SM CONTACT SM CRIMP 2000 User manual

NOTICE SM CRIMP 2000 (V7/5 July 2010) 1

SM CRIMP 2000

Operators

Manual

SM CONTACT

ZAC de la Bonne Rencontre - 20 à 22 Voie Gallo–Romaine

77860 QUINCY VOISINS

Tel : 00.33 (01).64.63.66.66 - Fax : 00.33 (01).64.63.67.22

E-mail:[email protected]

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 2

TECHNICAL DATA

Drive: .....................................Three-phase motor with worm gear

Stroke: ...................................35 mm

Crimping rate: .......................Up to 4,000 strokes/h

Motor power:........................0.25kW

Supply voltage.......................110V or 230 V single phase

Power consumption:.............2 A

Power frequency:..................50 Hz

Sound level:...........................< 75 db (A)

Dimensions:...........................W=291 x H 340 x D 490 mm

Weight:..................................59 kg (with tool cassette)

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 3

CONTENTS

1 SAFETY FIRST ............................................................................................................................................................................................................................................... 4

1.1 Presentation ................................................................................................................................................................................................................................... 4

1.2 The general safety device ............................................................................................................................................................................................................... 4

2 COMPLETENESS OF CONSIGNMENT ............................................................................................................................................................................................................ 5

2.1 Ordering spare parts and requesting Customer Service. ................................................................................................................................................................. 6

3 INITIAL START-UP ........................................................................................................................................................................................................................................ 6

3.1 Safety devices ................................................................................................................................................................................................................................. 6

3.2 Power connection ........................................................................................................................................................................................................................... 6

3.3 Starting the machine....................................................................................................................................................................................................................... 7

3.4 Keypad / Functions / Indicated Messages ....................................................................................................................................................................................... 8

3.4.1 The key ‘MODE’ .................................................................................................................................................................................................................. 8

3.4.2 The key ‘RESET’................................................................................................................................................................................................................. 10

3.4.3 The keys + and - .............................................................................................................................................................................................................. 10

3.5 Splice band feeding system : How to install a new reel and to introduce the banding............................................................................................................ 10

3.6 Checking the crimping height and clincher centring (assuming these have been correctly set, otherwise see section accordingly). ............................................ 12

3.6.1 Centring the clincher ....................................................................................................................................................................................................... 12

3.6.2 Controlling the crimping height ........................................................................................................................................................................................ 13

4 EXCHANGING THE TOOLING CASSETTE ......................................................................................................................................................................................................14

5 DISMANTLING THE tooling AND REPLACING SPARE PARTS ........................................................................................................................................................................16

5.1 Opening the tooling ...................................................................................................................................................................................................................... 16

5.2 Replacing the punch and/or the guide.......................................................................................................................................................................................... 17

5.3 Replacing the anvil........................................................................................................................................................................................................................ 19

5.4 Replacing the cutting block........................................................................................................................................................................................................... 20

5.6 Setting up the cutting-block.......................................................................................................................................................................................................... 22

5.7 The slice stop ................................................................................................................................................................................................................................ 22

5.8 Replacing and centring the clincher .............................................................................................................................................................................................. 23

6 THE tooling STORAGE DEVICE ....................................................................................................................................................................................................................25

6.1 View and data modifications of the technical datasheet .............................................................................................................................................................. 25

6.2 Updating the data of the technical sheet into the memory. ......................................................................................................................................................... 27

7 DISMANTLING AND REASSEMBLING ..........................................................................................................................................................................................................28

7.1 The frontal compartment ............................................................................................................................................................................................................. 28

7.2 The right-hand safety cover .......................................................................................................................................................................................................... 28

7.3 The left-hand safety cover ............................................................................................................................................................................................................ 29

7.4 The front panel ............................................................................................................................................................................................................................. 29

7.5 The belt......................................................................................................................................................................................................................................... 31

7.6 The gear motor ............................................................................................................................................................................................................................. 33

7.7 The convertor parameters ............................................................................................................................................................................................................ 34

The parameters are handed with the technical sheet on the USB key. ........................................................................................................................................................... 34

