Gastrofrit ELM Series User manual

ELM-Serie / BUILT IN

TW-Serie / BUILT IN

F-Serie / BUILT IN

Operating instructions BUILT IN

FRYERS / PASTACOOKERS

Built-in electronic or electro-mechanical controls

English

Version 8.7

Thank you for choosing a Gastrofrit® product. Your

product was entirely made in Switzerland. Your pro-

duct has been subjected to a long-term test. Please

note that the performance uctuations, safeguards

and frequency ranges 50 Hertz or 60 Hertz dier in

individual countries. Before commissioning, check

the exact requirements for carefree operation of the

device.

Installation, connection and commissioning of the

control may only be carried out by persons trained by

Gastrofrit.

2www.gastrofrit.ch © Switzerland Gastrofrit AG

contents

3 Modelle und Varianten

3 Power connection / technology

3 Electricity

3 Installation of the heating basin (normal case)

3 Installation of heating basin (additional parts)

3 Assembly instructions lift motor

6 Pastacooker error catalog

7 Fault catalog deep fryers

8 Installation description of the tting box with pan

8 Fittingbox

8 Installation situation / components

9 Installation of display box

10 Mounting the bracket on the built-in stove

13 Customer service, maintenance

14 Built in drawings:

3www.gastrofrit.ch © Switzerland Gastrofrit AG

Models and variants

ELM-300 built in Item No. 101135

ELM-400 built in Item No. 101145

ELM2-400built in Item No. 101146

ELM2-500 built in Item No. 101251

F-300 built in Item No. 100130

F-400 built in Item No. 101145

F2-400 built in Item No. 102240

F2-500 built in Item No. 100251

TW-350 built in Item No. 110135

TW-400 built in Item No. 110140

Power connection / technology

Please note that the power uctuations, safeguards

and frequency ranges 50 Hertz or 60 Hertz dier in

individual countries. Before commissioning, check

the exact requirements for carefree operation of the

device.

The electricity connection may only be provided by

trained qualied personnel can be connected. Accor-

ding to the requirements stipulated in the country.

• After switching on the main switch, the device

starts and lights up in the ON / OFF LED.

• The 3x400V (3L + N + PE) power connection is

made with a standard-compliant CE plug.

Electricity

Danger: Use silicone braids for the main connection of

the devices. To guarantee trouble-free operation:

• The specications regarding cable cross-section

and fuse protection must be strictly observed.

No other devices or power consumers may be

connected to the fuse protection of the sup-

ply line. The devices were tested for their EMC

compatibility. The test reports can be viewed at

Gastroifrit.

• You need to make sure that no cables or conduits

are pinched.

Design of the area around the collection container:

The base for the collecting container should consist

of low-wear, easy-to-clean material. It is important to

ensure that the container can be removed quickly for

easy cleaning. The container should also be guided to

the side and have a dened end position.

1. Protection against accidental contact must be pro-

vided during installation.

2. The devices must not be built into ammable

material.

3. If the device is installed next to a large heat

source, sucient ventilation of the control box

must be ensured. (maximum temperature of the

control box 70 ° C)

4. Wird das Gerät neben einer großen Hitzequelle

eingebaut, ist auf eine genügende Lüftung des

Steuerkastens zu achten. (maximale Temperatur

des Steuerkastens 70°C)

Installation of the heating basin (normal case)

Inlay and silicone seal

The heating basin is placed in the corresponding ope-

ning, the joint must be sealed with silicone. The holes

provided for frame assembly can be closed with blind

rivets or screws. The silicone joint must be checked re-

gularly for leaks in order to avoid the ingress of liquids

in the long term.

Installation of heating basin (additional parts)

With frame parts or upstand kitchen cover The

heating basin can also be attached to the table with

frame parts. The frame parts should be around 20mm

shorter than the outside dimensions of the pool. When

installing in a metal cover, this can also be folded up

analogously to the frame part. The frame parts are

not part of the Gastrofrit delivery. For the installation

of the frame parts, the opening must be 2mm larger.

The joint still has to be sealed with silicone. The frame

parts are bent from 1.5mm stainless sheet metal and

screwed to the table and basin.

Assembly instructions lift motor

Please make sure that you have connected the power

plug correctly if it was not installed by Gastrofrit AG.

The earth (color: yellow / green, symbol 0) and the

neutral wire (color blue, symbol N) are marked in the

connector housing, connect the phases so that the

brown wire is in the middle of the two black wires.

Electrical connection of the lifting motor

The connection cable contains the following 4

strands:

• yellow/green ground wire

• blue neutral conductor

• brown Phase lift motor up

• black Phase lift motor down

When you are standing in front of the device and have

tilted the cover towards you, you can connect the

strands as follows:

Please connect the earth to the metallic (gold-colored)

earth connection. The neutral conductor to the blue

clamp, the brown phase to the left gray clamp, the

4www.gastrofrit.ch © Switzerland Gastrofrit AG

Unternehmens-Dokumentation

Anschlussschema FittingBox (intern) Schütz

Dok-Nr.:ARAN-002 Dok-Typ: Arbeitsanweisung

Herausgeber Version Datum Datei: Anschlussschema_FittingBox_Schütz_Gastro8.DOC

COO/ Markus Rüsch 0 August 2010 Seite 1of 1

Power IN ST1

Power Out ST2

Power out/ Heizung

ST3

Schütz

A1 A2

+

-

S

Speisung

1

2

3

SSR

+/-

JP3

1

2

Schütz+

/-

JP3

1

2

Leiterplatte Gastro 8 Power

1

2

3

1

2

3

L1

L2

L3

1

2

3

black phase to the right gray clamp.clamp.

