Aerotech NPAQ MR User manual

P/N:EDU210

Revision: 1.06.00

Npaq MRHardware Manual

AEROTECH.COM

ON

OFF

Npaq MR

FEEDBACK COMMUNICATIONS

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

EXT DRIVE RS232

AUX ENCODER

JOYSTICK

ESTOPMOTOR

DIGITAL / ANALOG IO

Global Technical Support

Go to www.aerotech.com/global-technical-support for information and support about your Aerotech products. The website

provides downloadable resources (such as up-to-date software, product manuals, and Help files), training schedules, and PC-

to-PC remote technical support. You can also complete Product Return (RMA) forms and get information about repairs and

spare or replacement parts. For immediate help, contact a service office or your sales representative. Have your customer

order number available before you call or include it in your email.

United States (World Headquarters)

Phone: +1-412-967-6440

Fax: +1-412-967-6870

Email: service@aerotech.com

101 Zeta Drive

Pittsburgh, PA 15238-2897

www.aerotech.com

United Kingdom Japan

Phone: +44 (0)1256 855055

Fax: +44 (0)1256 855649

Email: service@aerotech.co.uk

Phone: +81 (0)50 5830 6814

Fax: +81 (0)43 306 3773

Email: service@aerotechkk.com.jp

Germany China

Phone: +49 (0)911 967 9370

Fax: +49 (0)911 967 93720

Email: service@aerotechgmbh.de

Phone: +86 (21) 3319 7715

Email: saleschina@aerotech.com

France Taiwan

Phone: +33 1 64 93 58 67

Email: sales@aerotech.co.uk

Phone: +886 (0)2 8751 6690

Email: service@aerotech.tw

This manual contains proprietary information and may not be reproduced, disclosed, or used in whole or in part without the

express written permission of Aerotech, Inc. Product names mentioned herein are used for identification purposes only and

may be trademarks of their respective companies.

Copyright © 2009-2016, Aerotech, Inc. All rights reserved.

