AGA155 Product Manual Rev.1.3 Page 3

Contents

1Product Description _____________________________________________________ 4

1.1 General Description ______________________________________________________________ 4

1.2 Part Numbering _________________________________________________________________ 4

1.3 System Design___________________________________________________________________ 5

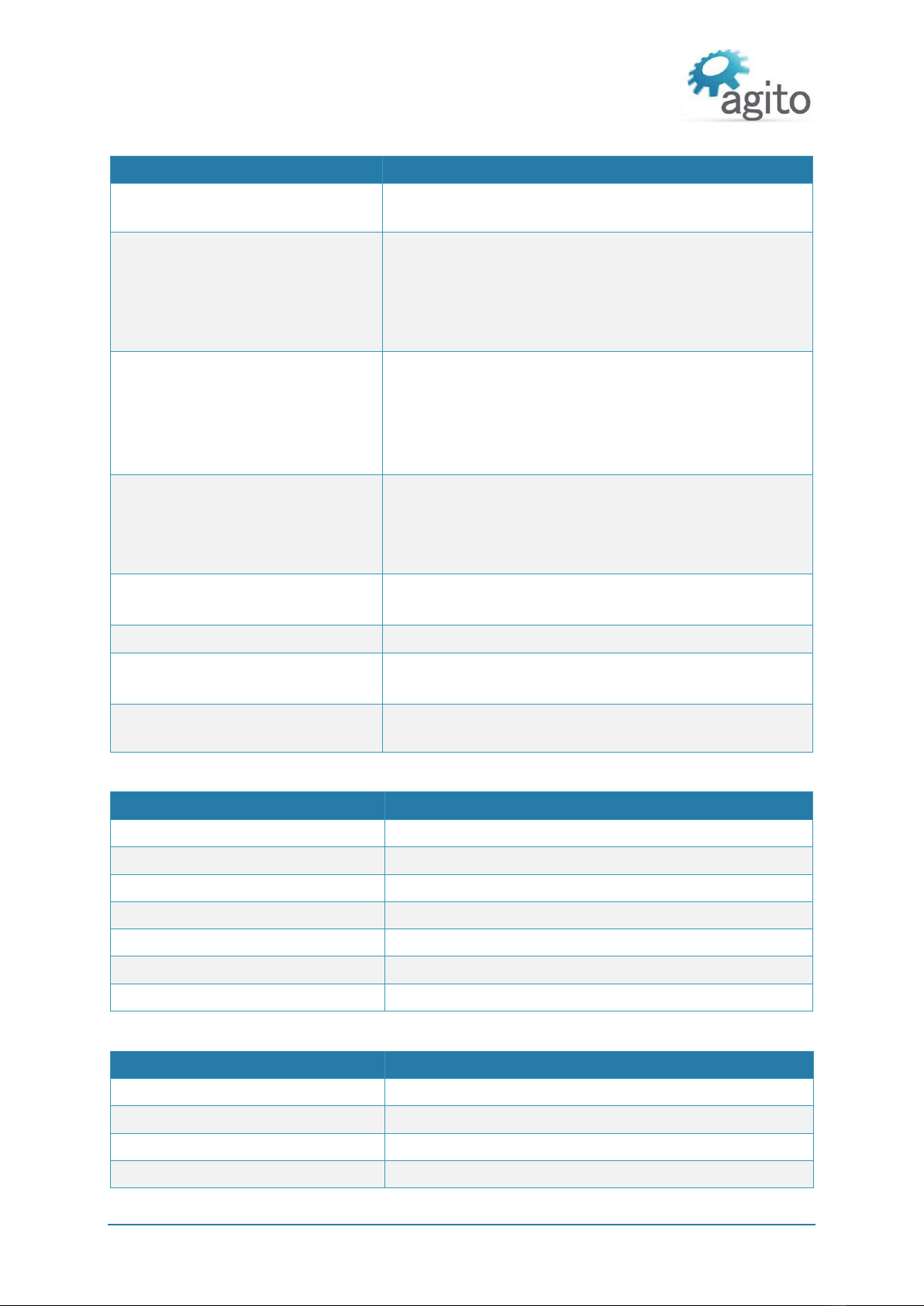

1.4 Technical Specifications ___________________________________________________________ 5

1.5 Environmental Specifications_______________________________________________________ 8

2Safety ________________________________________________________________ 9

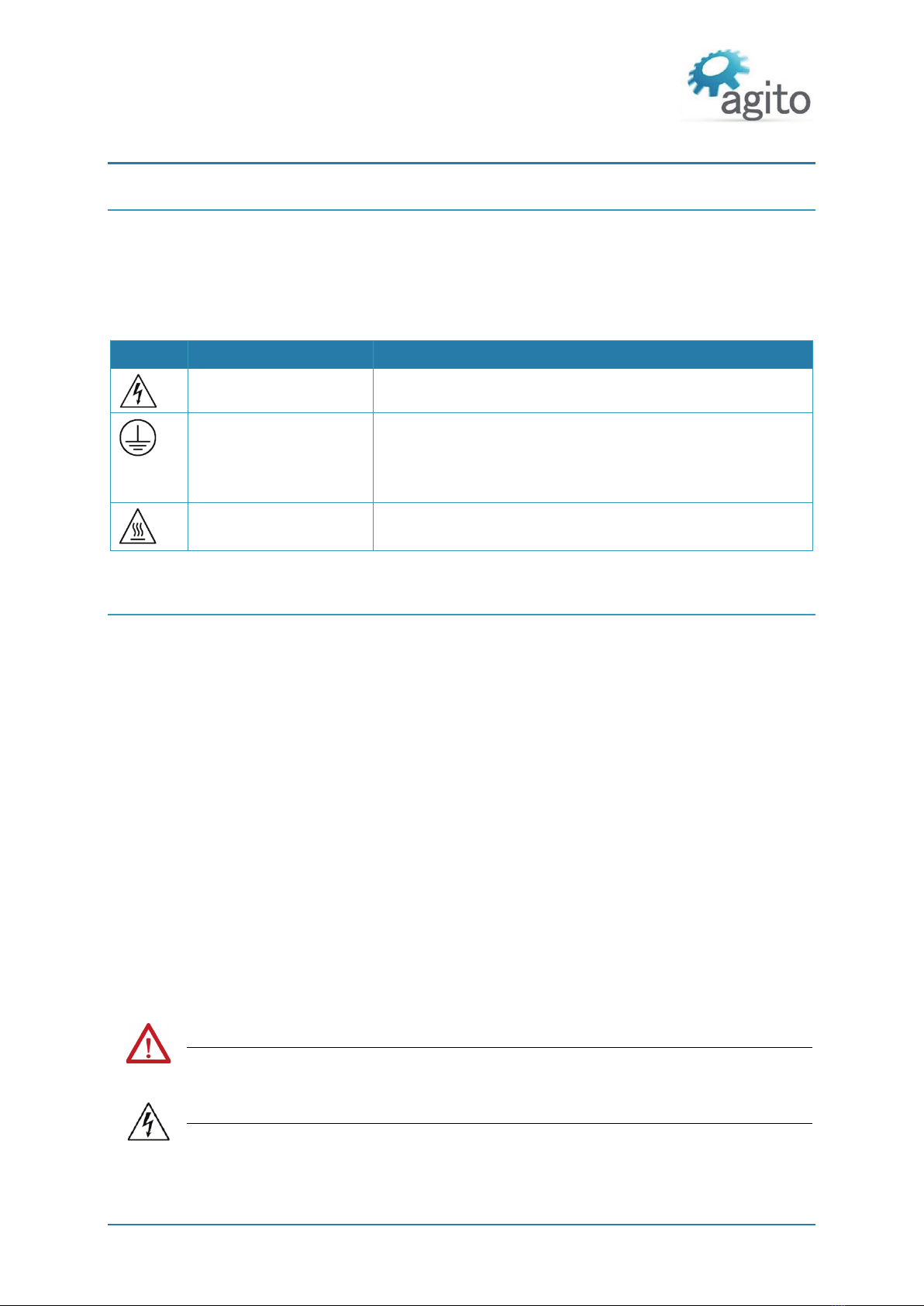

2.1 Safety Symbols __________________________________________________________________ 9

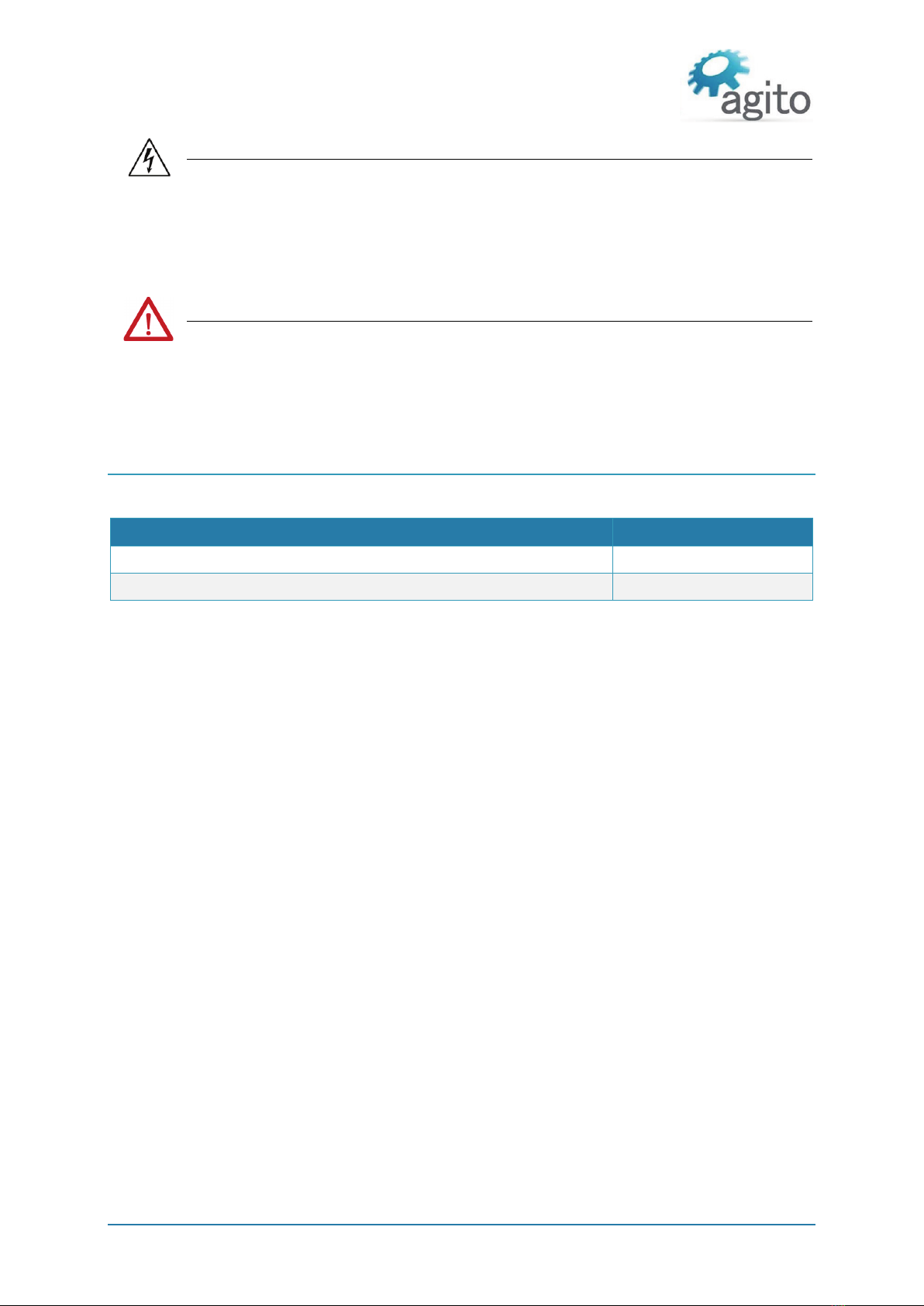

2.2 Safety Guidelines ________________________________________________________________ 9

2.3 Compliance ____________________________________________________________________ 10

3Installation ___________________________________________________________ 11