Mechanical attachment of the lifting motor

The underside of the plate on which the lifting mo-

tor rests must be cleaned of dirt, oil splashes, insu-

lation and other objects

1. Please extend the lifting rod (neutral conduc-

tor and brown phase).

2. Turn the bushing away from the square tube

with a 24 mm open-ended spanner.

3. Now you can push the lifting rod through

the hole in the pan from below. Make sure

that the oset in the square tube protru-

des against the pan. The washer with the

rounding must be placed on the underside of

the sheet.

4. If you now push the bushing over the lifting

rod, you can screw everything together.

ATTENTION: The bushing only needs to be tight-

ened slightly so that the lifting motor is xed in

position. Please do not forget to coat the thread

with Loctide 270 or an equivalent screw locking

agent.

5www.gastrofrit.ch © Switzerland Gastrofrit AG

Unternehmens-Dokumentation

Anschlussschema FittingBox (intern) SSR

Dok-Nr.:ARAN-001 Dok-Typ: Arbeitsanweisung

Herausgeber Version Datum Datei: Anschlussschema_FittingBox_SSR_Gastro8.DOC

COO/ Markus Rüsch 0 August 2010 Seite 1of 1

S1/ Thermoschalter

Power IN ST1

Power Out ST2

Power out/ Heizung

ST3

Solid State Relais

DC IN 3-30V

+

-

S

Speisung

1

2

3

SSR

+/-

JP3

1

2

A

C

a

c

Schütz

+/-

JP3

1

2

Leiterplatte Gastro 8 Power

1

3

2

2

3

1

Unternehmens-Dokumentation

Anschlussschema FittingBox (intern) SSR für Energieoptimierung

Dok-Nr.:ARAN-001-1

Dok-Typ: Arbeitsanweisung

Herausgeber

Version

Datum

Datei: Anschlussschema_FittingBox_SSR_Gastro8_Energieopt.doc

COO/ Markus Rüsch

0

August 2010

Seite 1 of 1

S1/ Thermoswitch

L1

L2

L3

N

GND

Power IN ST1

L1

L2

L3

N

GND

Power Out ST2

Energieoptimierung

Schütz/ Öffner (5V DC)

