Aerosonic OASIS User manual

Aerosonic Corporation September 18, 2012

1212 N. Hercules Ave.

Clearwater, FL 33765 USA

OASIS

Standby Instrument System

Installation Manual

Aerosonic Corporation September 18, 2012

1212 N. Hercules Ave.

Clearwater, FL 33765 USA

INSTALLATION MANUAL

OASIS

Original Aerosonic Standby Instrument System

Document No:

Revision: X

Title and Name

Signature and Date

OASIS Installation Manual

This page intentionally left blank

OASIS Installation Manual

1 Table of Contents

1 .......................................................................................................Table of Contents

.................................................................................................................................. 4

1 ........................................................................................ GENERAL DESCRIPTION

.................................................................................................................................. 6

1.1 Introduction.................................................................................................................. 6

1.2 Scope .......................................................................................................................... 6

2 ......................................................................................................... INSTALLATION

.................................................................................................................................. 6

2.1 UNPACKING AND INSPECTING ................................................................................ 6

2.2 INSTALLATION PROCEDURES ................................................................................. 6

2.2.1 Location................................................................................................................ 6

2.2.2 Electrical Connections .......................................................................................... 6

2.2.3 Installation ............................................................. Error! Bookmark not defined.

2.2.4 Installation Guidelines for the SLZ7367................................................................19

OASIS Installation Manual

This page intentionally left blank

OASIS Installation Manual

1 GENERAL DESCRIPTION

1.1 Introduction

This manual covers the OASIS standby instrument system, which includes the

Display Unit (DU), Aerosonic Sensor Unit (ASU) and the optional Magnetometer

(MSU).

NOTE

Installation must be made by qualified personnel, in conformance with applicable

government regulations. Standard installation practices described in FAA Advisory

Circular No. 43.1.-2B –Acceptable Methods, Techniques, and Practices –Aircraft

Alterations must be followed. The information furnished is for convenience only.

1.2 Scope

This manual applies to the installation of the OASIS standby display, remote sensor

unit and the optional external magnetometer.

2 INSTALLATION

2.1 UNPACKING AND INSPECTING

Carefully unpack the unit and note any damage to shipping containers or equipment.

Visually inspect each component for evidence of damage. Compare the equipment

received with that noted on the packing list. Immediately report any missing items or

evidence of damage to the carrier making delivery.

Every effort should be made to retain the original shipping containers for storage. If

the original containers are not available, a separate cardboard container should be

prepared that is large enough to accommodate sufficient packing material to prevent

movement.

2.2 GENERAL INSTALLATION PROCEDURES

NOTES

1. Standard installation practices prescribed in FAA Advisory

Circular Number AC 43.13-2B must be followed.

2.3 Electrical Connections

1. The installer must take the following into consideration before installation.

All wiring must be in accordance with industry-accepted methods, techniques,

and practices. Refer to FAA Advisory Circular AC43.13-2B, Section 4 and

Section 8 for aircraft wiring requirements.

The installer is responsible for supplying wires, cables and connectors.

All wires should be 22 AWG unless otherwise noted. Use IL-DTL16878 or

equivalent wire and M27500 or equivalent for twisted shielded wired for

installation.

The length and routing of the external cables must be carefully studied and

planned before attempting installation of equipment.

OASIS Installation Manual

Wire-marking identification is at the discretion of the installer.

The OASIS system should be placed on it’s own spare circuit breaker.

Use of any cable not meeting specifications voids all warranties.

2. Refer to the appropriate Interconnect Wiring Diagram in Figures #-# and :

3. Wires and cables associated with the OASIS installation shall be fabricated from,

Shielded cable shall be in accordance with MIL-C-27500 and non-shielded wire shall be

in accordance with MIL-W-22759/16.

Wires shall be cut to length as required at the time of installation. Wires shall be cut with

sufficient length to adhere to the main aircraft wire runs while maintaining specific aircraft

installation practices in accordance with the specific aircraft maintenance manual.

Reference the specific aircraft maintenance manual as the primary source for wiring

identification and installation practices. Wires are installed and terminated in accordance

with the system wiring diagrams in figures XX and XX

Figure #-# shows specific recommendation for shield termination for the MIL-27500

shielded cables for the OASIS system mating connectors.

It is recommended that no more than four shield wires be connected to a lug.

Solder sleeves shown in illustration are S03-03-R-100 from Allied Electronics/Tyco

FIGURE 1SHIELD TERMINATIONS

OASIS Installation Manual

2.4 DISPLAY UNIT INSTALLATION

When locating the OASIS DU in the instrument panel, take the following information

into consideration.

1. The OASIS DU should be located in an area where the softkey buttons are

within easy reach of the pilot.

2. The OASIS should be accessible for inspection , maintenance, or removal

and free from instrument panel structural flexure and excessive vibration or

heat.

