Aerospace Logic FL20 Series User manual

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

This document set is applicable to the following part number configurations:

Part Number

Description

FL202

Fuel level instrument, two tanks,

resistive senders

Part Number

Description

FL203

Fuel level instrument, three tanks,

resistive senders

Part Number

Description

FL204

Fuel level instrument, four tanks,

resistive senders

Part Number

Description

FL205

Fuel level instrument, five tanks,

resistive senders

Part Number

Description

FL206

Fuel level instrument, six tanks,

resistive senders

FL20X Fuel Level Resistive

Document # S200-FL20X-001

Rev 1.3 12/22/2014

Page 1 of 2

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

THIS IS A TRANSPORT CANADA APPROVED MANUAL

The following checklist outlines the required articles for all FL20X series part numbers.

Documentation Document Number

Introduction (this document) S200-FL20X-001

Warranty Statement S200-AWS

Installation Instructions S200-FL20X-002

Intensity Control Installation Options S200-DDC-INST

Wiring and Installation Schematic S200-FL20X-003

Human Interface Definition S200-HID

Instrument Setup S200-FL20X-004

Operations Guide S200-FL20X-005

Product Specifications S200-FL20X-006

Installation Compliance S200-FL20X-007

Instructions for Continued Airworthiness S200-ICA

Flight Manual Supplement S200-FMS (if applicable)

Calibration Log S200-FL20X-0XX

Authorized Release Certificate FORM ONE

Permission to Use STC S200-PTU

Canadian STC and Eligibility List STC & S200-CEL

FAA STC and Approved Model List STC & S200-AML

Components

FL20X Instrument

4 X Mounting Screws

FL20X Fuel Level Resistive

Document # S200-FL20X-001

Rev 1.3 12/22/2014

Page 2 of 2

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

The Fastest Way To Install And Start Using This Product

NOTE:This product is certified as a primary replacement, new or secondary instrument

only when installation is performed in accordance with the documented instructions and

procedures.

1. Review the Warranty Statement before performing any tasks. Do not remove the

instrument from the sealed package until you agree with the stated terms.

2. If this instrument is to be installed in a certified aircraft, verify that the aircraft

model is listed on the Eligibility List (Canadian registered aircraft) or the

Approved Model List (USA and all other countries).

If it is NOT listed, contact your local authority and obtain the necessary

requirements or approvals before proceeding further.

For all other vehicles, including experimental aircraft continue with Step 3.

3. Follow the Installation Instructions exactly as noted, referring to the Wiring

Diagram as and when required. Note: The installation process has been

optimized based on the sequence of components to be installed. Installing the

product in any other way will, in all likelihood, take longer and be more complex.

Ensure that one of the Intensity Control options has been installed in accordance

with document # S200-DDC-INST.

4. Perform the Instrument Setup using the required data as listed in the Instrument

Setup procedure.

5. Validate that all functions perform as outlined in the Operations Guide.

6. Complete all regulatory documentation, if required.

Document # S200-AWS

Rev 1.6 12/22/2014

Page 1 of 1

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

NO NONSENSE WARRANTY

Our warranty policy is simple …. It is even written in plain English!

Please read it BEFORE DOING ANYTHING WITH YOUR NEW INSTRUMENT!

If you require technical support when installing your instrument please call

our Technical Support department directly on

416-628-0725

We will:

Repair or replace (at our discretion) any instrument which becomes defective

within a period of 12 (twelve) months of manufacture date. You will pay for the

shipping costs to return the instrument to us and we will pay for the shipping

costs to return the instrument to you;

Replace all instruments that fail out of warranty for a flat rate of 50% of the cost

of a new instrument, at the time of the failure.

We are not:

Liable for any costs associated with the installation or removal of any of our

instruments, irrespective of the cause;

Liable for any misuse or non-use of the instrument in whatever form.

We will not:

Repair or replace your instrument free of charge, under warranty, if it has not

been installed by an appropriately licensed person.

