AG GFC400 User manual

Gas Countertop Fryer

Operating Instructions

Before you begin, please read these instructions carefully to

use this product correctly, to make the product perform ideally, and

to avoid hazards.

Models: GFC400

-

1

-

Dear customers and users:

Thank you for purchasing our products. In order to be able to better use

this product, please read these instructions carefully before any operation,

and follow the guide, to avoid any unnecessary trouble during using.

Please keep this instruction manual in a safe place for convenient

reference and operation.

This instruction manual is subject to any change without further notice,

and the manufacturer reserves the right of final interpretation.

The appliance is designed for commercial purposes, not for household

use.

This appliance is only for professional use and that it shall be used

by qualified people

DANGER

If you smell gas:

Shut off gas to the appliance.

Extinguish any open flame.

If odor continues, keep away from the appliance and immediately call

your gas supplier or your fire department.

-

2

-

Gas Countertop Fryer

The Installation, Operation and Maintenance Guide

Contents

1. Safety Protection ....................................... - 3 -

2. Brief Introduction ...................................... - 3 -

3. Manufacturer's Authority and Responsibility ............. - 3 -

4. Parameter Specifications ................................ - 4 -

5. Transport and Storage ................................... - 6 -

6. Installation and Debugging .............................. - 6 -

7. Safety Notices and Precautions .......................... - 7 -

8. Operating Instructions .................................. - 8 -

9. Cleaning and Maintenance ............................... - 11 -

10.Service (authorized technicians only) ................. - 12 -

11. Troubleshooting ....................................... - 13 -

-

3

-

1. Safety Protection

Please make sure that the operator is an authorized and licensed

technician before you allow him/her to install and operate the products.

Be sure to strictly follow this instruction guide during installation and

using. The manufacturer is not responsible for any danger or accidents caused

by improper operation or maintenance.

Do not store flammable or explosive objects around the product. Keep all

flammable and explosive objects at a safe distance away from the product

for normal use.

Place the product in a reasonable position. Regarding related matters

of gas, customer should execute the requirements of local gas supply sector;

If you smell a gas leak, turn off the gas valves immediately and call

the gas company;

The product should not be operated by those under 18 years of age, or

those with physical or mental disorders, or disabilities that lack the

necessary knowledge or experience unless with appropriate instructions and

sufficient safety.

2. Brief Introduction

The product is a series of gas countertop type fryer in our company

production, which is novel designed, reasonable structured, convenient

operated, durable used, and convenient maintained. It's equipped with a high

efficiency stainless steel burner and a pilot light, combining flame out

protection device and with ignition device, and convenient to ignite the main

fire burner. This is hotel, supermarket, western restaurant, noshery and food

industry's ideal fryer product equipment.

3. Manufacturer's Authority and Responsibility

Banning of all or partial transformation to the products without the

manufacturer's explicit authorization.

Manufacturers refused to undertake responsibility to third parties as

the following reasons:

Not follow this instruction guidance and warning in using and testing;

Not in accordance with the requirements of technical parameters using

this product;

Incorrectly or irrationally using the product by untrained personnel;

Not obey the local law using this product;

Be repaired or changed by unauthorized technicians;

Use the spare parts or accessories provided by non-manufacturers;

Accidents caused by force majeure;

Not strictly comply with related guide of instruction by any reason.

-

4

-

4. Parameter Specifications

4.1、Outline Dimensions(mm)

4.2:Size and package parameter information

<Table 1>

Model

Overall

dimensions

L x W x H

Packing size

L x W x H

AT65G4F-C

400*650*485

490*740*620

Gas Connection:

NOTE: ALL GAS FITTING MUST ONLY BE CARRIED OUT BY AN AUTHORISED PERSON.

1. The product do not require an electrical connection, as they function totally on the gas supply

only.

2. It is essential that the gas supply is correct for the appliance to be installed and that adequate

supply pressure and volume are available. The following checks should therefore be made

before installation:

-

5

-

a. Gas Type required for the appliance is shown in the rating label. Check that this is

correct for the gas supply the appliance is being installed for. The gas conversion

procedure is detailed in this manual.

b. Supply Pressure required for this appliance is shown in the ‘Gas supply requirements’

section of this manual. Check the gas supply to ensure adequate supply pressure

exists.

c. Input Rate of this appliance is stated on the Rating label .The input rate should be

checked against the available gas supply line capacity. Particular note should be taken

if the appliance is being added to an existing installation.