3. The OASIS wiring cable should not run adjacent to heaters, engine exhaust,

heat sources or any high energy electrical sources that may cause

electromagnetic interference.

4. Compare the space requirements of the OASIS with the installation area

being considered. Refer to Figure 3 for dimensional requirements.

FIGURE 2OASIS DU

OASIS Installation Manual

FIGURE 3DU DIMENSIONS

OASIS Installation Manual

Perform the following installation procedures to install the OASIS standby

display.

5. See figures 4 and 5 for typical instrument panel mounting location for the

Oasis DU.

FIGURE 4TYPICAL FIXED WING INSTRUMENT PANEL

FIGURE 5TYPICAL ROTARY WING INSTRUMENT PANEL

OASIS Installation Manual

6. The panel must be cutout if a suitable ATI-3 hole is not available, see Fig 6

for the Instrument cutout dimensions.

FIGURE 6DU PANEL CUTOUT

OASIS Installation Manual

7. The Oasis DU is secured in the Instrument panel using a 69020-6 ARINC

408A mooring plate, see figure 7.

FIGURE 7DU PANEL INSTALL

OASIS Installation Manual

8. The Display Unit connector views are shown in Figure 8. The mating

connector for the DU is D38999/26FD35S with a M85049/38s15 Strain Relief

Clamp.

FIGURE 8DISPLAY UNIT CONNECTOR FACE VIEWS

OASIS Installation Manual

2.5 AEROSONIC SENSOR UNIT INSTALLATION

The Aerosonic Sensor Unit (ASU) is a separate remote mounted LRU that provides

power and sensor data to the OASIS DU. The ASU is connected to the aircraft DC

buss and powers up to two DU’s and a MCU. Sensors within the ASU provide for

computation of Indicated Airspeed, Barometric Corrected Altitude, Pressure Altitude

and slip/skid. With the remote Magnetometer Heading information is provided to the

DU. The ASU can have a internal battery that allows operation for a minimum of 1

hour without aircraft power.

The ASU has a STATIC fitting and a PITOT fitting that connect into the aircraft

Pitot/Static system

FIGURE 9AEROSONIC SENSOR UNIT

For the dimensions of the ASU see Figure

OASIS Installation Manual

FIGURE 10 ASU DIMENSIONS

OASIS Installation Manual

For mounting dimensions for the ASU see Figure 11.

FIGURE 11 ASU MOUNTING DIMENSIONS

OASIS Installation Manual

Table 1 provides the installation limits for the ASU installation, Use the

following guidelines when measuring angles:

Roll angle is (+) right bank and (-) is left bank

Pitch angle is (+) nose up and (-) nose down

Yaw direction is (+) right yaw and (-) left yaw

The ASU must be mounted either parallel to the aircraft centerline or at 90

degrees to the aircraft centerline. The unit may be mounted upright on the

mounting surface or may be hung from the mounting surface.

TABLE 1ASUINSTALLATION LIMITS

PITCH

ROLL

YAW

The ASU allowed orientations are as shown in Table 2 following

TABLE 2ALLOWED ASU ORIENTATIONS

Orientation Bits

(3-0)

Connector End

Axis

ASU Mounting

Surface

0000

-X

+Z

0001

+Y

+Z

0010

+Y

+Z

0011

-Y

+Z

0100

+X

-Z

0101

-Y

-Z

0110

-X

-Z

0111

+Y

-Z

1000

-Z

+X

1001

+Y

+X

1010

+Z

+X

1011

-Y

+X

1100

-Z

-X

1101

+Y

-X

1110

+Z

-X

1111

-Y

-X

OASIS Installation Manual

See Figure 12 for the connector face views

FIGURE 12 ASU CONNECTOR FACE VIEWS

PITOT/STATIC CONNECTIONS

PITOT PORT CONNECTION

The Pitot fitting on the ASU is an AN4 Male fitting with MS33656-4 (7/16-20 thread for

¼” tubing).

STATIC PORT CONNECTION

The Static fitting on the ASU is an AN6 Male fitting with MS33656-6 (9/16-18 thread

for 3/8” tubing).

OASIS Installation Manual

2.6 INSTALLATION GUIDELINES FOR THE MSU

The SLZ7367 Magnetic Sensing Unit (MSU) can be seen in Figure x.

Note that the direction of flight (forward in the aircraft) is away from the cable

assembly. Strain reliefs are provided at both the housing and connector.

FIGURE 13 MAGNETIC SENSOR UNIT

See Figure 14 for the dimensions of the MSU

FIGURE 14 MSU DIMENSIONS

OASIS Installation Manual

Note: All mounting hardware must be non-ferrous materials.