3.1 Unpacking and Packing___________________________________________________________ 11

3.2 Mounting _____________________________________________________________________ 11

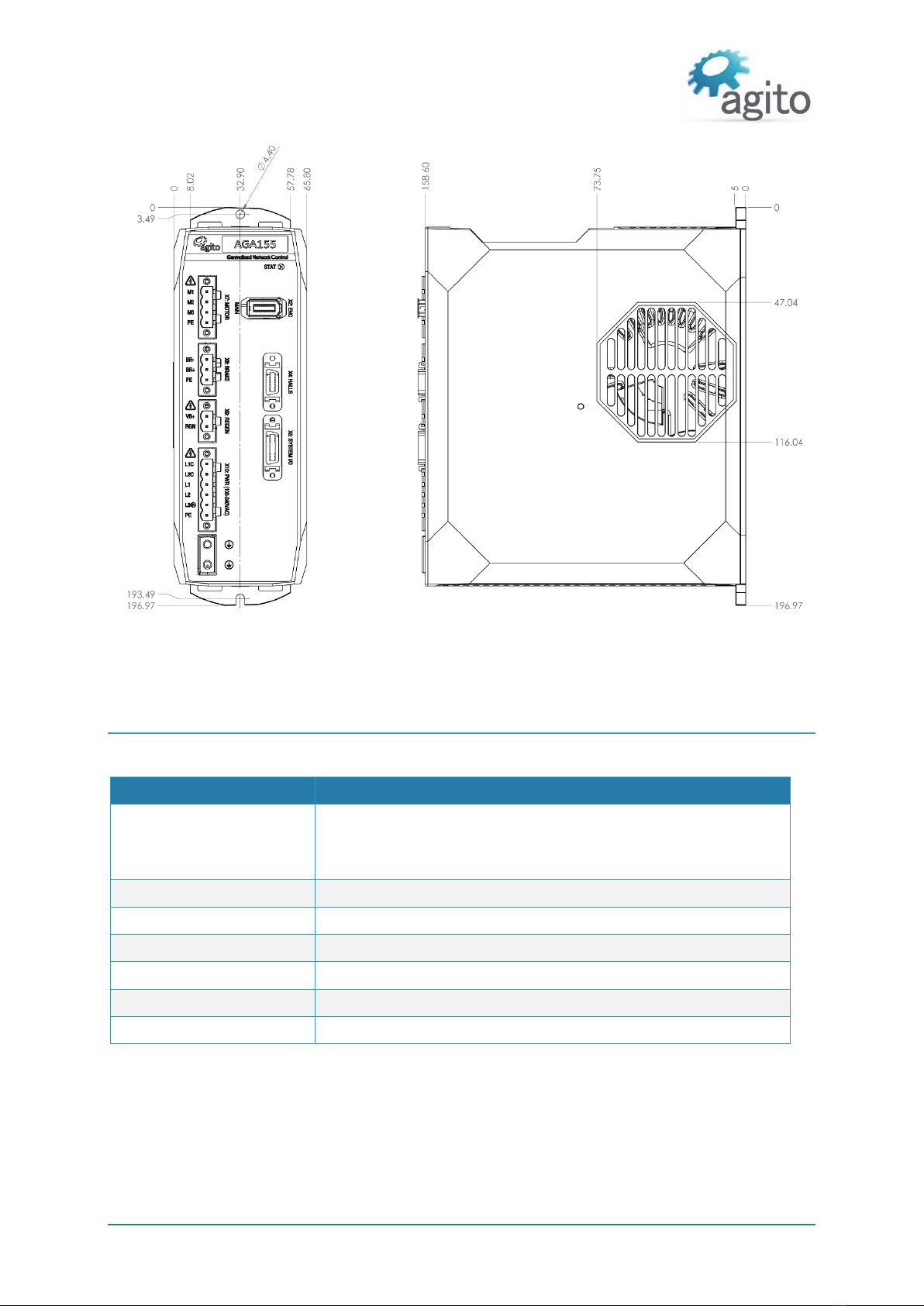

3.2.1 Mounting the AGA155 ____________________________________________________ 11

3.2.2 Mounting Multiple Power Amplifiers ________________________________________ 12

3.3 Electrical Installation ____________________________________________________________ 13

3.3.1 Power Wiring ___________________________________________________________ 13

3.3.2 Regeneration____________________________________________________________ 13

3.3.3 Circuit Breakers__________________________________________________________ 14

3.3.4 AC Line Filter ____________________________________________________________ 15

3.3.5 Safe Operating Area (SOA) _________________________________________________ 15

3.3.6 Grounding ______________________________________________________________ 16

Ground Domains_________________________________________________________ 17

Grounding Policy_________________________________________________________ 17

