Aerotech ACS100 User manual

Revision: 1.05.00

ACS Hardware Manual

Global Technical Support

Go to www.aerotech.com/global-technical-support for information and support about your Aerotech products. The website

supplies software, product manuals, Help files, training schedules, and PC-to-PC remote technical support. If necessary,

you can complete Product Return (RMA) forms and get information about repairs and spare or replacement parts. To get help

immediately, contact a service office or your sales representative. Include your customer order number in your email or have

it available before you call.

United States (World Headquarters)

Email: Support@aerotech.com

Phone: +1-412-967-6440

Fax: +1-412-967-6870

101 Zeta Drive

Pittsburgh, PA 15238-2811

www.aerotech.com

United Kingdom China

Email: Support@aerotech.com

Phone: +44 (0)1256 855055

Fax: +44 (0)1256 855649

Email: Support@aerotech.com

Phone: +86 (21) 5508 6731

Germany Taiwan

Email: Support@aerotech.com

Phone: +49 (0)911 967 9370

Fax: +49 (0)911 967 93720

Email: Support@aerotech.com

Phone: +886 (0)2 8751 6690

France

Email: Support@aerotech.com

Phone: +33 2 37 21 87 65

This manual contains proprietary information and may not be reproduced, disclosed, or used in whole or in part without the

express written permission of Aerotech, Inc. Product names mentioned herein are used for identification purposes only and

may be trademarks of their respective companies.

Copyright © 2006-2020, Aerotech, Inc., All rights reserved.

Table of Contents

ACS Hardware Manual 1

Table of Contents 3

List of Figures 4

List of Tables 5

Safety Procedures and Warnings 6

EU Declaration of Incorporation 7

Chapter 1: Overview 9

1.1. Environmental Specifications 12

1.2. Basic Specifications 13

1.3. Air Requirements 16

Chapter 2: Mechanical Specifications and Installation 17

2.1. Unpacking and Handling the Stage 17

2.2. Dimensions 18

2.3. Securing the Stage to the Mounting Surface 22

2.4. Clamping a Workpiece to the Collet 24

2.4.1. Load Capability 24

2.5. Changing the Workholding Devices 25

2.5.1. Collet Change Procedure 25

2.5.2. Changing Collet Chucks (ACS150) 27

2.5.3. Gripper Configurations (ACS150 and ACS200) 29

Chapter 3: Electrical Specifications and Installation 31

3.1. Motor and Feedback Connectors 32

3.2. Motor and Feedback Wiring 36

3.3. Motor and Feedback Specifications 39

3.4. Marker and Machine Direction 43

3.5. Motor and Feedback Phasing 44

Chapter 4: Maintenance 47

4.1. Stage Service and Inspection Schedule 47

4.2. Stage Cleaning and Lubrication 48

4.2.1. Collet and Collet Chuck Lubrication and Cleaning 49

4.3. Seal Replacement 50

4.3.1. Piston Seal Change Procedure 50

4.3.2. Rotary Union Seals for Three-Jaw Gripper Stages 54

4.4. Troubleshooting 56

Appendix A: Warranty and Field Service 57

Appendix B: Revision History 59

Index 61

www.aerotech.com 3

ACS Hardware Manual Table of Contents

List of Figures

Figure 1-1: ACSRotary Stage with Callouts 11

Figure 2-1: ACS100 Dimensions 18

Figure 2-2: ACS150 (-ER Chuck Style) Dimensions 19

Figure 2-3: ACS150 (-3J Chuck Style) Dimensions 20

Figure 2-4: ACS200 (-3J Chuck Style) Dimensions 21

Figure 2-5: ACS Stage Mounting Holes 23

Figure 2-6: Typical ACS150 Stage Showing Side Mounting Holes and T-Slot Detail 23

