AEROPOWER Powersky X6 User manual

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

A E R O P OW E R V E NTI L A T I O N CO. , L T D

INSTALLATION

GUIDE

Powersky○

RX6

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

HARDWARE

The fan hardware that suspends the fan and the wing is located on the hardware kit. Before installing,

ensure you have the following hardware.

Installation Hardware Kit 1

Upper Yoke Hardware

Extension Tube Hardware

Lower Yoke Hardware

Main Fan Unit Hardware

•(4) M12 x 50 MM Bolt

•(8) M12 Flat Washer

•(4) M12 Nylock Nut

•Shackle

•(2) M16 x 120 MM Bolt

•(4) M16 Flat Washer

•(2) M16 Nylock Nut

•(2) M16 x 120 MM Bolt

•(4) M16 Flat Washer

•(2) M16 Nylock Nut

•(4) M12 x 25 MM Bolt

•(8) M12 Flat Washer

•(4) M12 Nylock Nut

Airfoil And Winglet Hardware Kit

Airfoil Hardware

Winglet Hardware

Guy Wire 2

•(12) M10 x 50 MM Bolt

•(24) M10 Flat Washer

•(12) M10 Nylock Nut

•(24) M4 Flat Washer

•(24) M4 x 10 MM Bolt

•(4) Locking Carabiner

•(4) 10MM Beam Clamp

•(4) M10 X 25MM Eyebolt

•(4) M10 Nylock Nut

•(4) Gripples

•(4) Guy Wire

1. Square washers are included and are only used when the fan is mounted to the angle iron. The number of square washers required depends on the number of angle

irons used.

2. The guy wire is only supplied when it is necessary to limit the fan shake. If the extension tube is 4 ft (1.2 meters) or longer, the fan is susceptible to strong winds or the

like or the fan is close to the building structure. Aero Power Solutions recommends the use of guy wire.

Parts

Check that you have all the necessary parts before installation. If you order multiple fans, be sure to classify

the components of each fan separately. Each fan has different grades and is not interchangeable.

(2) Beam Clips Upper Yoke2 Lower Yoke Hub Cover Main Fan Unit

(2) Spacers1

Airfoil Winglet Airfoil Retainer Extension Tube3Controller

1. Spacers are only used if the beam flange exceeds 3/8” (10 mm).

2. Ensure you have the correct upper yoke for your mounting method. The upper yoke may differ from

the illustration.

3. Safety cable is attached to extension tube.

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

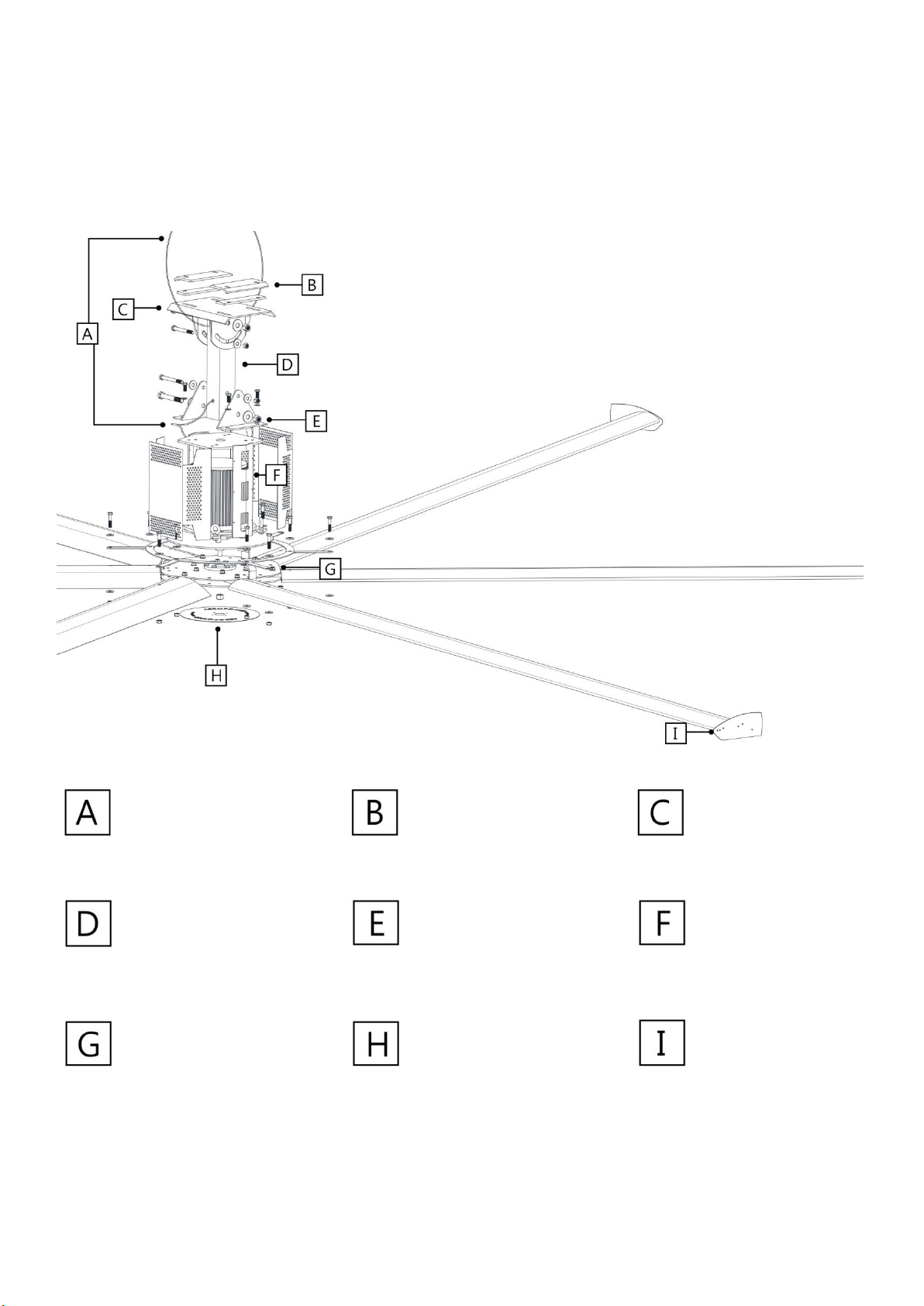

DECOMPOSITION

If you lose any parts or hardware required for installation, please contact customer service.

1. Used only if mounting fan to an I-beam. Spacers are used only when the I-beam flange exceeds 3/8”(10 mm).

Safety Cable

Beam Clips1

Spacers1

Upper Yoke

Extension Tube

Lower Yoke

Main Fan Unit

Hub

Hub Cover

Winglets

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

INSTALLATION LOCATION

Before installation, confirm the following requirements to check that the building structure and fan location

are in compliance with Aero Power Solutions' safety guidelines.

☐If the fan's extension boom is 4 inches (1.2 meters) or longer or the installation structure requires, the

cable must be used to limit fan shake. If the fan is close to any building equipment, Aero Power Solutions

recommends fixing the fan with a cable to ensure safety.

☐When installing the fan, the fan must be perpendicular to the ground.