NOTE: It is important that adequately sized piping runs directly to the connection joint on the

appliance with as few tees and elbows as possible to give maximum supply volume.

NOTE: Ensure the regulator is converted to the correct gas type that the appliance will operate on.

The regulator outlet pressure is fixed ex-factory for the gas type .

3. Correctly locate the appliance into its final operating position and using a spirit level, adjust

the legs so that the unit is level and at the correct height.

4. Connect the gas supply to the appliance through the regulator. A suitable jointing compound

which resists the breakdown action of propane must be used on every gas line connection,

unless compression fittings are used.

5. Check all gas connections for leakages.

6. Check that the gas operating pressure.

7. Turn off the mains gas supply and bleed the gas out of the appliance gas lines.

8. Turn on the gas supply and the appliance.

Verify the operating pressure remains correct

4.3、Information of Gas Supply and Burner

The minimum supplied gas pressure regulator is factory set at 1.13kPa for

Natural Gas and 2.75kPa for L.P. Gas. The external thread of product’s

intake-tube is 1/2 inches.

<Table 2>

Model

#of burners

and control

method

Gas

Species

Intake-

tube

pressure

(kPa)

Per Rate

MJ/h

Total Rate

MJ/h Nozzle (mm)

AT65G4F-C

1 pieces

I

ndependent

control

Natural

Gas 1.0 18 18 Φ1.90(190)

Propane

2.5

18 18 Φ1.22(122)

ULPG 2.5

-

6

-

5. Transport and Storage

In the process of transportation, handle carefully and keep upright to

prevent damage of the product packing. Wrapped equipment should not be in

open air for a long time, and shall be placed in a well-ventilated and

non-corrosive gases warehouse. When equipment needs temporary storage,

rainproof measures should be taken.

6. Installation and Debugging

Any erroneous installation, adjustment, refit, overhaul or maintenance

may cause property damage or personal injury. The work shall be performed

by authorized and licensed technicians, otherwise the manufacturer has the

right not to provide warranty service;

Only be installed in accordance with AS/NZS 5601, the local gas,

electricity and other relevant codes.

A qualified installer should be called in to install the appliance. The

appliances are to be installed with sufficient ventilation to prevent the

occurrence of unacceptable concentrations of substances harmful to health

in the room in which they are installed.

The gas supply tubing or hose shall comply with the national requirements

in force and shall be periodically examined and replaced as necessary.

6.1、Unpacking and Installation

Please dispose of all packaging materials and residues after unpacking;

Check the equipment. If it is damaged, please keep wrappers and receipts

which must be signed by the carrier representative (Driver), and contact the

carriers to pursue a claim within 15 days after receiving;

Be sure to install supporting legs before using, and do not tear up any

label or logo before normal using;

Please read these instructions carefully before installation and

operation. Please contact your local agent if you have any questions;

The equipment shall be installed on a level, solid, non-skid and

incombustible surface, and placed in a well-lighted work area with waterproof,

and away from children and customers;

The installation position is a well-ventilated place in accordance with

the local regulations;

The equipment must be installed under the matched cooking fume exhauster

according to the local regulations;

Important: Installation and ventilation laws, and codes are very

different, you should state and comply with all codes of the local competent

departments when it comes to requirements for installation of equipment;

Screw 4 adjustable stainless steel legs in the tapping hole with four

corners of the charbroiled bottom, ensure sufficient space for ventilation;

Adjustable stainless steel legs to make the equipment level, and get the

-

7

-

same level with other series of the same stove; Please lift the equipment

rather than drag if you need to move it.

Supplied gas pressure regulator is factory set at 1.0kPa for Natural Gas

and 2.5kPa for L.P. Gas;

The equipment can only be placed on the noncombustible floor,and keep

a distance of at least 6 inches(152mm) to equipment’s both sides 、 back,

and keep a distance of at least 39.4 inches(1000mm) to the top;

Do not put anything around the equipment, and on the counter top and bottom,

in order to avoid influencing combustion and air circulation;

It may be necessary to adjust the balance of air input by authorized and

licensed technicians;

Thread glue must be resistant to the action of liquefied petroleum gases.

