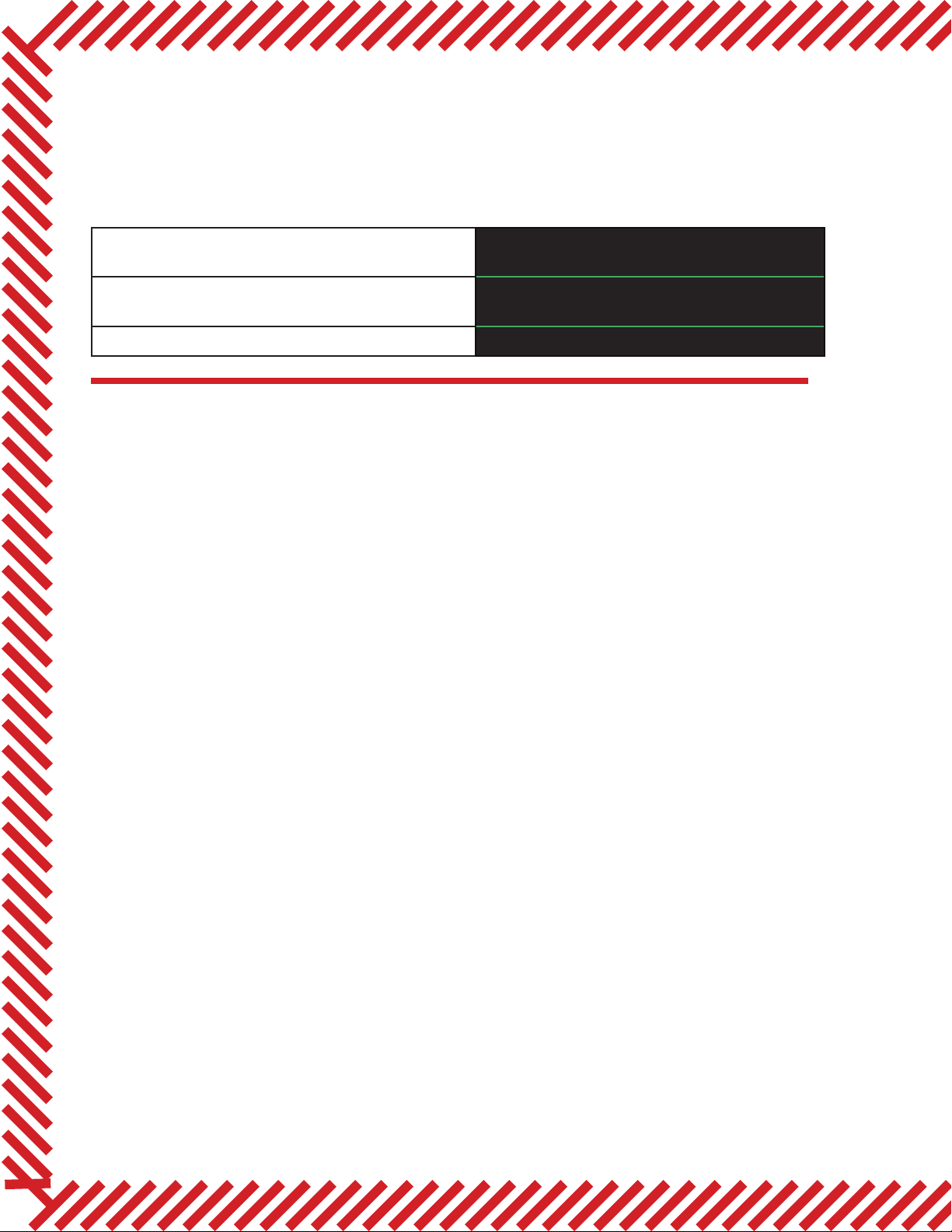

LETTER TO OWNER..................................................................................................................................5

SECTION 2 SAFETY INFORMATION

2.1 Introduction...................................................................................................................................................7