☐The distance between all fan parts and obstacles is ≥2 ft (61 cm). No obstacles such as lights, cables,

sprinklers or other structural components are allowed in the fan installation area.。

Net space distance guide

If fan usage does not meet these requirements, please contact customer service to discuss other fan

installations or select other fans.

General spacing

☐The distance between the center of the fan must not be less than 2.5x the diameter of the fan.

☐When installing the fan, the fan must be at least 10 ft (3 meters) above the floor.

Ceiling pitch

Depending on the fan size, the fan must be installed at the following distances. The distance between the fan

and the ceiling is the distance between the top of the winglet and the ceiling.

Powersky®X6

Fan diameter

Distance from the ceiling

10 ft(3.0 meters)

4 ft(1.2 meters)

13 ft(4.0 meters)

5 ft(1.5 meters)

16 ft(4.9 meters)

6 ft(1.8 meters)

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

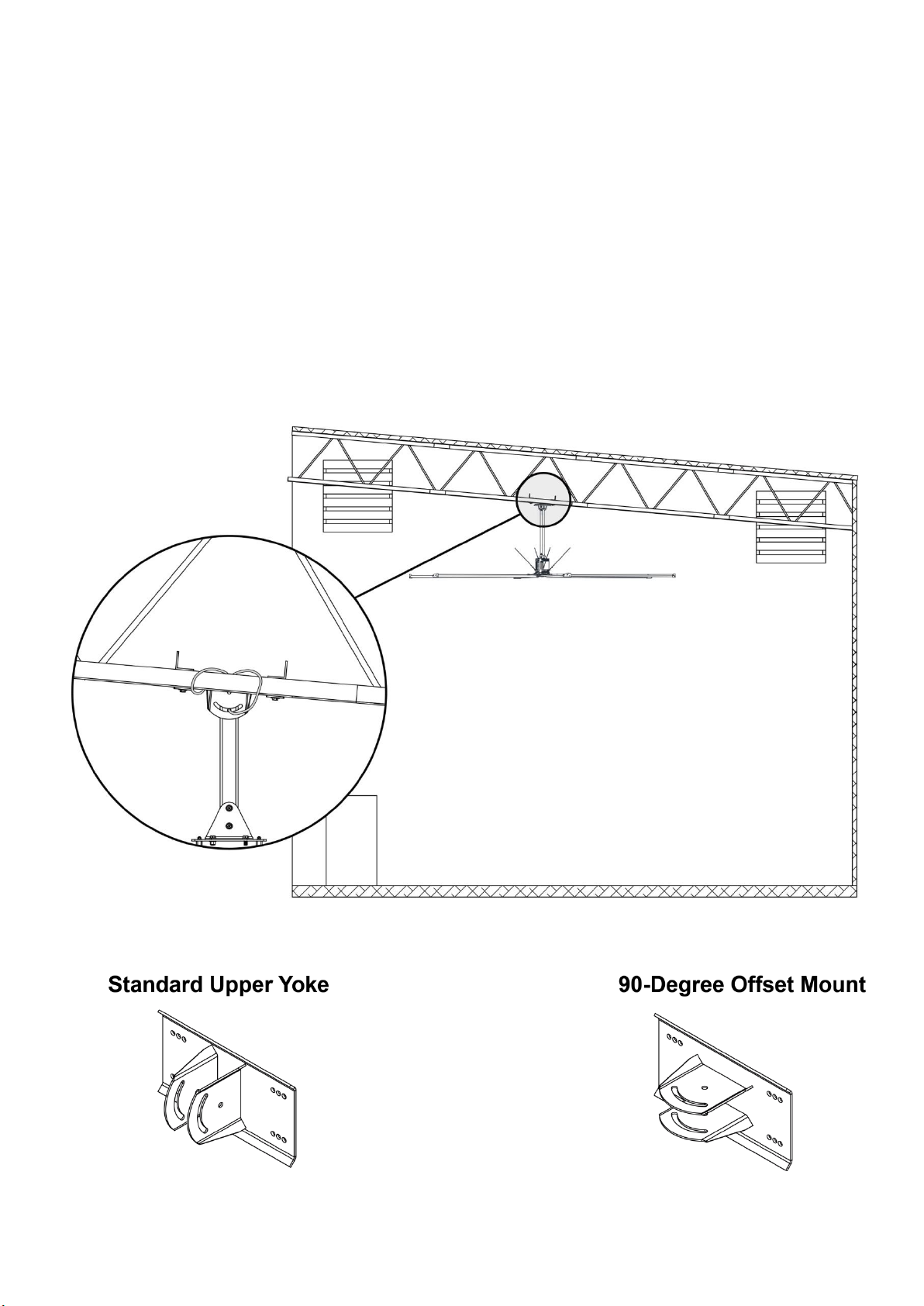

Understanding roof pitch

To ensure the fan is properly mounted, the fan must always hang plumb to the ground and the yoke must be

installed using the bolt holes at the widest locations possible. To accommodate building structures on which

the standard upper yoke does not allow the fan to properly orient itself, the 90-Degree Offset mount should

be purchased.

The example below shows one situation in which the 90-Degree Offset mount must be used so that the fan

hangs plumb to the ground and the widest stance for the upper yoke is ensured. If you are uncertain of your

roof pitch or do not have the correct mount to properly hang your fan, consult a structural engineer or contact

Aero Power Fans Customer Service.

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

Pre-Installation

Mechanical installation

•A 16-ft (4.9-m) Powersky®X6 fan weighs, at maximum, 275 lbs (125 kg). A suitable means for lifting the

weight of the fan, such as a scissor lift, and at least two (2) installation personnel will be required.

•Aero Power Fan can only be mounted to an I-beam or angle irons. If mounting to an I-beam, the I-beam

must be part of the existing building structure. Do not mount the fan to a single purlin, truss, or bar joist.

Consult a structural engineer for installation methods not covered in the guide.

•The mounting structure must be able to withstand the torque forces generated by the fan.

•Fans mounted on fabricated I-beams, which are common in steel buildings, could cause the beam to flex

and the fan to move significantly during operation. If this flexing causes a clearance problem, we suggest

installing the I-Beam Stabilizer kit.

•If the fan’s extension tube is 4 ft (1.2 m) or longer or if the mounting structure requires it, the fan’s lateral

movement must be secured using guy wires. If the fan is close to any building fixtures it is recommended

to secure the fan with guy wires as a safety measure.

•Adhere to the safety requirements in the table below when selecting where to mount the fan.