If you do not agree with ANY of the above statements, return

your new instrument to us immediately for a FULL refund LESS

shipping costs.

ALL RETURNS REQUIRE RETURN MATERIAL AUHORIZATIONS

(RMA). WE DO NOT ACCEPT RETURNS WITHOUT RMA

NUMBERS. CALL 416-628-0725 FOR AUTHORIZATION.

FL20X Installation Instructions

Document # S200-FL20X-002

Rev 1.4 02/28/2017

Page 1 of 1

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

1. The FL20X instrument uses resistive, float type senders for fuel level sensing.

Ensure that all senders are in a good working condition BEFORE proceeding to

step 2.

a. FL20X instruments use the existing aircraft fuel senders. For tanks with

multiple senders, ensure that the senders are connected in series with the

outermost sender in the series being grounded. The sender array must

represent a varying resistance with relationship to fuel level and NOT be

powered from any source.

b. FL20XD instruments use magnetoresistive aircraft fuel senders P/N

CC284022-()-(). Install in accordance with the manufacturer supplied

instructions for these senders.

2. Connect the wiring supplied with the DB25 interface connector in accordance

with the FL20X Wiring and Installation Schematic. DO NOT ATTACH THE

CONNECTOR TO THE INSTRUMENT UNTIL ALL WIRING HAS BEEN

CONNECTED.

3. Select the instrument location in the aircraft panel.

4. Ensure that the aircraft master switch and/or power to the instrument is OFF.

5. Attach the DB25 connector to the instrument. Ensure that the plug is fully

inserted into the instrument. Finger tighten the two plug locking screws, then

tighten 1/8 turn using a screwdriver. DO NOT OVERTIGHTEN.

6. The instrument can be installed with the DB25 connector orientated to the TOP

or BOTTOM of the instrument panel.

7. Install the instrument in the panel, attaching with four 6-32 X 5/16” screws.

8. Initial Power Up Sequence:

a. Adjust the instrument intensity control for maximum intensity.

b. Apply power to the instrument.

c. The instrument display will turn on. Ignore the orientation at this time.

d. Turn the instrument OFF.

9. If the instrument display does not turn on:

a. Ensure intensity control is set for maximum.

b. Turn off power.

c. Disconnect the DB25 connector from the instrument.

d. Check intensity control.

e. Check the wiring installation and breaker or fuse.

10. Proceed to “Instrument Setup”.

Intensity Control – Installation Options

Applicable to Rev 05 and later 200 Series Instruments

Document # S200-DDC-INST

Rev 1.2 02/28/2017

Page 1 of 1

Aerospace Logic Inc.

www.aerospacelogic.com

Choose ONE of the options listed below for connection of the BLUE intensity control wire

from the instrument harness.

Theory of Operation

•The instrument intensity control is voltage sensitive.

•When the sense input is grounded the instrument display will be at the dimmest

intensity. At bus voltage the instrument display will be at the brightest intensity.

•Voltages between these two will vary the display intensity.

1. Preferred Method – Independent Potentiometer

Connect the BLUE wire to P/N A200-POT Rev. 02 as below:

Ensure the “EXTERNAL” option in the Dimmer Control menu is set.

2. Connection of Existing Panel Intensity Control

Confirm the existing panel lighting control meets the following requirements:

•When set for DAY operation BUS voltage must be output.

•When used at NIGHT the output must vary from 0V (Ground) to BUS

voltage.

If these requirements are met connect the BLUE wire to the panel lighting control.

Ensure the “EXTERNAL” option in the Dimmer Control menu is set.

3. Day VFR Operation

Do not connect the BLUE wire. Set the intensity using the internal Dimmer Control.

Refer to document S200-HID, Intensity Control section for menu access instructions.

