aevit 2.0 User manual

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

AEVIT 2.0 Mounting Brackets Installation Manual

Table of Contents

1. Introduction 1

1.1 Overview 1

1.2 Installing the Mounting Ball Onto Input Devices 1

2. Primary Inputs 2

2.1 General Information 2-1

2.2 Mounting Base Installation - Floor 2-1

2.3 Mounting Base Installation - Door 2-3

2.4 Generic Adjustment Installation 2-5

2.5 Other Mounting Options 2-7

3. Secondary Inputs 3

3.1 General Information 3-1

3.2 Display Bracket Installation 3-1

3.3 Secondary Function Switches 3-2

4. Service Requirements 4

5. Before Operating... 4

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

1. INTRODUCTION Mounting Brackets

EMC provides many dierent options for mounting the AEVIT 2.0 devices.

These devices include the AEVIT 2.0 Primary Input Devices, the AEVIT 2.0

Display, and secondary switch options. This manual will show the recom-

mended mounting options for all of these devices. Also provided in this

manual are a few variations of the recommended mounting options that

may better suit your client.

This installation manual is broken down into two (2) major sections. The

rst section focuses on the Primary Input Mounting Brackets. This section

will show how to install brackets for mounting Steering and Gas/Brake

input devices. The second section will focus on Secondary Input Mounting

Brackets. This section deals with the mounting of the AEVIT 2.0 Display and

secondary activation switches.

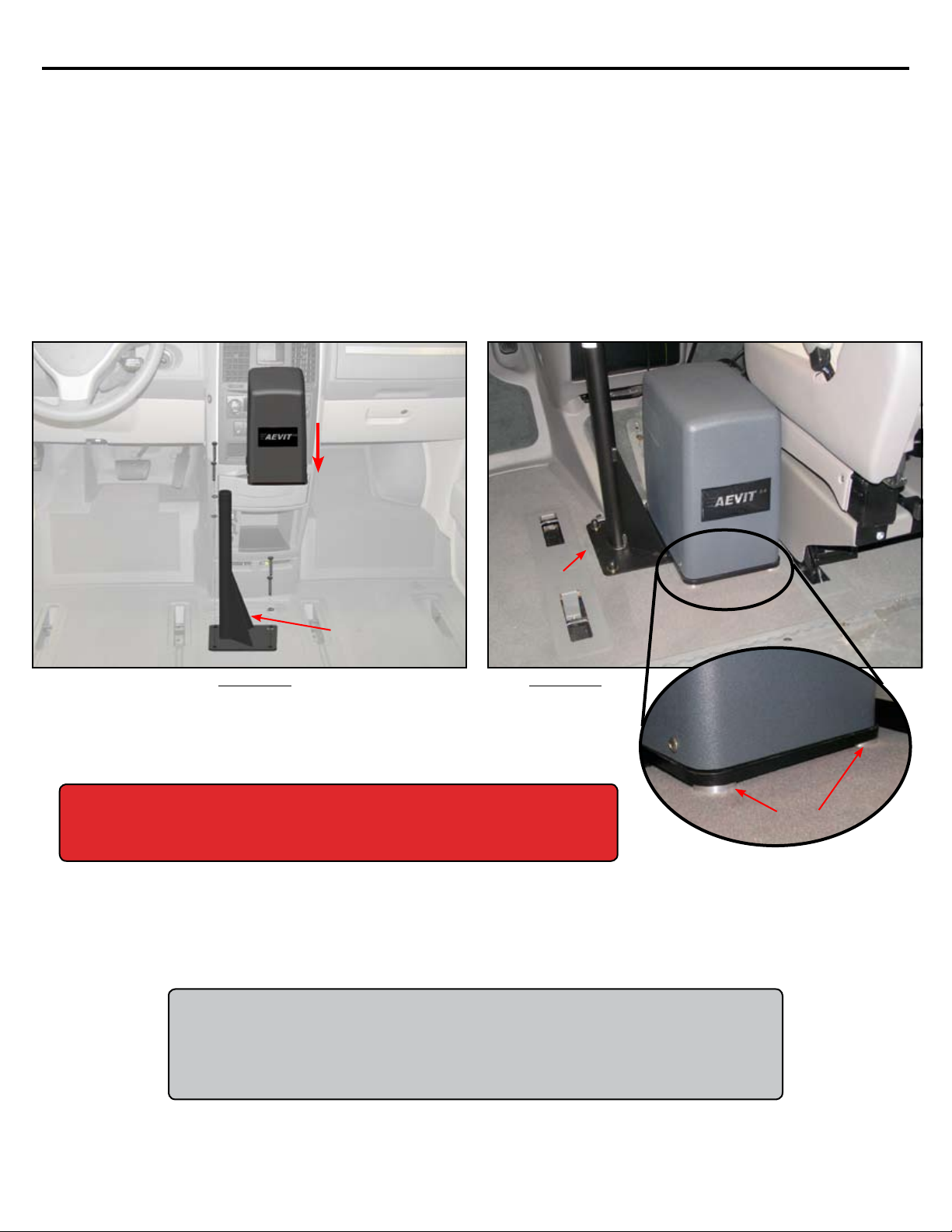

All EMC mounting options provide versatility with the use of ball-and-socket mounting brackets. Mounting Balls will

need to be attached to the input devices and the corresponding mounting brackets will have the mating sockets.

Therefore, the rst step in installing any of the input devices is to install the mounting ball to the bottom of them.

Each Input Device Install Kit should have a Mounting Ball and a Mounting Ball hardware kit that contains the follow-

ing:

(4) 10-32 x 1/2” Safety Torx Screws (1) Safety Torx Bit

(4) #10 Internal Tooth Lock Washers (1) Container of Blue Loctite®

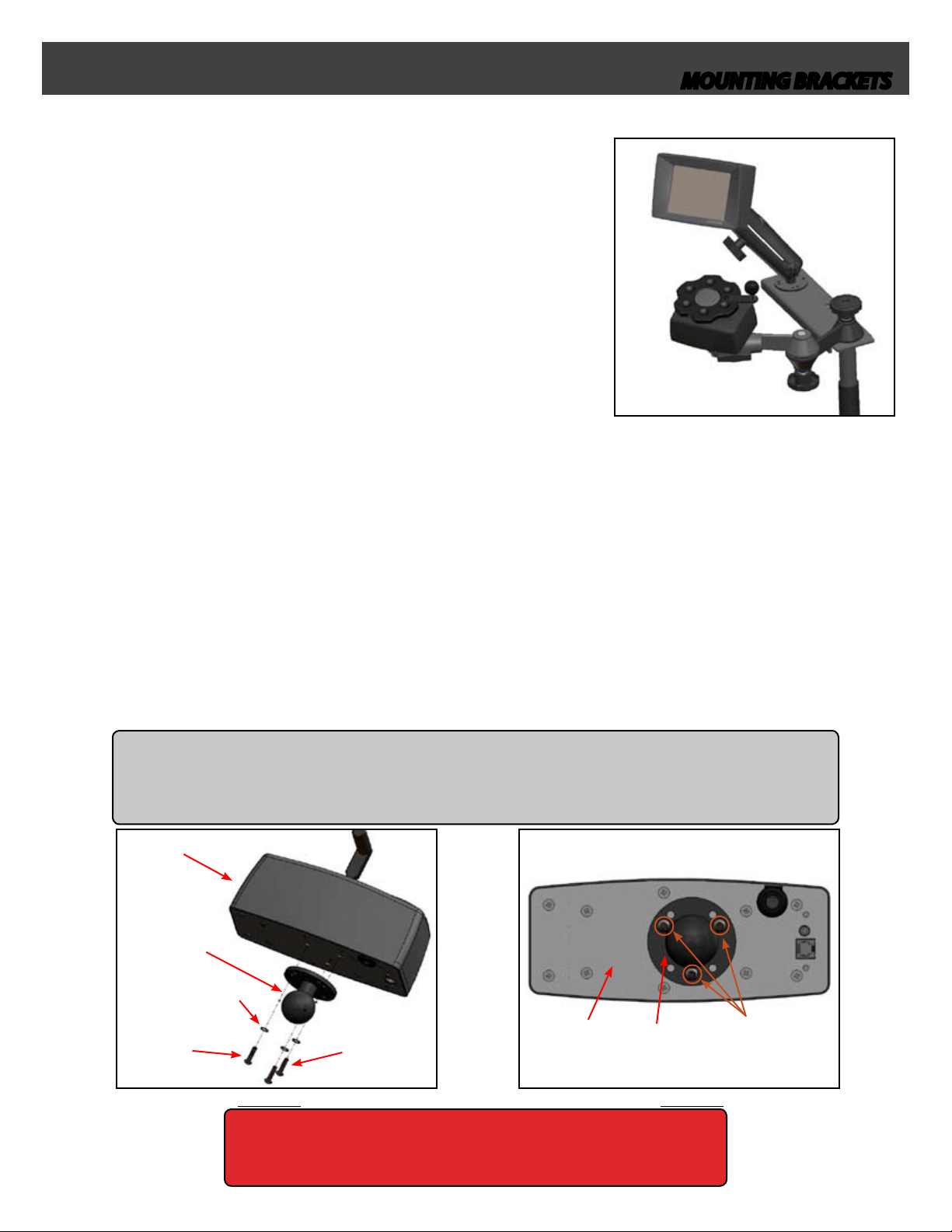

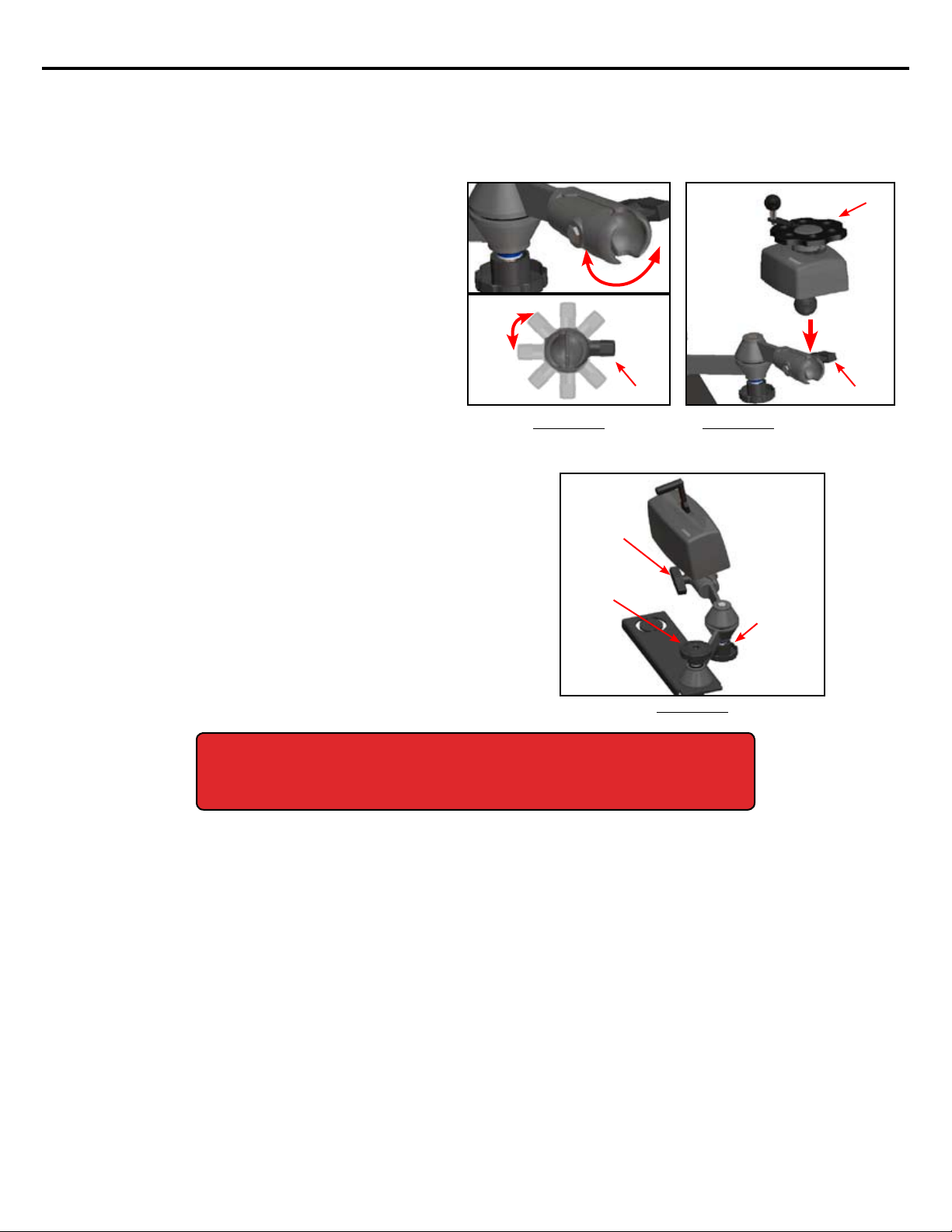

Install the Mounting Ball onto the input device using (3) 10-32 x 1/2” safety torx screws, (3) internal tooth lock washers

and the Blue Loctite® as shown in Figure 1. In order to install the (3) safety torx screws you will need to use the sup-

plied safety torx bit. There are (7) pre-drilled holes on the mounting ball. Figure 2 shows which holes should be used

to mount the ball onto the input device.

ALL AEVIT 2.0 PRIMARY INPUT DEVICES AND THE AEVIT 2.0 DISPLAY ARE DESIGNED TO HAVE THE SAME

MOUNTING BALL SCREW PATTERN. THEREFORE, THIS INSTALLATION STEP SHOULD BE PERFORMED FOR

ALL INPUT DEVICES LEVER, WHEEL, JOYSTICK... AND THE AEVIT 2.0 DISPLAY.

BE SURE TO PROPERLY TIGHTEN THE SCREWS TO THE PROPER TORQUE

SETTING OF 2.0 FTLBS AND USE BLUE LOCTITE®.

DEvICE

DEvICE

BALL

INTERNAL TOOTH

LOCk wASHERS

SCREwS

BALL

use these (3)