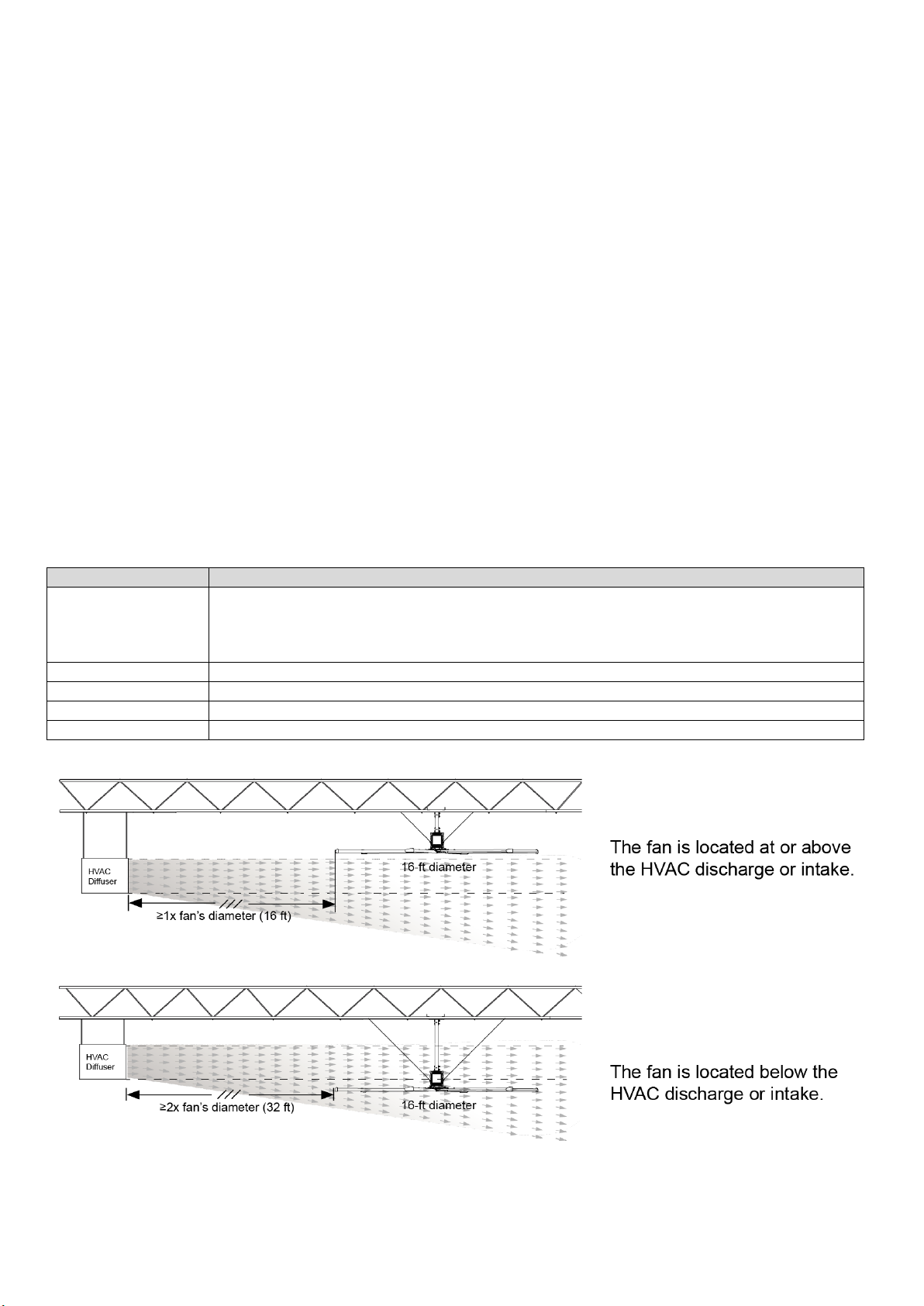

Safety requirement

Minimum distances

Clearance

≥2 ft from all fan parts. The fan installation area must be free of obstructions such as lights, cables,

sprinklers, or other building structure. See the tables on pp. 2–3 for recommended minimum ceiling

clearances.

Airfoil height

≥10 ft above the floor

HVAC equipment

≥1x fan diameter if above diffuser. ≥2x fan diameter if below diffuser. Refer to the illustration below.

Fan spacing

2.5x fan diameter, center-to-center

Radiant/IR heaters

See the manufacturer’s requirements for the minimum clearance to combustibles.

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

INSTALLATION

WARNING:The fan cannot be installed unless the structure of the installed fan is strong, undamaged,

and can support the load and installation method of the fan. Structural engineers should verify that the

structure is appropriate before installing the fan. The customer and/or end user is solely responsible for

confirming the stability of the installation structure.

Aero Power Solutions hereby expressly disclaims any liability, or do not use Aero Power Solutions to

provide or install any of the materials or hardware described in the instructions.

NOTICE:Before installation, make sure you have a upper yoke that fits the slope of the roof.

WARNING:Make sure there are no people under the fan during installation!

Overview

PowerSky X6 can only be hung from I-beams or bar joists. For structural installation methods not covered in

this manual, please consult a structural engineer.