FL20X Wiring and Installation Schematic S200-FL20X-003 Rev 1.4 02/28/2017

DB25 CONNECTOR

FL20X INSTRUMENT

RED

BLACK

ORANGE

6V - 36V SUPPLY

GROUND

EXTERNAL ALARM (MAX 100mA SINK)

COLOR DESCRIPTION

WHITE / #4

WHITE / #5

WHITE / #6

COLOR/TAG TANK NAME (DISPLAYED)

(C) Aerospace Logic Inc. (2008-2017)

NOTES:

1. * See S200-DDC-INST for additional intensity control options

Resistance grearter than 10 and less than 300 ohms1.

INSTALLATION NOTES:

Allow for current drain of 0.1A (100mA)

Install using breaker or panel fuse

Maximum 7 instruments per 1A of breaker capacity

For multiple instrument installations install breakers to comply

with redundancy requirements of AC 23.1309-1D Appendix 1

1.

2.

3.

4.

1

2

3

SENDER NOTES:

2. Multiple resistive senders per tank to be connected in series

3. Qualified for use with OEM or STC'd senders only

WHITE / #1

WHITE / #2

WHITE / #3

4

5

6

BLUE 0V-BUS VOLTAGE - VARIABLE INTENSITY INPUT *

TANKS NUMBERED LEFT TO RIGHT

(FUEL / LEFT / 1)

(RIGHT / 2)

(3)

(4)

(5)

(6)

NUMBER OF WHITE WIRES TO MATCH TANK CONFIGURATION

Frequency input greather than 10Hz and less than 300Hz

200 Series Human Interface Definition

Document # S200-HID

Rev 1.2 02/28/2017

Page 1 of 1

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

All 200 Series instruments have been designed around a standard Human Interface

protocol. This allows identical operation of the two panel switches between all

instruments while still allowing multiple functions. This document is a generic outline of

the functionality of the switches, based on the various functional states of the instrument.

Top Button

The top button is the action button. It invokes different screen displays, allows selection

of values and increments or decrements values. Examples of these actions are:

1. Moving between display screens

2. Selection of an action from a menu

3. Changing a value from within the setup menus

4. Entering a value during flight (clock instrument only)

Bottom Button

The bottom button is the navigation button. It will allow the cursor on the screen to move

between allowable selections. Examples of these actions are:

1. Selection of different cylinders (EGT and CHT) in the Single Cylinder mode

2. Selection of different tanks (Fuel Level)

3. Selection of limits and functional items from within the setup menus

4. Time field selection (clock instrument only)

There is one exception to the functionality of the bottom button. This is from the Primary

Display (the screen that first comes on from power up). Pressing the button will display

the instrument core status and support data.

General

1. Each instrument contains detailed button options in the Operations Guide.

2. During setup, instructions are provided on screen and use of the buttons is as

noted in this document.

Intensity Control

Press and hold the top button for 5 seconds to activate the Dimmer Control menu.

Select the “Up Arrow” and press the top button to disable external intensity and increase

intensity. Select the “Down Arrow” and press the top button to decrease the intensity and

enable external intensity control.

Select the “Save” option and press the top button to save your selection and return to

normal operations.

The Dimmer Control menu is not available during instrument setup.

FL20X Instrument Setup

Document # S200-FL20X-004

Rev 1.2 12/22/2014

Page 1 of 2

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

1. Before proceeding with the instrument setup you will require the following

information, for each tank pair or set, as it pertains to the aircraft that the

instrument is being installed on:

a. Maximum red line fuel quantity

b. Maximum yellow line fuel quantity

2. This information must be obtained from a current, traceable source for the aircraft

that the instrument is being installed on. Some possible sources are:

a. Pilot Operating Handbook

b. Maintenance Manual

c. Aircraft Type Certificate Data Sheet

d. Engine Type Certificate Data Sheet

e. Manufacturer

3. This instrument requires calibration before it will function. To calibrate each tank

you will be required to add fuel at TWO gallon increments, starting with the

unusable fuel in the tank (the legal, zero fuel point).