Figure 2-7: Schematic of Collet Insertion Into and Removal From Collet Nut 26

Figure 2-8: Installation Procedure for Collet 26

Figure 2-9: Collet Assembly Exploded View 27

Figure 2-10: Gripper Mounting Hole Locations in ACS Shaft 29

Figure 2-11: Mounting Holes for Three-Jaw Gripper 30

Figure 2-12: Air Inlets in Three-Jaw Grippers 30

Figure 3-1: Motor and Feedback Wiring (ACS100 -CN1) 36

Figure 3-2: Motor and Feedback Wiring (ACS100 -CN2) 37

Figure 3-3: Motor and Feedback Wiring (ACS150 and ACS200) 38

Figure 3-4: Machine Direction 43

Figure 3-5: Hall Phasing 44

Figure 3-6: Analog Encoder Phasing Reference Diagram 45

Figure 3-7: Encoder Phasing Reference Diagram (Standard) 45

Figure 4-1: Piston Seal Change Exploded View 50

Figure 4-2: Piston Seal Installation Procedure 53

Figure 4-3: Cross-Section View of Piston Showing Seal Orientation 53

Figure 4-4: Exploded Drawing of Rear Seal Components 54

Figure 4-5: Cross-section View of Rear Seal Showing Seal Orientations 55

List of Figures ACS Hardware Manual

4 www.aerotech.com

List of Tables

Table 1-1: ACS100 Model Numbering System 9

Table 1-2: ACS150 Model Numbering System 10

Table 1-3: ACS200 Model Numbering System 11

Table 1-4: Environmental Specifications 12

Table 1-5: ACS100 Series Specifications 13

Table 1-6: ACS150 Series Specifications 14

Table 1-7: ACS200 Series Specifications 15

Table 2-1: Stage to Mounting Surface Hardware 22

Table 3-1: Motor Pinouts (-CN1option on the ACS100; standard on the ACS150 and ACS200) 33

Table 3-2: Mating Connector Part Numbers for the Motor Connector (-CN1option on the ACS100;

standard on the ACS150 and ACS200) 33

Table 3-3: Motor Pinouts (-CN2 option on the ACS100 only) 34

Table 3-4: Mating Connector Part Numbers for the -CN2 Motor Option Connector 34

Table 3-5: Feedback Pinouts 35

Table 3-6: Mating Connector Part Numbers for the Feedback Connector 35

Table 3-7: Feedback Specifications 39

Table 3-8: Encoder Specifications 39

Table 3-9: Maximum Speed (rpm) Per Encoder Option 39

Table 3-10: Motor Specifications (ACS100) 40

Table 3-11: Motor Specifications (ACS150) 41

Table 3-12: Motor Specifications (ACS200) 42

Table 4-1: Recommended Lubricants 49

Table 4-2: Piston Seal Replacement Part Numbers 50

Table 4-3: Rotary Union Seal Replacement Part Numbers 54

www.aerotech.com 5

ACS Hardware Manual List of Tables

Safety Procedures and Warnings

This manual tells you how to carefully and correctly use and operate the ACS. Read all parts of this manual

before you install or operate the ACS or before you do maintenance to your system. To prevent injury to you

and damage to the equipment, obey the precautions in this manual. The precautions that follow apply when

you see a Danger or Warning symbol in this manual. If you do not obey these precautions, injury to you or

damage to the equipment can occur. If you do not understand the information in this manual, contact

Aerotech Global Technical Support.

This product has been designed for light industrial manufacturing or laboratory environments. The protection

provided by the equipment could be impaired if the product is used in a manner not specified by the

manufacturer.

D A N G E R : This product contains potentially lethal voltages. To reduce the possibility of

electrical shock, bodily injury, or death the following precautions must be followed.

1. Access to the ACS and component parts must be restricted while connected to a power

source.

2. Do not connect or disconnect any electrical components or connecting cables while

connected to a power source.

3. Disconnect electrical power before servicing equipment.

4. All components must be properly grounded in accordance with local electrical safety

requirements.

5. Operator safeguarding requirements must be addressed during final integration of the

product.

W A R N I N G : To minimize the possibility of electrical shock, bodily injury or death the

following precautions must be followed.

1. Moving parts can cause crushing or shearing injuries. Access to all stage and motor parts

must be restricted while connected to a power source.

2. Cables can pose a tripping hazard. Securely mount and position all system cables to avoid

potential hazards.