Table of Contents Npaq MR Hardware Manual

Table of Contents

Table of Contents iii

List of Figures v

List of Tables vi

EC Declaration of Conformity vii

Agency Approvals viii

Safety Procedures and Warnings ix

Quick Installation Guide xi

Chapter 1: Introduction 1

1.1. Electrical Specifications 4

1.1.1. System Power Requirements 7

1.2. Mechanical Specifications 8

1.3. Environmental Specifications 10

1.4. Drive and Software Compatibility 11

Chapter 2: Installation and Configuration 13

2.1. Unpacking the Chassis 13

2.2. Electrical Installation 14

2.2.1. ACPower Connections 15

2.2.2. Minimizing Conducted, Radiated, and System Noise 16

2.2.3. I/O and Signal Wiring Requirements 17

2.3. Motor Output Connections 18

2.3.1. Brushless Motor Connections 19

2.3.1.1. Powered Motor Phasing 20

2.3.1.2. Unpowered Motor and Feedback Phasing 21

2.3.2. DC Brush Motor Connections 22

2.3.2.1. DC Brush Motor Phasing 22

2.3.3. Stepper Motor Connections 23

2.3.3.1. Stepper Motor Phasing 23

2.4. Motor Feedback Connections 24

2.4.1. Encoder Inputs 25

2.4.1.1. RS-422 Line Driver Encoder (Standard) 26

2.4.1.2. Analog Encoder Interface 27

2.4.1.3. Encoder Phasing 29

2.4.2. Hall-Effect Inputs 31

2.4.3. Thermistor Input 32

2.4.4. Encoder Fault Input 33

2.4.5. End Of Travel Limit Inputs 34

2.4.5.1. End Of Travel Limit Phasing 35

2.4.6. Brake Output 36

2.4.7. Differential Analog Input 0 37

2.5. Digital / Analog IO Connections 38

2.5.1. Analog Input 1 39

2.5.2. Analog Output 1 40

2.5.3. Opto-Isolated Outputs 41

2.5.4. Opto-Isolated Inputs 43

2.6. Aux Encoder 45

2.6.1. Position Synchronized Output (PSO)/Laser Firing 47

2.7. Communications Connector 49

2.8. PC Configuration and Operation Information 50

Chapter 3: Options 51

www.aerotech.com iii

Table of Contents Npaq MR Hardware Manual

List of Figures

Figure 1-1: Chassis Layout 1

Figure 1-2: Functional Diagram 3

Figure 1-3: Dimensions (4 Axis Version) 8

Figure 1-4: Dimensions (8 Axis Version) 9

Figure 2-1: Power and Control Connections 14

Figure 2-2: Power Switch 14

Figure 2-3: ACLine Filter (UFM-ST) 16

Figure 2-4: Motor Output Connections 18

Figure 2-5: Brushless Motor Configuration 19

Figure 2-6: Encoder and Hall Signal Diagnostics 20

Figure 2-7: Motor Phasing Oscilloscope Example 21

Figure 2-8: Brushless Motor Phasing Goal 21

Figure 2-9: DC Brush Motor Configuration 22

Figure 2-10: Clockwise Motor Rotation 22

Figure 2-11: Stepper Motor Configuration 23

Figure 2-12: Clockwise Motor Rotation 23

Figure 2-13: Line Driver Encoder Interface 26

Figure 2-14: Analog Encoder Phasing Reference Diagram 27

Figure 2-15: Analog Encoder Signals 28

Figure 2-16: Encoder Phasing Reference Diagram (Standard) 29

Figure 2-17: Position Feedback in the DiagnosticDisplay 30

Figure 2-18: Hall-Effect Inputs 31

Figure 2-19: Thermistor Input 32

Figure 2-20: Encoder Fault Interface Input 33

Figure 2-21: End of Travel Limit Inputs 34

Figure 2-22: Limit Input Diagnostic Display 35

Figure 2-23: Analog Input 0 37

Figure 2-24: Analog Input 1 39

Figure 2-25: Analog Output 1 40

Figure 2-26: Outputs Connected in Current Sourcing Mode 42

Figure 2-27: Outputs Connected in Current Sinking Mode 42

Figure 2-28: Inputs Connected to a CurrentSourcing Device 44

Figure 2-29: Inputs Connected to a Current Sinking Device 44