Power out/ heating

ST3

Solid State Relais

DC IN 3-30V

+

-

S

supply

1

2

3

SSR

+/-

JP3

1

2

A

C

a

c

switch

+/-

JP3

1

2

Leiterplatte Gastro 8 Power

1

2

3

1

2

3

6www.gastrofrit.ch © Switzerland Gastrofrit AG

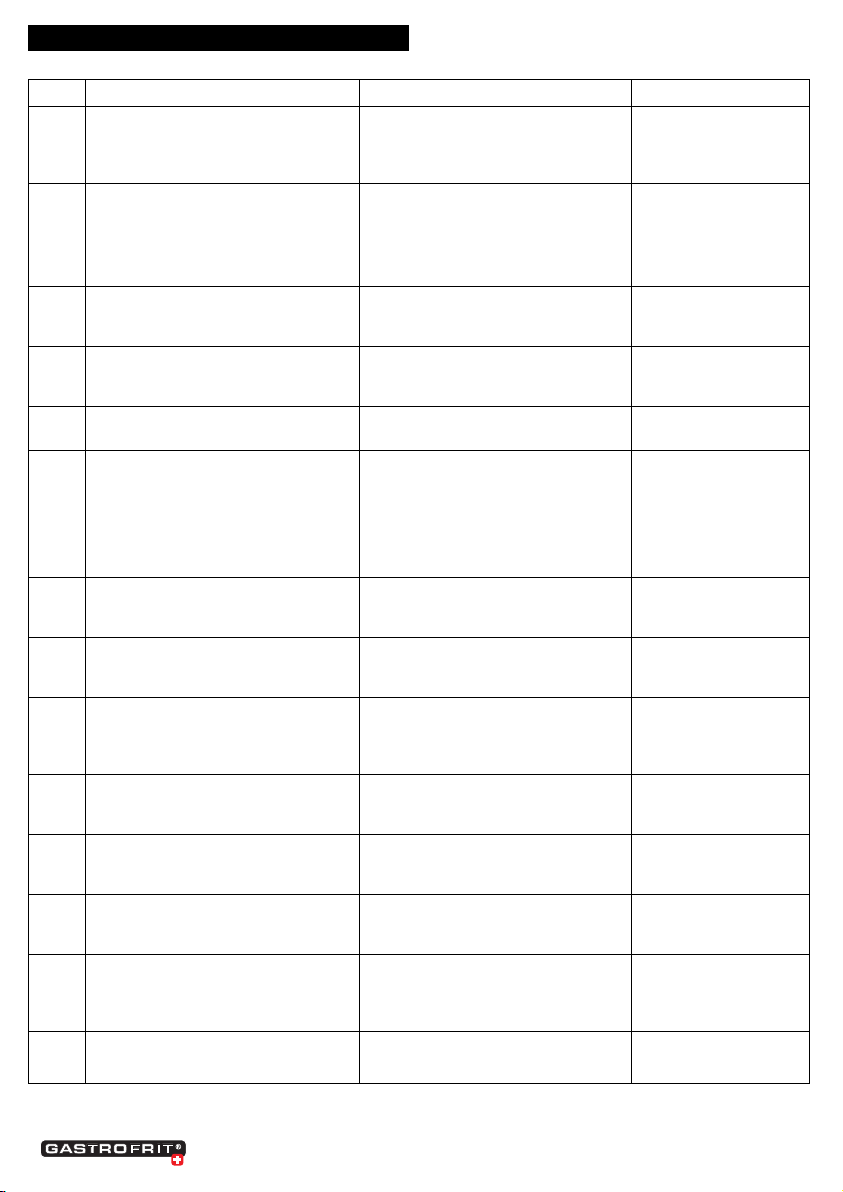

Pastacooker error catalog

Error description / display How to x Remarks

1 Error 1

Call up the PT 100 menu

Note the display

Check PT-1000 connection

If, ok, then measure the PT-1000

ohmic value

OK = about 108 ohms / 20 ° C

NOK = 0 ohms or innite

2 Machine heats up through unregulated Check contactor

Check software version

Perform a CPU reset

Reset limiter button

Contactor sticks, contactor has to

be checked and possibly replaced

3 conventional machine heats through

unregulated

Check thermostat

check contactor

Thermostat misadjusted and not

adjusted

4 The machine only heats when the red

heating pulse switch is pressed

Replace heating limit switch Can`t always be replaced

must be bridged

5 No indication on the display De-energize the device

Electronics defective

Change control

6 Residual current switch / fuse blows out The heater has a short circuit

Check wiring

burnt heater plug

Phase – Phase oder Phase-

0-wire short circuit

SSR/ Triac has short circuit

7 Conventional machine, power switch

green does not ligh up

Press the limiter button or

replace.

8 Lift motors only run halfway up/down Replace capacitor 33μF/ 270V

clean the lift motor

9 Lift motors are moving in the wrong

direction

Capacitors 33μF/ 270V

double mounted.

Check cable connection of hoist

motor (phases reversed)

Capacitor value cancels

corresponds to the value if no

capacitor is installed

10 No water supply Check solenoid valve Solenoid valve cold water up to

50ºC

Solenoid valve hot water up to

100ºC

11 Machine leaking Check PT-1000 seal

Check drain system

Check water supply

7www.gastrofrit.ch © Switzerland Gastrofrit AG

Fault catalog deep fryers

Error description / display How to x Remarks

1 Error 1 PT-1000

Call up the PT 1000 menu

Note the display

Check PT-1000 connection

If ok, then measure the PT-1000 ohmic

value

OK = about 108 Ohms/

20ºC

NOK = 0 Ohms or innite

2 Machine heats up through unregulated Check contactor

Check software version

Perform CPU reset

Reset limiter button

Contactor sticks,

contactor

must be controlled and

may need to be changed

3 Conventional machine heats through

unregulated

Check thermostat

Check contactor

Thermostat mostly

adjusted

4 The machine only heats when the red

heating pulse switch is pressed

Replace heating limit switch Cannot always be

replaced

it has to be bridged

5 No indication on the display De-energize the device

Elektronics defective

Change control

6 Residual current switch / fuse blows out The heater has a short circuit

Check wiring

Burnt heater plug

Phase – Phase oder Phase- 0-conductor

short circuit

SSR/ Triac has short circuit

7 Conventional machine, power switch

green does not light up

Press or replace the limiter button.

8 Lift motors only run halfway up / down Replace capacitor 33μF/ 270V.

Clean the lift motor

9 Lift motors are moving in the wrong

direction

Capacitors 33μF/ 270V double

assembled

Check lift motor cable connection (phase

twisted)

