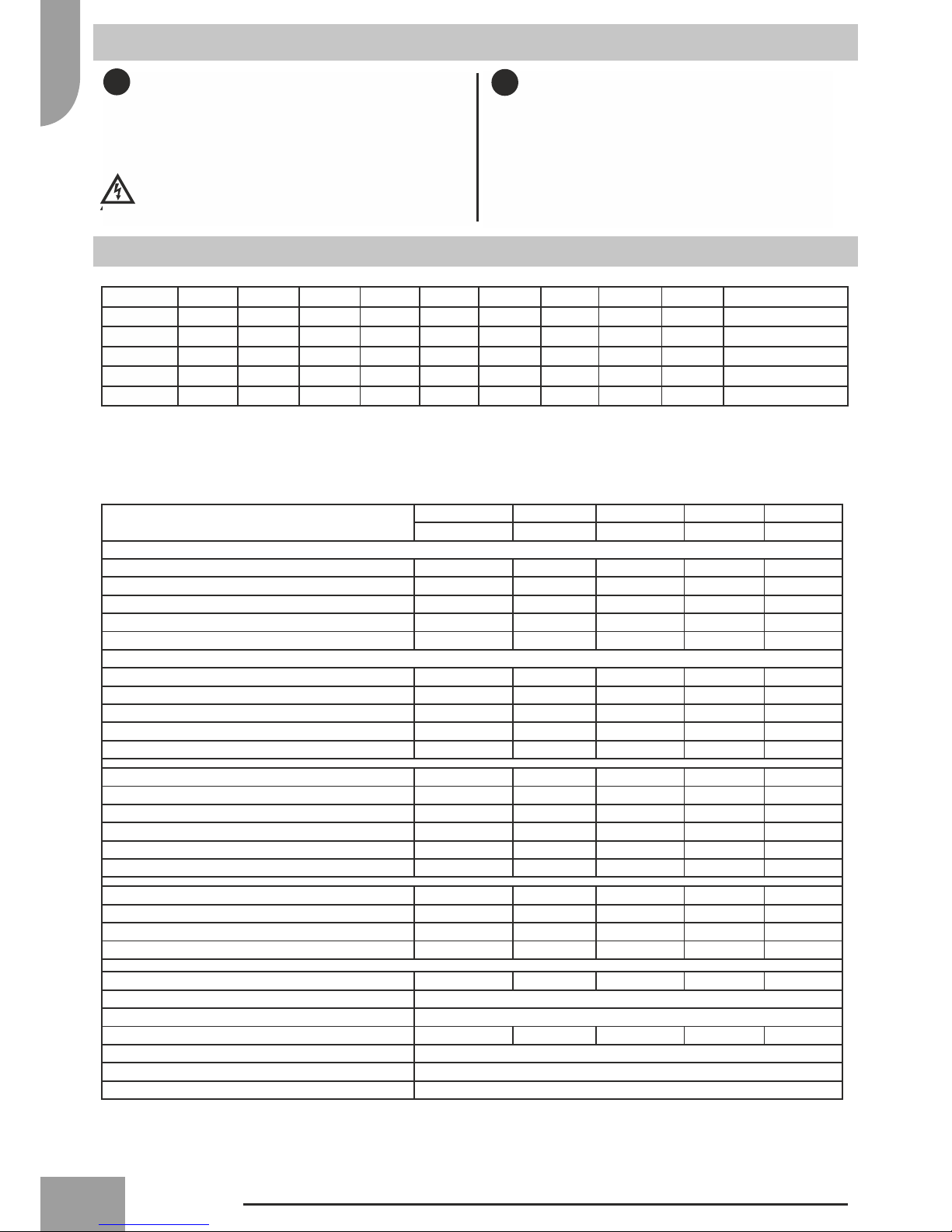

A B C D E F G H L weight

KHP0041 908 821 326 350 87 356 466 40 60 56

KHP0038 908 821 326 350 87 356 466 40 60 58

KHP0039 908 821 326 350 87 356 466 40 60 68

KHP0040 908 1363 326 350 174 640 750 44 69 99

KHP0042 908 1363 326 350 174 640 750 44 69 124

Safety procedures

!

CAUTION

• Ensure adequate personal protective equipment is used.

• Extraordinary maintenance operations must be carried

out by specially trained personnel.

Disconnect the mains power supply prior to any

maintenance operations or prior to handling any

internal parts ofthe unit.

CAUTION

• This equipment contains refrigerant that must be

disposed ofin a proper manner.

• When disposing of the unit after its operational life,

remove it carefully.

