3. Cut the insulated power conductors to length. Strip o 5mm of insulation from the conductors using an electrical wire

stripper (12 AWG – 2.0mm; 14 AWG –1.6mm; 16 AWG –

1.3mm; 18 AWG -1.0 mm; 20 AWG– 0.8mm; 22 AWG – 0.65mm; 24 AWG – 0.5mm).

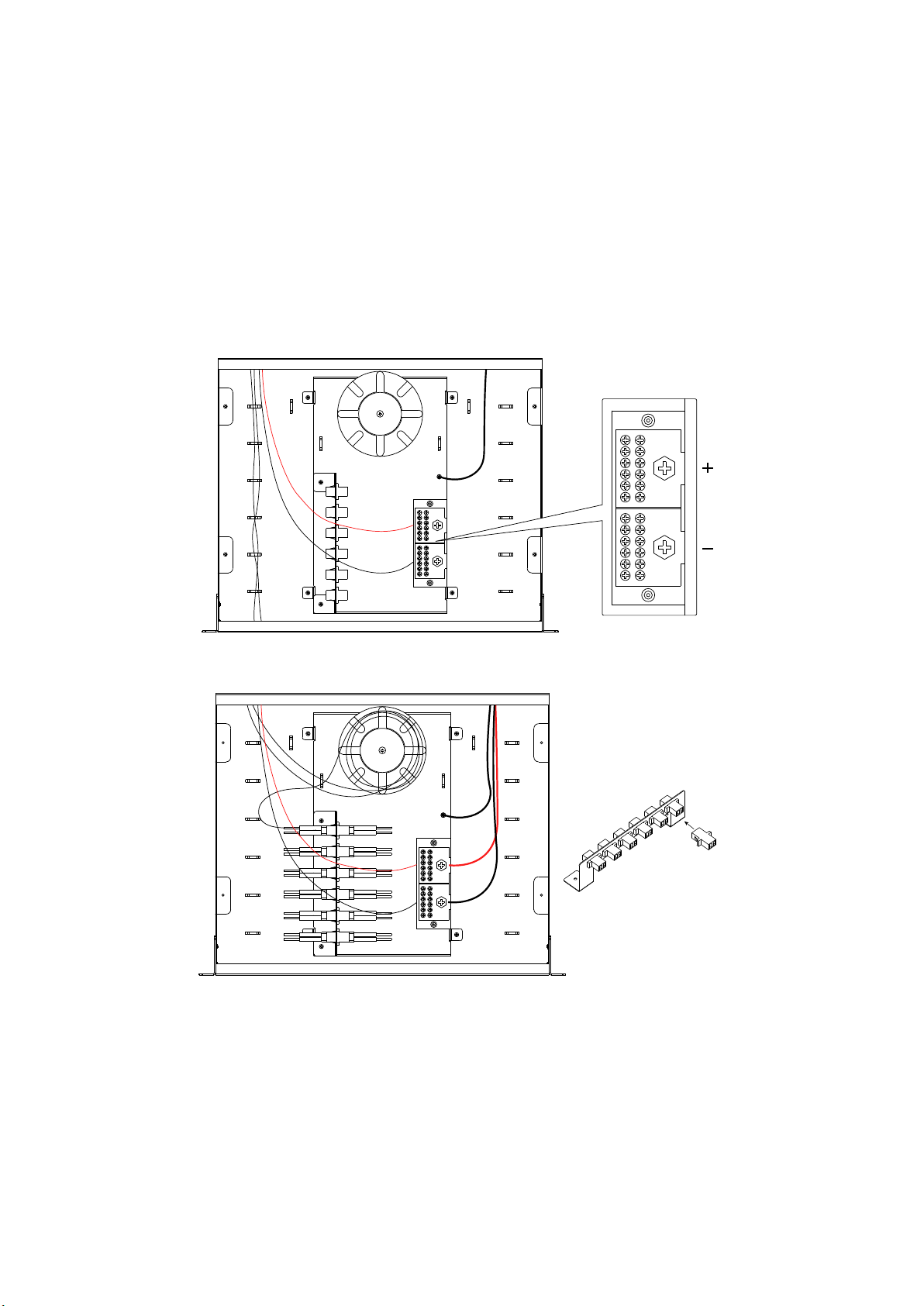

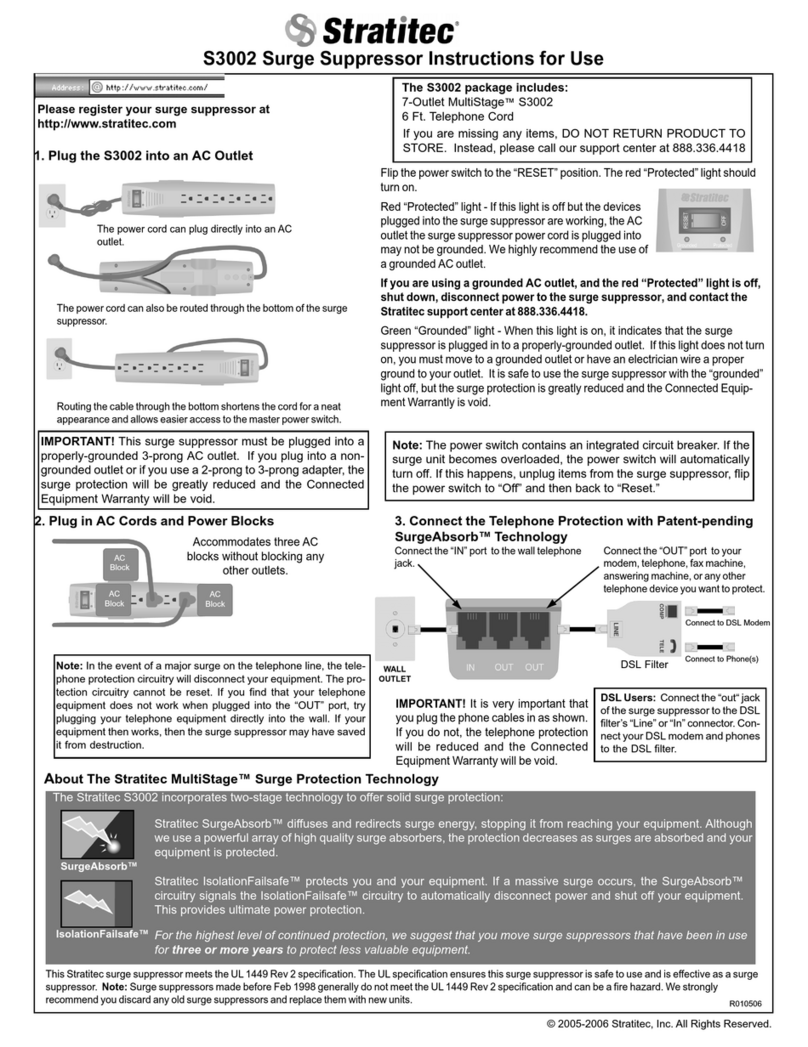

4. Match the wire polarity from the cable plant with the terminal strip polarity, as shown in Figure 4.

5. Using a small at screwdriver open the screw terminals until the wires insert into the terminal ports. Push each wire

into its port. Screw each terminal down hand tight to make contact between the terminal and the wire conductor. Verify

the wires are secure in the terminals with no exposed wire conductor, as shown in Figure 4.