Capacitor value cancels

out, corresponds to the

value if no capacitor is

installed

10 Device control does not work. Device back to the factory

modication

membrane keybord

Revision

11 Pump works, but no oil delivery, hose or

pump blocked

Clean with wire

12 Pump does not work Measure voltage at socket

Pump at normal 230V socket

plug in and check

Pump voltage = 230V

13 Machine leaking Replace O-ring

Check PT-1000 seal

Check oil check seal

Check ball valve

8www.gastrofrit.ch © Switzerland Gastrofrit AG

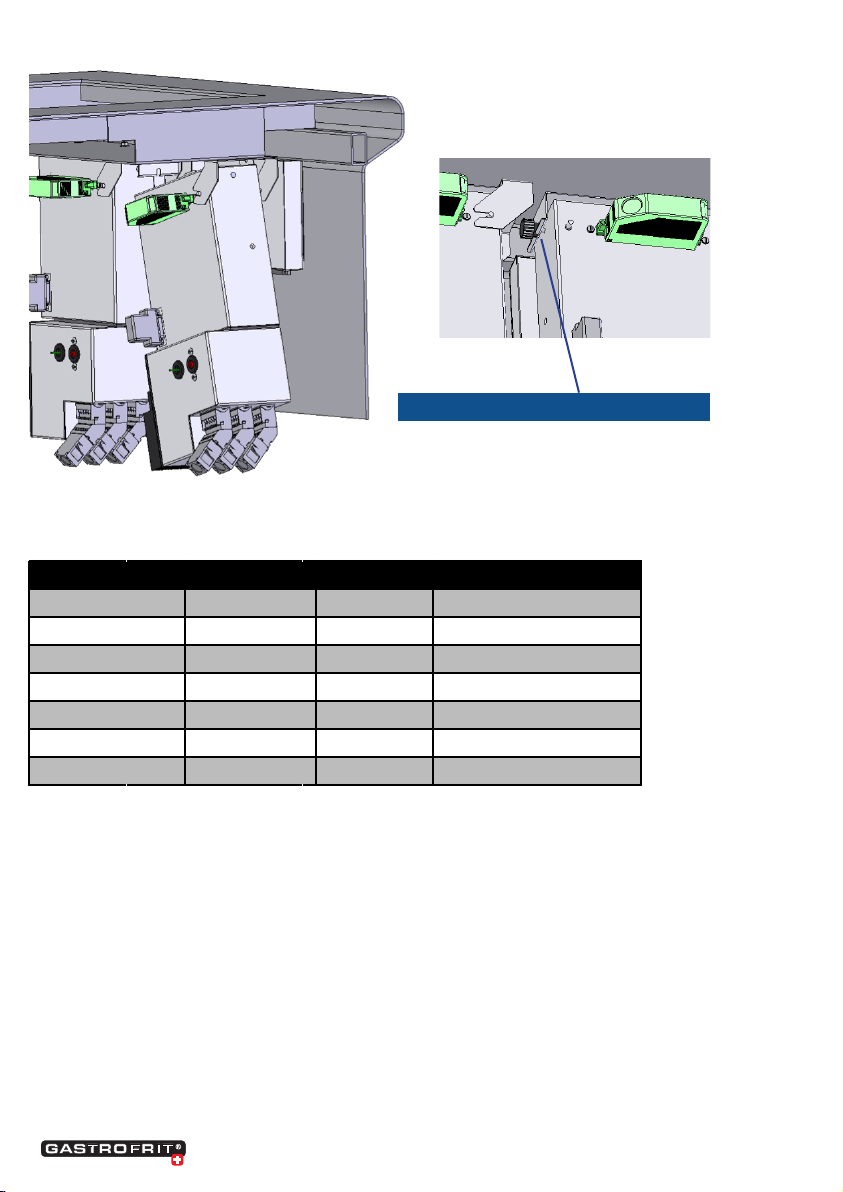

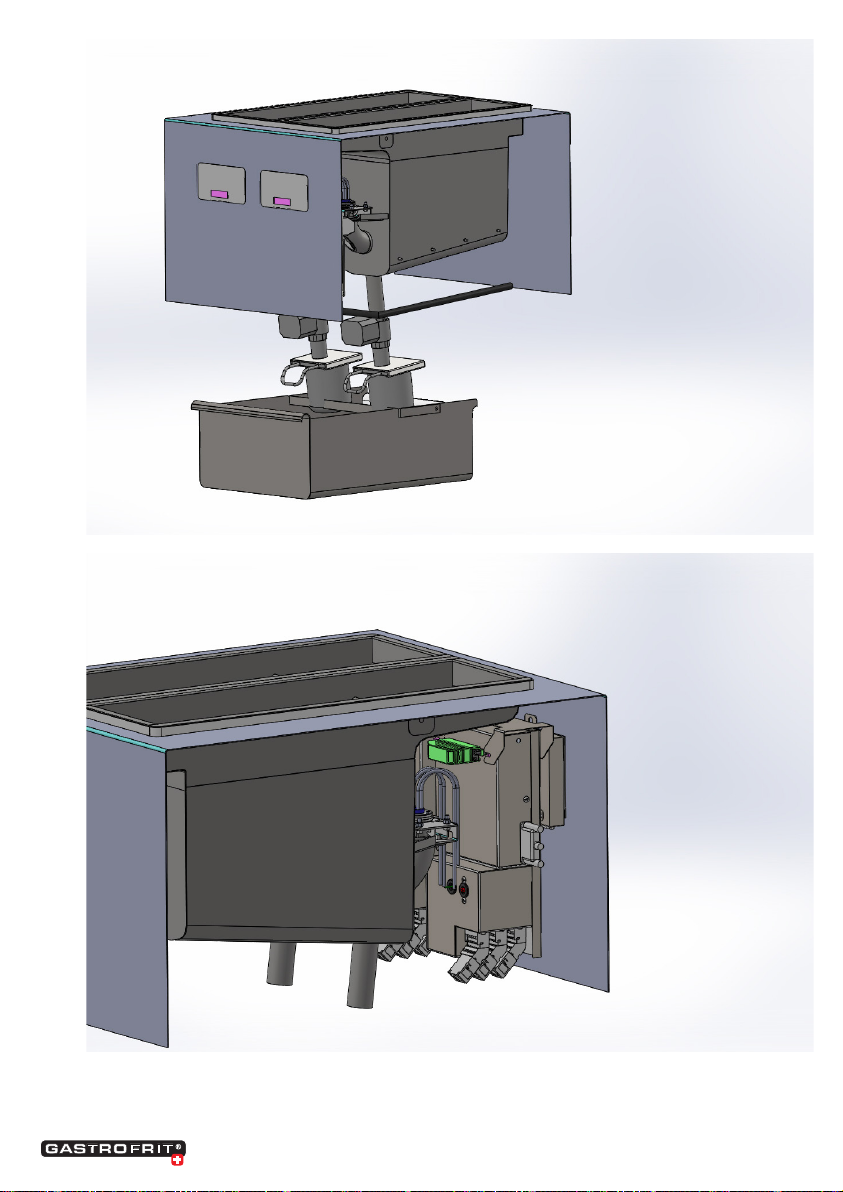

Installation description of the tting box with pan

Bracket

2 x Welding studs M4 x 8 mm

Knurled nut

Fittingbox

Installation situation / components

Pan as an example F2-400

Membrane keyboard

Built-in cover

9www.gastrofrit.ch © Switzerland Gastrofrit AG

Displaybox

Fittingbox

Installation of display box

1. 4 x Position Welko M4-8 mm symmetrically to the

cut.

2. Rectangle dimensions:

Hight 91 mm

Width 144 mm

3. Assembly seal

Apply seal

4. Assembly Display

Assembly of the display box

4x hexagon nut M4

5. close the lid

Tighten with a hexagon nut M3 with ange and

serrated lockwasher

6.