3. Do not expose this product to environments or conditions outside of the listed

specifications. Exceeding environmental or operating specifications can cause damage to

the equipment.

4. The ACS stage must be mounted securely. Improper mounting can result in injury and

damage to the equipment.

5. Use care when moving the ACS stage. Lifting or transporting the ACS stage improperly

can result in injury or damage to the ACS.

6. This product is intended for light industrial manufacturing or laboratory use. Use of this

product for unintended applications can result in injury and damage to the equipment.

7. If the product is used in a manner not specified by the manufacturer, the protection

provided by the product can be impaired and result in damage, shock, injury, or death.

8. Operators must be trained before operating this equipment.

9. All service and maintenance must be performed by qualified personnel.

Safety Procedures and Warnings ACS Hardware Manual

6 www.aerotech.com

EU Declaration of Incorporation

Manufacturer:

Aerotech, Inc.

101 Zeta Drive

Pittsburgh, PA 15238-2811

USA

herewith declares that the product:

ACS Stage

is intended to be incorporated into machinery to constitute machinery covered by the Directive 2006/42/EC

as amended;

and that the following harmonized European standards have been applied:

EN ISO 12100:2010

Safety of machinery - Basic concepts, general principles for design

EN 60204-1:2010

Safety of machinery - Electrical equipment of machines - Part 1:General requirements

and further more declares that

it is not allowed to put the equipment into service until the machinery into which it is to

be incorporated or of which it is to be a component has been found and declared to be in

conformity with the provisions of the Directive 2006/42/EC and with national

implementing legislation, for example, as a whole, including the equipment referred to in

this Declaration.

This is to certify that the aforementioned product is in accordance with the applicable requirements of the fol-

lowing Directive(s):

EU 2015/863 RoHS3 Directive

Authorized Representative:

Simon Smith, European Director

Address:

Aerotech Ltd

The Old Brick Kiln, Ramsdell, Tadley

Hampshire RG26 5PR

UK

Name

/ Alex Weibel

Position

Engineer Verifying Compliance

Location

Pittsburgh, PA

Date

3/31/2020

www.aerotech.com 7

ACS Hardware Manual EU Declaration of Incorporation

This page intentionally left blank.

EU Declaration of Incorporation ACS Hardware Manual

8 www.aerotech.com

Chapter 1: Overview

N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any

time. All drawings and illustrations are for reference only and were complete and accurate as of this

manual’s release. Refer to www.aerotech.com for the most up-to-date information.

Table 1-1: ACS100 Model Numbering System

ACS Mechanical-Bearing Direct-Drive Rotary Collet Stage, 100 mm diameter

Stage Size (Required)

-85 85 mm stage height; 0.6 N·m continuous torque

-135 135 mm stage height; 1.6 N·m continuous torque

Chuck Style (Required)

-ER8 ER8 ultra-precision collet

-ER8MB ER8 microbore collet

Feedback (Required)

-E1 Incremental encoder, 1 Vpp, sine wave output

-E2 Incremental encoder, Digital, RS422 line-driver, x5 interpolation

-E3 Incremental encoder, Digital, RS422 line-driver, x10 interpolation

-E4 Incremental encoder, Digital, RS422 line-driver, x25 interpolation

-E5 Incremental encoder, Digital, RS422 line-driver, x50 interpolation

NOTE: Digital output encoder signals are synthesized with a 16 MHz clock. Ensure that the encoder sample rate on the controller is

at least 16 MHz or higher (slower clock rates are available on request).