Mounting

holes

1.1 OVERVIEW

1.2 INSTALLING THE MOUNTING BALL ONTO INPUT DEVICES

use Blue

loctite®

1

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

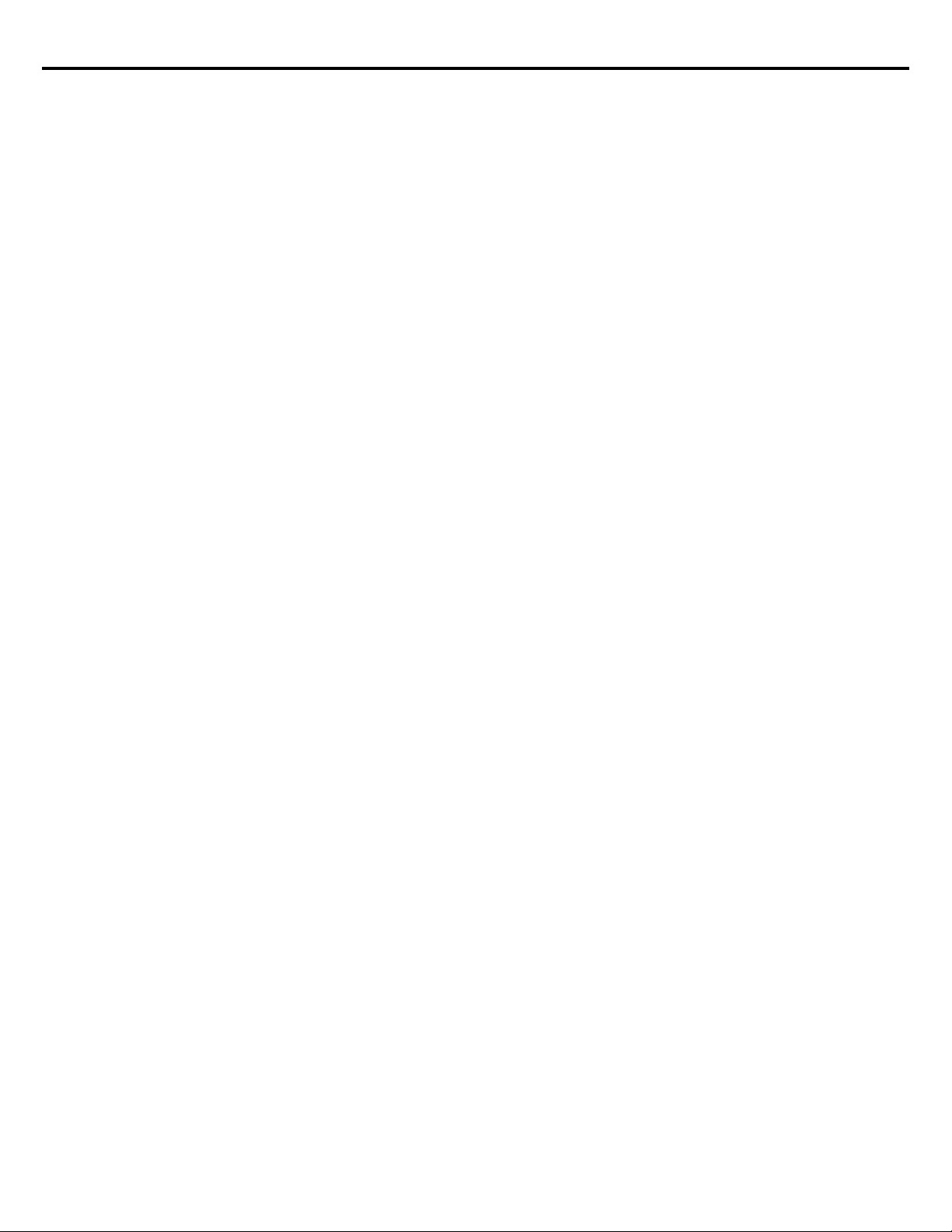

2. PRIMARY INPUT Mounting Brackets

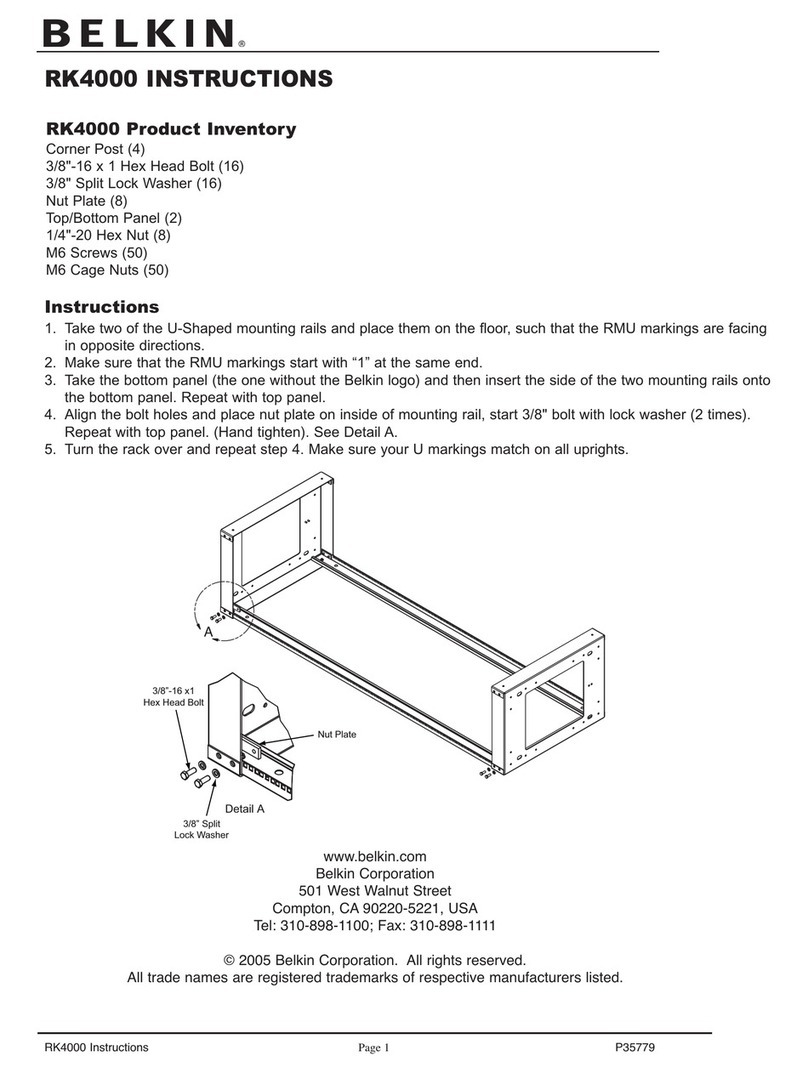

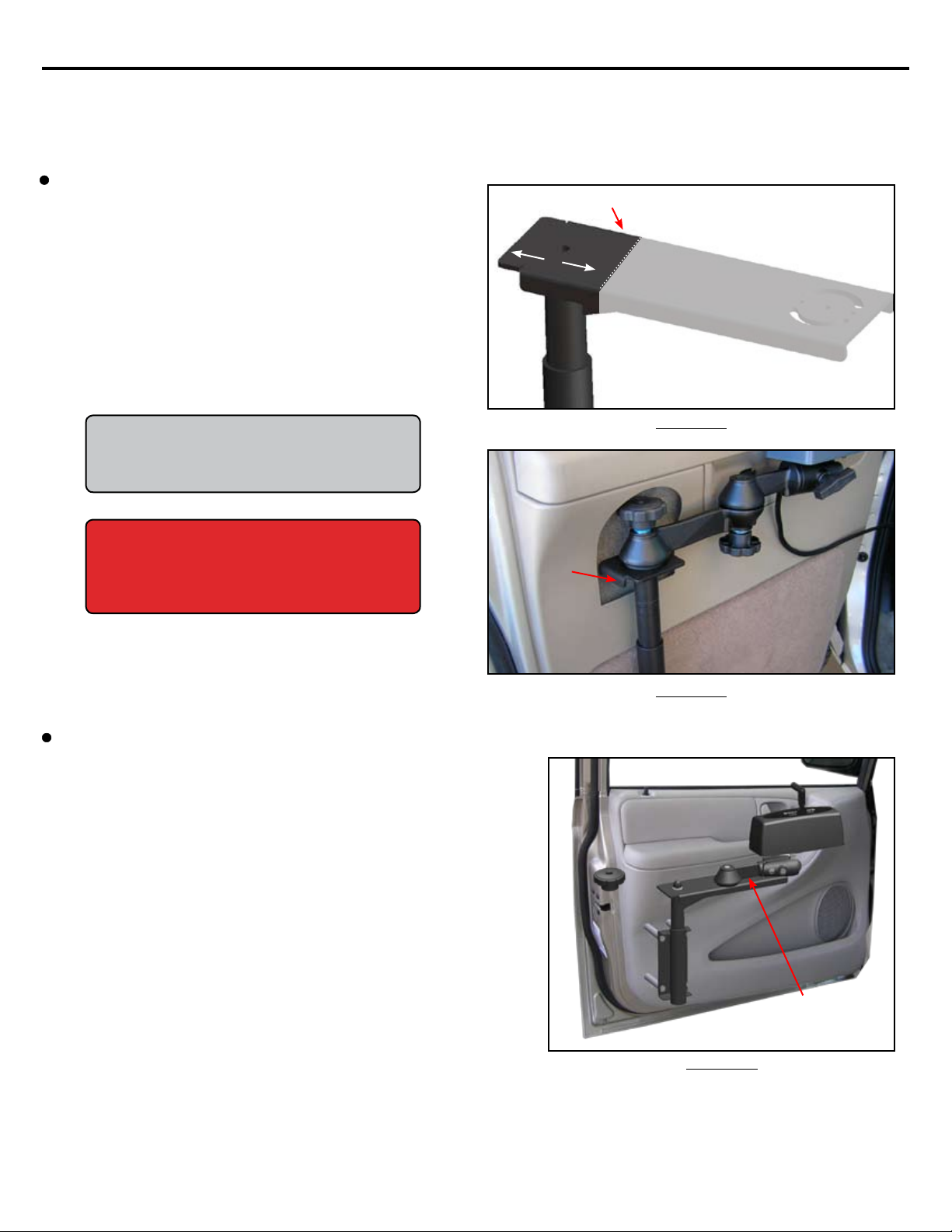

The primary input section will describe how to install the mount-

ing brackets for the Primary Inputs which include: Digital Lever,

Wheel, and single and dual axis Joysticks. As the name states, these

devices perform the tasks of operating the primary functions of the

vehicle: Steering and Gas/Braking. Generally, the Gas/Brake controls

are installed on the left hand side of the driver and utilize the door

mounting bracket system and the steering controls are installed

on the right hand side of the driver and utilize the oor mounting

bracket system. However, only the base plate of each mounting

system is dierent (See gure to the right for mounting system com-

ponents). Sections 2.2 and 2.3 will go into detail about installing the

bases of the Floor and Door mounting systems and section 2.4 will

discuss the generic adjustment section installation. Finally, section

2.5 will discuss other mounting options.

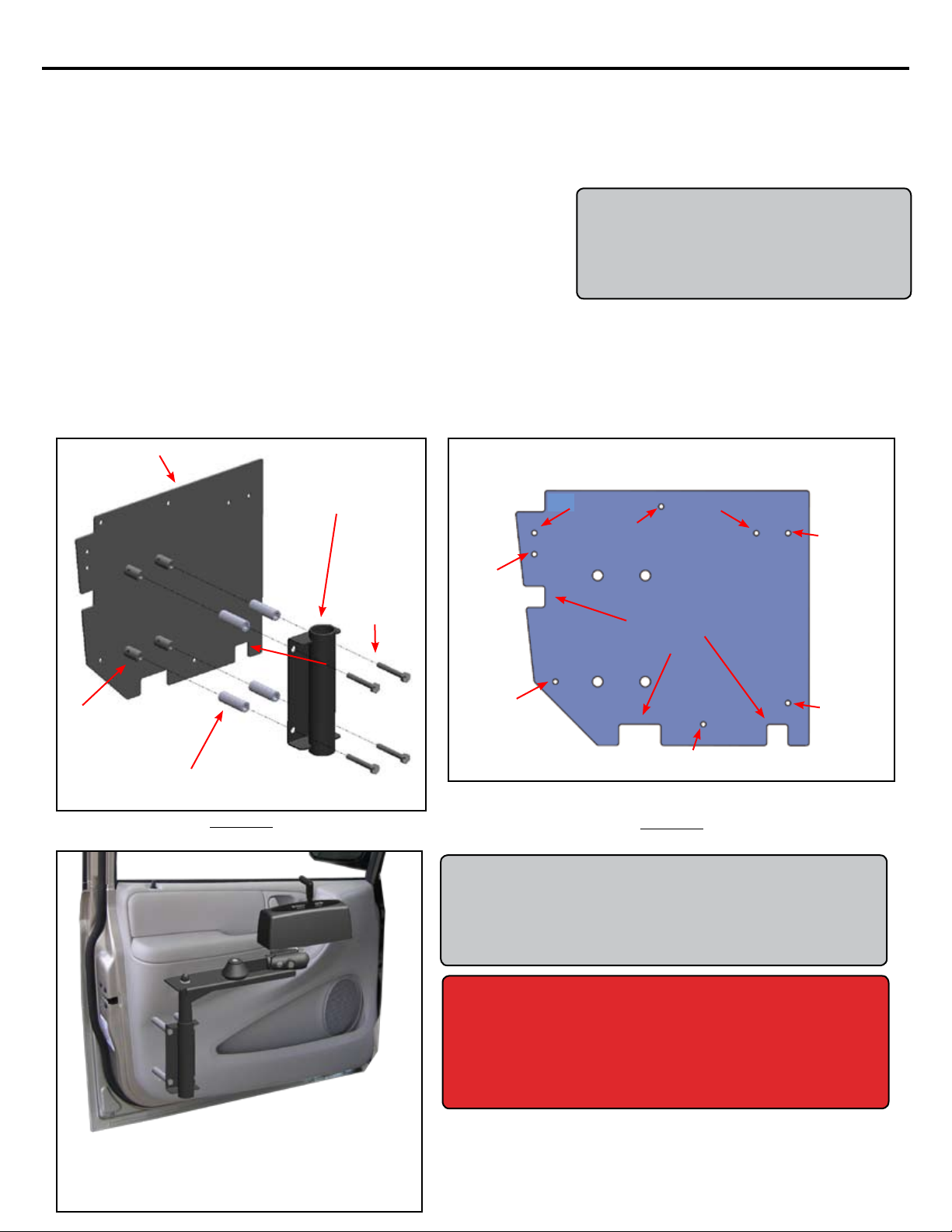

Before installing the Floor Mounting system, verify that the following components are included with the BRKT-AEVIT-

FLR mounting kit:

(1) Floor Base Plate (4) 3/8” x 2” Hex Head Bolts

(1) Input Device Articulating Swivel Brkt (8) 3/8” Flat Washers

(1) Input Device Mounting Ball (4) 3/8” Lock Nuts

(1) Mounting Ball Hardware Kit

2.1 GENERAL INFORMATION

2.2 MOUNTING BASE INSTALLATION FLOOR BRKTAEVITFLR

FLOOR BASE

SECTION

wHAT NOT TO DO

INSTALL THE EMC MOUNTING BRACKETS IF ALL COMPONENTS ARE NOT PROVIDED IN THE KITS.•

DEVIATE FROM ANY STEPS SHOWN IN THESE INSTRUCTIONS UNLESS APPROPRIATE. (I.E.“OTHER MOUNTING•

OPTIONS” SECTION).

INSTALL THIS EQUIPMENT IF YOU ARE UNSURE ABOUT ANY STEP IN THESE INSTRUCTIONS.•

THESE INSTRUCTIONS SHOULD BE READ THOROUGHLY BEFORE ATTEMPTING TO INSTALL THIS

EQUIPMENT. FAILURE TO DO SO COULD CAUSE THESE MOUNTING BRACKETS TO BE INSTALLED

INCORRECTLY LEADING TO AN ACCIDENT RESULTING IN SERIOUS INJURY AND/OR DEATH.

IF ANY OF THESE COMPONENTS ARE NOT INCLUDED WITH THE BRKTAEVITFLR, CALL THE EMC

SERVICE DEPARTMENT. DO NOT ATTEMPT TO INSTALL WITHOUT ALL PARTS.

21

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

22

PRIMARY INPUT

2.2 MOUNTING BASE INSTALLATION FLOOR BRKTAEVITFLR

CONTINUED

BEFORE DRILLING IN THE OEM VEHICLE, CHECK ALL AREAS ABOVE AND BELOW

TO AVOID DRILLING THROUGH WIRE HARNESSES OR OTHER EQUIPMENT.