10 www.gastrofrit.ch © Switzerland Gastrofrit AG

Mounting the bracket on the built-in stove

Sheet metal for

2 x holes 0 = 8 mm

fastening the bracket

Dimensioning

• Lower edge: panel cover to cover,

64.5 mm

• Inner surface: x the cover to the

center of the bracket, 87 mm

11 www.gastrofrit.ch © Switzerland Gastrofrit AG

Position the hole = 0 8 mm symmetrically to the display box

Holes

Bracket

Hexagon nut M4

12 www.gastrofrit.ch © Switzerland Gastrofrit AG

Hang in the tting box

Tighten the knurled nut

Type Width in mm Depth in mm max. radius in mm

F-200 180 580 3

F-300 280 580 3

F-400 380 580 3

F2-400 780 580 3

TW-300 280 580 3

TW-350 580 3

TW-400 780 580 3

Installation dimensions pans / basins

The heating basins are placed in the corresponding

opening, the joint must be sealed with silicone. The

holes provided for frame assembly can be closed with

blind rivets or screws.

The silicone joint must be checked regularly for leaks

in order to avoid the ingress of liquids in the long

term.

13 www.gastrofrit.ch © Switzerland Gastrofrit AG

Customer service, maintenance

In the event of operational disruptions, contact

GASTROFRIT AG in Rorschach

The device may only be repaired and connected by

trained specialists.

Note (only for repair service with Gastrofrit training).

Before you fold the cover forwards, the door must be

opened! Attention! All mains circuits must be switched

o before access to the connection terminals.

Important:

With every report to the service point, please state the

type and number of the device (inside of the door).

It is recommended to enter the type and number be-

low. Regular maintenance can extend the life of your

Extend the device. With a service and maintenance

contract, you can instruct the manufacturer to check

your device every six months.

You can nd more detailed information on the service

contracts at

GASTROFRIT AG in Rorschach

Datum: _____________________

Typ: _____________________

SerieNr: _____________________

Spannung: _____________________

mit Ölcheck

mit Hubtechnik

mit Ölltrieranlage

to ll in yourself:

14 www.gastrofrit.ch © Switzerland Gastrofrit AG

91

150.5

144

R9.5

80.5

Gewindebolzen M4

auf der Rueckseite

Wasseranschluss

Schalterlochbild

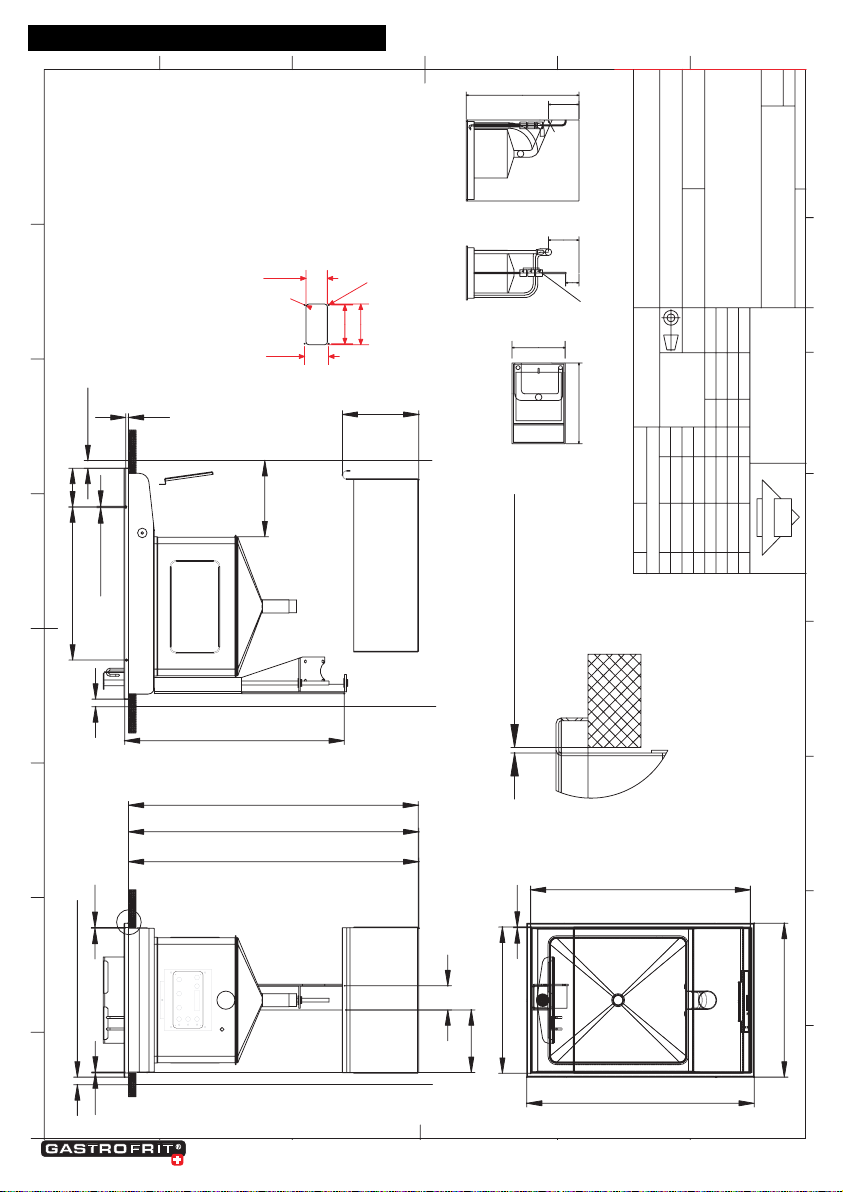

Grundriss SeitenansichtFrontansicht

850

230

300 / 400

230

100

3/8" Anschluss, Ventil, Filter

Geberit Ø50

600

DETAIL B

MAßSTAB 1 :1

2mm Spaltmass allseitig

600aussen

400/300 aussen

2

280/330/380 Öffnungsmass in Tischplatte

580 Öffnungsmass in Tischplatte

310 7

Ø4.3 Senk

398 100.5

580mm Für Hubvorrichtung freihalten

200

20 min. 20

B

63

163

680mm bei lose verdrahtet ohne Ablassstutzen

710mm beiAblassstutzen kurz

750mm beiAblassstutzen normal

2

2

20mm seitlicher Abstand

A-3000022

TW 300/350/400

GASTROFRIT

Gastrofrit AG

Friteusen und Teigwarenkoch-Automaten

Weiherstr. 11a

CH-9400 Rorschach

A3

8

76

5

8

7

6

5

D

D

C

B

A

F

E

C

B

A

4

3

2

4

3

2

1:10

DIN ISO 1302

Änderung

Bl.

Blatt

Oberflächen

Bearb.

Gepr.

Norm

Tolerierung ISO 8015

Allg.Toleranzen

DIN ISO 2786

Tol. Schweissen

DIN ISO 13920-AE

Kl.Nr. BG.

Datum Name

Urspr.

Ers. f. Ers. d.

Massstab:

Name

Datum

F

E

Zust.

Format:

Urheberrecht nach DIN 34

Fabrikat: Gastrofrit

Modell: TW-300/350/400

Inhalt: 15/20 lt.

Anschlusswert u. Spannung: 10/14 KW / 15/20 A / 3x400 V

Aussenmasse: ca.300/400x600 mm

Ausfuehrung:

- Apparat komplett in rostfrei

Pastacooker electronic

seitliche Wand

Rückwand

Front

Built in drawings:

15 www.gastrofrit.ch © Switzerland Gastrofrit AG

12

11

10

9

H

G

A

B

C

D

E

F

9

10

11

12

1

2

3

4

A

B

C

E

F

D

5

6

7

8

1

2

3

4

5

6

7

8

G

H

This representation is our intellectual property. You may without our written consent at all as

neither copied nor used for the manufacture of the work or nor to be announced to a thrid

party

Gastrofrit AG Weiherstrasse 11 CH-9400

Diese Darstellung ist unser geistiges Eigentum. Sie darf ohne unsere schriftliche Zustimmung

weder irgendwie kopiert noch zur Anfertigung des Werkes gebraucht oder Drittpersonen

bekanntgegeben werden.

Gastrofrit AG Weiherstrasse 11 CH-9400

Massstab:

Format:

Material:

Datum

Änd.

Änd.

Änd.Änd.

Änd.

e

f

a

b

g

c

Blatt:

Art.Nr.:

Gastrofrit AG

Weiherstrasse 11

CH-9400 Rorschach

Änd.

Datum

Name

erst. am

Name

Änd.

h

Änd.

d

Allg. Toleranzen:

Schweissen:

Oberfläche:

Datum

Freigabe

Name

Benennung:

Zeichn.Nr.:

Gewicht:

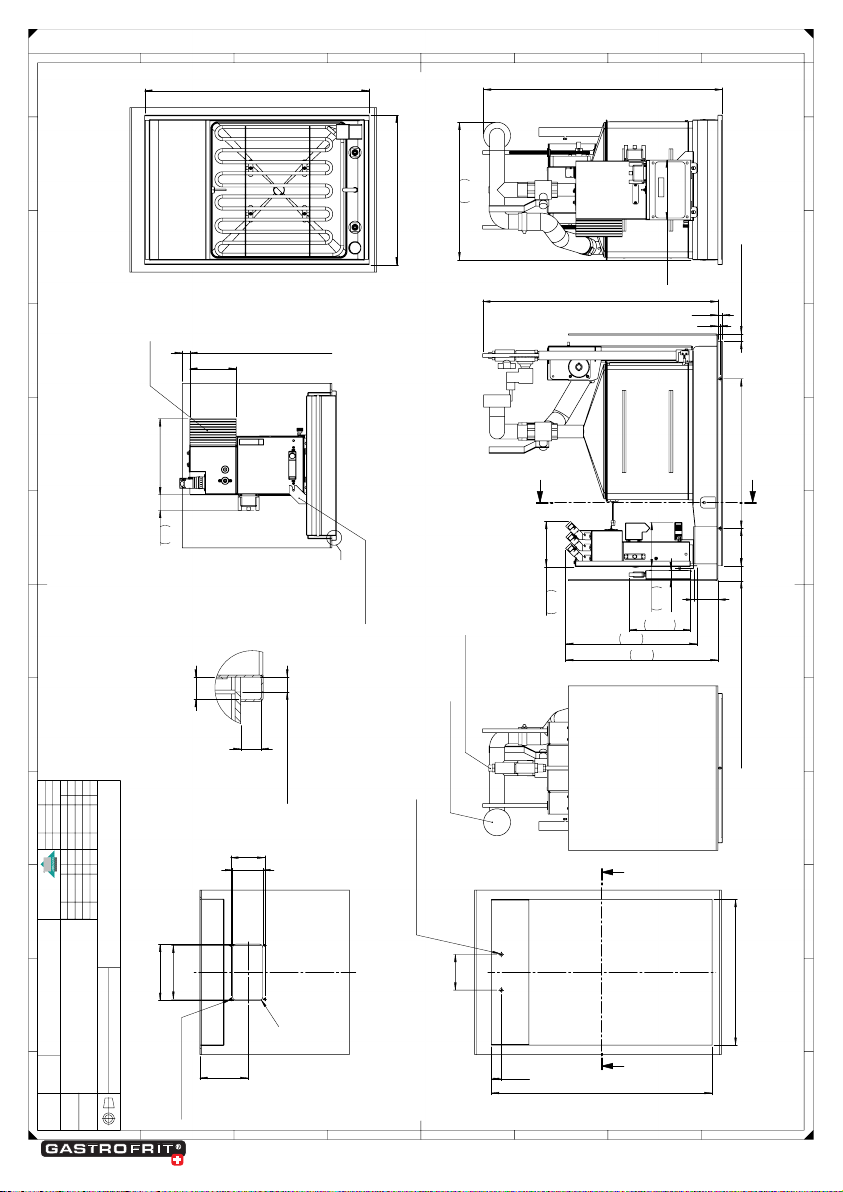

368

639

160

400

600

95

26

590

390

B B

2xØ8mm für Halterung Steuerbox

150.4

144

91

80.4

R

9.2

128

SCHNITT B-B

4x Schweissbolzen M4x8

65

allseitig min.

20mm 400 100 40

mm für Einbau Steuerbox laut Zeichnung

5

12

629

164.5

407

118

26.4

121

351

A

A

allseitig min.

20

mm (Kühlkörper)

203 41

124

C

SCHNITT A-A

Kühlkörper

Halterung Steuerbox

12

11

8

mm Spaltmass allseitig

ANSICHT C

MAßSTAB: 1 : 1

Wasserabfluss Geberit Ø50

Wasserzulauf 3/8" Anschluss

Ausschnitt für Tischplatte

Ausschnitt für Display

Ansicht ohne Bespielblende

TW-400

os

BG Einbau-16082012

30.04.2012

/ 06

A2

05

1:5

alle Angaben ohne Gewähr

technische Änderungen vorbehalten

16 www.gastrofrit.ch © Switzerland Gastrofrit AG

12

11

10

9

H

G

A

B

C

D

E

F

9

10

11

12

1

2

3

4

A

B

C

E

F

D

5

6

7

8

1

2

3

4

5

6

7

8

G

H

This representation is our intellectual property. You may without our written consent at all as

neither copied nor used for the manufacture of the work or nor to be announced to a thrid

party

Gastrofrit AG Weiherstrasse 11 CH-9400

Diese Darstellung ist unser geistiges Eigentum. Sie darf ohne unsere schriftliche Zustimmung

weder irgendwie kopiert noch zur Anfertigung des Werkes gebraucht oder Drittpersonen

bekanntgegeben werden.

Gastrofrit AG Weiherstrasse 11 CH-9400

Massstab:

Format:

Material:

Datum

Änd.

Änd.

Änd.Änd.

Änd.

e

f

a

b

g

c

Blatt:

Art.Nr.:

Gastrofrit AG

Weiherstrasse 11

CH-9400 Rorschach

Änd.

Datum

Name

erst. am

Name

Änd.

h

Änd.

d

Allg. Toleranzen:

Schweissen:

Oberfläche:

Datum

Freigabe

Name

Benennung:

Zeichn.Nr.:

Gewicht:

637

327

342

160

allseitig min.

20mm 398 40

mm für Einbau Steuerbox laut Zeichnung

100

5

12

629

26.4

65

118

121

407

164.5

351

A

A

350

600

95

26

590

340

B B

2xØ8mm für Halterung Steuerbox

150.4

144

91

80.4

128

SCHNITT B-B

Ausschnitt für Tischplatte

Ausschnitt für Display

4x Schweissbolzen M4x8

203 41

124

allseitig min.

20

mm (Kühlkörper)

C

SCHNITT A-A

Kühlkörper

Halterung Steuerbox

8

mm Spaltmass allseitig

11

12

ANSICHT C

MAßSTAB: 1 : 1

Wasserabfluss Geberit Ø50

Wasserzulauf 3/8" Anschluss

Ansicht ohne Bespielblende

TW-350

os

BG Einbau-16082012

30.04.2012

/ 06

A2

06

1:5

alle Angaben ohne Gewähr

technische Änderungen vorbehalten

17 www.gastrofrit.ch © Switzerland Gastrofrit AG

12

11

10

9

H

G

A

B

C

D

E

F

9

10

11

12

1

2

3

4

A

B

C

E

F

D

5

6

7

8

1

2

3

4

5

6

7

8

G

H

This representation is our intellectual property. You may without our written consent at all as

neither copied nor used for the manufacture of the work or nor to be announced to a thrid

party

Gastrofrit AG Weiherstrasse 11 CH-9400

Diese Darstellung ist unser geistiges Eigentum. Sie darf ohne unsere schriftliche Zustimmung

weder irgendwie kopiert noch zur Anfertigung des Werkes gebraucht oder Drittpersonen

bekanntgegeben werden.

Gastrofrit AG Weiherstrasse 11 CH-9400

Massstab:

Format:

Material:

Datum

Änd.

Änd.

Änd.Änd.

Änd.

e

f

a

b

g

c

Blatt:

Art.Nr.:

Gastrofrit AG

Weiherstrasse 11, CH-9400 Rorschach

Änd.