Rear Seal (Optional)

-SL Rear seal

Connector (Required)

-CN1 4-pin high-powered D-style motor and 25-pin D-style feedback connectors

-CN2 25-pin D-style motor and 25-pin D-style feedback connectors

Wrench (Optional)

-WR Wrench for changing the collet

Aerotech P/N:MFB25378-01 [Qty-2]

Air Purge (Optional)

-PR Air purge fitting to positive pressurize ACS stage to limit ingress of airborne

particulates

Metrology (Required)

-PL1 Uncalibrated with performance plots

-PL2 Calibrated (HALAR) with performance plots

Accessories (To be Ordered as a Separate Line Item)

Collet-ER8-CLTxx ER8 DIN6499AA electropolished collet, 0.5 mm to 5 mm part sizes diameter

available

Collet-ER8MB-CLTxx ER8 DIN6499AA electropolished mircro-bore collet, 0.2 mm to 0.9 mm part sizes

diameter available

CGF Collet and gripper filtration kit

www.aerotech.com 9

ACS Hardware Manual Chapter 1: Overview

Table 1-2: ACS150 Model Numbering System

ACS Mechanical-Bearing Direct-Drive Rotary Collet Stage, 150 mm diameter

Stage Size (Required)

-115 115 mm stage height; 2.9 N·m continuous torque

-135 135 mm stage height; 5.1 N·m continuous torque

-180 185 mm stage height; 9.3 N·m continuous torque

Chuck Style (Required)

-ER25 ER25 ultra-precision collet

-ER40 ER40 ultra-precision collet

-3J1 3-Jaw gripper, 10 mm stroke, normally closed

-3J2 3-Jaw gripper, 10 mm stroke, normally open

-3J3 3-Jaw gripper, 16 mm stroke, normally closed

-3J4 3-Jaw gripper, 16 mm stroke, normally open

Feedback (Required)

-E1 Incremental encoder, 1 Vpp, sine wave output

-E2 Incremental encoder, Digital, RS422 line-driver, x5 interpolation

-E3 Incremental encoder, Digital, RS422 line-driver, x10 interpolation

-E4 Incremental encoder, Digital, RS422 line-driver, x25 interpolation

-E5 Incremental encoder, Digital, RS422 line-driver, x50 interpolation

NOTE: Digital output encoder signals are synthesized with a 16 MHz clock. Ensure that the encoder sample rate on the controller is

at least 16 MHz or higher (slower clock rates are available on request).

Rear Seal (Optional)

-SL Rear seal

Wrench (Optional)

-WR

Wrench for changing the collet

Aerotech P/N:MCA01857 [Qty-1]

Aerotech P/N:MCA02007 [Qty-1]

Metrology (Required)

-PL1 Uncalibrated with performance plots

-PL2 Calibrated (HALAR) with performance plots

Accessories (To be Ordered as a Separate Line Item)

Collet-ER25-CLTxx ER25 DIN6499AA electropolished collet, 0.5 mm to 15 mm part holding sizes

available

Collet-ER40-CLTxx ER40 DIN6499AA electropolished collet, 15.5 mm to 25 mm part holding sizes

available

CGF Collet and gripper filtration kit

NOTE: ER40 collet sizes less than 15.5 mm diameter are not supported. Use the ER25 collect chuck if these sizes are required.

Chapter 1: Overview ACS Hardware Manual

10 www.aerotech.com

Table 1-3: ACS200 Model Numbering System

ACS Mechanical-Bearing Direct-Drive Rotary Collet Stage, 200 mm diameter

Stage Size (Required)

-155 155 mm stage height; 11.1 N·m continuous torque

-185 185 mm stage height; 15.9 N·m continuous torque

Chuck Style (Required)

-3J1 3-Jaw gripper with 12 mm clear aperture, 10 mm stroke, normally closed

-3J2 3-Jaw gripper with 12 mm clear aperture, 10 mm stroke, normally open

-3J3 3-Jaw gripper with 12 mm clear aperture, 16 mm stroke, normally closed

-3J4 3-Jaw gripper with 12 mm clear aperture, 16 mm stroke, normally open

-3J5 3-Jaw gripper with 25 mm clear aperture, 13 mm stroke, normally closed

-3J6 3-Jaw gripper with 25 mm clear aperture, 13 mm stroke, normally open

-3J7 3-Jaw gripper with 25 mm clear aperture, 20 mm stroke, normally closed

-3J8 3-Jaw gripper with 25 mm clear aperture, 20 mm stroke, normally open

Feedback (Required)

-E1 Incremental encoder, 1 Vpp, sine wave output

-E2 Incremental encoder, Digital, RS422 line-driver, x5 interpolation

-E3 Incremental encoder, Digital, RS422 line-driver, x10 interpolation

-E4 Incremental encoder, Digital, RS422 line-driver, x25 interpolation

-E5 Incremental encoder, Digital, RS422 line-driver, x50 interpolation

NOTE: Digital output encoder signals are synthesized with a 16 MHz clock. Ensure that the encoder sample rate on the controller is

at least 16 MHz or higher (slower clock rates are available on request).