Warning! Use soap water or testing instrument to test whether piping

joint leaks or not before using, and forbid using an open flame to test!

6.2、Debugging

It’s very important to debug the new stove. Through the comprehensive

system test of equipment, we can ensure function and safety performance of

products. Discovering any potential problems before use (such as

equipment’s placement, ventilation, operation, etc), can avoid costly

losses.

It is necessary to check the machine daily.

Check the machine regularly can avoid serious accident happens.

Stop using if user feels that there are some problems in the circuit or

machine.

Check the situation of the machine before or after using every day.

Before using: Whether the machine is tilted?

Whether the control panel is damaged?

During using: Whether there is strange odor or vibration noise?

Whether the burner flame is normal? Any light back or flameout?

Whether the power is normal?

If any of this case occurs, stop using and turn off gas supply, contact

the supplier or service department.

7. Safety Notices and Precautions

Warning! For your safety, do not place petrol and other flammables nearby.

Please keep clean and free of flammables surroundings.

Warning! Any erroneous installation, adjustment and refit may cause

property damage or personal injury and maintenance failure. Read the

instructions carefully before installation and using.

-

8

-

Warning! Operation instruction must be placed in a conspicuous location.

When customers smell gas in the process of using, should take safety

precautions immediately. Immediately turn off the main gas valve, extinguish

all heat and flames. Safety information can be obtained from your local gas

suppliers.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN

OPERATION.

When using this equipment, safety precautions should always

be followed, including the following:

Do not touch high-temperature smokestack plate to prevent burns when in

using or just after using;

Do not cover exhaust port with anything when in using to affect the

combustion effect, even cause severe accidents;

Turn off the equipment as not in using or no operator here;

Turn off the equipment as repairing, maintaining and cleaning;

If the equipment has any problems of equipment damage, gas piping leaks,

igniter or valves damage, or lose product accessories, do not operate by

yourself and call for the service immediately;

The use of attachments not recommended or sold by the manufacturer may

cause fire, personal injury or even death;

Do not use out of doors;

The equipment is used for frying, not available for any other using;

The equipment does not contain any user-serviceable parts. Dealers or

technicians will repair it. Do not take apart any spare parts without

authorization;

Never change any other parts without authorization to this equipment,

otherwise, may cause hazards, and the manufacturer has the right not to

provide warranty service;

Steel cutting producers used to manufacture with sharp edges. The

manufacturer has dealt with these sharp edges during production, however,

we insist the operator take care when in contact with this piece of equipment;

Always keep hands, hair and clothing away from heating source;

Wait the unit cools down before cleaning. Because the unit is too hot

to handle after using.

The parts protected by the manufacturer or his agent shall not be adjusted

by the installer.

8. Operating Instructions

Before operating, make sure to place the unit horizontally by adjusting

bottom adjustable legs.

NOTE: Ensure the gas supply to the equipment is turned ON.

8.1、Igniting the pilot

-

9

-

1、Turn ignition control knob anticlockwise from “●” to near “ ”, as

shown in Fig.1.

2、Then press ignition control knob to the bottom and keep pressing it about

10-15 seconds, then turn it anticlockwise till it rings and reaches“ ”.

Release the knob and observe stability of fire, the pilot is ignited and the

equipment is under standby mode. If the pilot is not ignited, please repeat

the steps above until the pilot is ignited. (Fig.2).

(If it is the first time to light up the fryer, it may take longer time for

the gas to flow to the pilot).

NOTE: There is air in the pipeline when the first time light the fire, then

can normally light the pilot light until flow out air.

NOTE: If the pilot flame were accidentally extinguished, the flame failure

safety device would operate and cut the gas flow to the main burner. It would

then be necessary to relight the pilot by following the above procedure.