Figure 2-30: Auxiliary Encoder Channel 46

Figure 2-31: PSO Interface 48

Figure 2-32: FireWire Interface 49

Figure 3-1: ESTOP Option Interface 52

Figure 3-2: ESTOP1 53

Figure 3-3: ESTOP2 54

Figure 3-4: ESTOP3 55

Figure 3-5: Joystick Interface 56

Figure 3-6: Joystick Interface 57

Figure 4-1: Power Board 60

www.aerotech.com v

Npaq MR Hardware Manual Table of Contents

List of Tables

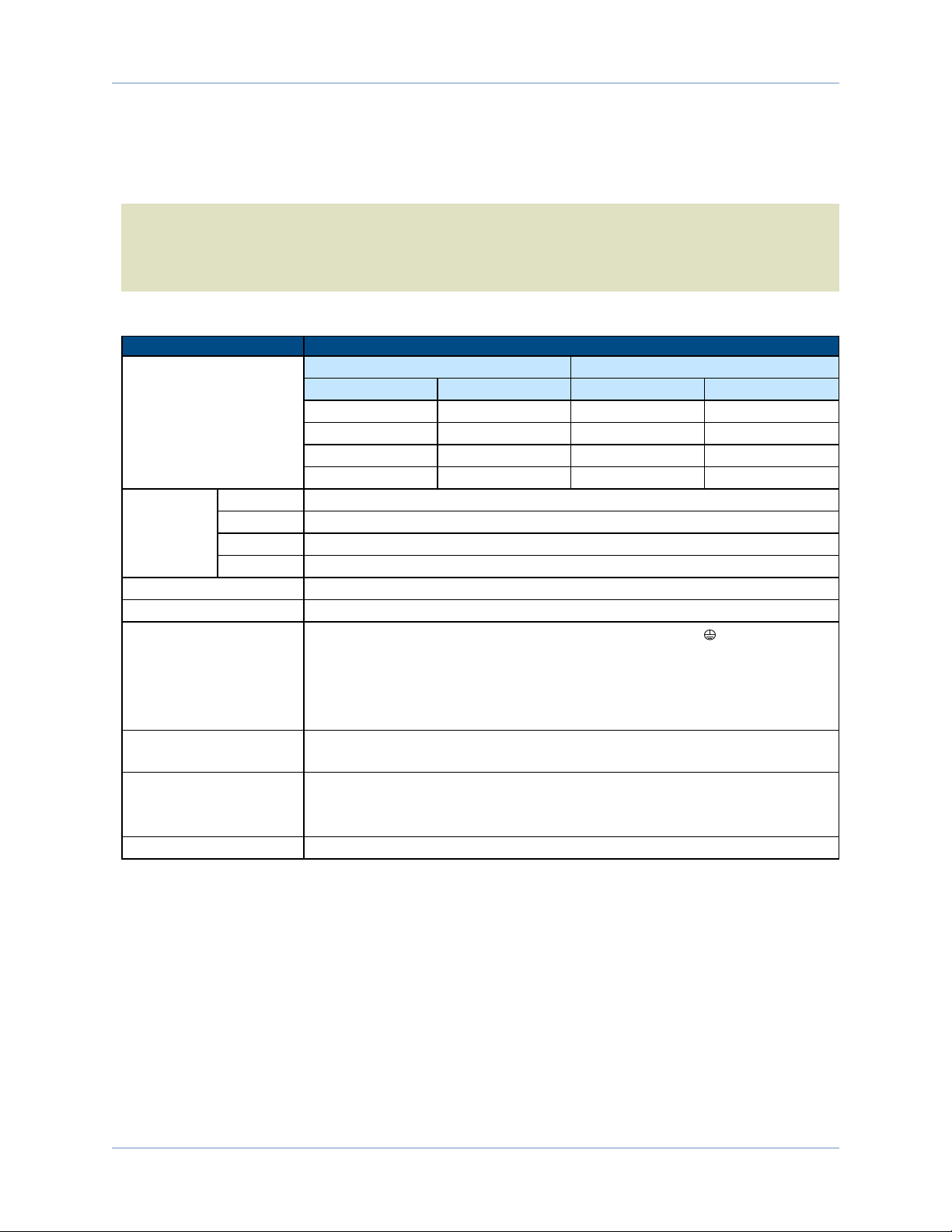

Table 1-1: FeatureSummary 2

Table 1-2: Chassis Electrical Specifications 4

Table 1-3: Servo Amplifier Electrical Specifications (MP) 5

Table 1-4: Linear Amplifier Electrical Specifications (ML) 6

Table 1-5: Unit Weight 9

Table 1-6: A3200 Drive and Software Compatibility 11

Table 2-1: Main ACPower Input Voltages and Current Requirements 15

Table 2-2: ACPower Wiring Specifications 15

Table 2-3: UFM-STElectrical Specifications 16

Table 2-4: ACPower Wiring Specifications 17

Table 2-5: Motor Power Output Connector Pin Assignment 18

Table 2-6: Motor Power Output Mating Connector 18

Table 2-7: Motor Feedback Connector Pin Assignment 24

Table 2-8: Encoder Pin Assignment 25

Table 2-9: Encoder Specifications 26

Table 2-10: Analog Encoder Specifications 27

Table 2-11: Hall-Effect Feedback Pin Assignment 31

Table 2-12: Thermistor Interface Pin Assignment 32

Table 2-13: Encoder Fault Pin Assignment 33

Table 2-14: End of Travel Limit Inputs Pin Assignment 34

Table 2-15: Brake Output Pin Assignment 36

Table 2-16: Relay Specifications 36

Table 2-17: Differential Analog Input 0 Specifications 37

Table 2-18: Differential Analog Input 0 Pin Assignment 37

Table 2-19: Digital / Analog IOConnector Pin Assignment 38

Table 2-20: Analog Input 1 Specifications 39

Table 2-21: Analog Inputs Connector Pin Assignment 39

Table 2-22: Analog Output Specifications (TB102B) 40

Table 2-23: Analog Output Connector Pin Assignment 40

Table 2-24: Opto-Isolated Output Connector Pin Assignment 41

Table 2-25: Output Specifications 41

Table 2-26: Digital Input Specifications 43

Table 2-27: Opto-Isolated Input Connector Pin Assignment 43

Table 2-28: Aux Encoder Specifications 45

Table 2-29: Auxiliary Encoder Channel Pin Assignment 45

Table 2-30: PSO Specifications 47

Table 2-31: FireWire Card Part Numbers 49

Table 2-32: FireWire Repeaters (for cables exceeding 4.5 m (15 ft) specification) 49

Table 2-33: FireWire Cables (copper and glass fiber) 49

Table 3-1: Options and Capabilities 51

Table 3-2: ESTOPOption Mating Connector 52

Table 3-3: ESTOPSafety Ratings 52

Table 3-4: Relay Specifications 53

Table 3-5: Joystick Interface Connector Pin Assignment 56

Table 4-1: Component Select 60

Table 4-2: Preventative Maintenance 61

vi www.aerotech.com

Declaration of Conformity Npaq MR Hardware Manual

EC Declaration of Conformity

Manufacturer

Aerotech, Inc.

Address

101 Zeta Drive

Pittsburgh, PA 15238-2897

USA

Product

Npaq MR

Model/Types

All

This is to certify that the aforementioned product is in accordance with the applicable requirements of the

following Directive(s):

2014/35/EU Low Voltage Directive LVD

2006/42/EC Machinery Directive

2011/65/EU RoHS2 Directive

and has been designed to be in conformity with the applicable requirements of the following documents when

installed and used in accordance with the manufacturer’s supplied installation instructions.