a. Place the aircraft in a level flight attitude and support the aircraft wings, if

necessary.

b. Drain all tanks to be calibrated.

c. Disable any cross feed between tanks.

d. Place the unusable fuel in each tank to be calibrated.

e. Complete the calibration process by following the interactive, instructions

provided throughout the process on the instrument display (See 4).

f. Calibration time is approximately one minute per two gallons of fuel.

g. Note the calibration values on the provided calibration sheets. This value

serves two purposes.

i. It demonstrates a compliant installation, and

ii. Provides a hard copy backup of all calibration data.

h. It is not necessary to complete the full calibration at once. Calibration can

be resumed at any point of the process by re-entering the setup.

FL20X Instrument Setup

Document # S200-FL20X-004

Rev 1.2 12/22/2014

Page 2 of 2

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

4. To enter parameters and perform the calibration, proceed as follows:

a. Turn off the power to the instrument

b. Press and hold both top and bottom buttons and turn on the power to the

instrument.

c. When instructed, release both buttons.

d. In the setup menus, use the bottom button to navigate and the top button

to select an option.

e. Follow the onscreen instructions to enter the correct operating

parameters. NOTE: Depending on the installation orientation of the

instrument the display may initially be upside down. The first prompt

in the setup is to press the button at the top of the instrument. This

will orientate it correctly.

f. To perform the instrument calibration, follow the instructions provided on

the instrument screen.

5. Once all calibration has been completed the instrument will be enabled and be

ready for use.