Metrology (Required)

-PL1 Uncalibrated with performance plots

-PL2 Calibrated (HALAR) with performance plots

Accessories (To be Ordered as a Separate Line Item)

CGF Collet and gripper filtration kit

Figure 1-1: ACSRotary Stage with Callouts

www.aerotech.com 11

ACS Hardware Manual Chapter 1: Overview

1.1. Environmental Specifications

W A R N I N G : Do not expose this product to environments or conditions outside of the listed

specifications. Exceeding environmental or operating specifications can cause damage to the

equipment.

Table 1-4: Environmental Specifications

Ambient

Temperature

Operating: 10° to 35° C (50° to 95° F)

The optimal operating temperature is 20° C ±2° C (68° F ±4° F). If at any time the

operating temperature deviates from 20° C, degradation in performance could occur.

Storage: 0° to 40° C (32° to 104° F) in original shipping packaging

Humidity

Operating: 20% to 60% RH

Storage: 10% to 70% RH, non-condensing in original packaging. The stage should be

packaged with desiccant if it is to be stored for an extended time.

Altitude

Operating: 0 m to 2,000 m (0 ft to 6,562 ft) above sea level

Contact Aerotech if your specific application involves use above 2,000 m or below sea

level.

Vibration

Use the system in a low vibration environment. Excessive floor or acoustical vibration

can affect system performance. Contact Aerotech for information regarding your spe-

cific application.

Protection

Rating

The ACS stages are not suited for dusty or wet environments. This equates to an

ingress protection rating of IP40.

Use Indoor use only

1.1. Environmental Specifications ACS Hardware Manual

12 www.aerotech.com

1.2. Basic Specifications

N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any

time. All drawings and illustrations are for reference only and were complete and accurate as of this

manual’s release. Refer to www.aerotech.com for the most up-to-date information.