• The unit must then be delivered to an appropriate

disposal centre or to the original equipment dealer

for proper environmentally compatible disposal.

!!

Dimensions and Clearances

Specifications KHP0041 KHP0038 KHP0039 KHP0040 KHP0042

4kW 6kW 8kW 12kW 15kW

Data at Condition 1: A 7db/6wb W30/35 (EN14511)

Nominal heating capacity kW 4.1 5.8 7.2 11.9 14.5

Power input kW 1.01 1.37 1.82 3.01 3.57

Current Input (A) 4.35 5.95 7.91 13.1 15.5

COP (kW/kW) 4.05 4.24 3.95 3.94 4.06

Eurovent class, heating A A B B A

Data at Condition 2: A 7db/6wb W40/45 (EN14511)

Nominal heating capacity (kW) 3.9 5.8 7.4 12.9 14

Power input (kW) 1.22 1.90 2.32 4.26 4.36

Current Input (A) 5.3 8.26 10.1 18.5 18.9

COP (kW/kW) 3.2 3.06 3.18 3.03 3.21

Eurovent class, heating A B B B A

Water pressure drop, kPa (Condition 1) 16 9.5 14.5 26 33

Fan Power Input (kW) (Condition 1) 0.09 0.09 0.099 0.191 0.19

Fan Speed (RPM) (Condition 1) 680 680 680 710 - 730 780-820

Current Input (A) (Condition 1) 0.65 0.65 0.85 1.63 1.18

Sound power level, heating‡ dB(A) 62 62 64 67 68

Sound pressure level, heating‡ dB(A) 42 42 44 47 48

Nominal Flow Rate (l/min) 12 16.8 19.8 34.8 41.4

Nominal Flow Rate (l/min) (Radiators) 8.0 9.8 10.8 21.0 31.7

Minimum Flow Rate (l/min) (to operate flow switch) 5 8 8 8 8

Maximum Flow Rate (l/min) 15 20 25 40 50

Refrigerant Content (g) R410A 1195 1350 1810 2450 3385

Oil Type Ester Oil VG68

Compressor Type Rotary DC Inverter Technology

Net Water Volume (L) 0.8 0.8 1 2.3 2.3

Water Connections 1" ISO228 (BSP) Male

Maximum Water Pressure (kPa) 300

Product Category (EN14511) – Packaged Monobloc.

Above data applies to new, clean heat exchangers

Factory defult settings for heating are 55°C flow temp. To alter this you will be required to purchase the advanced

controller KHP0008

9

2

3

1

150

500

1000

100

150 300 300 300

200

1000

300

200

300

1000

1000 300 1500 2000 200

150

200

150 300

500

1000 150

Dimensions and Clearances

10

Installation

Drain hose and base pan knockouts (Fig. 6)

How to remove the front panel (Fig. 5)

Opening cable knockouts

There is a pre-cut part that can be removed for running

wires. Do not remove the unit front panel for easier drilling

of the knockouts. The pre-cut section ofthe sheet can be

removed by punching the 3 connection points along the

line first using a screwdriver and finally with your hands

(See Fig. 4).

When the cable knockout is open, remove the burrs and

fit the cable protective bush supplied with the unit for

cable

1.Remove screws ofthe front panel (See fig. 5). 2. Pull the front panel downward with the handle.

See fig. 6.

In case ofdraining through the drain hose, attach the

drain nipple (A) and use the drain hose (Inner diam:

16mm) sold on the market. When there is a possibility of

freezing ofthe drain in cold weather maintain a

continuous downward slope in the drain pipe to prevent

the drain becoming blocked by ice.

The drainage ability increases when knockout holes on

the base pan are opened. (Open the knockout hole to

outside using a hammer (B), etc.). Take care not to

damage the evaporator coil when opening the knockout

holes. We recommend that the knockout holes are opened

for all UK & Ireland installations.