FL20X Operations Guide

Document # S200-FL20X-005

Rev 1.3 02/28/2017

Page 1 of 2

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

This manual outlines the operating procedures for all FL20X series products

FUEL INSTRUMENT NOT INSTALLED CORRECTLY

FLIGHT PROHIBITED

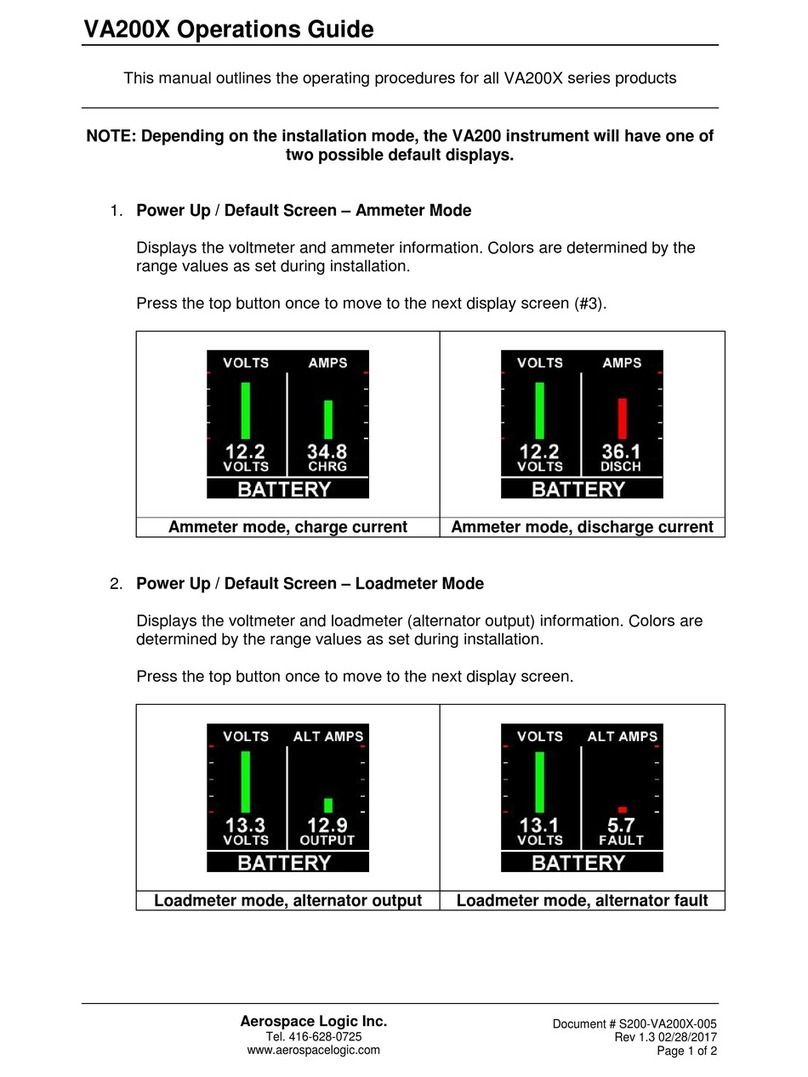

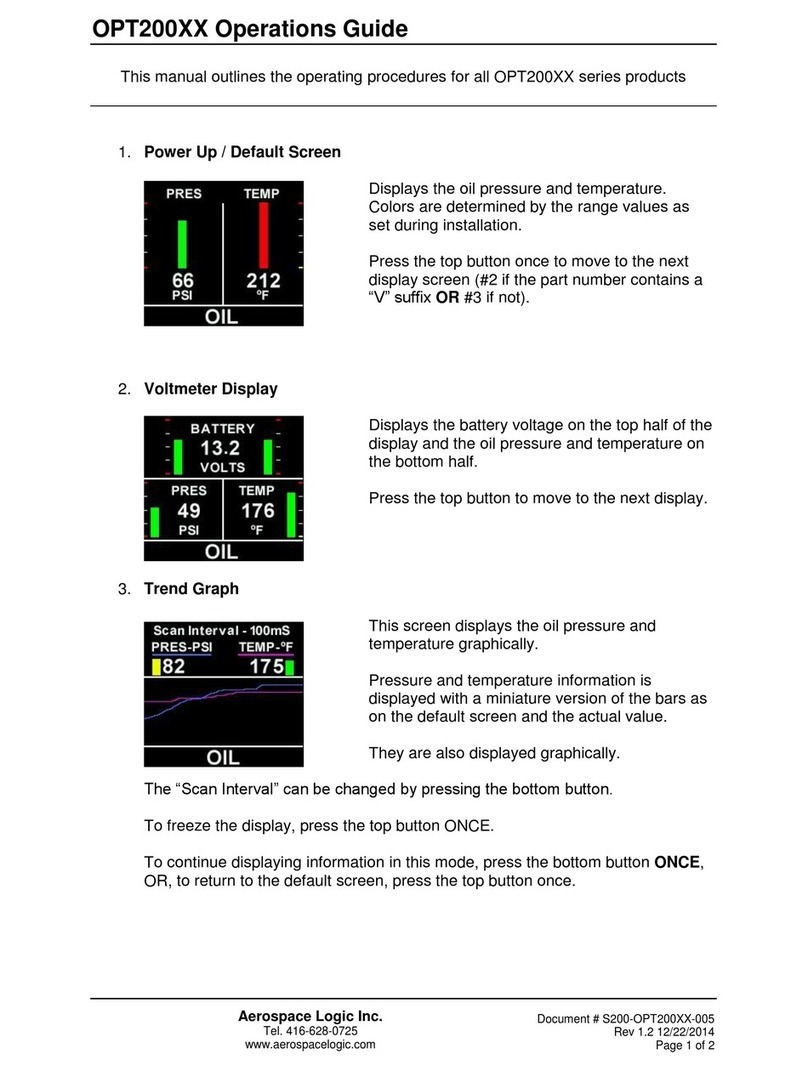

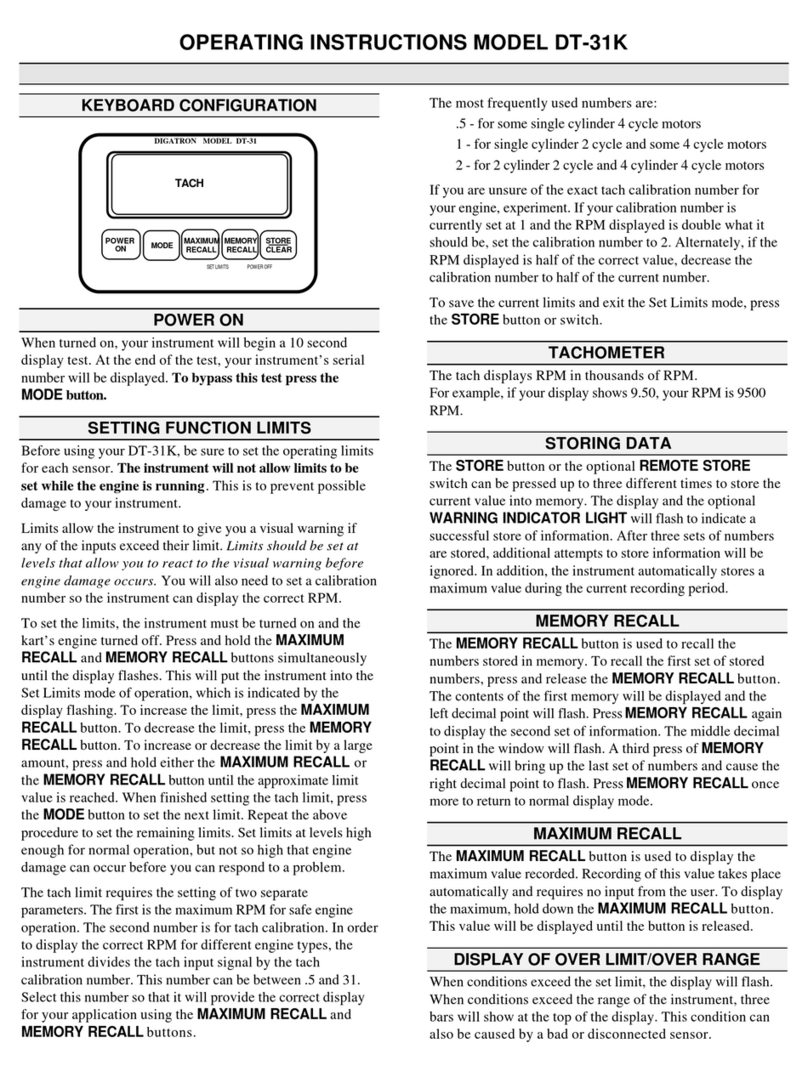

1. Power Up / Default Screen

Displays the fuel level in each tank. Colors are determined by the range values

as set during installation. Tanks are indicated from leftmost to rightmost.

For the FL202 instrument, the quantity in each tank is permanently displayed

beneath each indicator bar. For all other instruments, use the bottom button to

scroll between tanks. The fuel quantity displayed corresponds to the tank number

with the arrow beneath the bar indicator.

Press the top button to move to the next display screen.

FL202

FL203

FL204

FL205

FL206

FL20X Operations Guide

Document # S200-FL20X-005

Rev 1.3 02/28/2017

Page 2 of 2

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

2. Trend Graph

This screen provides a graphical display of fuel

usage, since the most recent power on.

The graph spans a time period of 130 minutes (2

hours 10 minutes). Once this graph area has

been populated it will scroll to the left.

The fuel value displayed at the bottom of the

screen relates to the selected tank as indicated

by the bracketed tank number at the top of the screen. Use the bottom button to

scroll between tanks.

Press the top button to return to the default screen.

3. Other Options

To display the instrument serial number and core information press and hold the

bottom button when the instrument is first powered on.

WARNING

NEVER RELY SOLELY ON ANY FUEL INDICATION INSTRUMENT FOR THE

DETERMINATION OF AVAILABLE FUEL.