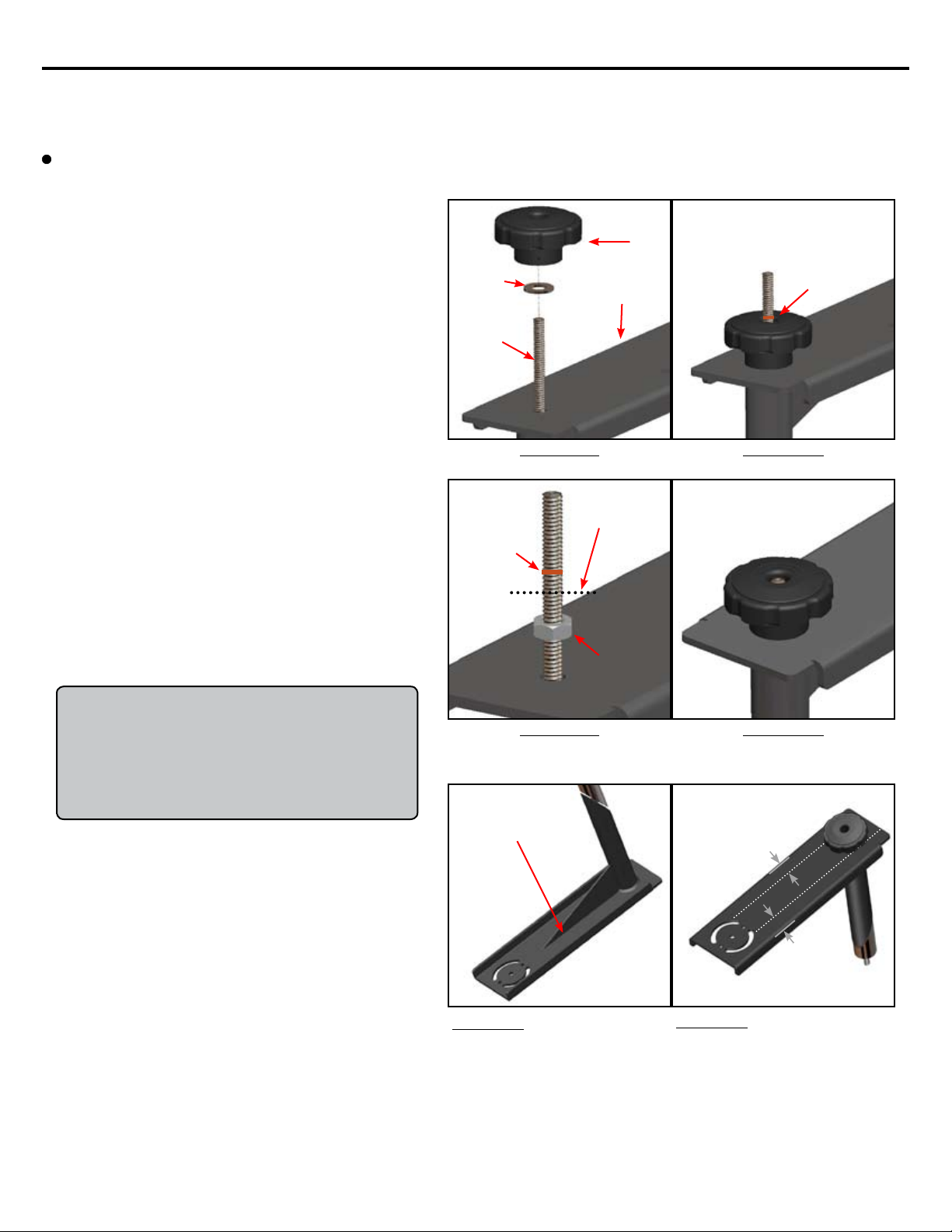

Determine the location for the Floor Base Plate. This will change depending on the needs of the client. EMC recom-

mends that it be mounted between the two front seats with the webbing facing towards the passenger seat and the

AEVIT 2.0 Chassis be mounted partially on top of it as shown in the gures below (See your vehicle specic AEVIT 2.0

Installation Manual for information on mounting the AEVIT 2.0 Chassis). The Floor Base Plate and the AEVIT 2.0 Chassis

should also be mounted as far forward in the vehicle as possible. This will reduce the overall footprint of the system

and allow the client to move their wheelchair in and out of the driver’s area more eectively. It is also very important

to make sure that the Floor Base Plate does not extend to the left into the drivers area as this will interfere with the cli-

ent’s wheelchair movements.

Once the location of the mounting bracket is selected, drill (4) 3/8”

holes through the oor.

Mount the Floor Base Plate to the oor of the vehicle using (4) 3/8”x 2”hex head bolts, (8) 3/8”at washers, and (4)

Lock nuts. Once the Base Plate is mounted, skip to section 2.4 for the adjustment and input device installation infor-

mation.

WHEN MOUNTING THE AEVIT 2.0 CHASSIS IN THIS CONFIGURATION, YOU WILL NEED TO

PROVIDE FOUR 4 SPACERS WHICH ARE AT LEAST 1/2”THICK TO RAISE THE CHASSIS OVER

THE FLOOR BASE PLATE AND ITS MOUNTING BOLTS. THESE SPACERS ARE SHOWN IN

FIGURE 4B.

SPACERS

Mount the

floor Base

plate with

the weBBing

towards the

passenger’s

seat

WEBBING

Mount the

aevit 2.0

chassis

over the

floor Base

plate

verify that

the floor

Base plate

does not

extend into

the driver’s

area

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

23

PRIMARY INPUT

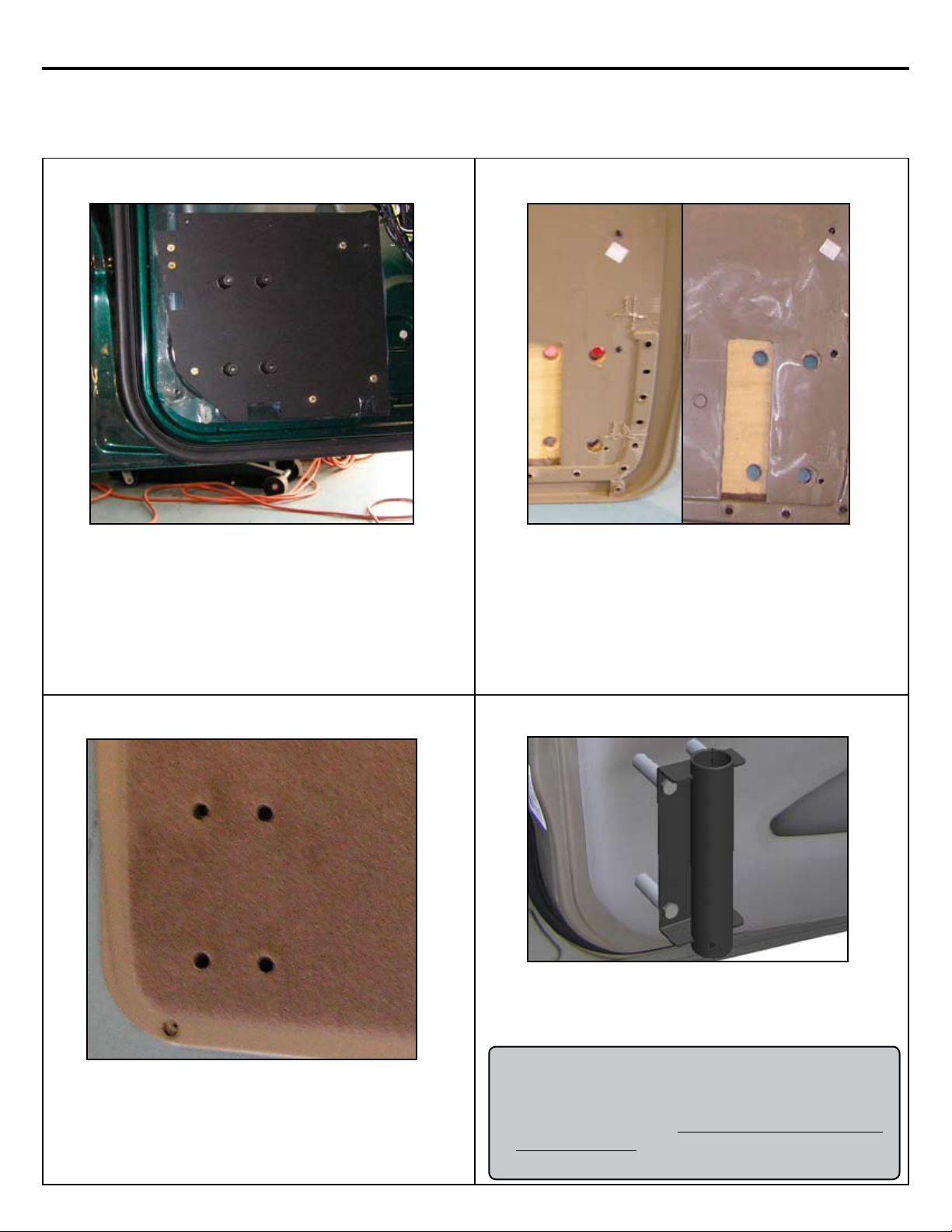

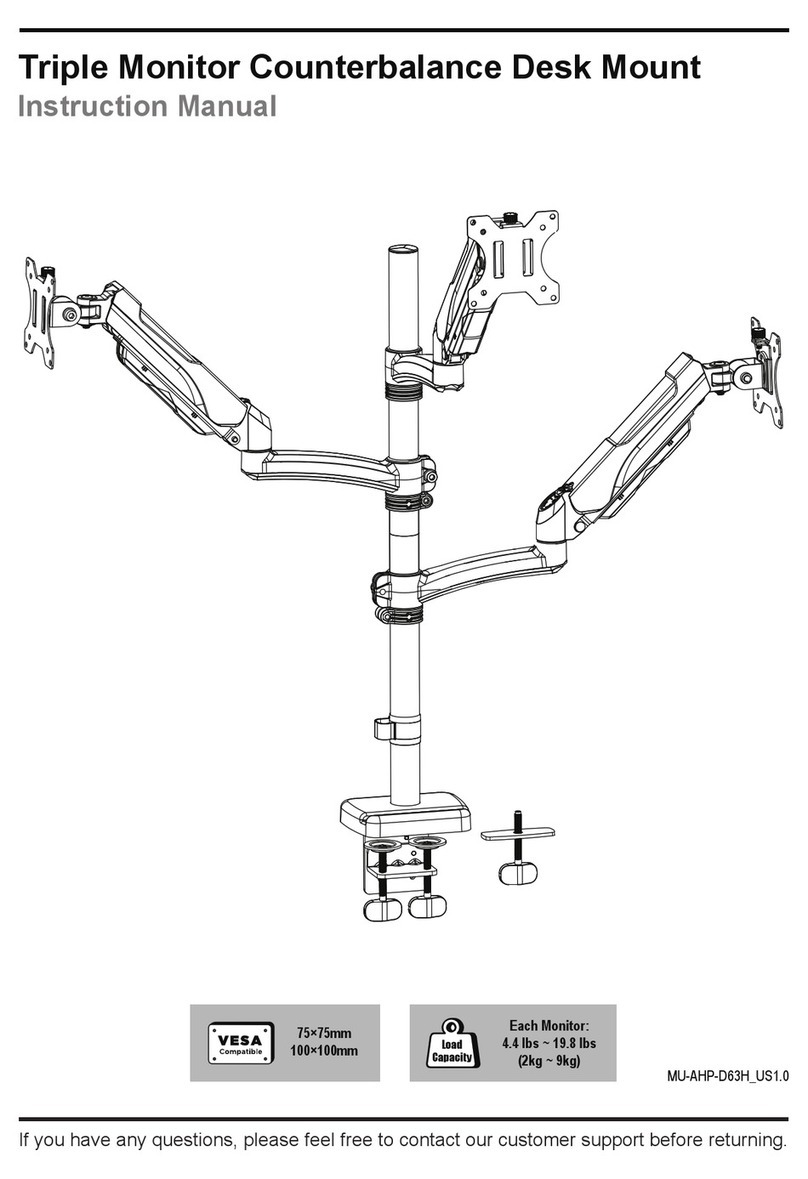

2.3 MOUNTING BASE INSTALLATION DOOR BRKTAEVITDOOR

Before installing the Door Mounting system, verify that the following components are included with the BRKT-AEVIT-