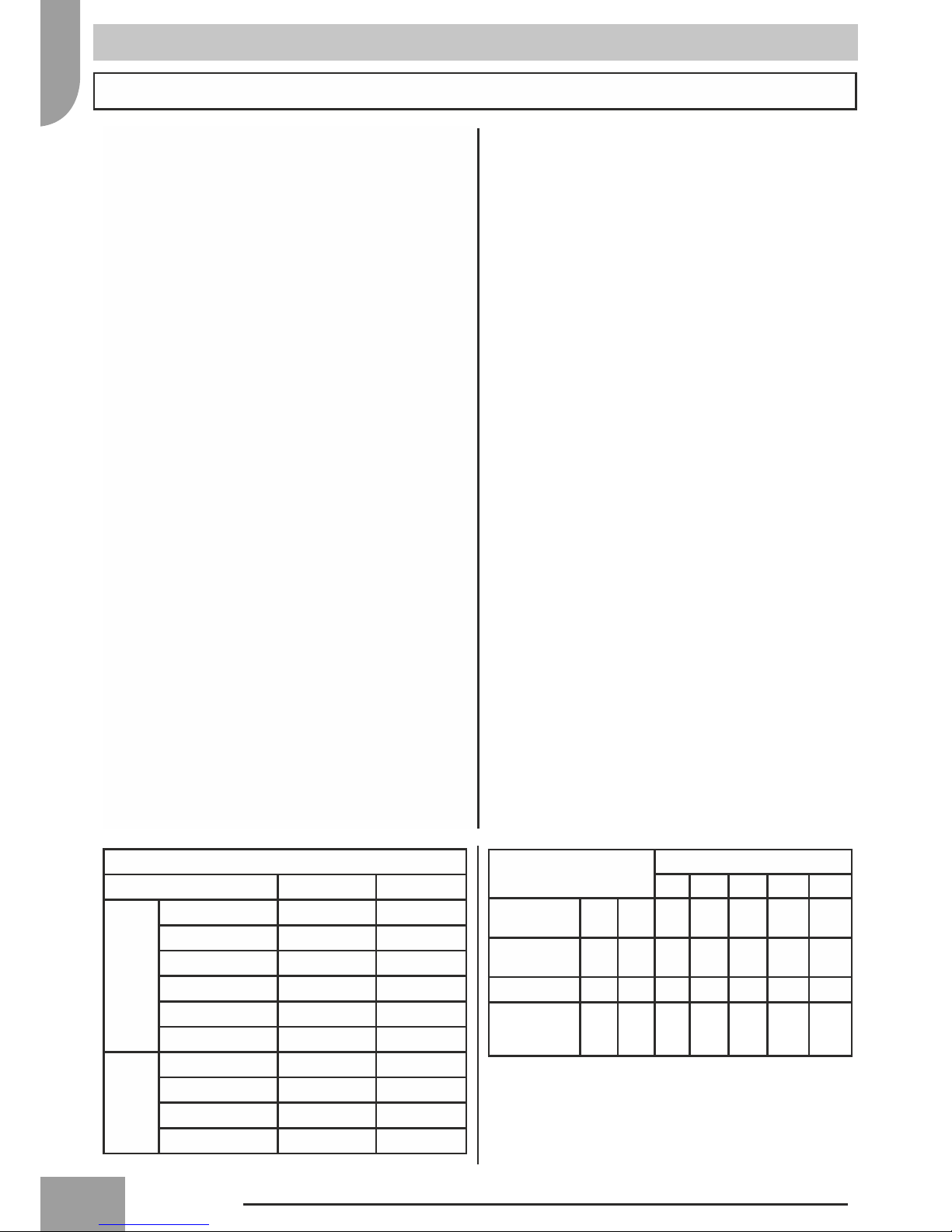

Operating limits (Fig. 10)

Operation in heating: See fig. 10

A- Outdoor air temperature (°C)

B- Outlet water temperature (°C)

Before installation, check strength and levelness ofthe

base so that abnormal noise is not generated. According

to the dimensions and clearances, fix the base firmly

with the anchor bolts (Anchor bolt, nut: 4 off M10).

If the outdoor unit is installed in a very windy place,

protect the fan with a wind protection screen and check

that it works correctly.

Radiator Design / Defrost Cycle

The Aeromax Plus system typically requires at least one

radiator (usually located in the same location as the room

thermostat) to remain “open circuit” with no thermostatic

radiator valve fitted.

The minimum design criteria to be employed by the

installer is to allow 3 ltr per kW ofnominal out ofthe heat

pump.

For example:

8kW Aeromax Plus x 3ltr = 24 ltr ofwater to act as open

loop.

(Fig. 4)

Circulating Pump

A circulating pump is not supplied as part of the

Aeromax Plus installation pack. A suitable circulating

pump must be specified based on the pressure loss in the

system.

Pressure loss curves for the Aeromax Plus are shown in

fig. 11.

(Fig. 11)

Climatic Curve

To qualify as a Weather Compensated heat pump the

Aeromax Plus is pre-programmed with a climatic curve.

See fig. 12.

Care must be taken to ensure this curve is suitable for

the application and heat emitters used. There are 12

pre-programmed climatic curves selectable using the

User Comfort Interface KHP0008. A custom climatic

curve can also be programmed.