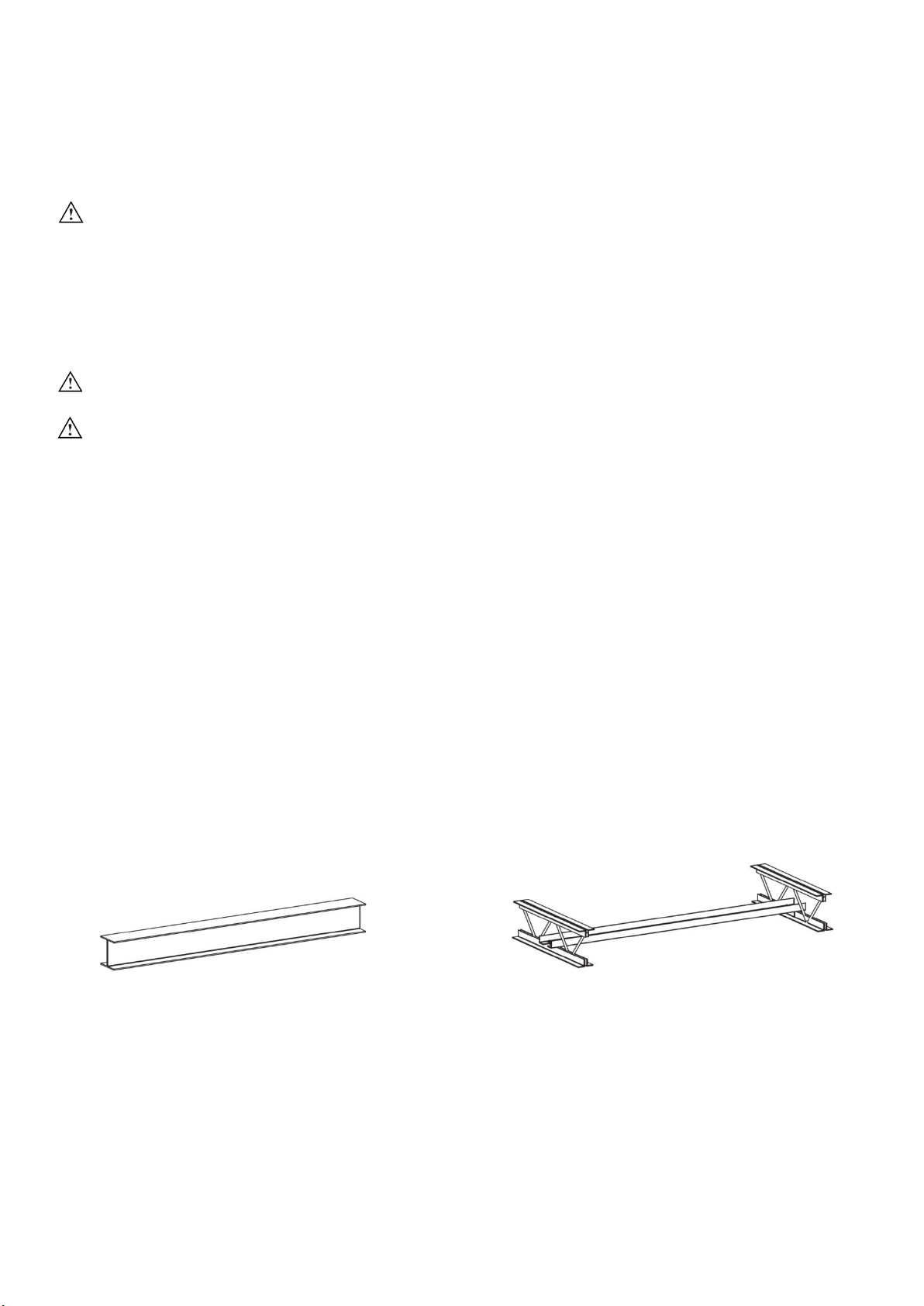

I-Beam

•It is not recommended to install the fan on the

prefabricated I-beam.

•Do not install the fan directly on the I-beam.

•The I-beam must be part of the existing building

structure.

Angle Iron

•Do not install a fan from a single purlin, truss or

bar joists.

•The unsupported angle iron span should not

exceed 3.7 meters.

•The angle iron must be fixed to the roof structure

at each end.

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

1a. Prepare The I-beam

NOTICE

If you install the fan on the angle iron, continue reading the next page.

Measure the width of the beam edge of the suspended fan. Select the mounting hole that matches the width

of the I-beam as shown in the figure below.

Continue with step 2.

Small upper yoke

13-3/4 inches x10 inches

(349 mm x 258 mm)

I-beam width

5 inches to 9-7/8 inches

(127 至250 mm)

Large upper yoke

18-1/2 inches x10 inches

(470 mm x 258 mm)

I-beam width

9-7/8 inches to 14-5/8 inches

(250 至371 mm)

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

1b.Prepare Angle Irons

WARNING:Do not install a fan from a single purlin, truss or bar joists.

WARNING:The unsupported angle iron span should not exceed 12 ft (3.7 meters).

WARNING:Angle iron must be fixed to the roof structure at each end.

For mounting the fan on the I-beam, see the previous page. For structural installation methods not covered

in this manual, please consult the structural engineer.

A. Select proper angle irons

Using the table and diagrams below, select the proper angle irons for fan installation.

Note: Angle irons and angle iron hardware are not included with the fan.

Angle iron span

(Between installation points)

Minimum angle iron size

(Width X Height X Thickness)

Number of angle irons

required

6 ft(1.8 m)or less

2.5”x2.5”x0.25”

(6.4 cmx 6.4 cm x 0.6 cm)

2

6 ft to 8 ft(1.8 m to 2.4 m)

3”x3”x0.25”

(7.6 cm x 7.6 cm x 0.6 cm)

2

8 ft to12 ft(2.4 m to 3.7 m)

3”x3”x0.25”

(7.6 cm x 7.6 cm x 0.6 cm)

4*

*Two pairs of angle irons. Pairs should be placed back to back and fastened in center

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

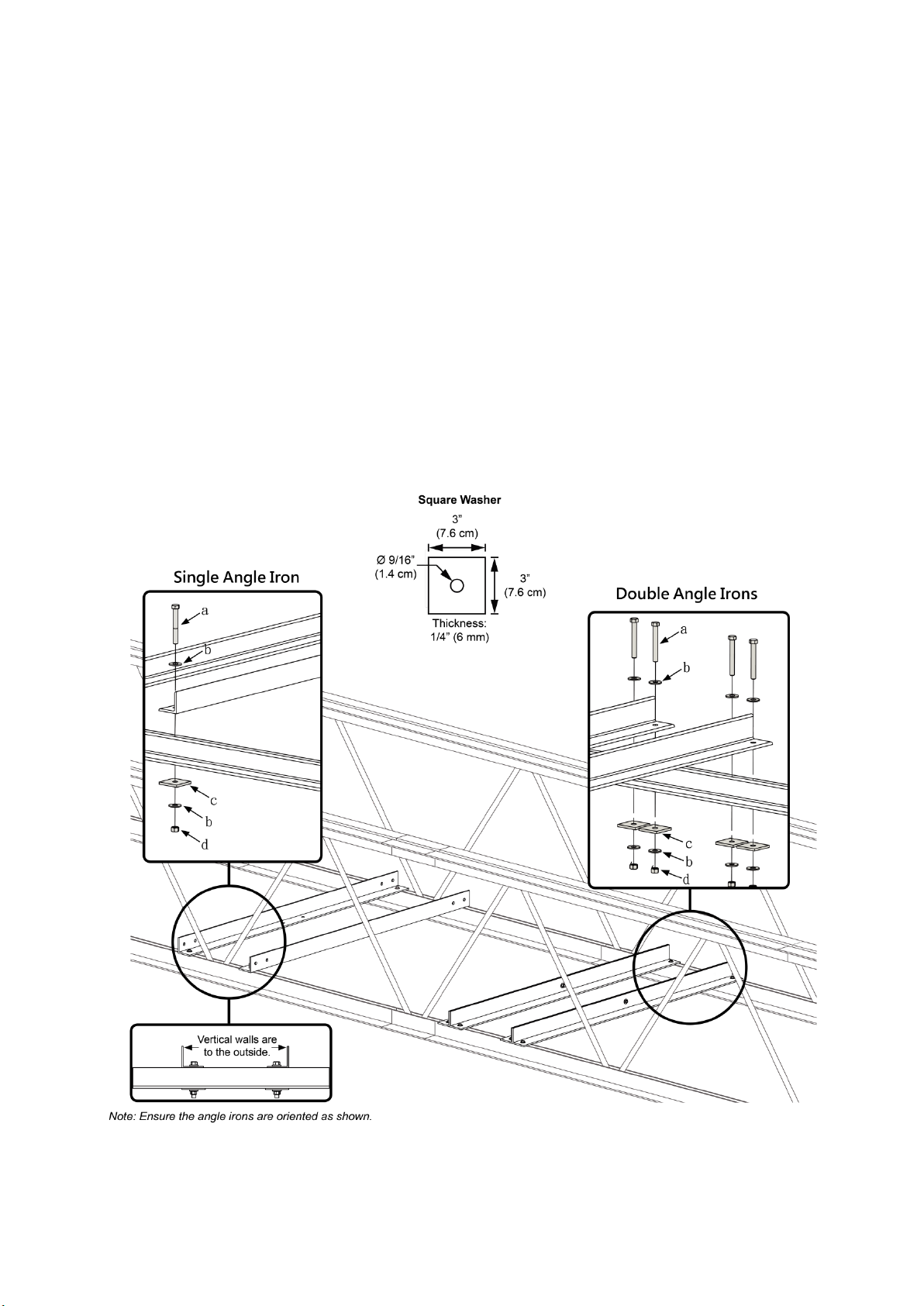

B. Fasten angle irons to roof structure mounting points

Fasten the angle irons to the roof structure mounting points at each end with Grade 8 hardware. Do

not fully tighten the hardware.