DOOR mounting kit:

(1) Door Base Plate (4) 5/16” x 3” Hex Head Bolts

(1) Input Device Articulating Arm Bracket (6) 1/4” x 1” Hex Head Bolts

(1) Upper Pole Mounting Plate (4) 5/16” Lock Washers

(1) Input Device Mounting Ball (6) 1/4” KEP Nuts

(1) Mounting Ball Hardware Kit (4) Base Plate Spacers

(5) Bolt Caps (1) Additional Spacer*

IF ANY OF THESE COMPONENTS ARE NOT

INCLUDED WITH THE BRKTAEVITDOOR, CALL

THE EMC SERVICE DEPARTMENT. DO NOT AT

TEMPT TO INSTALL WITHOUT ALL PARTS.

Once all components are veried as present, the Door Base Plate can be attached directly to the door as shown in Fig-

ure 5 below. This universal plate will be mounted to the OEM driver’s door with no less than (5) bolts and locknuts for

the vehicles shown. The four bosses protruding out from the door plate will go through the door panel to accept the

Quick Adjust Upper Pole. Figure 6 shows the Door Base Plate and references possible mounting holes for individual

vehicle manufacturers.

DOOR BASE

PLATE

BASE PLATE

SPACERS

UPPER POLE

MOUNTING PLATE

DOOR BASE

PLATE BOSSES

C - Chrysler F - Ford T - Toyota H - Honda

C F H

C F T H

C F H

C F H T s

C F sH

T

T

F T

Door Panel Mounting

Clip Area

(Holes marked with F s & T s will require the additional spacer* behind the plate.)

BOLTS

THE DOOR BASE PLATE IS DESIGNED TO AVOID OEM DOOR

PANEL MOUNTING CLIPS FOR ALL VEHICLES. THESE VOID AREAS

MUST BE CONSIDERED WHEN PLACING THE PLATE FOR HOLE

DRILLING.

This rendering shows how the door mounting sys-

tem will eventually go together. The Door Base Plate

is hidden behind the panel with the (4) protrusions

and/or spacers coming through the OEM door panel.

ALL MOUNTING HARDWARE AND FASTENERS MUST BE PROP

ERLY TIGHTENED TO PREVENT UNINTENDED MOVEMENT OF

THE INPUT DEVICES AND MOUNTING BRACKETS. FAILURE TO

OBSERVE THIS WARNING MAY RESULT IN AN ACCIDENT CAUS

ING SERIOUS INJURY AND/OR DEATH.

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

24

PRIMARY INPUT

2.3 MOUNTING BASE INSTALLATION DOOR BRKTAEVITDOOR

CONTINUED

Once the holes are drilled, cut away any

plastic areas that will interfere with the door

plate being mounted parallel with the door.

Be sure that the areas that were cut away

remain neat.

You may need to use other tools to remove

the carpet on the other side of the panel.

Remove the driver’s door panel and mark

the area where the Door Base Plate will be

mounted. See hole diagram on previous

page. Mount the door plate with no less than

(5) 1/4-20 x 1” bolts and locknuts. After the

plate is mounted, mark and drill (4) 5/8” holes

for the standos.

THE 4 5/16 X 3” HEX HEAD BOLTS ARE LONG ENOUGH

FOR USE WITH THE SPACERS AT FULL LENGTH. IF YOU CUT

THE SPACERS, HOWEVER, YOU WILL NEED TO PROVIDE

A SMALLER BOLT THAT WILL OFFER AT LEAST 1/2” OF

ENGAGEMENT INTO THE DOOR BASE PLATE BOSSES.

Your mounting system comes with (4) spacers that

can be cut to any length to bring the Upper Pole

Mounting Plate out from the door, depending on the

vehicle.

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

25

PRIMARY INPUT

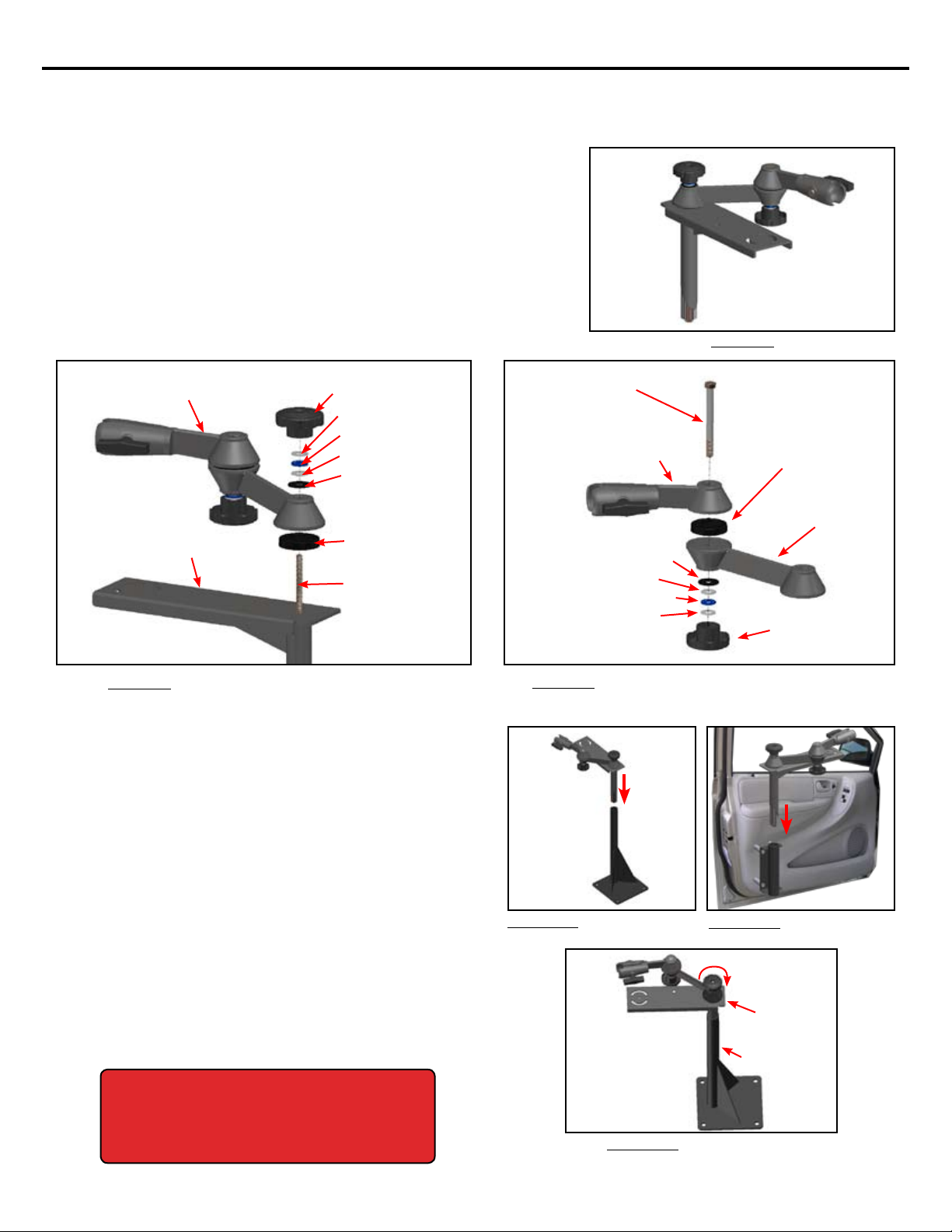

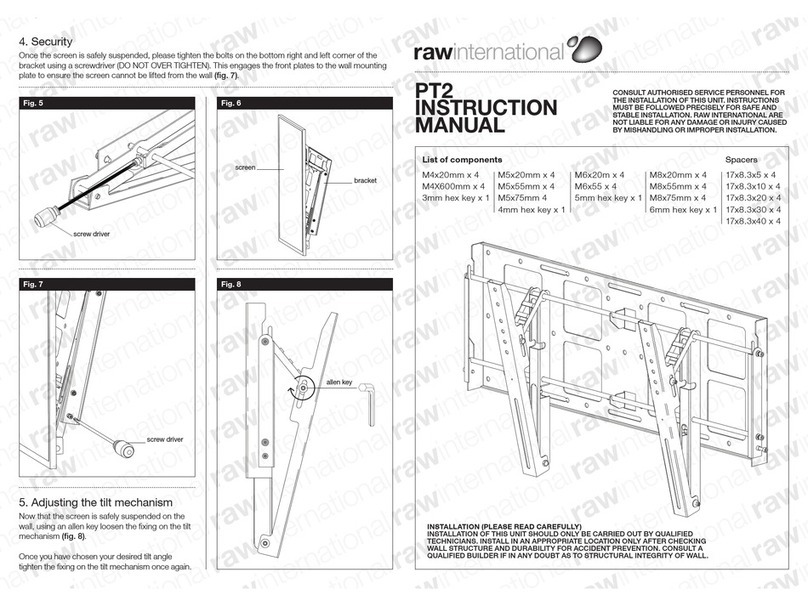

2.4 GENERIC ADJUSTMENT INSTALLATION BRKTAEVITFLR & BRKTAEVIT

DOOR

Now that the bases are installed, the adjustment section can now be

mounted. Both the Floor Mounting System and the Door Mounting

System will come with the same adjustment section. Therefore, this

section pertains to both installs. The adjustment section comes pre-

assembled from EMC; however, Figures 8 & 9 show exactly how they are

assembled in case you need to disassemble or replace a component. The

main components of the Adjustment Section are the Input Device Ar-

ticulating Swivel Bracket and the Quick Adjust Upper Pole (Figure 8). The

main components of the Input Device Articulating Swivel Bracket are the

Input Device Swivel Bracket and the Extension Arm (Figure 9).