(Fig. 12)

11

6

5

4

1

2

3

1

2

3

600150 150

430

400

363

B

A

37

Foundation Specification

Foundation bolt M10 (3/8”)

Thickness ofconcrete 120mm

Length ofbolt 70mm

Weight-bearing capacity 320kg

7

12

Water connections

Make the plate heat exchanger hydraulic connections with

the necessary components, using material which will

guarantee that the screwed joints are leak proof. The

typical hydraulic circuit diagram shows a typical water

circuit installation in an air conditioning system.

For an application with a water circuit, the following

recommendations must be taken into account:

1. The pump must be fitted immediately before the heat

exchanger and after the connection to the system

return (unit without hydronic module).

2. It is advisable to install shut-off valves to allow

isolation ofthe most important circuit components, as

well as the heat exchanger itself.

These valves (ball, globe or butterfly valves) should

produce a minimum loss ofcharge when they are open.

3. Provide unit and system drains and vents at the lowest

and highest system points respectively.

4. Install purges in the higher sections ofthe installation.

5. Flow setter should be installed after the pump on the

return circuit. Leaving approx 200mm to avoid any

turbulence from the pump

6. All piping must be adequately insulated and

supported.

Installation ofthe following components is obligatory:

1. The presence ofparticles in the water can lead to

obstructions in the heat exchanger. It is therefore

necessary to protect the heat exchanger inlet with a

filter or dirt separator. The filter mesh gauge must be at

least 10 mesh/cm2.

2. After assembling the system, or repairing the circuit,

the whole system must be thoroughly cleaned with

special attention paid to the state ofthe filters.

3. Flow rate control is made by the control valve on the

flowmeter/setter installed after the pump (see fig 9

item 11).

4. When water has to reach temperatures below 5°C, or

the equipment is installed in areas subject to

temperatures below 0°C, it is necessary to mix water

with inhibited monopropolyne glycol in a suitable

concentration.

System cleaning and Water Characteristics

In the case ofa new installation, or cleaning the

circuit, it is necessary to perform a preventive

cleaning ofthe system. In order to guarantee the

good operation ofthe product,each time you clean

the system, replace the water or add glycol, check

that the liquid appears clear, without visible

impurities and that the hardness is less than 20 °f

Fig. 8 - Integrated water circuit

1.Automatic valve with air vent

2.Flow switch

3.Pressure relief valve (300kPa, outlet 1/2’)

4.Temperature probe

Fig. 11

A- Water flow rate, (l/s)

B- Pressure drop (kPa)

Water Connections (Fig. 8/9/11)

Pipe water content

Internal Diameter Outer diameter Liters / meter

copper 12 mm 14 mm 0,11 l/m

14mm 16 mm 0,15 l/m

16mm 18 mm 0,20 l/m

20mm 22 mm 0,31 l/m

25mm 28 mm 0,49 l/m

32mm 35 mm 0,80 l/m

steel 12.7 mm (1/2'')" " 3/8''Gas 0,13 l/m

16.3 mm (5/8'')" " 1/2''Gas 0,21 l/m

21.7 mm (7/8'')" " 3/4''Gas 0,37 l/m

27.4 mm (11/16'')" " 1”Gas 0,59 l/m

Unit Aeromax Plus

4kw 6kw 8kw 12kw 15kw

Nominal water

flow Std l/s 0.2 0.28 0.33 0.58 0.69

Working

pressure

Max kPa 300 300 300 300 300

Filling pressure Min kPa 120 120 120 120 120

Difference in

level with unit

at lowest level

Max m 20 20 20 20 20

13

11

1

2

3

4

4

1

2

3

4

4

Integrated water circuit - Safety Devices

1Automatic valve with air vent

2Flow switch

3Pressure relief valve (300kPa, outlet 1/2’)

4Temperature probe

-5 0 5 10 15 20 25 30 35 40 45 50

10

15

20

25

30

35

40

45

50

55

60

65

70

10

15

20

25

30

35

40

45

50

55

60

65

70

-25 -20 -15 -10 -5 0 5 10 15 20 25 30 35

8

OAT °C

LWT °C

10

9

11

8

1 Isolating valves

2 System filter

3 Expansion vessel with PRV & Gauge (Robokit)*

4 Flush & Fill Ports

5 System drain valve (at lowest point ofsystem)*

6 Air purge (at highest points ofsystem)*

7 3-way valve

8 Hot water cylinder

9 Heating system

10 Circulating pump with isolating valves*

11 Flowmeter/setter

*not included in installers pack

14

11

30AWH012X

0

10

20

30

40

50

60

0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9

30AWH006X

0

5

10

15

20

25

30

35

40

45

50

55

0 0,1 0,2 0,3 0,4 0,5 0,6

6 kW

30AWH004X

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

0,1

B (kPa)