The MSU is a 3 axis magnetic sensor that is extremely sensitive to magnetic fields;

therefore, the use of non-magnetic materials to secure the MSU to the airframe is

required. The MSU requires 3 #10-32 socket head screws (i.e. MS16996-11 or

Series 300 Non-Magnetic Stainless Steel) torqued to 31.7 inch lbs. Aluminum or

brass screws may also be used provided that they are torqued appropriately.

NAS620-C10L Washers (or equivalent non-magnetic washers) may also be used with

the screws. The pattern for the mounting holes of the MSU is shown in Figure . The

mounting holes are slotted to allow the installer flexibility in aligning the direction of

flight axis of the MSU with the aircraft’s longitudinal axis. The MSU must be installed

in the aircraft such that the forward direction of the MSU box is within ±0.5° of parallel

alignment with the aircraft’s longitudinal axis.

The direction of flight (aircraft forward) is away from the cable assembly.

Note that the MSU mounting flange is 0.25” above the bottom of the MSU. An

aluminum bracket is recommended with a 3” round hole for the MSU.

The MSU should be mounted such that it is within 2 degrees of aircraft level.

Refer to Maintenance manual for the aircraft to determine aircraft level.

The MSU must be installed in the aircraft in a location where there is minimal

magnetic interference from other devices in the aircraft and in such a location where

physical excursions resulting from natural oscillations are minimal. To insure this, the

MSU must be placed as far away as possible from ferromagnetic metals such as iron,

cobalt and permalloy. It should also be placed as far away as possible from wires

carrying any significant current. Failure to install the MSU in a magnetically

friendly environment will result in heading errors which cannot be removed by

field calibration.

The following guidelines are recommended for MSU installation:

The MSU shall be mounted no closer than 10 ft to electric motor and relays.

The MSU shall be mounted no closer than 8 ft to ferromagnetic structures greater than 1

kg.

The MSU shall be mounted no closer than 4 ft to ferromagnetic structures less than 1 kg.

The MSU shall be mounted no closer than 4 ft to any electrical component/conductor

drawing in excess of 100mA.

The MSU shall be mounted no closer than 2 ft to any electrical component/conductors

drawing less than 100 mA.

Typical installation areas are the tail section or wing tips (See Appendix X). In rotor

craft, installation is usually below the main cabin or in the tail boom away from any

rotating ferromagnetic shafts. Installation of the MSU within 2 feet of the cabin is not

recommended due to potential interference that would affect the performance of the

device.

When mounting the MSU in the wing, it is recommended that the wing tip lights have

a dedicated power ground supplied through a twisted pair of wire back into the

fuselage as opposed to a ground reference back to airframe ground. This will prevent

current flow in the wing skin that may degrade the performance of the MSU.