BOLT

SwIvEL BRACkET

wASHER

ExTENSION

ARM

kNOB 2

THREADED ROD

INg SwIvEL BRACkET

BRACkET ASSEMBLY

Once the Adjustment Section Assembly is inserted into

the base, it can be adjusted vertically 4”. Once it is at the

correct height, tighten Adjustment Knob 1 thoroughly

(Figure 12). Verify that the Quick Adjust Upper Pole will

not move under normal operating conditions.

Insert the Adjustment Section into either the Floor Base

Plate or the Door Base that was installed in sections 2.2

and 2.3. Adjustment Knob 1 may need to be loosened for

the Adjustment Section to t into the base. When Adjust-

ment Knob 1 is loosened, it pushes down on the threaded

rod located inside of the Quick Adjust Upper Pole. This,

in turn, loosens the wedge at the bottom of the Quick

Adjust Upper Pole.

tighten

adjustMent

knoB 1 to lock

Quick adjust

upper pole

in place

SECTION

FAILURE TO TIGHTEN ALL ADJUSTMENT KNOBS

COMPLETELY COULD CAUSE AN ACCIDENT RE

SULTING IN SERIOUS INJURY AND/OR DEATH.

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

26

PRIMARY INPUT

2.4 GENERIC ADJUSTMENT INSTALLATION BRKTAEVITFLR & BRKTAEVIT

DOOR CONTINUED

The Input Device Articulating Swivel Bracket, as

the name implies, swivels in 45O increments to

allow for multiple angles for the Input Devices

(Figure 13). To install the Input Device, simply

place the ball of the Input Device into the socket

of the Input Device Horizontal Swivel Bracket and

tighten, using the“T” handle as shown in Figure

14.

Once the Input Device is installed, it can be tted for

the client. Adjustment Knobs 1 & 2 are used to con-

gure the Input Device Articulating Swivel Bracket

such that the client can operate the input device both

comfortably and eectively. The “T” handle can also

be used to adjust the angle of the input device to the

client’s needs. Once the input device and Input Device

Articulating Swivel Bracket is in the correct position,

tighten all adjustments such that neither the input

devices nor the mounting systems move under normal

operating conditions.

kNOB 2

FAILURE TO TIGHTEN ALL ADJUSTMENT KNOBS COMPLETELY COULD CAUSE AN

ACCIDENT RESULTING IN SERIOUS INJURY AND / OR DEATH.

O

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

27

PRIMARY INPUT

2.5 OTHER MOUNTING OPTIONS BRKTAEVITFLR & BRKTAEVIT DOOR

REVERSING ADJUSTMENT KNOB 2

The Adjustment Section of the mounting systems

comes pre-assembled with Adjustment Knob

2 on the bottom of the Input Device Articulat-

ing Swivel Bracket as shown in Figure 16. In this

position, the knob will not interfere with the

input device. However, if the client wishes to have

Adjustment Knob 2 on top of the bracket (Figure

17), the following steps should be followed for

reversing it.

Unscrew Adjustment Knob 2 from the 4” hex head bolt

shown in Figure 18. Remember to keep track of the hard-

ware and the order of the at washers when disassembling

the Input Device Articulating Swivel Bracket.

FAILURE TO TIGHTEN ALL ADJUSTMENT KNOBS COMPLETELY COULD CAUSE AN

ACCIDENT RESULTING IN SERIOUS INJURY AND / OR DEATH.

Insert the 4” hex head bolt into the bottom of the Input

Device Articulating Swivel Bracket and attach the remain-

ing hardware to the bracket in the following order:

-3/8” fender washer

-3/8” at washer

-3/8” bearing

-3/8” at washer

-Adjustment Knob 2

See Figure 19 for the full assembly.

BOLT

SwIvEL BRACkET

wASHER

ExTENSION

ARM

kNOB 2

BOLT

SwIvEL BRACkET

wASHER

ExTENSION

ARM

kNOB 2

Once Adjustment Knob 2 is reversed, repeat step 4 from

the Generic Adjustment Section to t the client. Once the

client is tted, tighten all adjustments such that neither

the input devices nor the mounting systems move under

normal operating conditions.

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

28

PRIMARY INPUT

2.5 OTHER MOUNTING OPTIONS BRKTAEVITFLR & BRKTAEVIT DOOR

CONTINUED

CUTTING THE QUICK ADJUST UPPER POLE

If only one input device is being mounted to the Quick

Adjust Upper Pole, the extra length of the bracket can

be removed. EMC recommends that the cut be made

3” from the“pole side” of the quick adjust upper pole as

shown in Figure 20.

Figure 21 shows an application where cutting the

Quick Adjust Upper Pole was necessary in order for the

mounting bracket to t the door panel.

FAILURE TO TIGHTEN ALL ADJUSTMENT KNOBS

COMPLETELY COULD CAUSE AN ACCIDENT RE

SULTING IN SERIOUS INJURY AND / OR DEATH.

DEBUR ALL EDGES AFTER CUTTING THE QUICK

ADJUST UPPER POLE.

ATTACHING ONLY THE INPUT DEVICE SWIVEL BRACKET

There are a few applications where the entire Input Device

Articulating Swivel Bracket is not needed and only the Input

Device Swivel Bracket is used (Figure 22). If this is the case,

the installer will have to provide the following hardware:

(1) 3/8” x 2 1/2” Grade 8 Hex Head Bolt

(2) 3/8” Flat Washers

(1) 3/8” Lock Nuts

Some of the hardware from the Input Device Articulating

Swivel Bracket will be used as well. EMC recommends that

the installer review page 2-5 to familiarize themselves with

the components that make up the Input Device Articulating

Swivel Bracket assembly.

SwIvEL BRACkET

ONLY

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

29

PRIMARY INPUT

2.5 OTHER MOUNTING OPTIONS BRKTAEVITFLR & BRKTAEVIT DOOR

CONTINUED

ATTACHING ONLY THE INPUT DEVICE SWIVEL BRACKET CONTINUED

Remove the Input Device Articulating Swivel

Bracket from the Quick Adjust Upper Pole. (See

Figure 8, Page 2-5 for information on this assem-

bly). Also, remove the Input Device Swivel Bracket,

(1) 2” Dia rubber washer, and Adjustment Knob

1 (Figure 9, Page 2-5). These components will be

used in step 5 of this section.

At this point, there will be a threaded rod protrud-

ing from the Quick Adjust Upper Pole. Insert the

3/8” Flat Washer and Adjustment Knob 1 onto the

Threaded rod (Figure 23a). This hardware will be

used to lock the Quick Adjust Upper Pole in place

much like step 2 Page 2-5. Tighten the adjustment

knob and make a mark on the threaded rod such

that it can be cut as to not protrude from the top

of the adjustment knob when the installation

is completed (Figure 23b). This can be done by

simply making a mark on the rod at the top of

Adjustment Knob 1 and then removing the knob

and washer and cutting the threaded rod approxi-

mately 1/4”beneath the mark. (Figure 24a).

Reinstall Adjustment Knob 1 and (1) 3/8” at

washer as shown in Figure 23a

wASHER

THREADED

ROD

Once the Quick Adjust Upper Pole is in position, a

3/8” thru hole will need to be drilled into it. Notice

in Figure 25, there is a support webbing under-

neath the Quick Adjust Upper Pole. The 3/8” thru

hole can be drilled anywhere along either of the

two (2) dotted lines shown in Figure 26. Basically,

the 3/8” hole will need to be drilled 7/8” from ei-

ther side of the Quick Adjust Upper Pole such that

the nylon and at washers of the Input Device

Swivel Bracket will not interfere with the support

webbing underneath.

7/8”

wEBBINg

ALONg EITHER DOTTED

LINE SHOwN

7/8”

a

PRIOR TO CUTTING THE THREADED ROD, THREAD

1 3/8” NUT NOT INCLUDED ONTO THE THREAD

ED ROD, THEN MAKE THE CUT. AFTER THE ROD IS

CUT, REMOVE THE 3/8” NUT FROM THE CUT END OF

THE ROD TO CLEAN/DEBUR THE THREADS.

b

Make cut Mark flush with the

top of the adjustMent knoB

ab

Figure 24b shows what this assembly should look

like after cutting the threaded rod.

Make cut

here

(see hint)

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

210

PRIMARY INPUT

2.5 OTHER MOUNTING OPTIONS BRKTAEVITFLR & BRKTAEVIT DOOR

CONTINUED

ATTACHING ONLY THE INPUT DEVICE SWIVEL BRACKET CONTINUED

The Input Device Horizontal Swivel Bracket, as the

name implies, swivels in 45O increments to allow for

multiple angles of the Input Devices (Figure 28).

To install the Input Device, simply place the ball of

the Input Device into the socket of the Input Device

Horizontal Swivel Bracket and tighten using the“T”

handle as shown in Figure 29. The completed install

should resemble Figure 30.

Mount the Input Device Horizontal Swivel Bracket

to the Quick Adjust Upper Pole using (1) 3/8” x 2.5”

Grade 8 Bolt, (1) 2” Dia. Rubber Washer, (1) 3/8” Flat

Washer, and (1) 3/8” Lock Nut. The 3/8” bolt, 3/8” at

washer and 3/8” lock nut will need to be supplied by

the installer while the 2” Dia rubber washer and Input

Device Swivel Bracket are from the disassembled In-

put Device Articulating Swivel Bracket (Step 1, Page

2-9)

SwIvEL BRACkET

(FLAT SIDE DOwN

FLAT wASHER

Tighten the 3/8”Lock Nut such that there is NO

MOVEMENT DURING NORMAL OPERATION OF

THE INPUT DEVICE.

FAILURE TO TIGHTEN THE 3/8” LOCK NUT COM

PLETELY COULD CAUSE AN ACCIDENT RESULT

ING IN SERIOUS INJURY AND/OR DEATH.