4 kW

12 kW & 15 kW

30AWH008X

0

5

10

15

20

25

30

35

40

0 0,1 0,2 0,3 0,4 0,5 0,6

8 kW

0,2 0,3 0,4 0,5

A (l/s)

0,0

8

12

15

Installation

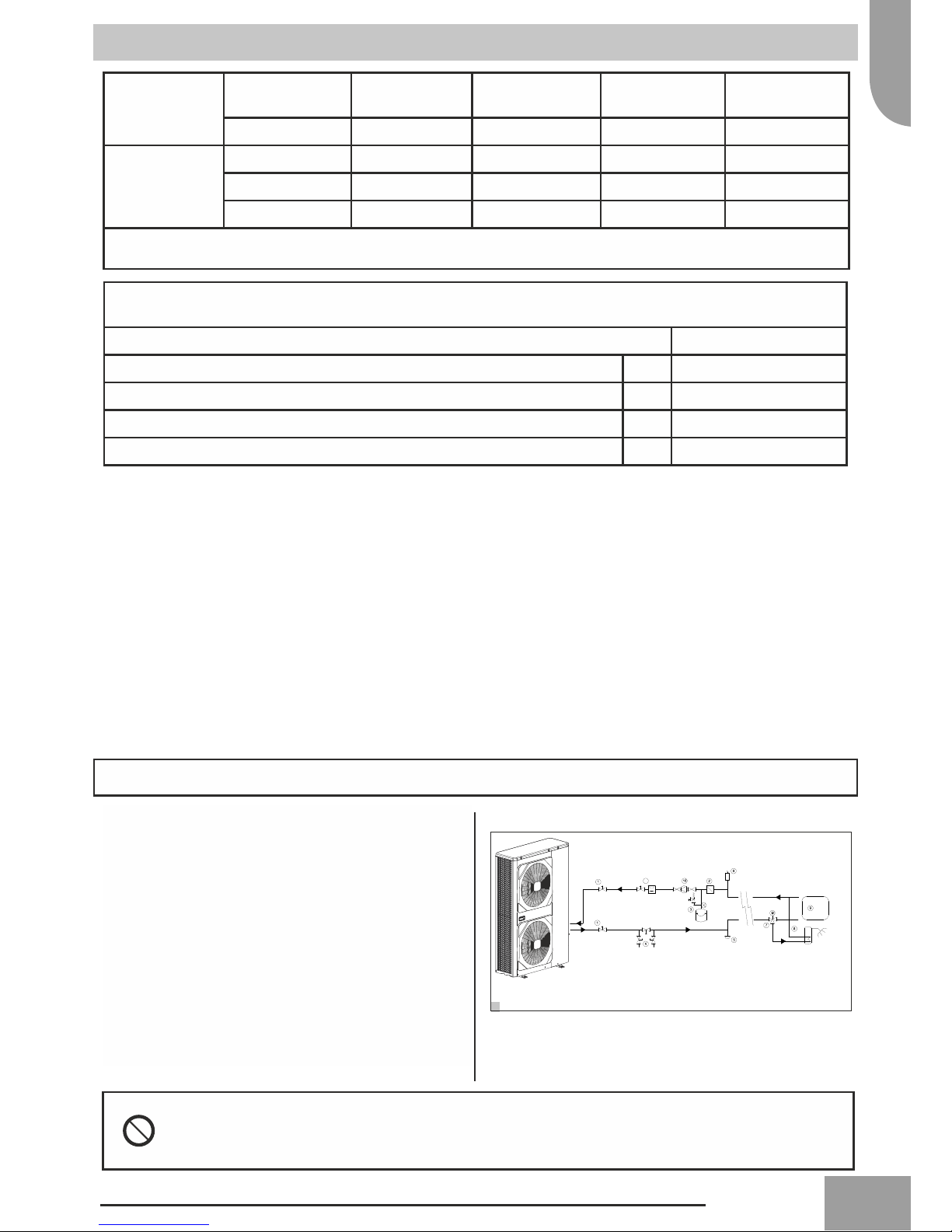

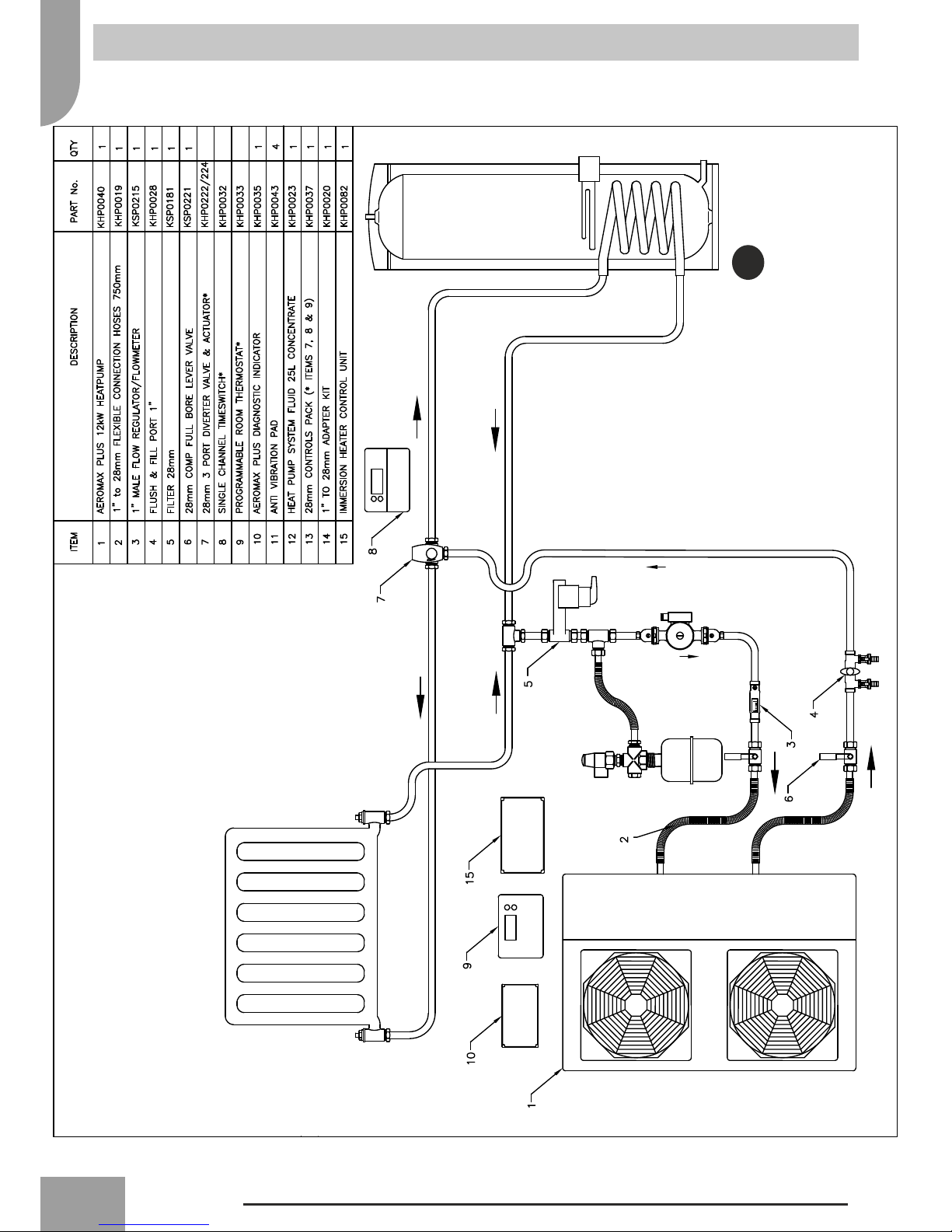

Recommended water diagram (Fig. 9)

Typical water circuit diagram for Aeromax Plus unit

(see fig. 9)

1 Isolating valves

2 System filter

3 Expansion vessel with PRV & Gauge (Robokit)*

4 Flush & Fill Ports

5 System drain valve (at lowest point ofsystem)*

6 Air purge (at highest points ofsystem)*

7 3-way valve

8 Hot water cylinder

9 Heating system

10 Circulating pump with isolating valves*

11 Flowmeter/setter

*not included in installers pack

% Inhibited Propyl-

ene Glycol

10% 20% 30% 40%

Freezing time (*) -4 °C -9 °C -15 °C -23°C

Correction

Factors

Capacity 0,996 0,991 0,983 0,974

Absorbed power 0,990 0,978 0,964 1,008

Loss ofhead 1,003 1,010 1,020 1,033

(*) Note: Temperature values are indicative.

Always refer to the temperatures indicated for the specific product used

TABLE TO USE FOR CALCULATING THE WATER CONTENT IN THE SYSTEM

Installed Unit .............

Unit content (*) l .............

Pipe content (**) l .............