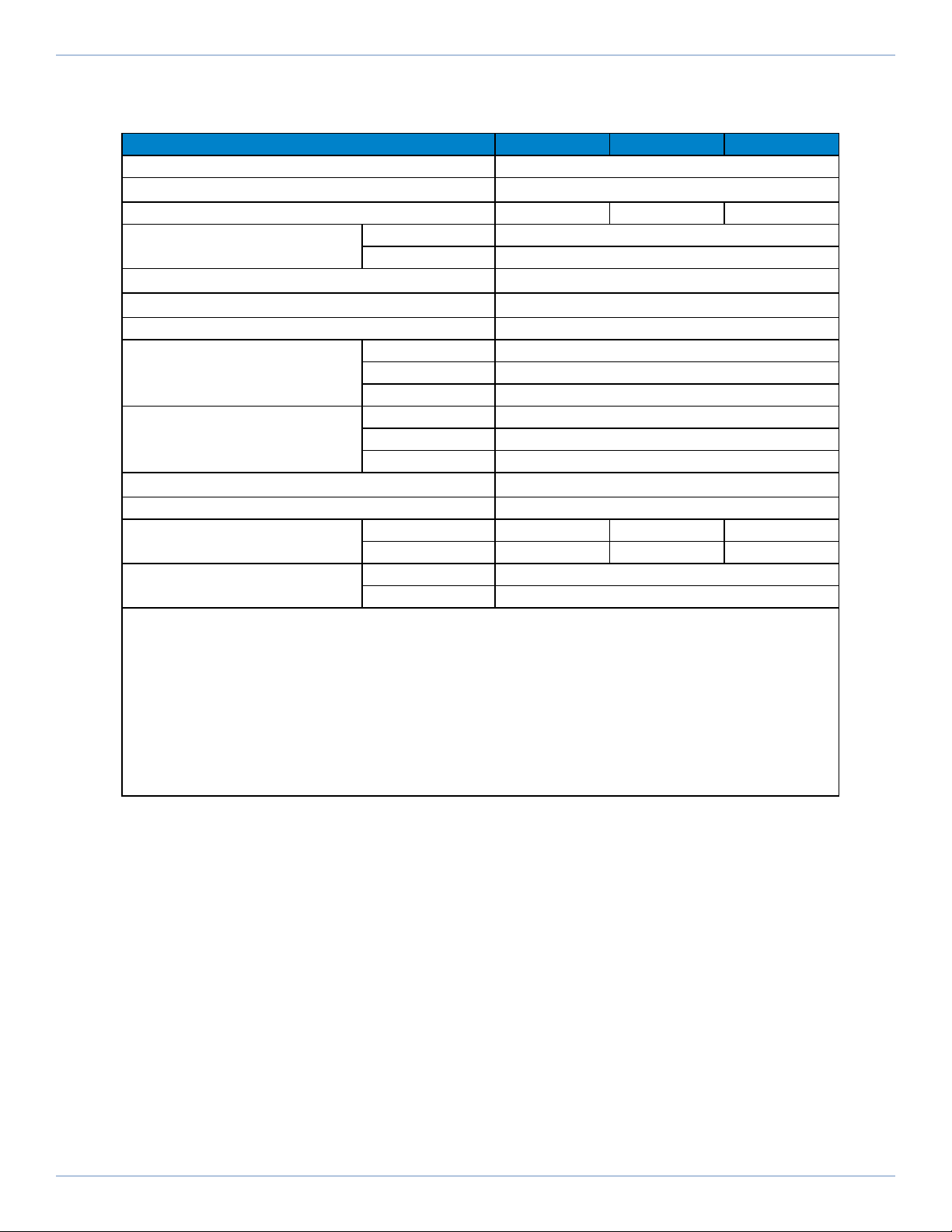

Table 1-5: ACS100 Series Specifications

ACS Series ACS100-85 ACS100-135

Total Travel ±360° Continuous

Collet Option(1)(6) ER8

Maximum Torque (Continuous) 0.48 N·m 1.6 N·m

Accuracy(2) Calibrated ±73 µrad (±15 arc sec)

Uncalibrated ±146 µrad (±30 arc sec)

Repeatability(2) ±29 µrad (±6 arc sec)

Pin/Collet Runout (ERCollets)(3) <25 µm

Grip Repeatability / Max Jaw Length (3 Jaw) ± 20 µm / 50 mm

Maximum Aperture ER8 5 mm 5 mm

Maximum Load(4) ER8 1.5 kg (Axial); 0.5 kg (Radial); 0.75 N·m

(Moment)

Rated Speed(5) 800 rpm

Bus Voltage Up to 340 VDC

Total Mass 2.5 kg 4.5 kg

Finish Table Hardcoat

Stage Black Anodize

1. ACS collet chuck accepts Rego-Fix ER collets manufactured to DIN6499 specifications only.

2. Repeatability and accuracy are dependent on encoder resolution. To achieve the listed specifications, encoder resolution must

be 1.2 arc sec or less.

3. Measured TIR of precision gage pin chucked with an ultra precision ER collet (DIN6499) 6 mm away from collet face with no load.

4. Maximum loads are mutually exclusive. Loading limits are due to the collet chuck mechanism. Contact Aerotech directly if part

load requirement exceeds specifications.

5. Maximum speed based on stage capability. Maximum application velocity may be limited by system data rate and system

resolution.