O

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

3. SECONDARY INPUT Mounting Brackets

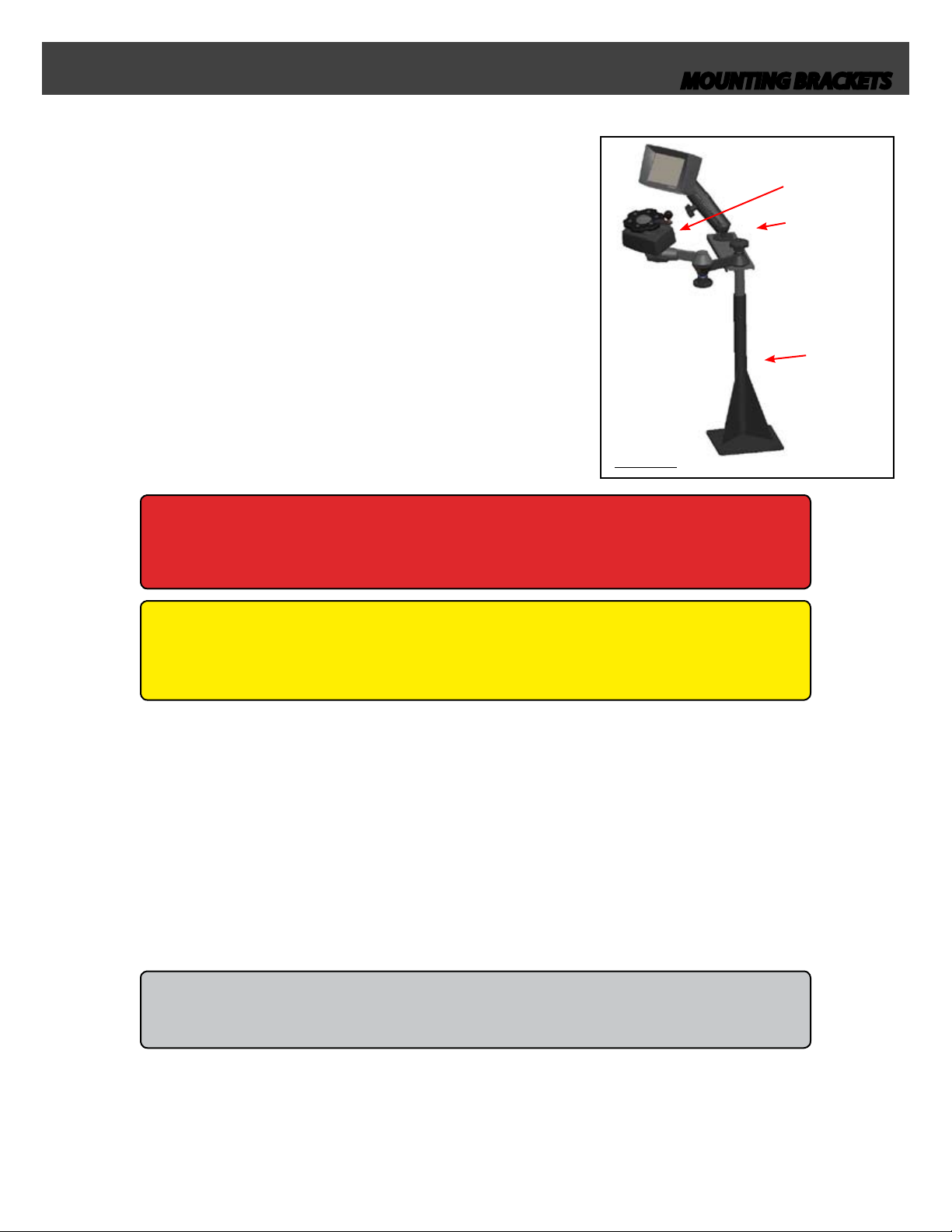

The secondary input section will describe how to install the mount-

ing brackets for the AEVIT 2.0 Display and switches to operate the

secondary functions of the vehicle. Generally, the AEVIT 2.0 Display

is mounted to the same Quick Adjust Upper Pole as the AEVIT 2.0

Wheel as shown in Figure 31; however, with the hardware provided,

it can be installed just about anywhere. Section 3.3 will discuss

mounting the switches that control the secondary functions of the

vehicle. These include: Digitone 2.0, VIC 2.0, plus others.

Before installing the Display Mounting system, verify that the following components are included with the BRKT-

AEVIT-DISP mounting kit:

(1) Display Vertical Support

(2) Input Device Mounting Balls

(1) Mounting Ball Hardware Kit

3.1 GENERAL INFORMATION

3.2 DISPLAY BRACKET INSTALLATION BRKTAEVITDISP

IF ANY OF THESE COMPONENTS ARE NOT IN

CLUDED WITH THE BRKTAEVITDISP, CALL THE

EMC SERVICE DEPARTMENT. DO NOT ATTEMPT

TO INSTALL WITHOUT ALL PARTS.

Attach (1) mounting ball to the AEVIT 2.0 Display (see

page 1 for instructions). Determine a location to attach the

second mounting ball to the Quick Adjust Upper Pole. This

bracket was designed such that the mounting ball can be

mounted anywhere along the Quick Adjust Upper Pole.

Mark and Drill (3) 3/16” thru holes into the Quick Adjust

Upper Pole and install the second mounting ball to the

bracket (hardware not included).

Mount the Display to the Display Vertical Support and the

Vertical Support to the Mounting Ball that was installed in

step two (Figure 32).

The standard length of the Display Vertical Support is 8” .

Other lengths are available on special order. Contact EMC

SALES at (207) 512-8009 for more information.

vERTICAL

BALL

HARDwARE FOR

INSTALLINg SECOND

ALL MOUNTING HARDWARE AND FASTENERS MUST BE PROPERLY TIGHTENED TO PRE

VENT UNINTENDED MOVEMENT OF THE INPUT DEVICES OR DISPLAY. FAILURE TO

OBSERVE THIS WARNING MAY RESULT IN AN ACCIDENT CAUSING SERIOUS INJURY AND/

OR DEATH.

31

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

32

SECONDARY INPUT

3.3 SECONDARY FUNCTION SWITCHES

The most commonly used switch to operate secondary functions

is the 1.5” Push-Button switch (Figure 33). This switch can be used

to operate the 2.0 Digitone, VIC 2.0 and other single secondary

functions. The same bracket system used to mount the AEVIT 2.0

Display can be used to mount this single switch.

Attach the 1.5”Push-Button switch to a Mounting

Ball using a small piece of double sided tape.

BALL

SwITCH

Attach this assembly and the second mounting

ball to the Vertical Support as shown in Figure 35.

The completed assembly should look like Figure

36.

Finally, this assembly can be mounted anywhere

convenient for the client to access. A common

place to locate this switch is on the “B” Pillar as

shown in Figure 37. In this position, a client could

easily use their elbow to activate the switch. How-

ever, any place where the Mounting Ball can be

securely attached can be used. EMC recommends

that a bracket be fabricated and mounted to a sup-

port pillar of the vehicle and the Mounting Ball be

attached to it (hardware not included). Figure 38

shows an example of this.

vERTICAL

SECOND

BALL

FABRICATED

BRACkET

(ATTACHED

DIRECTLY TO THE

HARDwARE FOR

INSTALLINg SECOND

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

4. SERVICE REQUIREMENTS

4

The AEVIT 2.0 Mounting Systems does not have any mandatory service requirements. However, the client should

periodically check to make sure that all adjustment knobs are tightened completely. Please contact EMC Service if you

have any questions regarding the AEVIT 2.0 Mounting Systems.

Mounting Brackets

EACH MOUNTING SYSTEM WAS DESIGNED TO BREAKAWAY UNDER LOADS THAT EXCEED THE NORMAL FORCES EX

ERTED ON THE INPUT DEVICE. SINCE NO AEVIT 2.0 INPUT DEVICE REQUIRES A FORCE OF MORE THAN 4 POUNDS, IF THE

BRACKETS ARE INSTALLED CORRECTLY AND TIGHTENED PROPERLY, THESE BRACKETS WILL REMAIN STATIONARY UNDER

NORMAL OPERATING CONDITIONS.

HOWEVER, IF AN EXCESSIVE FORCE IS APPLIED TO THESE BRACKETS I.E. ACCIDENTAL IMPACTS WITH WHEEL CHAIRS,

ETC..., THESE BRACKETS ARE DESIGNED TO BREAK AWAY. IF THERE ARE ANY FORCED MOVEMENTS OF THE MOUNTING

BRACKETS SUCH AS THIS, IT IS EXTREMELY IMPORTANT THAT ALL ADJUSTMENTS BE RETIGHTENED, IF POSSIBLE.

THE REASON FOR THIS IS WHEN THE BRACKETS “BREAK AWAY” AND ARE FORCED BACK INTO THEIR ORIGINAL POSITION,

MOST ADJUSTMENT KNOBS BECOME LOOSENED IF BLUE LOCTITE® IS NOT APPLIED AND THEREFORE WOULD NEED TO

BE RETIGHTENED.

FAILURE TO OBSERVE THIS WARNING MAY RESULT IN THE CLIENT OPERATING THE VEHICLE WITH LOOSE MOUNTING

BRACKETS WHICH COULD CAUSE AN ACCIDENT RESULTING IN SERIOUS INJURY AND/OR DEATH.

5. BEFORE OPERATING... Mounting Brackets

It is extremely important for your client to be fully informed about the capabilities (and limits) of these mounting

bracket systems. These mounting bracket systems were designed to provide nearly unlimited options for mounting

of the input devices. By adjusting both Adjustment Knobs, it is possible for the client to have their input device in any

position where they can operate it both eectively and comfortably. Refer to section 2.4 if you client wishes to have

the mounting system adjusted and refer to section 2.5 for other mounting options that your client may wish to utilize.

Once the client is tted for the input devices and they are satised with the input device’s position, time should be

taken to go over the following NOTES, CAUTIONS and WARNINGS with them.

EMC RECOMMENDS THAT ONCE THE CLIENT IS SATISFIED WITH THE LOCATION AND POSITION OF THE INPUT DEVICES,

ALL ADJUSTMENT KNOBS SHOULD BE REMOVED AND BLUE LOCTITE® SHOULD BE APPLIED TO THE THREADS. AFTER THE

LOCTITE® IS APPLIED, THE KNOBS SHOULD BE REINSTALLED AND TIGHTENED COMPLETELY. THIS WILL PREVENT THEM

FROM LOOSENING UNDER NORMAL OPERATION AND ACCIDENTAL IMPACTS SEE WARNING #3.

IT IS EXTREMELY IMPORTANT FOR THE CLIENT KNOW THAT IT IS THEIR RESPONSIBILITY TO VERIFY THAT ALL INPUT DEVIC

ES AND MOUNTING BRACKETS ARE SECURE BEFORE OPERATING THE VEHICLE. THEY SHOULD BE INFORMED ABOUT ALL

POSSIBLE ADJUSTMENTS SO THEY CAN CHECK FOR LOOSE BRACKETS EACH TIME THEY ENTER THE VEHICLE.