7.8 List of inputs and outputs ............................................................................................................................................................................................................. 34

7.8.1 Inputs ............................................................................................................................................................................................................................... 34

7.8.2 Outputs............................................................................................................................................................................................................................. 34

8 TRANSPORTATION .....................................................................................................................................................................................................................................35

8.1 Lifting/transporting the machine manually................................................................................................................................................................................... 35

8.2 Transportation in a vehicle ........................................................................................................................................................................................................... 35

9 POSSIBLE ERRORS: HOW TO RECTIFY THEM? .............................................................................................................................................................................................35

9.1 Punch guide centring problem ...................................................................................................................................................................................................... 37

9.2 Punch guide colliding or too far from the top of the clincher........................................................................................................................................................ 37

9.3 Splice shape imperfect .................................................................................................................................................................................................................. 38

9.4 Display is showing error “index the pin” ....................................................................................................................................................................................... 39

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 4

1SAFETY FIRST

1.1 Presentation

These operating instructions relate to the SM CRIMP 2000 crimping press.

The SM CRIMP 2000 is state of the art in design and operationally reliable.

It is used exclusively for producing spliced crimped connections.

Any use over and above this application is deemed to be other than for its intended purpose.

The following potential hazards exist in the event of use other than the intended purpose, or

with improper use:

Danger to life and limb.

Danger to the machine.

Danger to other material assets.

The machine should be operated only by personnel trained in its use. The new owner of the

machine or his representative has been instructed in and made aware of the operation of the

machine and all sensitive details. He is responsible for the further training of his personnel.

Any person involved with the operation, maintenance, repair, or inspection of the crimping

press at the user’s premises must have read and understood the Operating Instructions and,

in particular, this Section on “Safety”.

The responsibilities relating to operation of the machine must be clearly stipulated and

adhered to.

1.2 The general safety device

1. In addition to the information in these Operating Instructions, the general accident

prevention regulations of your country must be observed.

2. Before starting work, you must familiarise yourself with all the functions and controls and

how they work.

3. Safety devices must be checked once per shift for externally visible damage or defects.

Damage must be rectified without delay. Do not continue operating with safety devices off!

4. The safety devices must never be removed or put out of operation.

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 5

You may be subject to very serious injury if you remove or disable the safety devices.

Following removal for any necessary setting-up, repair or maintenance work, the

safety devices must be properly re-installed immediately before resuming production.

Always withdraw disconnect the power for any setting-up, repair or maintenance

work.

The machine’s power cable must always be freely accessible.

Left-hand safety covers Finger guard Right-hand safety covers

The components to be processed should preferably be brought to the machine with

both hands.

The machine must never be operated with the safety covers or finger guard removed.

Any materials that are caught in the clincher should not be removed before the machine

has been switched off.

The machine must always be switched off before changing the splice band reel.

Switch off the machine before any intervention into the machine and when changing

the tooling.

Only qualified personnel should perform adjustment and maintenance operations.

See Sections 8 for transportation of the machine, either manually or by vehicle.

The manufacturer is not liable for damage arising from failure to observe the Operating

Instructions. We reserve the right to make technical modifications for reasons of quality

enhancement or extended application, or for production reasons.

SM CONTACT is not obliged to supply spare parts hereby.

2COMPLETENESS OF CONSIGNMENT

Your delivery should contain the parts listed below:

SM CRIMP 2000 Splicing Crimping Press.

Power cable.

Foot pedal.

Operating Instructions, including:

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 6

Please check that the consignment is complete and that there is no concealed or obvious

transport damage.

2.1Ordering spare parts and requesting Customer Service.

Please note:

When ordering spare parts or seeking customer service, please provide the following:

Part numbers from the enclosed spare parts list.

Machine Serial and Model number.

Tool Cassette number.

3INITIAL START-UP

3.1 Safety devices

1. The machine must only be operated with the safety devices on!

2. Never extend your hands into the danger area!

3. Should a fault or an accident occur, immediately press the E-Stop (Emergency) button and

disconnect the power cable.