EN 61010-1 Safety requirements for electrical equipment

ISO 13849-1 & -2 Safety related parts of control systems

Name

/ Alex Weibel

Position

Engineer Verifying Compliance

Location

Pittsburgh, PA

www.aerotech.com vii

Npaq MR Hardware Manual Declaration of Conformity

Agency Approvals

Aerotech, Inc. Model Npaq MR Drive Racks have been tested and found to be in accordance to the following

listed Agency Approvals:

Approval / Certification: CUS NRTL

Approving Agency: TUV SUD America Inc.

Certificate #: U8 13 10 68995 012

File / Report #: 092-1304522-100

Standards: UL 61010-1; CAN/CSA-C22.2 No. 61010-1

viii www.aerotech.com

Electrical Safety Npaq MR Hardware Manual

Safety Procedures and Warnings

The following statements apply wherever the Warning or Danger symbol appears within this manual. Failure

to observe these precautions could result in serious injury to those individuals performing the procedures

and/or damage to the equipment.

D A N G E R : This product contains potentially lethal voltages. To reduce the possibility of

electrical shock, bodily injury, or death the following precautions must be followed.

1. Ensure that all electrical power switches are in the off position when servicing the

equipment.

2. Disconnect electrical power before servicing equipment.

3. Disconnect electrical power before performing any wiring.

4. Access to the Npaq MR and component parts must be restricted while connected to a

power source.

5. Residual voltages greater than 60V may be present inside Npaq MR chassis for longer

than 10 seconds after power has been disconnected.

6. To minimize the possibility of electrical shock and bodily injury, extreme care must be

exercised when any electrical circuits are in use. Suitable precautions and protection must

be provided to warn and prevent persons from making contact with live circuits.

7. Install the Npaq MR inside a rack or enclosure.

8. Do not connect or disconnect any electrical components or connecting cables while

connected to a power source.

9. All components must be properly grounded in accordance with local electrical safety

requirements.

10. Operator safeguarding requirements must be addressed during final integration of the

product.

W A R N I N G : To minimize the possibility of electrical shock, bodily injury or death the

following precautions must be followed.

1. Use of this equipment in ways other than described by this manual can cause personal

injury or equipment damage.

2. Moving parts can cause crushing or shearing injuries. Access to all stage and motor parts

must be restricted while connected to a power source.

3. Cables can pose a tripping hazard. Securely mount and position all system cables to avoid

potential hazards.

4. Do not expose this product to environments or conditions outside of the listed

specifications. Exceeding environmental or operating specifications can cause damage to

the equipment.

5. If the product is used in a manner not specified by the manufacturer, the protection

provided by the product can be impaired and result in damage, shock, injury, or death.

6. Operators must be trained before operating this equipment.

7. All service and maintenance must be performed by qualified personnel.

8. This product is intended for light industrial manufacturing or laboratory use. Use of this

product for unintended applications can result in injury and damage to the equipment.

www.aerotech.com ix

Npaq MR Hardware Manual Electrical Safety

x www.aerotech.com

This page intentionally left blank.

Quick Installation Guide Npaq MR Hardware Manual

Quick Installation Guide

This chapter describes the order in which connections and settings should typically be made to the Npaq

MR. If a custom interconnection drawing was created for your system (look for a line item on your Sales

Order under the heading “Integration”), that drawing can be found on your installation device.

There are four standard connections that must be made to the Npaq MR.

FEEDBACK COMMUNICATIONS

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

EXT DRIVE RS232

AUX ENCODER JOYSTICK

ESTOPMOTOR

DIGITAL / ANALOG IO

FEEDBACK

1

2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

EXT DRIVE RS232

AUX ENCODER JOYSTICK

ESTOPMOTOR

DIGITAL / ANALOG IO

COMMUNICATIONS

PC Connection

Motor Feedback

4

2

Motor Power

3

PC Connection

Motor Feedback

4

2

Motor Power

3

Connect the power source to the AC Power input

8 Axis Model

4 Axis Model

1

Connect the Motors to the Motor Power inputs

4Connect the Motors to the Motor Feedback inputs

2Connect the PC

3

AC Power

1

AC Power

1

Figure 1: Quick Start Connections

Quick Start Summary

Topic Section

ACPower Section 2.2.1. ACPower Connections

PCCommunication Section 2.7. Communications Connector

Motor Power Section 2.3. Motor Output Connections

Motor Feedback Section 2.4. Motor Feedback Connections

www.aerotech.com xi

Npaq MR Hardware Manual Quick Installation Guide

xii www.aerotech.com

This page intentionally left blank.