6. Collet chuck mechanism is normally-closed. Collet mechanism requires air to open collet chuck. Air supply must be dry (0ºF dew-

point) oil-less air OR 99.99% pure Nitrogen. Air or nitrogen must be filtered to 1 micron particle size or better.

www.aerotech.com 13

ACS Hardware Manual 1.2. Basic Specifications

Table 1-6: ACS150 Series Specifications

ACS Series ACS150-115 ACS150-135 ACS150-180

Total Travel ±360° Continuous

Gripper/Collet Option(1)(6) ER25, ER40, 3J-12

Maximum Torque (Continuous) 2.85 N·m 5.06 N·m 9.29 N·m

Accuracy(2) Calibrated ±73 µrad (±15 arc sec)

Uncalibrated ±146 µrad (±30 arc sec)

Repeatability(2) ±29 µrad (±6 arc sec)

Pin/Collet Runout (ERCollets)(3) <25 µm

Grip Repeatability/Max Jaw Length (3 Jaw) ±20 µm/50 mm

Maximum Aperture

ER25 16 mm

ER40 30 mm

3J-12 12 mm

Maximum Loads(4)

ER25 10 kg (Axial); 5 kg (Radial); 6 N·m (Moment)

ER40 15 kg (Axial); 10 kg (Radial); 12 N·m (Moment)

3J-12 20 kg (Axial); 11 kg (Radial); 6 N·m (Moment)

Rated Speed(5) 600 rpm

Bus Voltage Up to 340 VDC

Total Mass ER25 / ER40 8.0 kg 10.0 kg 14.0 kg

3J-12 7.8 kg 9.7 kg 13.7 kg

Finish Table Hardcoat

Stage Black Anodize

1. ACS collet chuck accepts Rego-Fix ER collets manufactured to DIN6499 specifications only.

2. Repeatability and accuracy are dependent on encoder resolution. To achieve the listed specifications, encoder resolution must

be 1.2 arc sec or less.

3. Measured TIR of precision gage pin chucked with an ultra precision ER collet (DIN6499) 6 mm away from collet face with no load.

4. Maximum loads are mutually exclusive. Loading limits are due to the collet chuck mechanism. Contact Aerotech directly if part

load requirement exceeds specifications.

5. Maximum speed based on stage capability. Maximum application velocity may be limited by system data rate and system

resolution.

6. Collet chuck mechanism is normally-closed. Collet mechanism requires air to open collet chuck. Air supply must be dry (0ºF dew-

point) oil-less air OR 99.99% pure Nitrogen. Air or nitrogen must be filtered to 1 micron particle size or better. With 3-jaw gripper, air

or nitrogen should be filtered to 20 micron particle size or better.

1.2. Basic Specifications ACS Hardware Manual

14 www.aerotech.com

Table 1-7: ACS200 Series Specifications

ACS Series ACS200-155 ACS200-185

Total Travel ±360° Continuous

Gripper Option 3J1 through 3J8

Maximum Torque (Continuous) 11.2 N·m 15.93 N·m

Accuracy(1) Calibrated ±73 µrad (±15 arc sec)

Uncalibrated ±146 µrad (±30 arc sec)

Repeatability(1) ±29 µrad (±6 arc sec)

Grip Repeatability(2) ±20 µm

Max Jaw Length from Chuck

Face

3J-12 50 mm

3J-25 70 mm

Aperture 3J-12 12 mm

3J-25 25 mm

Maximum Loads(3) 3J-12 20 kg (Axial); 11 kg (Radial); 6 N·m

(Moment)

3J-25 30 kg (Axial); 18 kg (Radial); 13 N·m

(Moment)

Rated Speed(4) 600 rpm

Bus Voltage 340 VDC

Total Mass 20.2 kg 24.3 kg

Finish Table Hardcoat

Stage Black Anodize

1. Repeatability and accuracy are dependent on encoder resolution. To achieve the listed specifications, encoder resolution must

be 1.2 arc sec or less.

2. Measured TIR of precision gage pin 10 mm away from gripper face with no load.

3. Maximum loads are mutually exclusive. Loading limits are due to the collet chuck mechanism. Contact Aerotech directly if part

load requirement exceeds specifications.

4. Maximum speed based on stage capability. Maximum application velocity may be limited by system data rate and system

resolution.

www.aerotech.com 15

ACS Hardware Manual 1.2. Basic Specifications

1.3. Air Requirements

The air pressure supplied to the collet holder or gripper is important in ensuring that the material or tool is

released properly, or for the optional gripper, that the material is held securely.

lIf compressed air is used, it must be filtered to 1 micron, dry to 0º F dew point, and oil free.

lIf nitrogen is used, it must be 99.99% pure and filtered to 1 microns.