3.2 Power connection

Only qualified personnel must perform any work on the electrical system, such as

connection to power, maintenance or repairs.

Even with the Emergency Stop button pressed, parts of the machine still carry live voltage.

The connection is made via the power cable delivered with the machine. It must be ensured

that the operating voltage corresponds with the mains voltage (230 V/110V). Actuating the

power switch on the rear starts the crimping press.

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 7

3.3Starting the machine.

-Connect power cable (K).

-Connect foot pedal cable (P)

-Turn on the main switch (N) (if the switch is in the off position (lamp not lit), the machine is

not live.

-Unlock Emergency Stop button by turning it to the right.

Main Switch module

The machine is ready

K

K

K

P

N

2 x fuses

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 8

3.4 Keypad / Functions / Indicated Messages

The power switch, in the form of a toggle switch with a red knob (N) is located at the top on the

rear of the machine.

All the other controls and display components are located on the front of the machine.

If the Emergency Stop button is depressed (see picture 8), no crimping cycle can take place. If

the Emergency Stop button is depressed and you press on the foot pedal, “Emergency Stop” is

indicated but the cycle does not start.

The following functions can be regulated with 4 buttons on the front of the machine:

3.4.1 The key ‘MODE’

From the main screen display, access those following functions:

Quantity

150

Total quantity

439870

123456789

123456789

Show the normal operating state of the

machine:

The figures highlighted on the first line

show the inputs activities.

The figures highlighted on the second

line show the outputs activities. See

chapter 7.8

Pic. 9

Pic.. 8

Put the counter en zero through reset:

When the display shows up « Quantity »,

Rest 5 seconds on the bottom « reset » to

put back the quantity at zero on the

counter.

Note: The total quantity cannot be put at

zero

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 9

Only if the tooling memory is programmed.

Version

1.24

Lamplight

Use the keys + and –to activate

or disengage the lamp light

Choose

your language

Use the key + and –to select the

language:

French, English, German, Spanish, Italian,

Japanese, Chinese, or Korean. Press the

key ‘MODE’ to confirm the selection.

Cassette SM CRIMP

Use the key + and –to scroll the tooling

technical data: Components to crimp,

spare parts, crimping height, pull force,

type of splice.

Enter the access code

0000

Restricted to manufacturer

Please be aware, that the soft version

noted on this view is only indicative

information

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 10

3.4.2 The key ‘RESET’

The ‘RESET’ key allows you to return automatically to the main display and deleting any error

messages.

3.4.3 The keys + and -

The keys + and –have two different functions:

In the main display, under quantity, the keys + and –allow you to control to the feeding

system.

In the others displays, the keys + and –allow you to scroll the menu options.

3.5 Splice band feeding system : How to install a new reel and to introduce the

banding

Position the splice banding reel vertically

Remove the safety film

Install the reel onto the shaft.

The tag with the reference must be facing the operator.

Unwind the ribbon.

Cut off the bent section of banding.

Position the banding at the entrance of the feeding

system.

The serrations of the banding must be facing down.

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 11

While holding the banding at the entrance of the feeding

system, press the key +. This button also works as the

forward feed button.

Verify that the banding is not bent after it exits the feed

rollers. If the banding is not straight, cut it with cutting

pliers.

Under no circumstances, should the banding be

distorted, this will cause a feeding problem.

The banding should not be bent when inserted into the

tooling.

While holding the banding at the entrance of the cutting

block, press key +.

Keep pressing the + key until the feeding motor system

stops automatically.

The banding must form a curve toward the highest point

of the frame.

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 12

3.6 Checking the crimping height and clincher centring (assuming these have been

correctly set, otherwise see section accordingly).

In order to eliminate any risk of damaging the tool, we would recommend checking the two

following parameters, prior to starting the first cycle:

clincher centring

Crimping height.

Important recommendation:

Before you cycle the press either by turning the hand wheel or by using the foot pedal,

it is strongly recommended that you first check that the punch and clincher will not collide.

Otherwise these components would be severely damaged on initial impact.