Introduction Npaq MR Hardware Manual

Chapter 1: Introduction

Aerotech’s Npaq MR is a 3U height, 19” wide, rack-mountable, intelligent drive chassis, that consists of up

to eight ultra-compact PWM and Linear network digital drives providing up to eight axes of motion. Each

drive provides deterministic behavior, auto-identification, and easy software setup. High performance double

precision floating point DSP controls the digital PID and current loops. All system configuration is done using

software-settable parameters, including control loop gains and system safety functions.

Communicate with the PCwith a standard commercial FireWire communication bus. I/O options are

configurable per axis and include a 16 channel digital I/O interface (8 inputs and 8 outputs), one analog input,

one analog output, and a single axis Position Synchronized Output (PSO) signal. Other features and options

available with the MR drive chassis include: an external joystick connection port, integral encoder resolution

multiplication, and integral emergency stop components.

N O T E : The Npaq MR can contain a mix of multiple discrete ML and MP drives. When using the A3200

software, the drives inside the Npaq MR will appear as if they were individual drives on the network.

Motion and I/O commands on axes within the Npaq MR are programmed in the same manner as would be

done for discrete units.

AEROTECH.COM

ON

OFF

Npaq MR

FEEDBACK COMMUNICATIONS

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

EXT DRIVE RS232

AUX ENCODER JOYSTICK

ESTOPMOTOR

DIGITAL / ANALOG IO

Power Switch / Circuit Breaker

Motor OutputAC Power Input Digital / Analog IO

Motor Feedback Auxiliary Encoder

ESTOP

JoystickFireWire

Figure 1-1: Chassis Layout

www.aerotech.com Chapter 1 1

Npaq MR Hardware Manual Introduction

Table 1-1: FeatureSummary

Standard Features

lLine driver square wave quadrature encoder input for standard position and velocity feedback

lOne 12 or 16-bit(1) differential analog input (±10 V)

lDedicated 5-24 V Emergency Stop sense input

lDedicated Hall inputs (3 per axis)

lDedicated over travel and home input limits

Options

-IO lOne 16-bit analog output (±10 V)

lOne 12 or 16-bit(1) differential analog input (±10 V)

lOne fail-safe brake or user relay output

l8 optically isolated logic inputs (5 - 24 VDC), may be connected in

current sourcing or sinking mode

l8 optically isolated logic outputs (5 - 24 VDC), user defined as current

sourcing or sinking

lAuxiliary encoder input channel

lRS-422 differential PSOsignal

-MXU (option on the MP) x4,096 encoder interpolation for sine/cosine encoders

-MXU (option on the ML) x4,096 encoder interpolation for sine/cosine encoders

-MXH (option on the ML) x65,536 encoder interpolation for sine/cosine encoders

(1) Only the Ndrive MP has a 12-bit differential analog input

2 Chapter 1 www.aerotech.com

Introduction Npaq MR Hardware Manual

The following block diagram illustrates the features and options of the Npaq MR.

Analog Input 1 +/-

Analog Output 1

8 Opto Outputs

(Sinking or Sourcing)

8 Opto Inputs

(Sinking or Sourcing)

DIGITAL /

ANALOG IO

(up to x8,

optional)

Encoder +5V / Common

Analog Input 0 +/-

Brake +/-

SIN, COS, MRK

-MXU or -MXH

Option(1)

MOTOR

FEEDBACK

(up to x8)

CW, CCW, Home Limits;

Encoder Fault; Hall A, B, C;

Motor Over Temperature

MOTOR

OUTPUT

(up to x8)

Amplifier

Control

Power

Motor

Power

ESTOP

AC Power

Input

Amplifier

Heatsink Over

Temperature A

B

C

Switch

ESTOP

(optional)

SIN, COS, MRK

Encoder +5V / Common

PSO Output, Encoder Echo

AUX

ENCODER

(up to x8,

optional)

Control

Power

Supply

Analog Input +/- (x2)

Digital Input (x3)

JOYSTICK

(optional)