3.3.7 PT100/PT1000 Temperature Sensors ________________________________________ 17

3.4 Electrical Interfaces _____________________________________________________________ 18

3.4.1 Interface X14: I/O and Brake Power _________________________________________ 18

3.4.2 Interface X15: Safety _____________________________________________________ 19

3.4.3 Interface X7: Motor ______________________________________________________ 21

For Brushless Motor ______________________________________________________ 21

For Brushed (or Voice Coil) Motor ___________________________________________ 21

3.4.4 Interface X8: Static Brake __________________________________________________ 22

3.4.5 Interface X9: Regeneration_________________________________________________ 23

3.4.6 Interface X10: Power _____________________________________________________ 24

3.4.7 Interface X13: Central-i____________________________________________________ 25

3.4.8 Interface X2: Main Encoder ________________________________________________ 26

3.4.9 Interface X4: Halls ________________________________________________________ 27

3.4.10 Interface X5: System I/Os __________________________________________________ 29

I/Os Circuit Diagrams _____________________________________________________ 30

4Operation____________________________________________________________ 33

4.1 Motor Configuration_____________________________________________________________ 33

4.2 Drive/Motor Overload Protection __________________________________________________ 35

4.2.1 I2T Over Load protection __________________________________________________ 35

4.2.2 Motor Stuck ____________________________________________________________ 37

4.2.3 Motor Temperature Protection _____________________________________________ 37

4.3 Tuning ________________________________________________________________________ 38

4.3.1 Commissioning __________________________________________________________ 38

4.3.2 Current Loop Tuning______________________________________________________ 39

4.3.3 Auto Velocity and Position Loop Tuning ______________________________________ 40

4.3.4 Manual Velocity and Position Loop Tuning ____________________________________ 43

5Maintenance and Servicing ______________________________________________ 45