Table of contents

Popular Avionic Display manuals by other brands

Garmin

Garmin Cessna Caravan G1000 manual

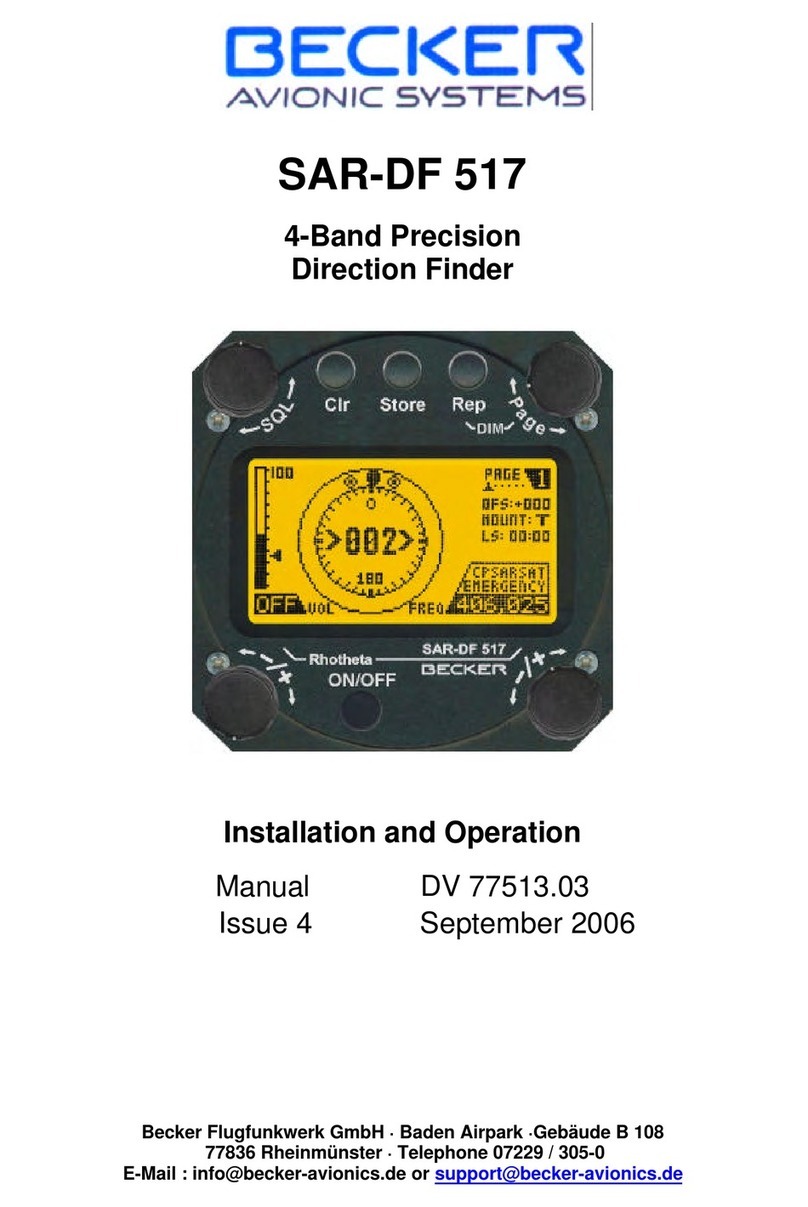

Becker

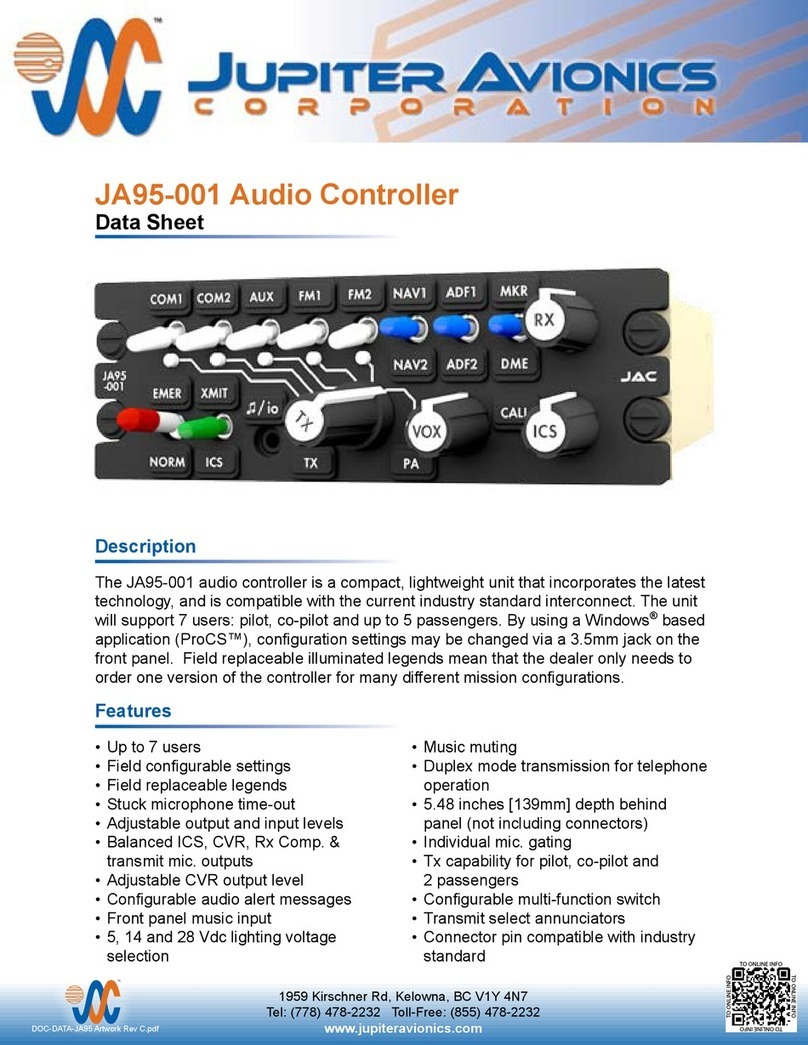

Becker SAR-DF 517 Installation & operation manual

Avlite

Avlite AV-OL-70 Installation & service manual

Garmin

Garmin GMA 340 pilot's guide

Dynon

Dynon SkyView HDX System AIRPLANE FLIGHT MANUAL SUPPLEMENT

Hypetrain Electronics

Hypetrain Electronics Riot Control user manual

Garmin

Garmin Beil 407GX Cockpit reference guide

Logitech

Logitech TR1478BD user guide

Garmin

Garmin Cirrus Perspective SR20 Cockpit reference guide

Dynon Avionics

Dynon Avionics EFIS-D10 installation guide

Planar

Planar LC-3ATI Specifications

Garmin

Garmin Approach G5 - GPS-Enabled Golf Handheld Maintenance manual