8.2 Igniting the main burner

1、After the pilot is lighted, Turn ignition control knob anticlockwise to

“ ”, as shown in Fig.3.Ignite the main burner by the pilot light, turn

temperature control knob to proper temperature according to user demand;

<Table 3>

Setting

1 2 3 4 5 6 7

oC 115 130 145 160 170 180 190

NOTE: When the oil temperature reaches the desirable temperature (normally

at this point of time, the main burner will be temporarily closed).

Ensure there are liquid edible oil or solid shortening in hydro-cylinder

before light the main fire;

Caution: Add oil to fry pot between the maximum and minimum level;

Ignition

control knob

Temperature

control knob

Fig.1

Fig.2

Fig.3

-

10

-

Do not ignite the main fire without any oil in hydro-cylinder to damage

equipment, even cause severe accidents;

8.3、Turn off the fryer

1、Turn ignition control knob clockwise from “ ” to “ ”, as shown

in Fig. 2. Then, the main burner is extinct, the pilot is igniting and the

equipment is under standby mode.

2、Then, press ignition control knob to the bottom and turn it clockwise from

“ ” to “●”. Release the knob and the pilot is extinct.

3、Turn off gas valve of pipe.

8.4、Cooking

●Before using the equipment for the first time, please use a mild detergent

to wipe it for cleaning. Do not use corrosive or abrasives detergent.

●Pour liquid edible oil or solid shortening into hydro-cylinder, Add oil

to fry pot between the maximum and minimum level;

●If there is shortening, change to the lowest temperature as shortening

melting to prevent burning and charring;

●Put the frying basket when the temperature reaches the preset temperature;

●When you smell peculiar in the process of frying because of too high

temperature or too many impurities in the oil,change or filter oil to solve

it;

Install the matched cooking fume exhauster according to the local

regulations of the char broiler;

Make sure to keep the air natural circulation in the kitchen.

Note: Each burner nozzle has been installed before delivery, normal use

without change.

8.5、Thermal circuit breaker

Temperature of temperature limiter is set as 230 oC. In case temperature

exceeds 230 oC under an emergency, temperature limiter will be started to

Protective cover of thermal circuit breaker

Button of thermal circuit breaker

-

11

-

prevent a fire caused by continuous rise of oil temperature.

If the thermal circuit breaker is activated, follow these steps:

●Wait for about 15 minutes for the oil to cool down.

●Press the button on the thermal cut out. If the thermal cut out cannot

be manually reset, Please wait a moment, it may be that the oil temperature

has not dropped to a certain temperature, or call your service agent.

●Repeat from Lighting the pilot light to light up the fryer again.

9. Cleaning and Maintenance

The equipment is made by high quality stainless steel raw materials, should

be maintained carefully. Please clean it frequently for better performance.

Cleaning frequency depends on the use intensity. Daily maintenance can improve

the life of the boiler. And the climate factors must also be taken into

consideration, regular cleaning can ensure the best efficiency of equipment.

●Instructions to clean appliance regularly with recommended cleaning

agents, if necessary.

●Clean the inner part of the hydro-cylinder, fryer basket, grid and drain oil

pipe:

1、Pour moderate water and detergent into hydro-cylinder(do not over the

highest height of the oil level line )

2、After mix fully, turn on the main fire burner heating, turn off the main

fire burner after heating about 5-10 minutes;

3、Soak the hydro-cylinder, fryer basket and drain oil pipe in the solution

for a period of time;

4、When water temperature cools down to suitable body temperature, wipe the

smudginess of the hydro-cylinder inner wall and combustion tube surface with

clean clothing, meanwhile on the fryer basket, grid and drain oil pipe as the

same, do not use wire brush or a hard object to wipe surface of the hydro-cylinder,

wipe along the direction of metal original polishing lines;

5、Finished wipe, turn on oil drain valve to emptying slops;

6、Once again pour clean water into the hydro-cylinder to wash.

●Clean the equipment surface:

First, wipe clean the dust, grease and residue on the surface of equipment

with clean and mixed detergent clothing, second, wipe it dry with a clean clothing,

do not use vinegar or corrosive liquid wiping.

Do not use any abrasive or flammable detergent to wipe;

Do not hose down, immerse or pressure wash any part of the cooker;

Do not use abrasive cleaning matters to wash, even not use corrosive

detergent!

