6

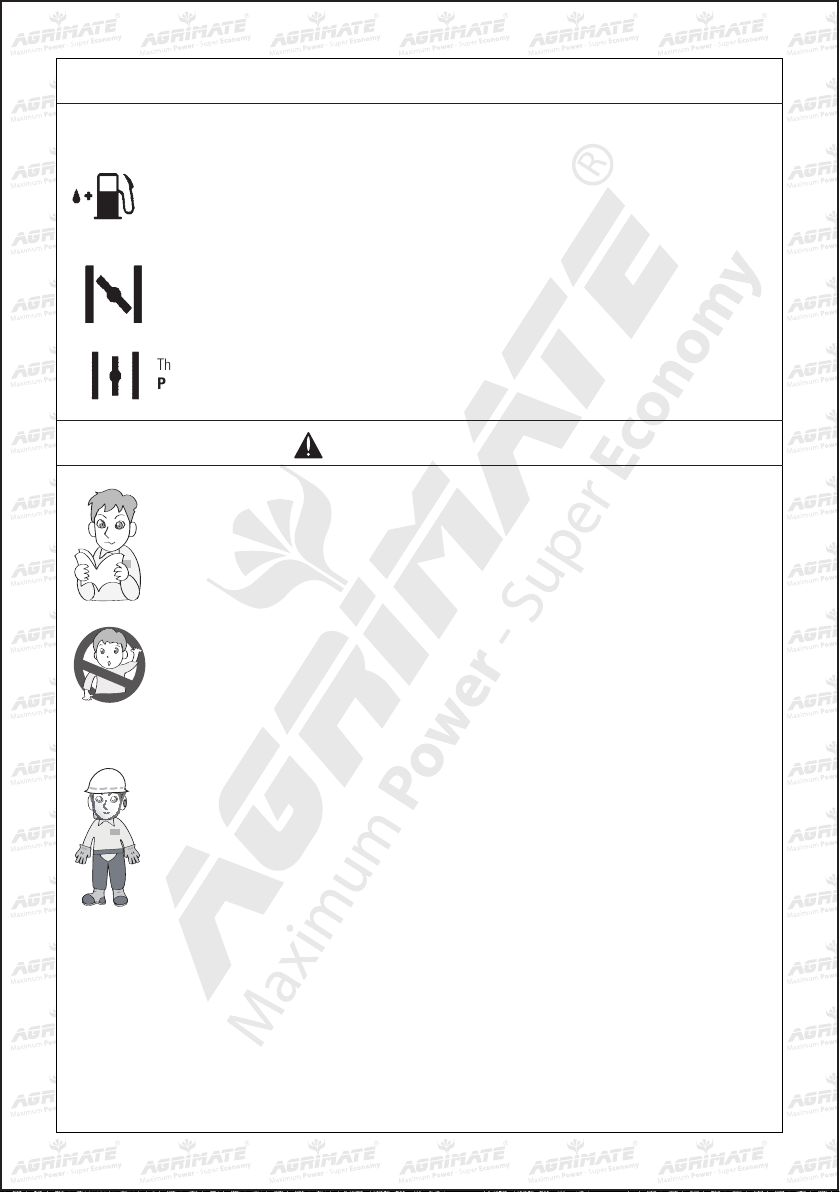

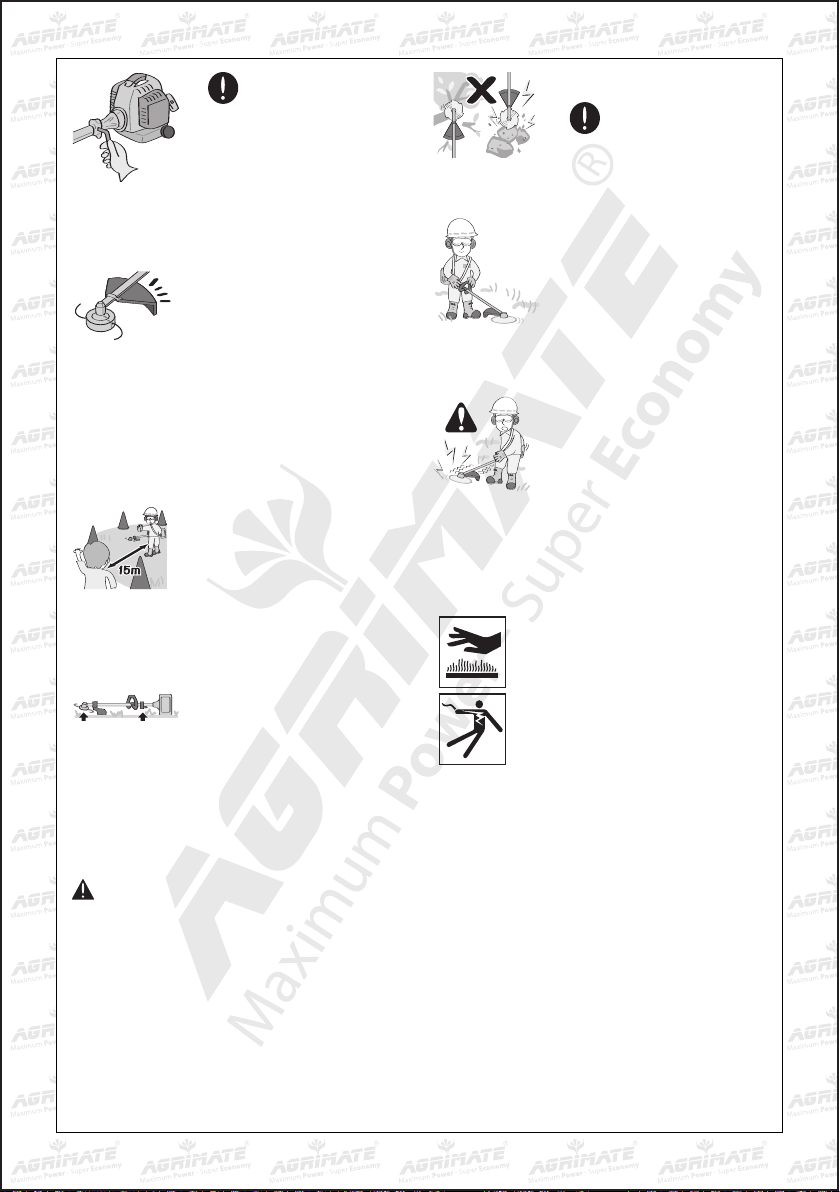

3. Do not wear loose clothing,

jewelry,short trousers, sandals, or

go barefoot. Do not wear anything

which might be caught by a

moving part of the unit. Secure

hair so it is above shoulder length.

WORKING CIRCUMSTANCE

1. Never start the engine inside a

closed room or building. Exhaust

gases contain dangerous carbon

monoxide.

2. Never use the product,

a. when the ground is slippery

or when you can’t maintain

a steady posture.

b. At night, at times of heavy

fog,or at any other times

when your field of vision

might be limited and it

would be difficult to gain a

clear view of the working

area.

c. During rain storms, during

lightning storms, at times of

strong or gale-force winds,

or at any other times when

weather conditions might

make it unsafe to use the

product.

WORKING PLAN

1. You should never use the product

when under the influence of

alcohol, when suffering from

exhaustion or lack of sleep,

when suffering from drowsiness

as a result of having taken cold

medicine or at any other time

when a possibility exists that

your judgment might be impaired

or that you might not be able to

operate the product properly and

in a safe manner.

2. When planning your work

schedule,allow plenty of time

to rest. Limit the amount of time

over which the product is to be

used continuously to somewhere

around 30 ~ 40 minutes per

session,and take 10 ~ 20 minutes

of rest between work sessions.

Also try to keep the total amount

of work performed in a single day

under 2 hours or less.

WARNING

1. If you don’t observe the working

time, or working manner

(See“USING THE PRODUCT”),

Repetitive Stress Injury (RSI) could

occur.

If you feel discomfort, redness

and swelling of your fingers or

any other part of your body, see a

doctor before getting worse.