Single Angle Iron

Position the angle irons so that the horizontal legs

face each other (vertical legs are on the outside).

Double Angle Irons

Position the angle irons with fan mounting holes on

the inside, facing each other.

Grade 8 Angle Iron Hardware (Installer-Supplied):

a. (4 or 8) M12 GR 8 Bolt

b. (8 or 16) M12 GR 8 Washer

c. (4 or 8) 2”x 3”(51 x 76 mm) Rectangular Washer (APF-supplied; see diagram)

d. (4 or 8) M12 GR 8 Nylock Nut

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

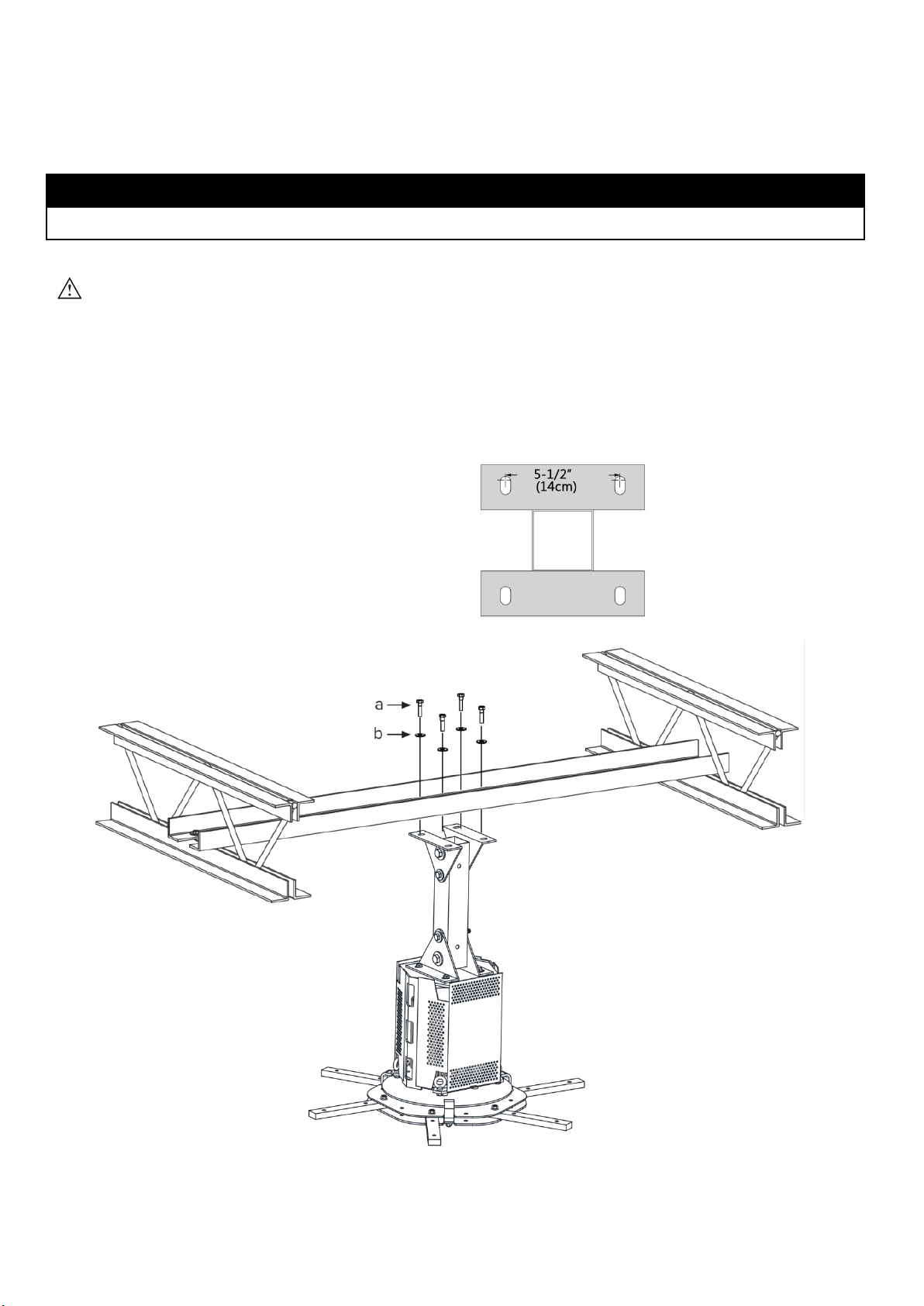

2. Install The Main Fan Unit On The Angle Iron

注意

NOTICE

If using the extension tube to install the fan, skip to step 3a (I-beam) or 3b (angle iron).

CAUTION: The main fan unit is heavy. Use caution when raising it.

Use the fan main assembly kit to secure the fan main unit directly to the angle iron. The distance between

the angle irons is shown in the figure below.

After fixing the main fan part to the angle iron, fix the angle iron to the roof structure.

Proceed to 5.Secure Upper Safety Cable

Main Fan Unit Hardware(APF-Supplied):

a. (4) M12 GR 8 Bolt

b. (8) M12 GR 8 Washer

c. (4) M12 GR 8 Nylock Nut

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

3a.Install Upper Yoke Fixing On The I-beam注意

NOTICE

If you are installing the fan on the angle iron, skip step 3b on the next page.

Measure the flange width of the I-beam from which the fan will be hung. Select the upper yoke mounting

holes that match the flange width of the I-beam.

Secure the upper yoke to the I-beam using the upper yoke hardware kit.

Proceed to 4.Installation Extension Tube

Upper Yoke Hardware(APF-Supplied):

a. (4) M12 X 55 MM GR 12 Bolt

b. (8) M12 Flat Washer

c. (4) M12 Nylock Nut

d. (2) Beam Clip

e. (2) Spacer

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

3b. Attach Upper Yoke (To Angle Irons)

Secure the upper yoke directly to the angle irons with the Upper Yoke Hardware as shown.

Upper Yoke Hardware (APF-Supplied):

a. (4) M12 X 50 MM GR 8 Bolt

b. (8) M12 Flat Washer

c. (4) M12 Nylock Nut

The angle irons should be aligned with the outermost holes on the upper yoke. Do not use beam

clips on angle irons!