Before this check, we recommend to make 10 to 20 cycles with the splice band inserted in the

tool (without the clincher and clincher holder). This ensures that all the parts of the upper tool

have taken their correct position.

3.6.1 Centring the clincher

This operation must be done without splice band and lamp light. Place the clincher and clincher

holder back on the machine.

Using the hand wheel, bring the punch down slowly until the

punch is in middle of the clincher.

Be careful, if the punch is not correctly positioned

compared to the clincher, do not complete the cycle.

Continue slowly turning the hand wheel by monitoring the

movement of the punch downwards from the side (with a

magnifier if necessary). Stop turning as soon as the tip of the

punch enters into the clincher.

The clincher is correctly centred if the clearance between the

punch and the flanks of the clincher is identical to the left

and right.

If the centring is correct, check the crimping height.

If the centring is not correct, refer to the manual for performing adjustments.

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 13

3.6.2 Controlling the crimping height

When delivering a machine with the tooling, our technical department will indicate the crimping

height listed on the technical datasheet.

Before putting the machine into production, it is advised to verify if the dimensions of the

connections are compatible with our recommendations. Refer to the technical data sheet and check

the information.

The tooling can also be delivered independently from the machine. This can have the obligation

updating the information ‘under advice set-up’ with the customer’s technical datasheet.

E5

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 14

4EXCHANGING THE TOOLING CASSETTE

This operation must be done only with the index pin.

Press the key ‘-‘, and remove the banding from the tooling.

Next, press the ‘Emergency Stop ‘switch button

DISMANTLING

Unscrew the clincher

holder.

In order to not damage

the finger guard, pull the

clincher holder forward.

Remove the tooling

mounting screw.

Remove the tooling

1

2

3

4

5

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 15

SETTING-UP

Ensure that contact

surfaces are perfectly

clean, and have no

conductors or insulation

residues adhering to

them.

Push both tool sliders in the

tooling upwards using the

end of a screw-driver.

Lay new tooling on the machine. Tap lightly with the first to introduce both

centring pins.

The instantaneous contact of the tooling with the machine must make a clear

“CLICK”. This metallic sound indicates that both surfaces are perfectly in

contact with each other.

Tighten the tooling

mounting screw

Ensure that the clincher

mounting surface is perfectly

clean, and has no conductors

or insulation residues

adhering to it.

In order prevent

damaging to the finger

safety shield; introduce

the clincher holder

carefully

Tighten the clincher

mounting screw.

1

2

3

4

5

6

7

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 16

5DISMANTLING THE TOOLING AND REPLACING SPARE PARTS

The names of the spare parts that constitute the tooling:

5.1 Opening the tooling

Place the tooling onto a clean surface.

When handling the tooling, be careful not to

damage the finger guard.

Loosen the screw of the cutting block.

The screw should be placed 8 to 10 mm above the

face of the tooling.

Push the cutting block slightly sideways with small

screwdriver.

Contact sonde

1

K

K

1

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 17

Remove the front screw on the cover of the

tooling.

Remove the screw located on the rear of the

tooling.

Slowly open the cover of the tooling.

Place all of the components on a clean surface.

5.2 Replacing the punch and/or the guide

To dismantle the tooling, refer to chapter 5.1

Holding the tooling in your left hand, you must

now check that the sliders can easily slide up and

down simultaneity.

Do not turn the tooling; avoid any damage on

cutting-block and anvil.

Separate the punch slider from the punch-guide

slider by rotating the punch slider as shown on

the picture.

Ensure that the punch pin does not fall on the

floor.

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 18

It’s now possible to separate the punch from the

punch-guide.

Ensure that you don’t lose the punch pin

To replace the punch-guide pin, unscrew the

bolts.

The new punch-guide can now be installed.

Before tightening the screw, be sure that punch

guide is facing upward.

Introduce the punch at the guide extremity.

Do not grease the punch.

Only punches for 4mm splice profiles are

symmetrical (punches for 2 and 6mm splice profiles have

an offset hole).

In the case of 2 or 6mm punch, the hole must be placed

close to the slider body.