FAILURE TO OBSERVE THIS WARNING MAY RESULT IN THE CLIENT OPERATING THE VEHICLE WITH LOOSE MOUNTING

BRACKETS WHICH COULD CAUSE AN ACCIDENT RESULTING IN SERIOUS INJURY AND/OR DEATH.

THE ADJUSTMENT SECTION OF THE MOUNTING SYSTEMS IS DESIGNED FOR USE WITH ONE OR MORE 2”RUBBER WASH

ERS SEE FIGURES 8 & 9 PG 24. THE PURPOSE OF THIS RUBBER WASHER IS TO FULLY SECURE TWO MOUNTING BRACK

ETS. IN ORDER TO SUFFICIENTLY SECURE THE MOUNTING BRACKETS TOGETHER AND COMPRESS THE RUBBER WASHER,

IT IS IMPORTANT THAT ALL ADJUSTMENT KNOBS BE TIGHTENED FULLY SUCH THAT THERE IS NO MOVEMENT UNDER

NORMAL OPERATING CONDITIONS.

DAMAGE MAY OCCUR TO THE ADJUSTMENT KNOBS IF THEY NEED TO BE REMOVED AFTER THE BLUE LOCTITE® IS APPLIED.

MAKE SURE THE CLIENT IS SATISFIED WITH THE INPUT DEVICE POSITION BEFORE APPLYING THE BLUE LOCTITE®.

AEVIT 2.0 MOUNTING BRACKETS INSTALL MANUAL

NOTES:

Table of contents

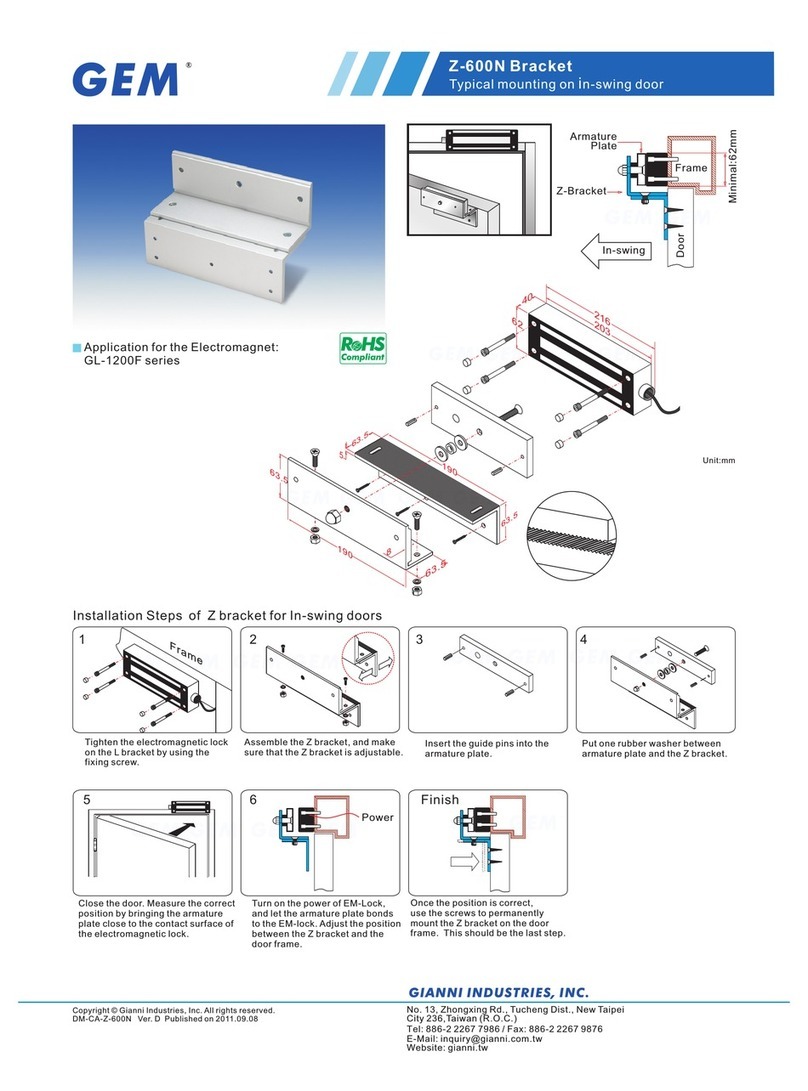

Popular TV Mount manuals by other brands

Sanus Systems

Sanus Systems New VisionMount VLMF109-B1 Brochure & specs

Mountup

Mountup MU6013A instruction manual

Rawinternational

Rawinternational PT2 instruction manual

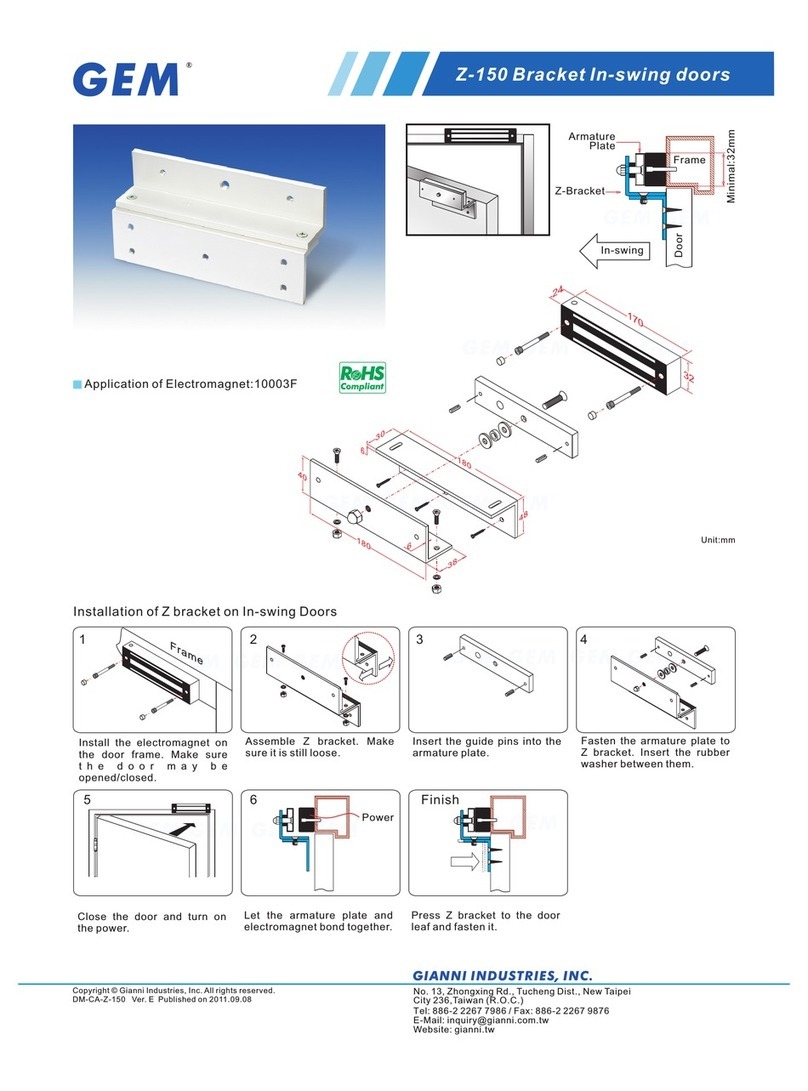

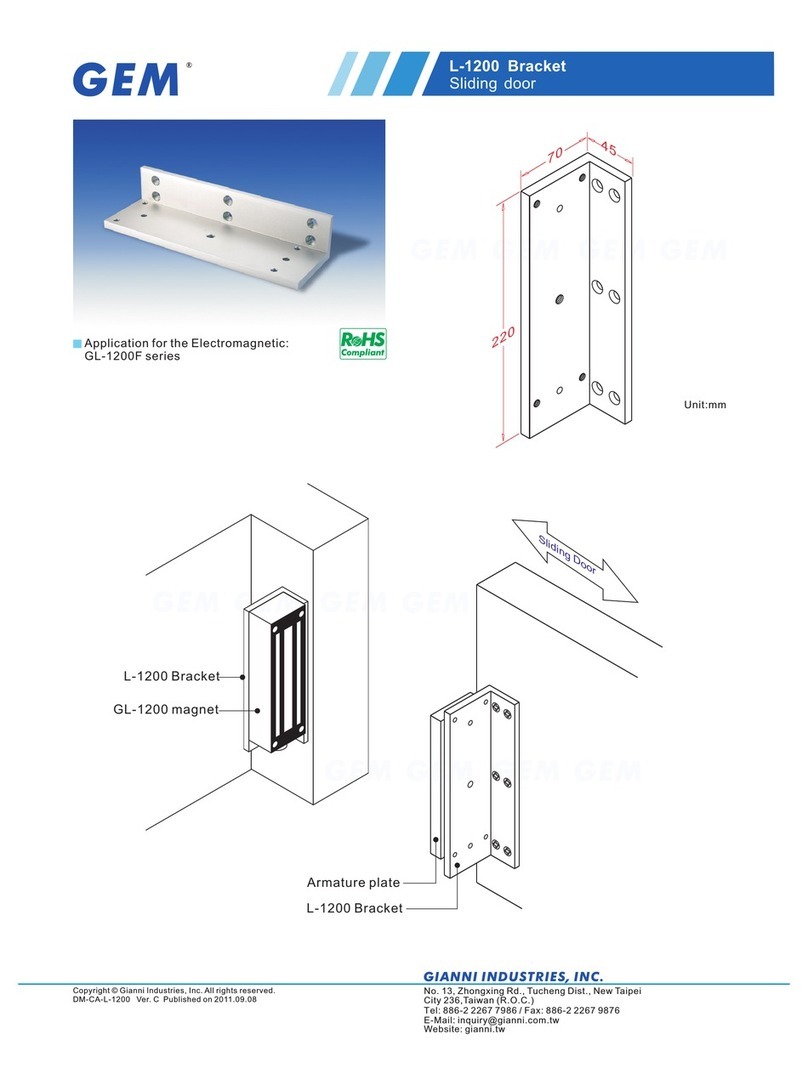

Gianni Industries

Gianni Industries Z-600N installation instructions

Dynex

Dynex DX-TVM111 Quick setup guide

Garden Treasures

Garden Treasures 1050004276 quick start guide