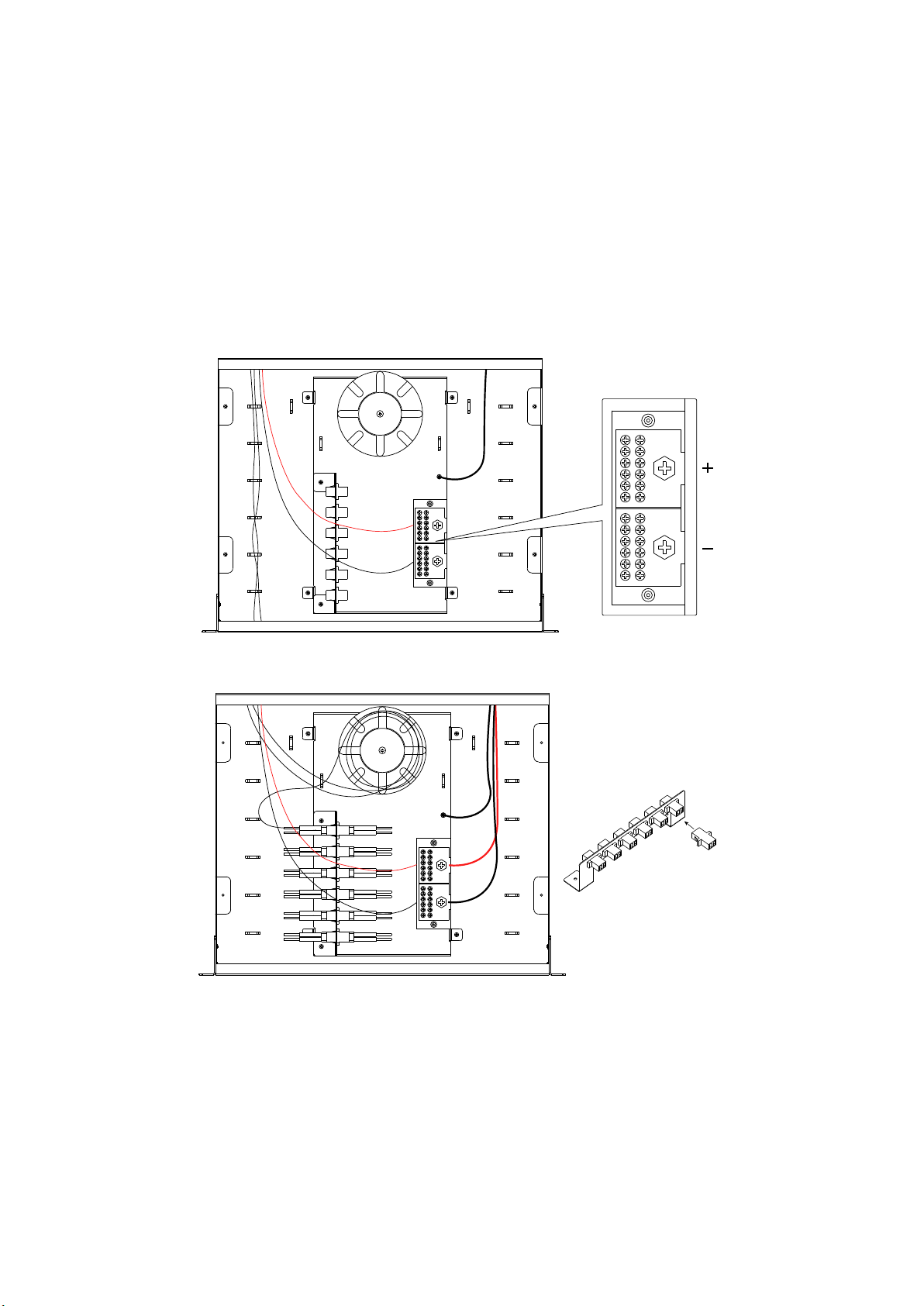

6. Terminate the LC Fiber Optic plugs , Clean and install the LC terminations into the adapter Store excess ber on the

spool, as shown in Figure 5.

7. Repeat steps 1 – 5 for all incoming Powered Fiber Cable's

Step 2 – Route and terminate outgoing/outdoor Powered Fiber Cable

1. Route the outgoing Powered Fiber Cable into the CH-200 and secure to the cable clamp with a supplied cable tie, as

shown in Figure 6. Ensure adequate length for ber slack (1-1.5 meters).

2. Separate the cable into two sections along the tear lines

3. For the outgoing power termination repeat steps 3 – 5 from Section 6 Step 1, verifying any end device powered

equipment wiring polarity with polarity connections on terminal strip, as shown in Figure 6.

Note: Polarization indentation along one side of the cable for polarity identication

Figure 4

Figure 5