Grease the punch and guide slider face (no

grease on the punch and inside the punch-guide).

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 19

Lightly grease components on all sides.

You can now fit the new punch.

5.3 Replacing the anvil

To dismantle the cassette, refer to chapter 5.1

Holding tooling in your left hand, you must now

check that the sliders can easily slide up and

down inside it.

To do this, take a screwdriver and first push the

punch guide slider and then the punch slider up

and down. (The punch slider is difficult to move

because it is pressing the anvil sideways. This

resistance is normal).

Undo the old anvil.

Clean the anvil using a degreaser.

Lubricate both faces of the anvil.

Lubricate the anvil spring.

Place the new anvil.

Before re-assembling, clean up every part of the

tooling.

You can now fit the new anvil.

NOTICE SM CRIMP 2000-V8.0 / Mai 2012 20

5.4 Replacing the cutting block

To dismantle the tooling, refer to chapter 5.1

Holding tooling in your left hand, you must

now check that the sliders can easily slide up

and down inside it.

To do this, take a screwdriver and firstly push

the punch guide slider and then the punch

slider up and down. (The punch slider is

difficult to move because it is pressing the

anvil sideways. This resistance is normal).

Remove the anvil

By pushing behind, slightly slide the cutting

block.

Clean up the cutting-block location with

degreaser.

Replace the anvil.

Before re-assembling, clean up every part of

the tooling.