Uses (fan-coil, panels, radiators, etc.) (***) l .............

Total content (****) l .............

(*) Consult the technical data table.

(**) Consult the pipe water content table.

(***) Consult the manual from the relevant manufacturer.

(****) The water content ofthe system must be greater than the minimum value for units without hydronic kit. The minimum

value is necessary to provide optimal comfort.

Detailed installation schematics can be found at the back ofthe manual.

Should you require further technical assistance call your local office – details on the back page of this manual.

Do not use the heat pump to treat industrial process, swimming pool or sanitary water. In all these

cases, provide an intermediate heat exchanger.

9

11

16

If the system details are outside ofthe range shown in

the table the expansion vessel size can be calculated

using the following formula:

V = e * C / {1-[ (Ppre + 1)/(Pmax + 1) ] }

Where:

e = Coefficient of Fluid Expansion with respect to 10°C

(30% Glycol/Water)

C = total System Volume (litres).

Ppre = Pre-charge Pressure (Bar)

Pmax = Max System Pressure (Bar)

Maximum Working Temperature

30 40 50 60 70 80 90

Coefficient of Fluid Expansion with respect to 10°C (30% Glycol/

Water)

0.00272 0.00499 0.00779 0.01108 0.0148 0.01891 0.02336

Pre-charge

Pressure

(Air side ofvessel)

Max System Pressure

(Pressure ReliefValve

Rating)

System

Volume

(Litres)

Approximate Expansion Vessel Volume Required (Litres) as a

Function ofthe Max Working Temperature

0.5 1 100 1.1 2 3.1 4.4 5.9 7.6 9.3

0.5 1.5 100 0.7 1.2 1.9 2.8 3.7 4.7 5.8

0.5 2 100 0.5 1 1.6 2.2 3 3.8 4.7

0.5 2.5 100 0.5 0.9 1.4 1.9 2.6 3.3 4.1

1 1.5 300 4.1 7.5 11.7 16.6 22.2 28.4 35

1 2 300 2.5 4.5 7 10 13.3 17 21

1 2.5 300 1.9 3.5 5.5 7.8 10.4 13.2 16.4

1 3 300 1.6 3 4.7 6.6 8.9 11.3 14

1.5 2 500 8.2 15 23.4 33.2 44.4 56.7 70.1

1.5 2.5 500 4.8 8.7 13.6 19.4 25.9 33.1 40.9

1.5 3 500 3.6 6.6 10.4 14.8 19.7 25.2 31.2

2 2.5 1000 19.1 34.9 54.5 77.5 103.6 132.4 163.5

2 3 1000 10.9 19.9 31.2 44.3 59.2 75.7 93.5

Aeromax Plus Expansion Vessel Sizing – Sizing Examples

Note: the required vessel volume will almost certainly

not correspond exactly to an existing size, therefore the

nearest available size above the value returned for V

must be selected from the available vessels in the

range.

The calculation is valid provided the expansion vessel

and the safety valve are at the same height. The

maximum system pressure for Aeromax Plus Heat

Pumps is 3 bar.

Cylinder Installation for Domestic Hot Water

We recommend the Kingspan Albion Aerocyl is used as it

has a heat pump specific coil fitted.

!Note...

Ifthe Aerocyl is used in conjunction with the 3 port valve

supplied with the Aeromax plus there is no requirement for

the additional 2 port valve.

17

Water connections (Typical Schematic for Radiator System)

4, 6 & 8 kW

No 2 port

required if

using with

heat pump

NOTE

18

Water connections (Typical Schematic for Radiator System)

No 2 port

required if

using with

heat pump

NOTE

12 kW

19

Water connections (Typical Schematic for Radiator System)

15 kW

No 2 port

required if

using with

heat pump

NOTE

20

Electrical connections (Fig. 13)

!All field electrical connections are the responsibility of the installer.

!WARNING

Make water connections before electrical connections. Make ground connection prior to any other electrical

connections.

Unit Aeromax Plus

KHP041 KHP0038 KHP0039 KHP0040 KHP0042

4kW 6kW 8kW 12kW 15kW

Power Supply V - ph - Hz 230 - 1 - 50

Allowable Voltage Range V 207/253

Maximum Power Drawn kW 2 2.3 2.7 5.1 5.1

Maximum Current Drawn A 7.2 11 14 23 20

Power Fuses Type gL Type

Current (A) 10 Type B 15 Type B 15 Type B 25 Type D 25 Type D

Power Supply Cables mm2 H07RN-F 3 x 2.5mm2

Maximum Circulating Pump Current A 2

Use cables H03VV-F 4x0.75 mm² to connect the control to

wire User Comfort Interface (KHP0008)

Cables from Indoors – Heat Pump

2x 3 core 240v

1x 7 core for 0-12v

1x 3 core mains to HP

Wired control For installation of wired remote controller please refer to the control installation manual.