For stages equipped with a three-jaw gripper, air must be regulated to between 3 and 7 bar (45 and 100 psig).

Higher pressures could cause damage to the gripper assembly and should be avoided. The chuck becomes

fully open at approximately 4-7 bar (60-100 psig) depending on the collet size. Higher pressures will not

cause damage to the rotary union, but high flow rates will result. Because of the noncontact rotary union

design on collet-equipped stages, a small amount of leakage will occur. Approximate leakage rates of

between 10 Lpm (0.5 CFM) and 40 Lpm (1.4 CFM), depending on pressure, will be observed when the collet

is open.

1.3. Air Requirements ACS Hardware Manual

16 www.aerotech.com

Chapter 2: Mechanical Specifications and Installation

W A R N I N G : ACS installation must be in accordance to instructions provided by this manual

and any accompanying documentation. Failure to follow these instructions could result in injury

or damage to the equipment.

2.1. Unpacking and Handling the Stage

W A R N I N G : It is the customer's responsibility to safely and carefully lift the stage.

lMake sure that all moving parts are secure before moving the ACS. Unsecured moving

parts may shift and cause bodily injury.

lImproper handling could adversely affect the performance of the ACS. Use care when

moving the ACS.

lLift only by the base. Do not use the tabletop or cables as lifting points.

N O T E : If any damage has occurred during shipping, report it immediately.

Carefully remove the ACS stagefrom its protective shipping container. Gently set the ACS stage on a

smooth, flat, and clean surface.

Before operating the ACS stage, it is important to let it stabilize at room temperature for at least 12 hours.

Allowing it to stabilize to room temperature will ensure that all of the alignments, preloads, and tolerances are

the same as they were when tested at Aerotech. Use compressed nitrogen or clean, dry, oil-free air to

remove any dust or debris that has collected during shipping.

Each ACS has a label listing the system part number and serial number. These numbers contain information

necessary for maintaining or updating system hardware and software. Locate this label and record the

information for later reference.

Shipping Clamps

If the ACS has shipped as part of a system, shipping clamps (typically red, anodized aluminum) may have

been installed to secure the system prior to shipment. The shipping clamps, if installed, will need to be

removed prior to machine start up.

www.aerotech.com 17

ACS Hardware Manual Chapter 2: Mechanical Specifications and Installation

2.2. Dimensions

N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any

time. All drawings and illustrations are for reference only and were complete and accurate as of this

manual’s release. Refer to www.aerotech.com for the most up-to-date information.

Figure 2-1: ACS100 Dimensions

2.2. Dimensions ACS Hardware Manual

18 www.aerotech.com

Figure 2-2: ACS150 (-ER Chuck Style) Dimensions

www.aerotech.com 19

ACS Hardware Manual 2.2. Dimensions

Figure 2-3: ACS150 (-3J Chuck Style) Dimensions

2.2. Dimensions ACS Hardware Manual

20 www.aerotech.com

This manual suits for next models

9

Table of contents

Popular Power Tools manuals by other brands

Parkside

Parkside PBSG 95 E6 Translation of the original instructions

SM CONTACT

SM CONTACT SM CRIMP 2000 Operator's manual

Bosch

Bosch GSC 160 Professional Original instructions

Bosch

Bosch GST Professional 65 Original instructions

Rockwell

Rockwell Shop Series instruction manual

Kyocera

Kyocera TJEP FH 21/90 GAS 2G manual

Bartell

Bartell BR3570 Owner's manual and parts book

Stanley

Stanley FATMAX V20 SFMCN618 manual

BorMann

BorMann PRO BDC3200 user manual

RAMSET

RAMSET LOW VELOCITY POWDER ACTUATED TOOL Operator's instruction & training manual

Bosch

Bosch GDR 14 Original instructions

Cembre

Cembre RH50 Operation and maintenance manual