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

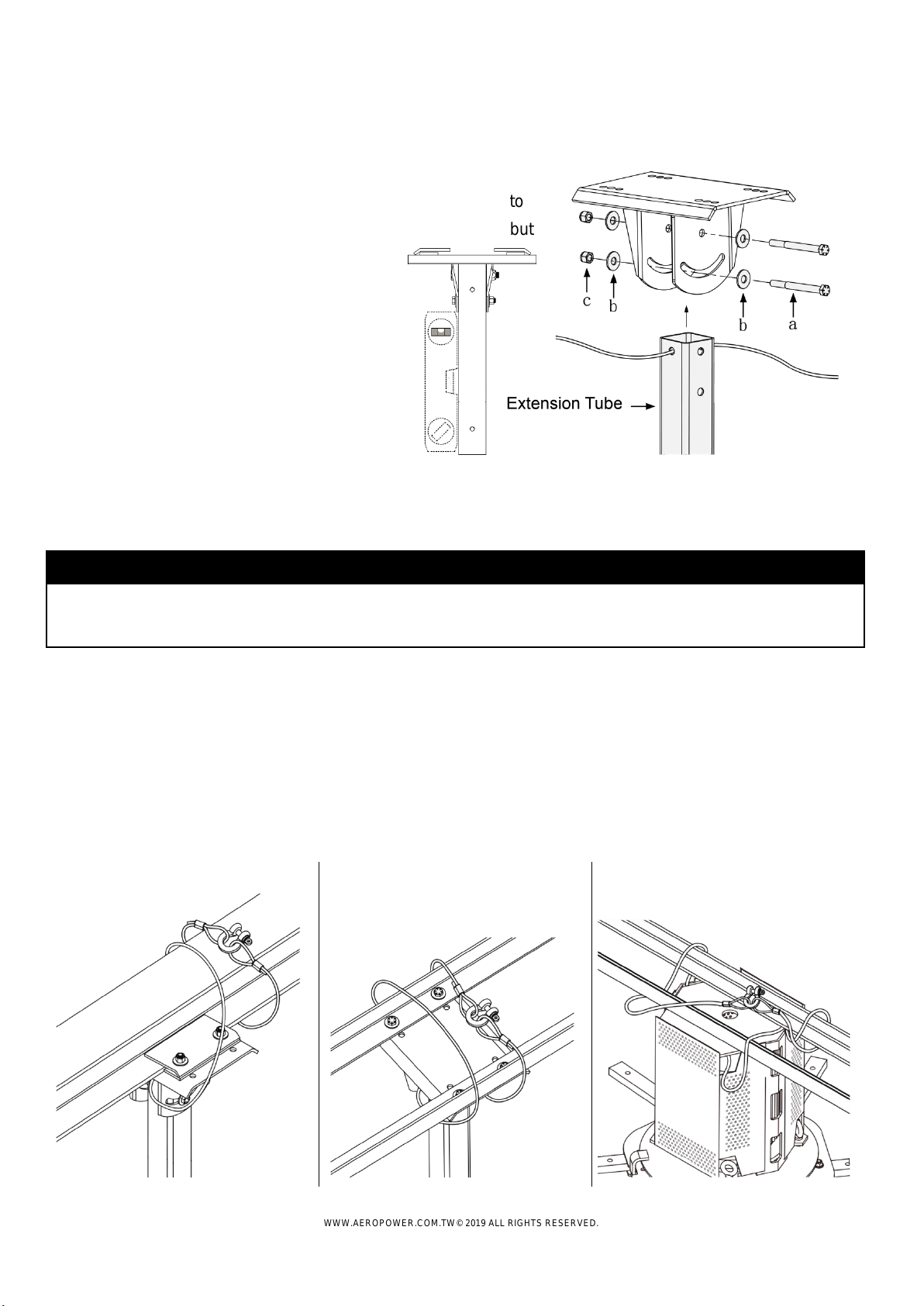

4. Attach Extension Tube (To Upper Yoke)

Secure the extension tube to the upper yoke using the extended

tube hardware. Ensure the extension tube is hanging plumb to

the ground, and then tighten the hardware so that it is snug, but

not fully tightened.

Extension Tube Hardware (APF-Supplied):

a. (2) M16 x 120 MM GR 8 Bolt

b. (4) M16 Flat Washer

c. (2) M16 Nylock Nut

5. Secure Upper Safety Cable

NOTICE

The safety cable is a crucial part of the fan and must be installed correctly. If you have questions

or require assistance, call Customer Service for assistance.

Note: If the fan installation contains an extension tube, the safety cable is pre-connected to the extension

tube. If the fan without an extension tube is installed, the safety cable is individually packaged.

Wrap the safety cable around the mounting structure and secure the looped ends with the shackle as shown.

The cable must be drawn tightly around the I-beam or angle iron, leaving as little slack as possible. The

shackle should be on the topside of the I-beam or angle iron if possible. Securely tighten the shackle.

I-Beam Mount

Angle Iron Mount

Direct Mount

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

6. Attach Lower Yoke (To Extension Tube)

Attach the lower yoke to the bottom of the extension tube with the

Lower Yoke Hardware as shown.

Tighten the hardware so that it is snug, but not fully tightened.

Lower Yoke Hardware (APF-Supplied):

a. (2) M16 x 120 MM GR 8 Bolt

b. (4) M16 Flat Washer

c. (2) M16 Nylock Nut

7. Attach Main Fan Unit (To Lower Yoke)

CAUTION: The main fan unit is heavy. Use caution when raising it.

Attach the main fan unit to the lower yoke with the Main Fan Unit

Hardware as shown. Do not rest the main fan unit on the ground!

Make sure the lower cable is positioned between the lower yoke

brackets as shown on the right.

Main Fan Unit Hardware (APF-Supplied):

a. (4) M12 x 30 MM GR 8 Bolt

b. (8) M12 Flat Washer

c. (4) M12 Nylock Nut

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

8. Confirm Orientation

After securing the main fan unit to the lower yoke, allow the fan to hang so

that the extension tube is plumb to the ground. When it is properly positioned,

fully tighten the mounting hardware (Lower Yoke Hardware and Extension

Tube Hardware).

9. Installing Guy Wires

注意

NOTICE

Guy wires may not be included in your fan order. They are intended to constrain the fan’s lateral movement

and are only included with fans that have extension tubes 4 ft (1.2 m) or greater in length. Depending on

the conditions at the installation site, guy wires may be needed for fans with shorter tubes to prevent any

lateral movement. If guy wires are needed and were not included with your fan order, contact Aero Power

Customer Service.

WARNING : Ensure power is disconnected from the fan before installing the guy wires.