(1) -MXH or -MXU on ML drives; -MXU on MP drives

FireWire PortCOMMUNICATIONS

Figure 1-2: Functional Diagram

www.aerotech.com Chapter 1 3

Npaq MR Hardware Manual Introduction

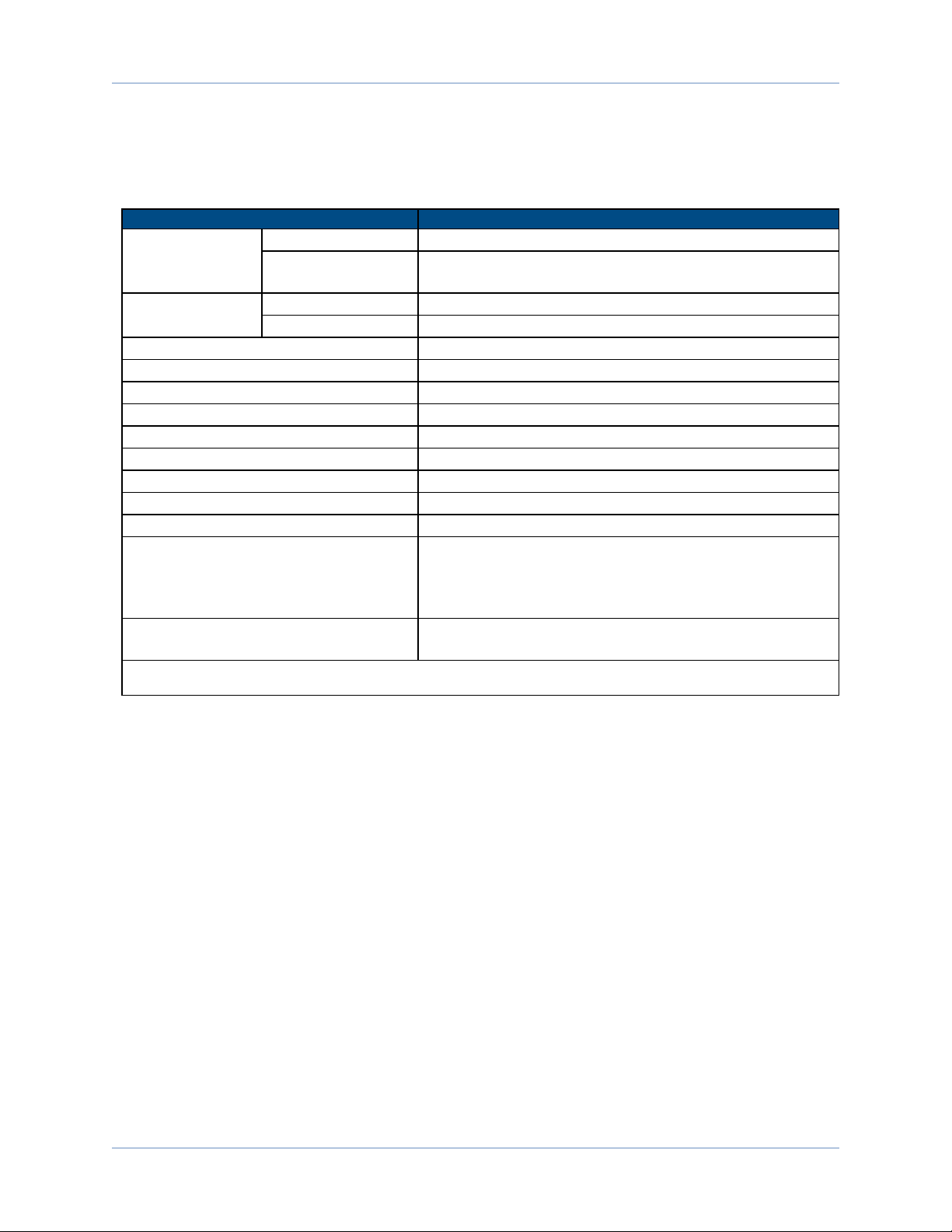

1.1. Electrical Specifications

The electrical specifications for the Npaq MR drive chassis are listed in Table 1-2 and the electrical

specifications for the servo amplifiers in Table 1-3 and Table 1-4.

N O T E : Specifications represent the maximum capability of a feature. Other system constraints may res-

ult in significantly less performance. This is particularly applicable to the motor output specifications. The

motor output specifications are affected by the Bus supply, the number of axes that are operating at the

same time, the type of motion, the AC Line voltage, and motor requirements.