Datum

Name

erst. am

Name

Änd.

h

Änd.

d

Allg. Toleranzen:

Schweissen:

Oberfläche:

Datum

Freigabe

Name

Benennung:

Zeichn.Nr.:

Gewicht:

531

178

191

802

13.3

allseitig min. 20mm

56mm für Einbau Steuerbox laut Zeichnung

480

240

67.00

A

A

E

E

400

600

816

157.00

Ansicht ohne Beispielblende

214.00

61

157.00

SCHNITT A-A

380

580

EE

Ausschnitt für Tischplatte

128.00

48.00

196.03

125.00

80.40

150.40

R9.20

198.40

SCHNITT E-E

8x Schweissbolzen M4x8

Ausschnitt für Display

380

F

SCHNITT E-E

2.00

DETAIL F

MAßSTAB 1 : 1

alle Angaben ohne Gewähr

technische Änderungen vorbehalten

BG Einbaugerät

18.02.2021

/ 01

A2

01

1:5

ELM2-400

19.02.2021

Ilie R.

Ilie R.

-

18 www.gastrofrit.ch © Switzerland Gastrofrit AG

19 www.gastrofrit.ch © Switzerland Gastrofrit AG

12

11

10

9

H

G

A

B

C

D

E

F

9

10

11

12

1

2

3

4

A

B

C

E

F

D

5

6

7

8

1

2

3

4

5

6

7

8

G

H

This representation is our intellectual property. You may without our written consent at all as

neither copied nor used for the manufacture of the work or nor to be announced to a thrid

party

Gastrofrit AG Weiherstrasse 11 CH-9400

Diese Darstellung ist unser geistiges Eigentum. Sie darf ohne unsere schriftliche Zustimmung

weder irgendwie kopiert noch zur Anfertigung des Werkes gebraucht oder Drittpersonen

bekanntgegeben werden.

Gastrofrit AG Weiherstrasse 11 CH-9400

-0.2

-0.5

+0.5

+0.2

unbemasste

Werkstückkanten

DIN ISO 13715

Massstab:

Format:

Material:

Datum

Änd.

Änd.

Änd.Änd.

Änd.

e

f

a

b

g

c

Blatt:

Art.Nr.:

Gastrofrit AG

Weiherstrasse 11, CH-9400 Rorschach

Änd.

Datum

Name

erst. am

Name

Änd.

h

Änd.

d

Allg. Toleranzen:

Schweissen:

Oberfläche:

Datum

Freigabe

Name

Benennung:

Zeichn.Nr.:

Gewicht:

531

178

192

802

13.3

allseitig min. 20mm

56mm für Einbau Steuerbox laut Zeichnung

479.50

67.00

240

155

A

A

E

E

811

157.00

Ansicht ohne Bespielblende

280

578

B B

Ausschitt für Tischplatte

196

125

118

80.40

150.40

R9.20

128.00

SCHNITT B-B

Ausschitt für Display

4x Schweissbolzen M4x8

61

214.00

157.00

SCHNITT A-A

300

600

280

F

SCHNITT E-E

2.00

DETAIL F

MAßSTAB 1 : 1

Alle Angaben ohne Gewähr

technische änderungen vorbehalten

ELM-300

-

-

-

Ilie R.

Ilie R.

17.02.2021

BG Einbaugerät

16.02.2021

/ 01

A2

01

1:5

20 www.gastrofrit.ch © Switzerland Gastrofrit AG

12

11

10

9

H

G

A

B

C

D

E

F

9

10

11

12

1

2

3

4

A

B

C

E

F

D

5

6

7

8

1

2

3

4

5

6

7

8

G

H

This representation is our intellectual property. You may without our written consent at all as

neither copied nor used for the manufacture of the work or nor to be announced to a thrid

party

Gastrofrit AG Weiherstrasse 11 CH-9400

Diese Darstellung ist unser geistiges Eigentum. Sie darf ohne unsere schriftliche Zustimmung

weder irgendwie kopiert noch zur Anfertigung des Werkes gebraucht oder Drittpersonen

bekanntgegeben werden.

Gastrofrit AG Weiherstrasse 11 CH-9400

-0.2

-0.5

+0.5

+0.2

unbemasste

Werkstückkanten

DIN ISO 13715

Massstab:

Format:

Material:

Datum

Änd.

Änd.

Änd.Änd.

Änd.

e

f

a

b

g

c

Blatt:

Art.Nr.:

Gastrofrit AG

Weiherstrasse 11, CH-9400 Rorschach

Änd.

Datum

Name

erst. am

Name

Änd.

h

Änd.

d

Allg. Toleranzen:

Schweissen:

Oberfläche:

Datum

Freigabe

Name

Benennung:

Zeichn.Nr.:

Gewicht:

531

178

192

802

619

433

13.3

allseitig min. 20mm

56mm für Einbau Steuerbox laut Zeichnung

392

153

32

155

A

A

E

E

811

157.00

Ansicht ohne Bespielblende

280

578

B B

Ausschitt für Tischplatte

91

144

144

80.40

150.40

R9.20

128.00

SCHNITT B-B

Ausschitt für Display

4x Schweissbolzen M4x8

157.00

351

61

SCHNITT A-A

300

600

280

F

SCHNITT E-E

2.00

DETAIL F

MAßSTAB 1 : 1

G

G

351

41

51

157

SCHNITT G-G

Halterung Steuerbox

Alle Angaben ohne Gewähr

technische änderungen vorbehalten

F-300

-

-

-

Ilie R.

Ilie R.

17.02.2021

BG Einbaugerät

16.02.2021

/ 01

A2

01

1:5

This manual suits for next models

21

Table of contents