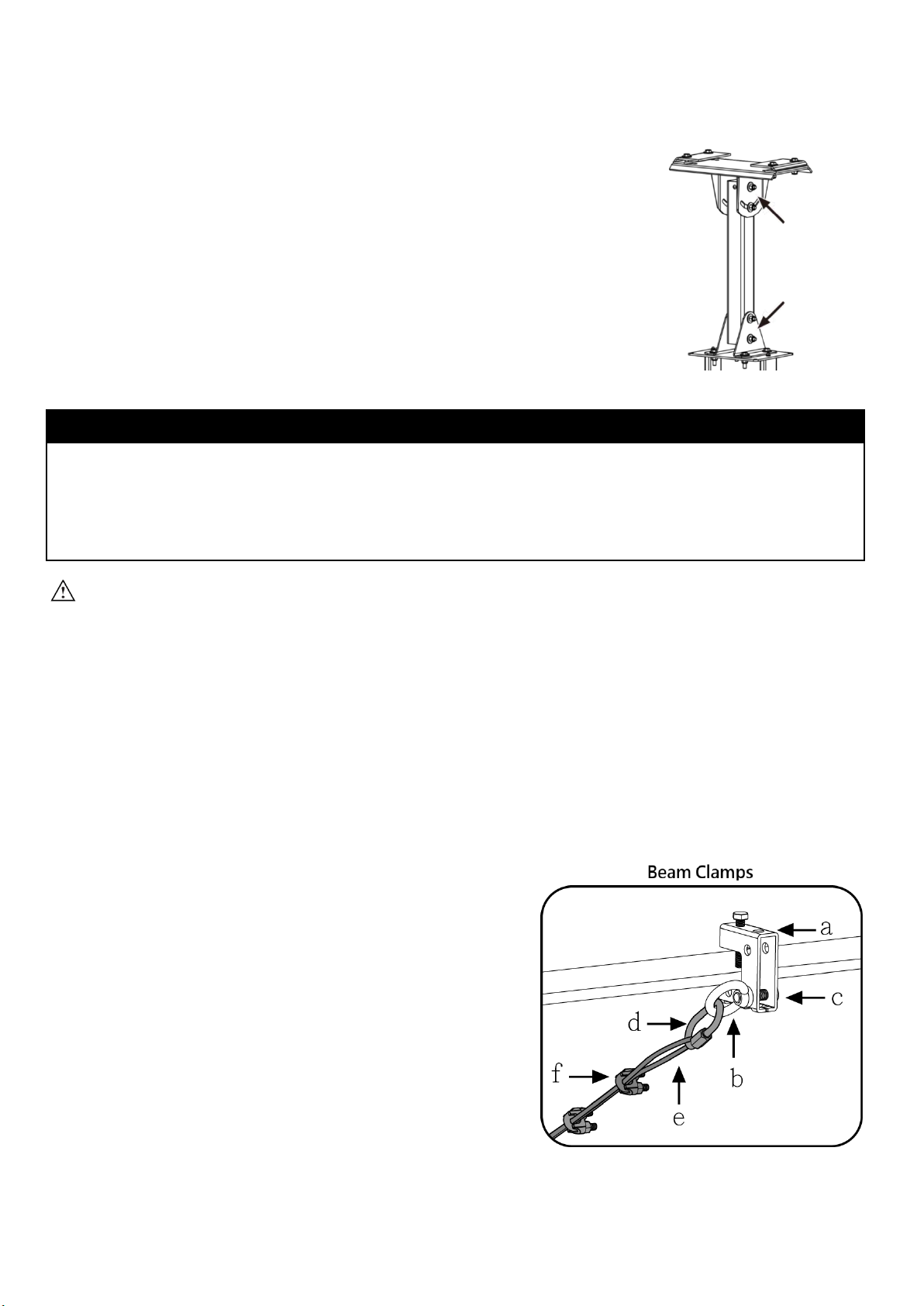

A. Attach beam clamp

Attach the beam clamp to the mounting structure. The guy wire should

be approximately 45°from the horizontal plane. Place the beam clamp

accordingly. Refer to the illustrations on the following page. Fully tighten

the set screw to secure the clamp.

Fasten the small eyebolt and nut onto the beam clamp. The nut will be

on the outside of the beam clamp.

Loop the crimped end of the guy wire into the locking carabiner and

secure to the eyebolt as shown. Securely tighten the carabiner.

Guy Wire Hardware (APF-Supplied):

a. (4) 8MM Beam Clamp

b. (4) M10 X 15 MM Eyebolt

c. (4) M10 x 35 MM Bolt

d. (4) Locking Carabiner

e. (4) Guy Wire

f . (4) Wire Rope Clip

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

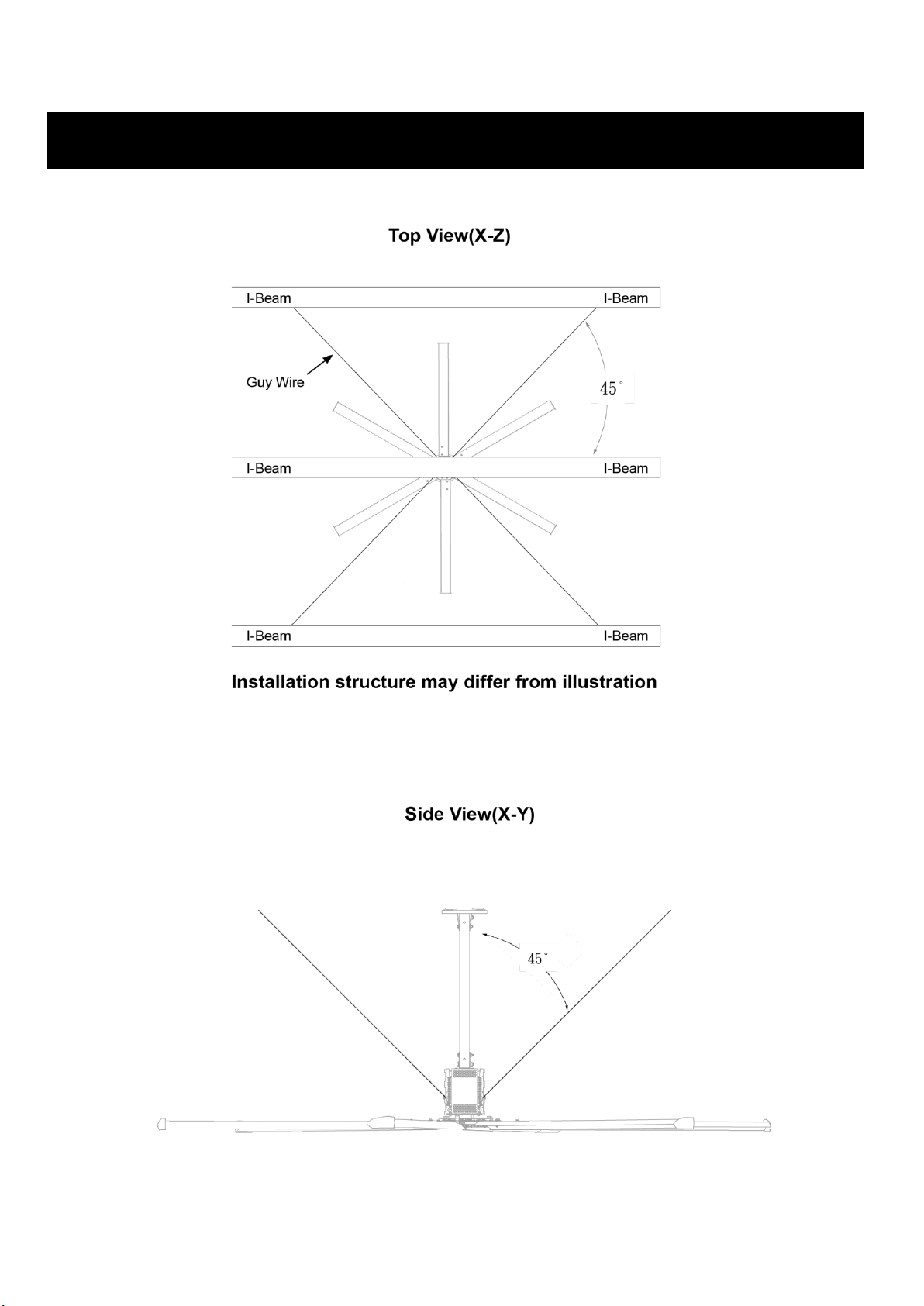

For best results, the guy wires should be installed at 45°in the X-Y, Y-Z, and X-Z planes as shown

below. If the angle deviates by more than 15°, contact Customer Service for assistance.