Table 1-2: Chassis Electrical Specifications

Description Specifications

Bus Voltage Options

4-Axis 8-Axis

Unipolar Bipolar Unipolar Bipolar

40 LP@ 300W 10B @ 400W 40LP @ 500W 10B @ 400W

80 LP @ 300W 20B @ 500W 40LP @ 500W 20B @ 500W

40 @ 600W 30B @ 500W 40LP @1000W 30B @ 500W

80 @ 600W 40B @ 600W 40LP @1000W 40B @ 1000W

Input

Current

100 VAC 10 A Maximum

115 VAC 10 A Maximum

200 VAC 6 A Maximum

230VAC 5 A Maximum

Inrush Current 100 A @ 254 VAC

Leakage Current <1/5 mA @ 60 Hz / 254 VAC

AC Power Input

AC input (factory configured): AC Hi, AC Lo, Earth Ground ( ),

l100 VAC (90-112 VAC, 49-63 Hz)

l115 VAC (103-127 VAC, 49-63 Hz)

l200 VAC (180-224 VAC, 49-63 Hz)

l230 VAC (207-254 VAC, 49-63 Hz)

Auxiliary Power Outputs +5 V is provided on all axis feedback connectors for encoder, Hall, and limit

power.

Protection

lPower switch breaker (10 Amps, Supplemental Protection only).

lFuses on motor bus supply transformer.

lBus supply inrush current limit during power-on.

Indicator (Power) Power switch contains a power-on indicator.

4 Chapter 1 www.aerotech.com

Introduction Npaq MR Hardware Manual

Aerotech doesn't specify the input current or power to the drives because it is dependent on the amount of

real power being delivered to the drive(refer to Section 1.1.1.).

Table 1-3: Servo Amplifier Electrical Specifications (MP)

MP 10

Motor Supply

Input Voltage 10-80 VDC

Input Current

(Continuous) 5 Arms

Control Supply Input Voltage 24-80 VDC (±10%)

Input Current 1 Amax

Output Voltage (1) 10-80 VDC

Peak Output Current (1 second) 10 A

Continuous Output Current 5 A

Power Amplifier Bandwidth 2500 Hz maximum (software selectable)

Power Amplifier Efficiency 85% - 95%(2)

PWM Switching Frequency 20 kHz

Minimum Load Inductance 0.1 mH @ 80 VDC

User Power Supply Output 5 VDC (@ 500 milliamps)

Modes of Operation Brushless; Brush; Stepper

Protective Features

Output short circuit; Peak over current, DCbus over

voltages; RMSover current; Over temperature; Control

power supply under voltage; Power stage bias supply under

voltage

Isolation Optical and transformer isolation between control and power

stages.

1. AC input voltage and load dependent.

2. Dependent on total output power: efficiency increases with increasing output power.

www.aerotech.com Chapter 1 5

Npaq MR Hardware Manual Introduction

Table 1-4: Linear Amplifier Electrical Specifications (ML)

Description ML 10

Motor Supply

Input Voltage ±40 VDC (max)

Input Current

(continuous) 5 A

Input Current (peak) 10 A

Control Supply Input Voltage 24 VDC typical(18-36 VDC)

Input Current 700 mA (max)

Output Voltage (1) ±38V @ 10 A

Peak Output Current (2) 10

Continuous Output Current (2) 5

Power Amplifier Bandwidth 2500 Hz maximum (software selectable)

Minimum Load Resistance 0.5 Ω

Output Impedance 0.2 Ω (each phase)

User Power Supply Output 5 VDC (@ 500 mA)

Modes of Operation Brushless; Brush; Stepper

Protective Features Peak current limit; Over temperature; RMScurrent limit;

Dynamic power dissipation limit

Isolation Isolation between control and power stages.

1. Load Dependent

2. Peak and continuous output current is load dependent (the amplifier will limit its output current based on motor speed and motor

resistance).

6 Chapter 1 www.aerotech.com

Introduction Npaq MR Hardware Manual

1.1.1. System Power Requirements

The following equations can be used to determine total system power requirements. The actual power

required from the mains supply will be the combination of actual motor power (work), motor resistance

losses, and efficiency losses in the power electronics or power transformer.

For switching amplifier types:

An EfficiencyFactor of approximately 90% should be used in the following equations.

Brushless Motor

Output Power

Rotary Motors Pout [W] = Torque [N·m] * Angular velocity[rad/sec]

Linear Motors Pout [W] = Force [N] * Linear velocity[m/sec]

Rotary or Linear Motors Pout [W] = Bemf [V] * I(rms) * 3

Ploss = 3 * I(rms)^2 * R(line-line)/2

Pin = SUM (Pout + Ploss ) / EfficiencyFactor

DC Brush Motor

Pout [W] = Torque [N·m] * Angular velocity[rad/sec]

Ploss = I(rms)^2 * R

Pin = SUM (Pout + Ploss ) / EfficiencyFactor

For linear amplifier types:

An EfficiencyFactor of approximately 50% should be used in the following equations.