Table of contents

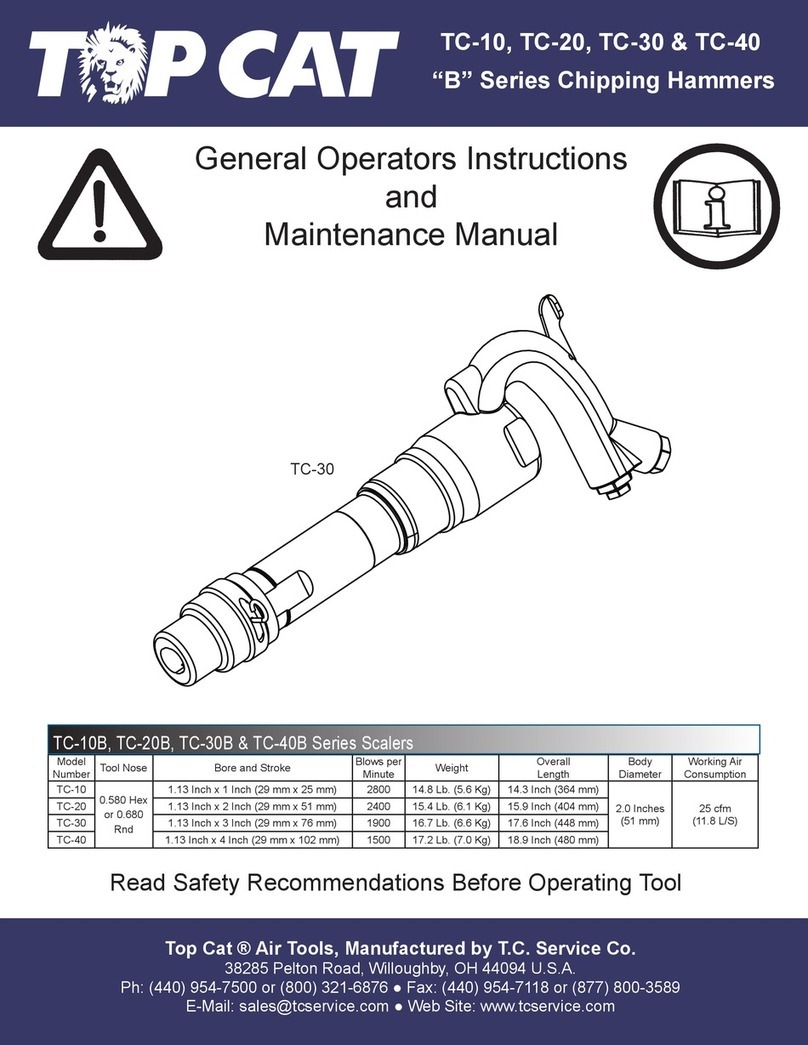

Popular Power Tools manuals by other brands

alzaTools

alzaTools AT-CAP20V user manual

MEISTER CRAFT

MEISTER CRAFT MPS 710 E-P manual

OEM Tools

OEM Tools 24812 Operating instructions and parts manual

FLORABEST

FLORABEST FSG 85 C2 Translation of the original instructions

FLORABEST

FLORABEST ian 271071 Operation and safety notes

MasterForce

MasterForce 241-0834 Operator's manual

BLACK DECKER

BLACK DECKER BCNG01N Original instructions

FLORABEST

FLORABEST FAA 79 A1 Blade changing guide

BLACK DECKER

BLACK DECKER BL188 manual

BLACK DECKER

BLACK DECKER EVO185 Original instructions

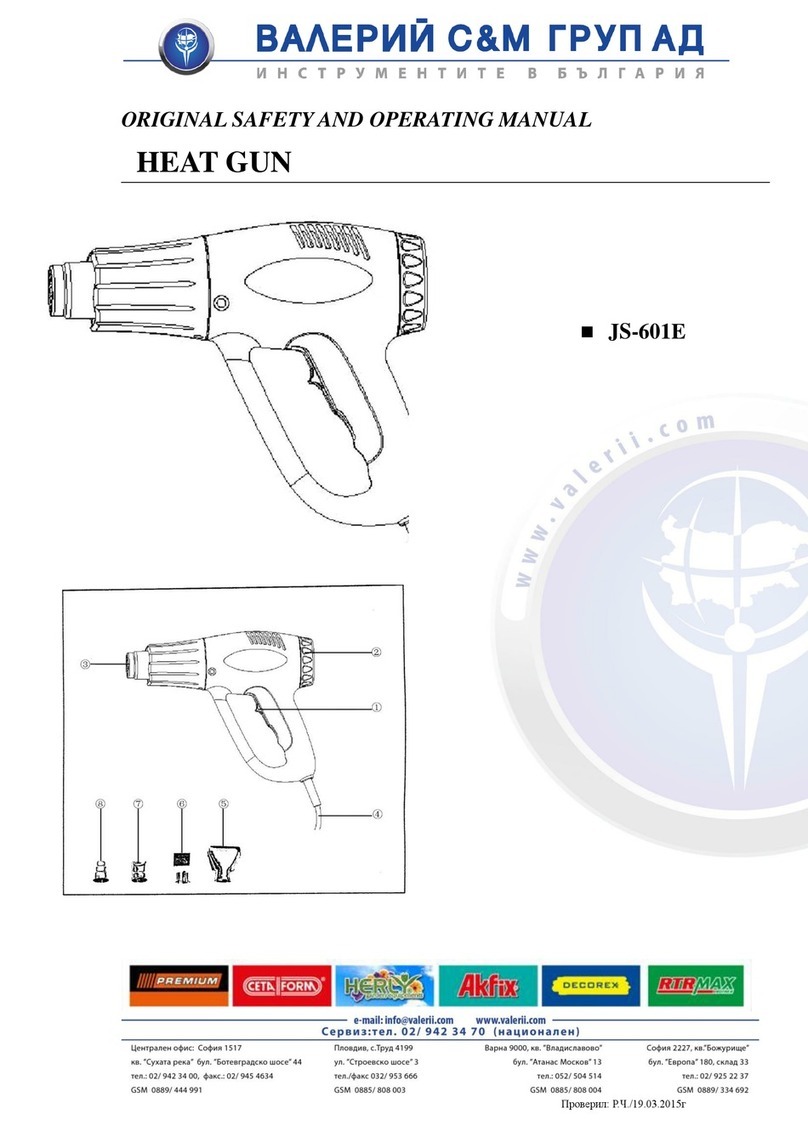

VALERII S & M GROUP

VALERII S & M GROUP JS-601D Safety and operating manual

parktool

parktool DT-5.2 instructions