iv

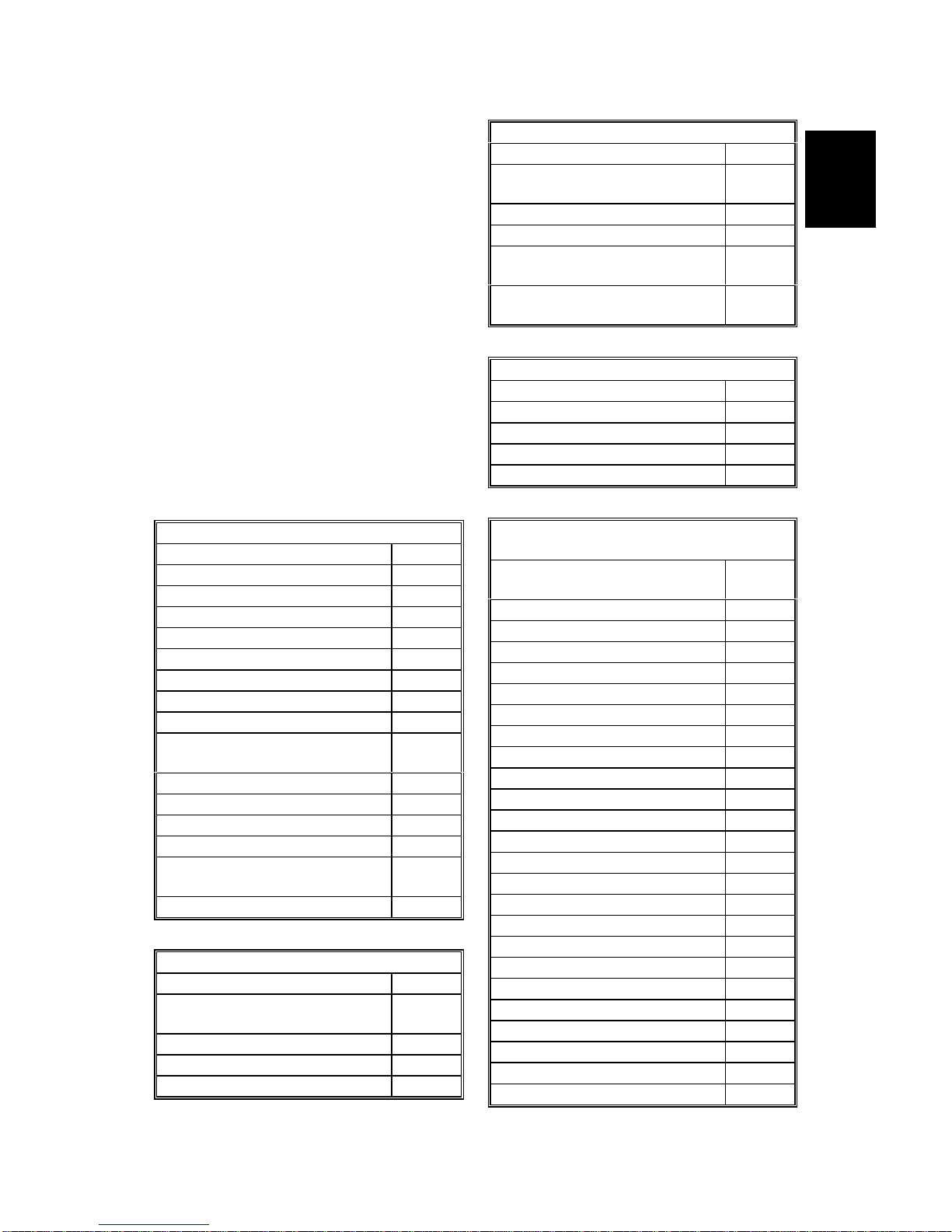

6.6 SENSORS.............................................................................................. 6-21

6.6.1 REPLACING THE ADF/MDF SENSORS AND SWITCHES .......... 6-21

6.6.2 REPLACING THE PAPER-END LED BOARD

AND PAPER SIZE SENSOR SWITCH........................................... 6-23

6.6.3 REPLACING THE AIO CARTRIDGE SENSOR............................. 6-24

6.6.4 REPLACING THE PAPER EXIT SENSOR.................................... 6-25

6.6.5 REPLACING THE PAPER NEAR-END SENSOR......................... 6-26

6.6.6 REPLACING THE PAPER END SENSOR .................................... 6-27

6.6.7 REPLACING THE TONER END SENSOR.................................... 6-28

6.6.8 REPLACING THE REGISTRATION SENSOR.............................. 6-29

6.7 FUSING UNIT......................................................................................... 6-30

6.7.1 REPLACING THE FUSING UNIT (PART OF THE FUSING

MAINTENANCE KIT)..................................................................... 6-30

6.7.2 DISASSEMBLING THE FUSING UNIT.......................................... 6-31

6.7.3 REPLACING THE PRESSURE ROLLER...................................... 6-32

6.7.4 REPLACING THE HOT ROLLER, FUSING LAMP, AND

THERMOFUSE............................................................................... 6-33

6.7.5 REPLACING THE THERMISTOR ................................................. 6-34

6.7.6 REPLACING THE HOT ROLLER STRIPPERS............................. 6-35

6.8 PCBS...................................................................................................... 6-36

6.8.1 REPLACING THE PSU.................................................................. 6-36

6.8.2 REPLACING THE NCU/FCU......................................................... 6-37

6.8.3 REPLACING THE OPERATION PANEL, LCD CONTROLLER,

AND INVERTER BOARD ............................................................... 6-38

6.9 DATA AND FIRMWARE DOWNLOAD/UPLOAD ................................... 6-39

6.9.1 FCU PROGRAM DOWNLOAD (IC CARD TO MACHINE) ............ 6-39

6.9.2 FCU PROGRAM UPLOAD (MACHINE TO IC CARD)................... 6-40

6.9.3 FCU SRAM RESTORE (IC CARD OR PREVIOUS FCU TO

MACHINE)...................................................................................... 6-41

6.9.4 FCU SRAM BACKUP (MACHINE TO IC CARD)........................... 6-42

6.9.5 OPTIONAL G3 UNIT CONTROL PROGRAM DOWNLOAD

(IC CARD TO MACHINE)............................................................... 6-42

6.9.6 OPTIONAL G3 UNIT MODEM PROGRAM DOWMLOAD

(IC CARD TO MACHINE)............................................................... 6-43

6.9.7 G4 UNIT PROGRAM DOWNLOAD (IC CARD TO MACHINE)...... 6-43

6.9.8 NICF PROGRAM DOWNLOAD (IC CARD TO MACHINE)............ 6-44

6.10 OPTIONAL PAPER FEED UNIT........................................................... 6-45

6.10.1 REMOVING THE PAPER FEED TRAY....................................... 6-45

6.10.2 REMOVING THE VERTICAL FEED UNIT................................... 6-45

6.10.3 REMOVING THE REAR COVER................................................. 6-46

6.10.4 REPLACING THE PAPER-END LED BOARD AND PAPER

SIZE SENSOR SWITCH............................................................... 6-46

6.10.5 REPLACING THE PAPER FEED ROLLERS............................... 6-47

6.10.6 REPLACING THE PAPER FEED SENSOR................................ 6-48

6.10.7 REPLACING THE UPPER LIMIT AND PAPER END

SENSORS................................................................................... 6-49

6.10.8 REPLACING THE PAPER NEAR-END SENSOR....................... 6-50

6.10.9 REPLACING THE LEFT SIDE COVER SWITCH AND PAPER

FEED CLUTCH............................................................................ 6-51