Linear Motor

Pdiss[W] = MotorCurrentPeak[A] * TotalBusVoltage[V] * 3 / 2

Pin = SUM (Pdiss ) / EfficiencyFactor

www.aerotech.com Chapter 1 7

Npaq MR Hardware Manual Introduction

1.2. Mechanical Specifications

The Npaq MR must be installed in a rack mount console to comply with safety standards. Mount the Npaq

MR so free airflow is available at the rear of the chassis. Allowance must also be made for the rear panel

connections and cables.

W A R N I N G : Use both handles to lift and carry the Npaq MR.

AEROTECH.COM

ON

OFF

Npaq MR

FEEDBACK

1

2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

EXT DRIVE RS232

AUX ENCODER JOYSTICK

ESTOPMOTOR

DIGITAL / ANALOG IO

COMMUNICATIONS

424.9 [16.93]

333.7 [13.14]41.7 [1.64]

566.1 [22.29]

132.5 [5.22]

57.2 [2.25] 37.7 [1.48]

7.1 [0.28]

(4 pls)

482.6 [19.00]

8.3 [0.33] (TYP.) 465.9 [18.34]

444.5 [17.50]

Drawing Number: 620E1408-

Dimensions: MM [IN]

Figure 1-3: Dimensions (4 Axis Version)

8 Chapter 1 www.aerotech.com

Table of contents

Popular Enclosure manuals by other brands

TESTO

TESTO TopSafe 0516.0220 Application Information

Lian-Li

Lian-Li O11 DYNAMIC XL installation guide

Rockford Fosgate

Rockford Fosgate R1-1X10 Installation & operation

CRU Dataport

CRU Dataport Data Express DE275 install guide

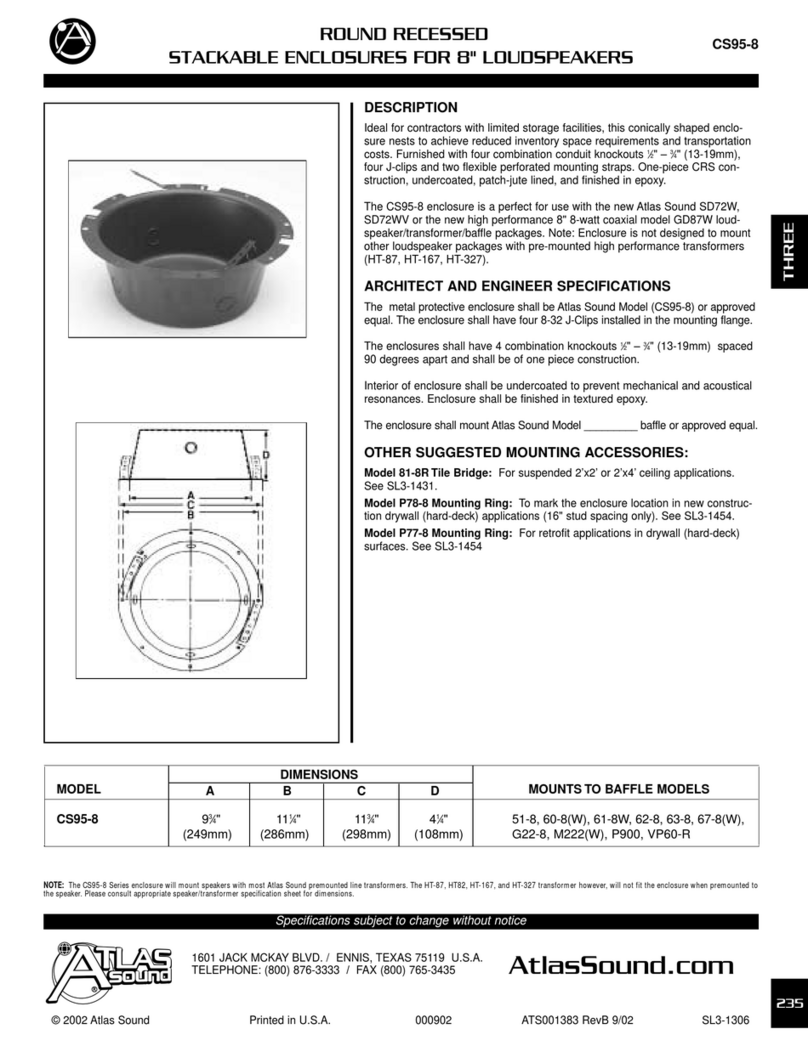

Atlas

Atlas CS95-8 Specifications

Watts

Watts HIU2VSA-2 Installation and operating manual