2. To avoid noise complaints,

in general,operate product

between8 a.m. and 5 p.m. on

weekdays and 9 a.m. to 5 p.m. on

weekends.

NOTE

Check and follow the local regulations as to sound

level and hours of operations for the product.

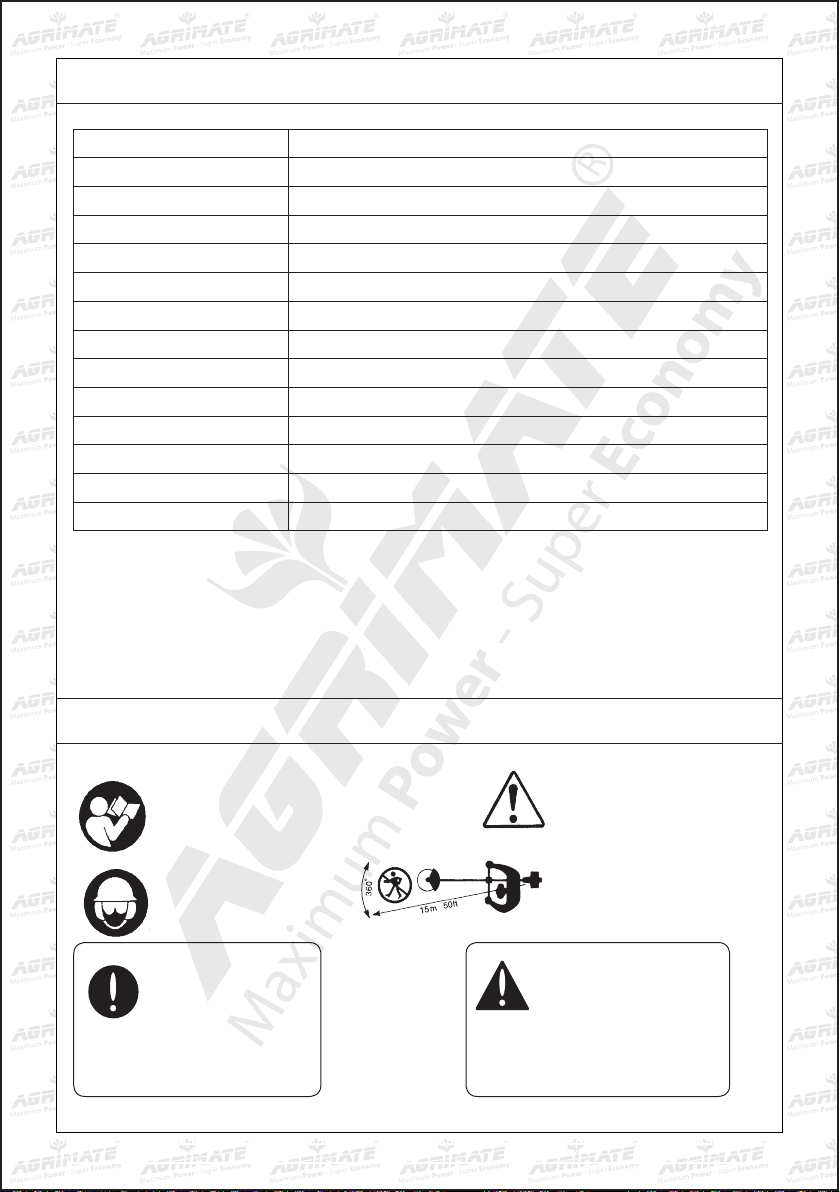

BEFORE STARTING THE ENGINE

1. The area within a perimeter

of15 m (50 ft) of the person

using the product should be

considered a hazardous area

into which no one should enter.

If necessary,yellow warning

rope, warning signs should be

placed around the perimeter of

the area. When work is to be

performed simultaneously by

two or more persons,care should

also be taken to constantly look

around or otherwise check for the

presence and locations of other

people working so as to maintain

a distance between each person

sufficient to ensure safety.

2. Check the condition of working

area to avoid any accident by

hitting hidden obstacles such as

stumps, stones, cans, or broken

glass.