Power supply Size the cable, the cables must be H07RN-F type (3 x 2.5 mm2).

According to the installation instructions, all devices for disconnection from the power supply

mains must have a contact opening (4 mm) to allow total disconnection according to the

conditions provided for the overvoltage class III.

To prevent any risk, the power cable must only be replaced by the technicians ofthe after-sales

service.

Remove the front panel, the electric parts appear at the

front side. The power supply cables can be inserted into

the holders. Be sure to fix the power cable with bundling

band sold on the market so that they do not make contact

with the compressor and the hot pipes.

To ensure good tensile strength, the electric cables must

be fastened using the cable-holder on the plate.

The unit can be controlled and set via:

• User Comfort Interface wire control KHP0008

(Optional)

• Aeromax Plus Controls Pack KHP0036/37

• Switches (not supplied)

For the electrical connections refer to wiring diagram,

while, for use, refer to the relative manuals.

Only for KHP0042 use the strain reliefsupplied with the

unit.

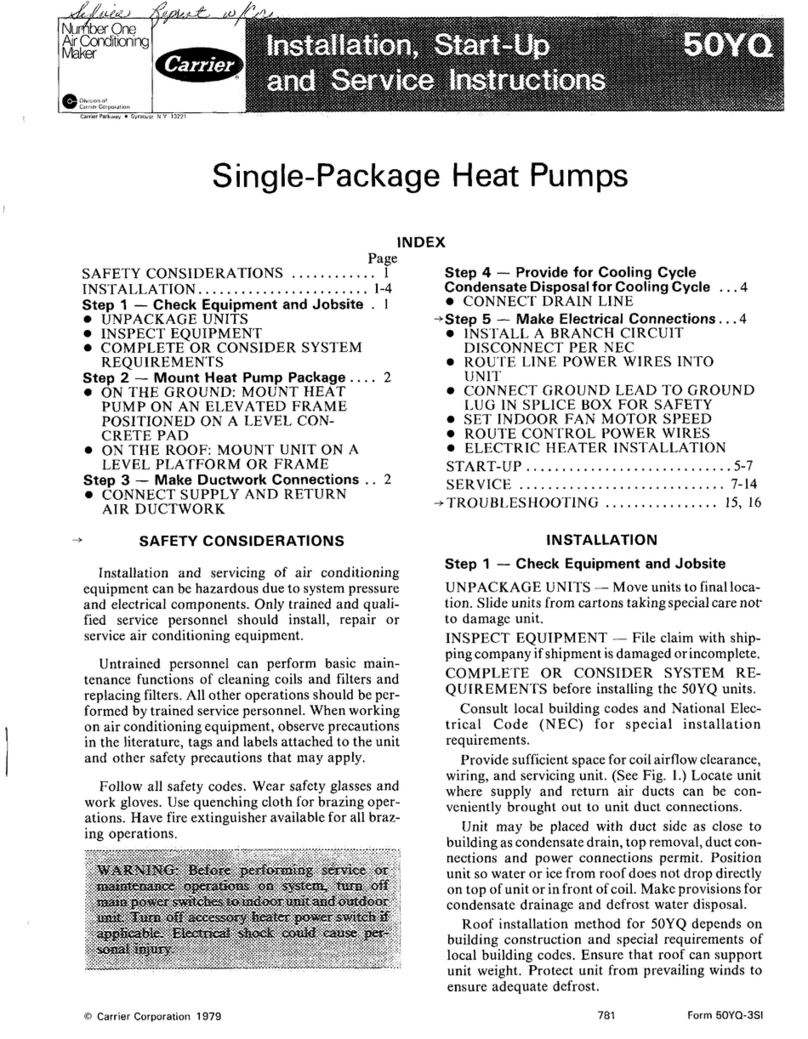

This manual suits for next models

9

Table of contents

Popular Heat Pump manuals by other brands

Airwell

Airwell CKD Series Service manual

Carrier

Carrier 50YQ Installation, Start-Up and Service Instructions

Mitsubishi

Mitsubishi ESA30EH2-25 Technical manual

Nibe

Nibe F1255 Series user manual

STIEBEL ELTRON

STIEBEL ELTRON HPA-O 4 CS Plus Operation and installation instruction

Nibe

Nibe FIGHTER 1310 Installation and maintenance instructions