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

B. Route guy wires through Gripples

Route each guy wire through a Gripple and a eyebolt on the fan, and then back through the Gripple. Do not

tighten the Gripples until all guy wires have been installed.

C. Secure guy wires

WARNING:Over-tightening the guy wires could throw the fan off balance.

Repeat step B to install the remaining three guy wires.

Evenly cinch all four guy wires into place using the Gripples. The guy wires should be taut, evenly spaced

around the fan, and away from the path of the airfoils. Maintain a distance of 6”to 8”(152 to 203 mm)

between the Gripples and the carabiners.

Once all of theguy wires are taut and correctlypositioned, secure their loose ends with the wire rope clips and

tighten. Ensure all electrical cords/cables are unobstructed by the guy wire system.

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

10. Install Airfoils

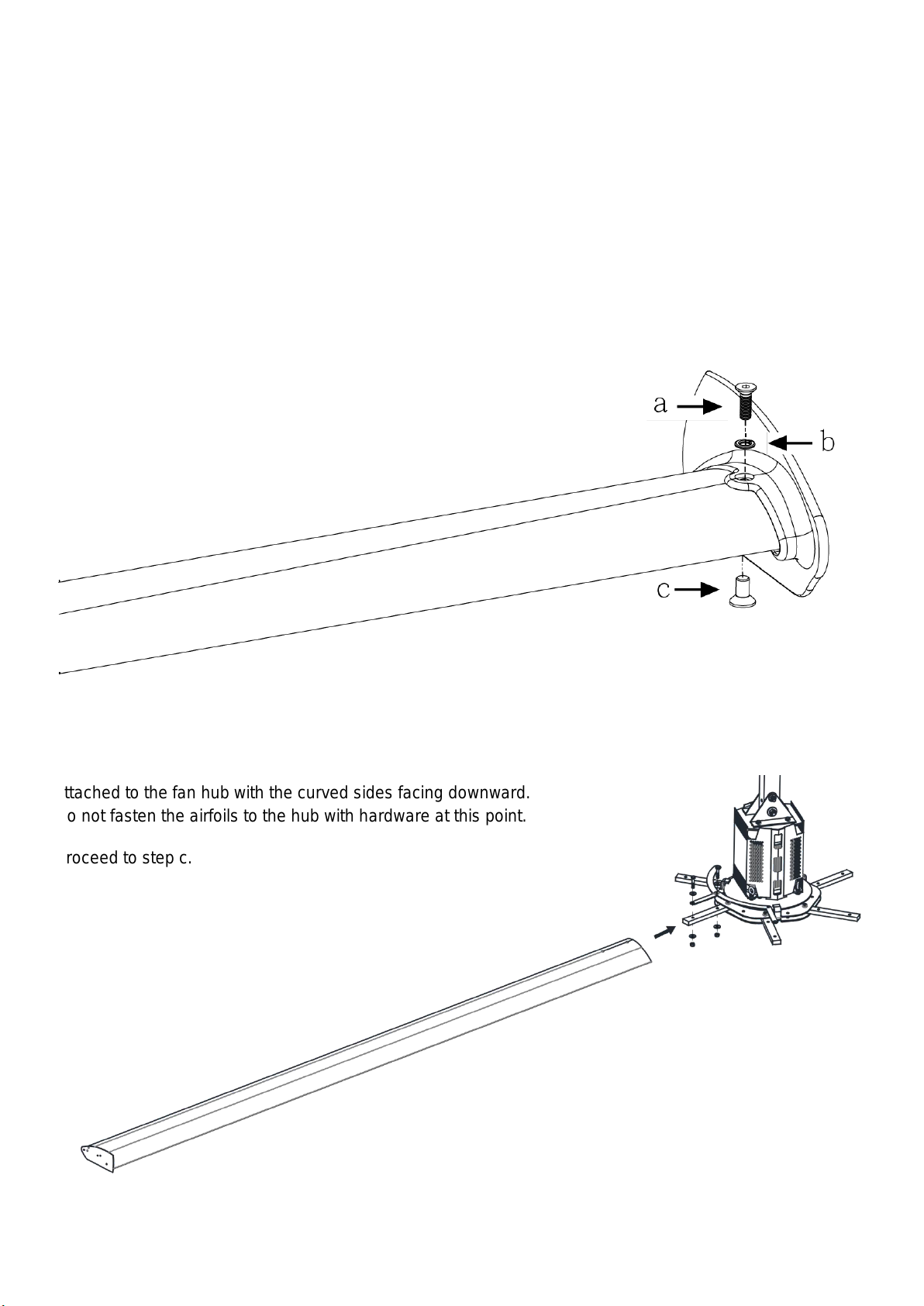

A. Attach winglets to airfoils

NOTE : Examine each airfoil to ensure the winglets is still securely attached before proceeding.

Attach a winglet to each airfoil with the Winglet Hardware. Secure winglets to all airfoils before attaching

the airfoils to the fan.

Winglet Hardware(APF-Supplied):

a. (6) M8 X 25MM Bolt

b. (6) M8 Spring Washer

c. (6) M8 Long Nut

B. Secure airfoils to hub

Slide the airfoils onto the tabs of the fan hub. The airfoils must be

attached to the fan hub with the curved sides facing downward.

Do not fasten the airfoils to the hub with hardware at this point.

Proceed to step c.

WWW.AEROPOWER.COM.TW© 2019 ALL RIGHTS RESERVED.

C. Attach airfoils to hub

Attach the 6airfoilretainers with the Airfoil Hardware. Moving clockwise around the fan hub, positionthe airfoil

retainers end over end as shown. Hole A of the retainer should be positioned over top of Hole B. Do not

tighten the bolts until all the airfoil retainers have been attached!

Airfoil Hardware (APF-Supplied):

a. (12) M10 x 50 MM GR 8 Bolt

b. (48) M10 Flat Washer

c. (12) M10 Nylock Nut

11. Install Hub Cover

Secure the hub cover to the fan hub with the Hub Cover Hardware.

Hub Cover Hardware(APF-Supplied):

a. (4) M4 Bolt

Table of contents

Popular Fan manuals by other brands

Movex

Movex FB Series installation instructions

Activejet

Activejet Action Selected WKS-120CPJ OPERATING MANUAL & WARRANTY

Emerson

Emerson SUMMERHAVEN CF850GES00 owner's manual

Hunter

Hunter Type 3 Models Owners and installation manual

Westinghouse

Westinghouse 73040 instruction manual

Craftmade

Craftmade Quest CQ52 Specifications

Ruck Ventilatoren

Ruck Ventilatoren EM 100L EC 02 Assembly instruction

Varma

Varma FS40-16JA instruction manual

Kichler Lighting

Kichler Lighting Wilton instruction manual

Ventamatic

Ventamatic HVPF 30 WM owner's manual

impress

impress IM-709V manual

Somogyi Elektronic

Somogyi Elektronic Home SFE 41/BK instruction manual