●Inner smokestack cleaning/maintenance: after use 3-6 months or when necessary

must clean/maintenance smokestack by the manufacturer or its service agent or

a similarly qualified person in order to avoid a hazard.

Warning: Before cleaning, all control valves must be turned off.

-

12

-

Strictly follow the lighting instructions to work again after cleaning!

Warning: Wait for the equipment to cool down after the unit has been

turned off before you cleaning!

Cut off the gas source as not using;

If the equipment is not used for a long time, clean the surface by wiping

it with a soft cloth and place it in a well-ventilated area;

Comprehensively check the equipment at least once every year by

authorized and licensed technicians;

The product is made of 90% metals, and can not be discarded everywhere.

Deal with it in accordance with the local codes.

10.Service (authorized technicians only)

All equipments have been debugged before delivery. If have the following

problems, such as initial installation, gas or piping pressure issues, please

refer to the relevant information on the equipment label or instructions.

●Test point pressure

Use a pressure gauge which is equipped with liquid (such as U-type pressure

gauge, the minimum value is 0.1mbar) or a digital pressure gauge to test.

Steps are as following:

1、Open postnotum, remove needle type pressure joint screw arbor (Fig.4),

then slip rubber tube of pressu

re gauge over needle type pressure joint;

Fig.4

2、Start the equipment in accordance with the instructions, measuring gas

supply pressure (dynamic pressure) in the work state;

3、Access to the equipment if measured data within the limits of Table 2,

otherwise, you will need to adjust gas pressure regulating valve or contact

gas supplier;

4、Unplug pressure gauge after you accomplish pressure testing, then install

needle type pressure joint screw arbor. Important: must screw joint arbor

in order to avoid gas escaping!