WHEN USED IN CONJUNCTION WITH A PHYSICAL INSPECTION,

DETERMINATION OF AVAILABLE FUEL PLUS NECESSARY FLIGHT DURATION

AND CONDITION CALCULATIONS, A FUEL LEVEL INSTRUMENT BECOMES A

VALUABLE COCKPIT INFORMATION RESOURCE.

WARNING

All operations are to be performed in accordance with the specific instructions pertaining

to your aircraft, including those provided by the engine manufacturer. The FL20X series

instruments are only parameter reporting devices which can assist in engine and flight

management when used in conjunction with these instructions.

All FL20X products are certified as primary replacements ONLY, within the limits as

described above. THEY MAY NOT BE INSTALLED AS SECONDARY INSTRUMENTS.

FL20X Product Specifications

Document # S200-FL20X-006

Rev 1.3 02/28/2017

Page 1 of 1

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

Certification / Compliance

TSO C55a

Environmental DO-160F

A1CAASXXXXXXZBXXBBBCSBA1C11XXAX

Software DO-178B

DC Power Source Input voltage 6 to 36 VDC

Power consumption 100mA

Load dump tolerance +60V

Direct spike tolerance +/- 60V

Cable spike tolerance > +/- 1KV

Operating Temperature Constant operating -15ºC to +55ºC

Short term operating (1hr) -40ºC to +70ºC

Storage -55ºC to +85ºC

Signal Input Sender resistance 0.25 Ώ to 300 Ώ

Sender Orientation Installer selectable. Resistance proportional or

Inversely proportional to fuel quantity

Display Fuel Quantity US Gallons or Litres

Accuracy Fuel Quantity AS405C +/- 1 USG

Range 0 to 120 USG (defined by fuel sender/tank size)

Display Sunlight readable LCD

80/80/80/80 Degree viewing angle

Annunciator Output 100mA sink with reverse EMF protection

Interface Connector DB-25

Software Functionality

Primary Fuel level in all tanks

Trend Graph Graphic display of level vs time

Dimensions 2.45” X 2.45” X 0.9”

Weight (excluding harness) 4.05 oz

Finish Black anodized 6061 aluminum

FL20X Installation Compliance

Document # S200-FL20X-007

Rev 1.3 12/22/2014

Page 1 of 1

Aerospace Logic Inc.

Tel. 416-628-0725

www.aerospacelogic.com

1. Installation Procedures and Limitations

Should your specific aircraft not be listed on our STC Approved Model List

(AML), contact your local FSDO or flight authority for installation requirements

BEFORE commencing any installation tasks.

Installation must be in accordance with the following FL20X published

documents:

a. Installation Instructions,

b. Wiring and Installation Schematic, and

c. Instrument Setup.

2. Installation Location and Visibility

The products are to be installed in existing panel holes and will replace existing

instrumentation. As primary replacement products it is recommended and

preferred that they be placed in the same panel location as the original

equipment. Their visibility and placement relative to other instruments are the

same or similar to the existing instruments. Where they are installed in a different

location it is the responsibility of the installer to ensure that they are visible to the

pilot under all conditions.

3. TSO COMPLIANCE NOTICE

The conditions and tests required for TSO approval of this instrument are

minimum performance standards. Those installing this instrument on or in a

specific type or class of aircraft, must determine that the aircraft installation

conditions are within the TSO standards. TSO articles must have separate

approval for installation in an aircraft. The instrument may be installed only

according to 14 CFR part 43 or the applicable airworthiness requirement.

This manual suits for next models

5

Other Aerospace Logic Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

4B

4B Digimatic DML4W Operation manual

Laserworld

Laserworld RGB-0.7 manual

ALFAMATIC

ALFAMATIC PRESS -RIGHT installation manual

MICRO-EPSILON

MICRO-EPSILON thicknessCONTROL MTS 8201.LLT operating instructions

Novanta

Novanta p400 OEM Series user manual

Endress+Hauser

Endress+Hauser Micropilot FMR20 technical information