Needle type pressure

joint

Needle type pressure

joint screw arbor

-

13

-

11. Troubleshooting

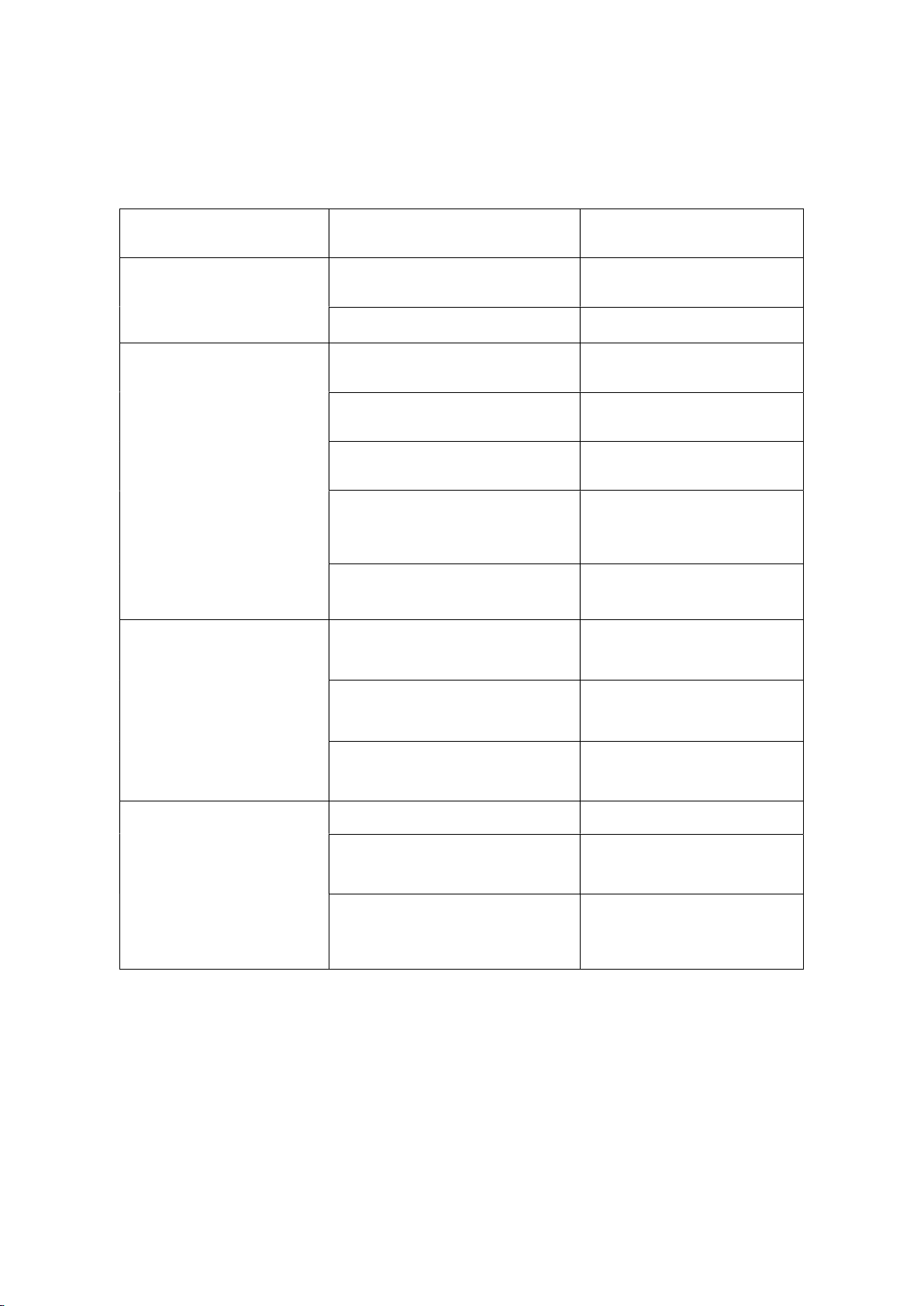

<Table 4>

Problems Possible causes Problem solving

Not lighting

1.Insufficient gas

pressure in pipe

1.Contact the local

gas supply dept.

2.Nozzle occlusion 2.Dredge nozzle

Ignite the pilot

light but not the

main fire

1.Insufficient gas

pressure in pipe

1.Contact the local

gas supply dept.

2.The main fire nozzle

occlusion 2.Dredge nozzle

3.Gas control valves

have problems

3.Change gas

control valves

4.The pilot light and the

main fire’

s distance is too

far

4.Adjust the

distance of them

5.Flame is too low 5.Adjust the height

of the pilot light

Close gas and

heard a sound of

fire

1.Insufficient gas

pressure in pipe

1.Contact the local

gas supply dept.

2.Not match nozzle

aperture

with gas resources

2.Adjust nozzle

diameter

3.Flow of connection

pipe is not enough

3.Increase pipe’

s

allowable flow

Yellow flame and

black smoke

1.Use bottom gas 1.Change gas

2.N

ot match nozzle aperture

with gas resources

2.Adjust nozzle

diameter

3.In the peak of using

gas, sources of gas

float heavy

3.Turn down valves

flow. Turn it up

after the peak

The problems mentioned above are only for reference. If any fault occurs,

please stop using, and contact technicians to check and repair. Safety first,

turn off the power and gas supply before maintenance.

-

14

-

Notice:

1、Pressure maintaining valve connects with air intake, must be installed by

authorized and licensed technicians, to ensure interface tightness.

2、When the regulator is connected, the maximum load value of natural gas can

not exceed 1.13kPa, the maximum value of liquefied gas can not exceed 2.75kPa.

3、Screw the hex nut (Fig.5) before connect air intake, ensure gas mark (Fig.6)

on the plastic core match with connected gas source, if not, then pull out the

plastic core and change another head, insert it again. The same as exchanging

gas source.

4、When exchange gas source, adjust the adjusting screw (figure.7) with a wrench

to meet the normal requirements of pilot light flame.

NOTICE: Each fire seat has been adjusted before delivery, normal use without

adjustment and exchange. Only replace it when converse gas source, and operate

by qualified professionals.

5、The nozzle in the accessories used in the replacement of the gas resource.

Fig.5 Fig.6 Fig.7

Our products have the advantages of good durability and low maintenance

charge. But to update some components and necessary maintenance, can prolong

life length of the products. Contact the dealer for assistance.

For service and spare part inquiry, please contact following

Atosa Catering Equipment Australia Pty Ltd

3-9 Forge Street,Blacktown,Sydney

TEL: 1800 886 888

Table of contents