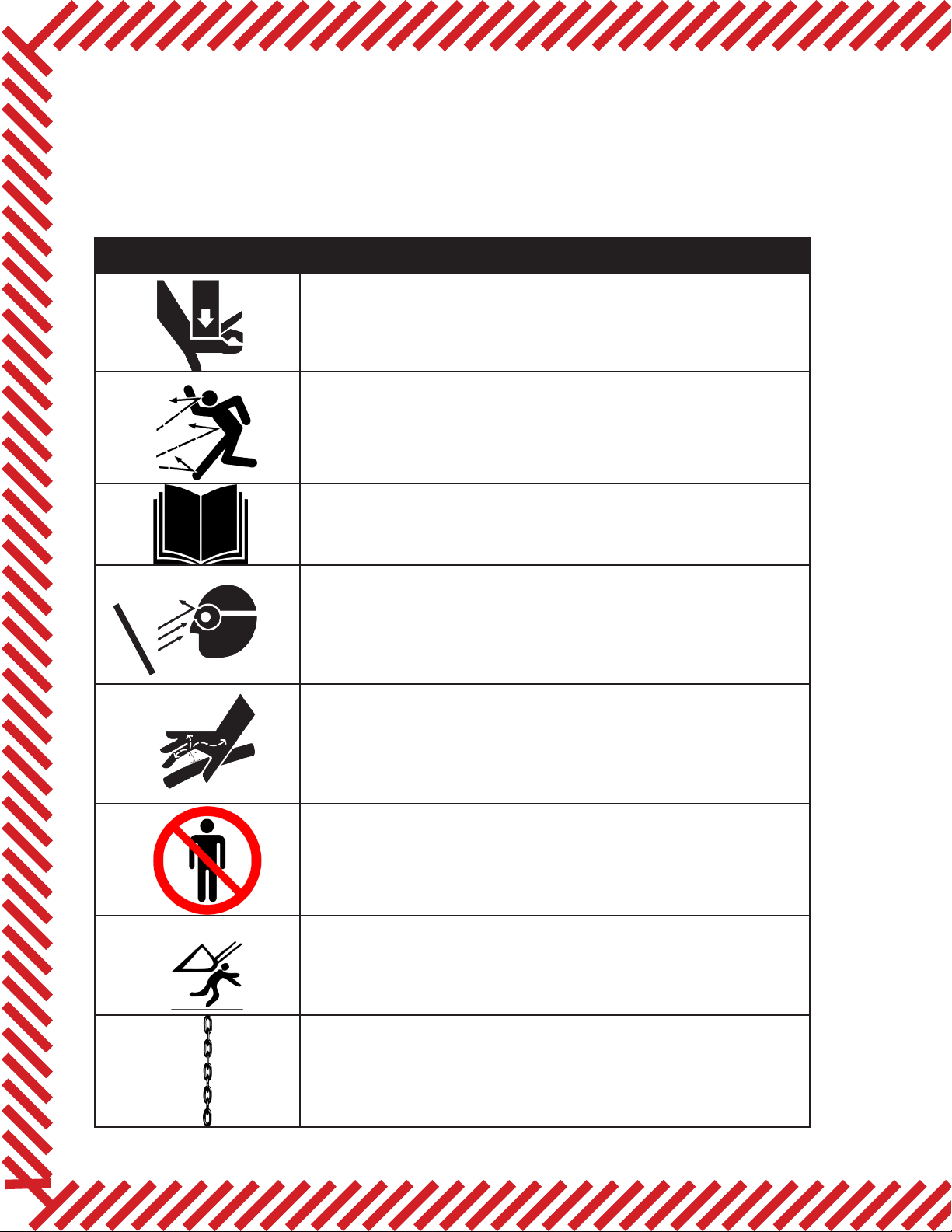

2.2 Safety Symbols.......................................................................................................................................8-10

2.3 Safety Decals.........................................................................................................................................10-12

2.4 Skid Steer Tractor Requirements.............................................................................................................13

2.5 General Safety Instructions.......................................................................................................................14

SECTION 3 OPERATING PROCEDURES

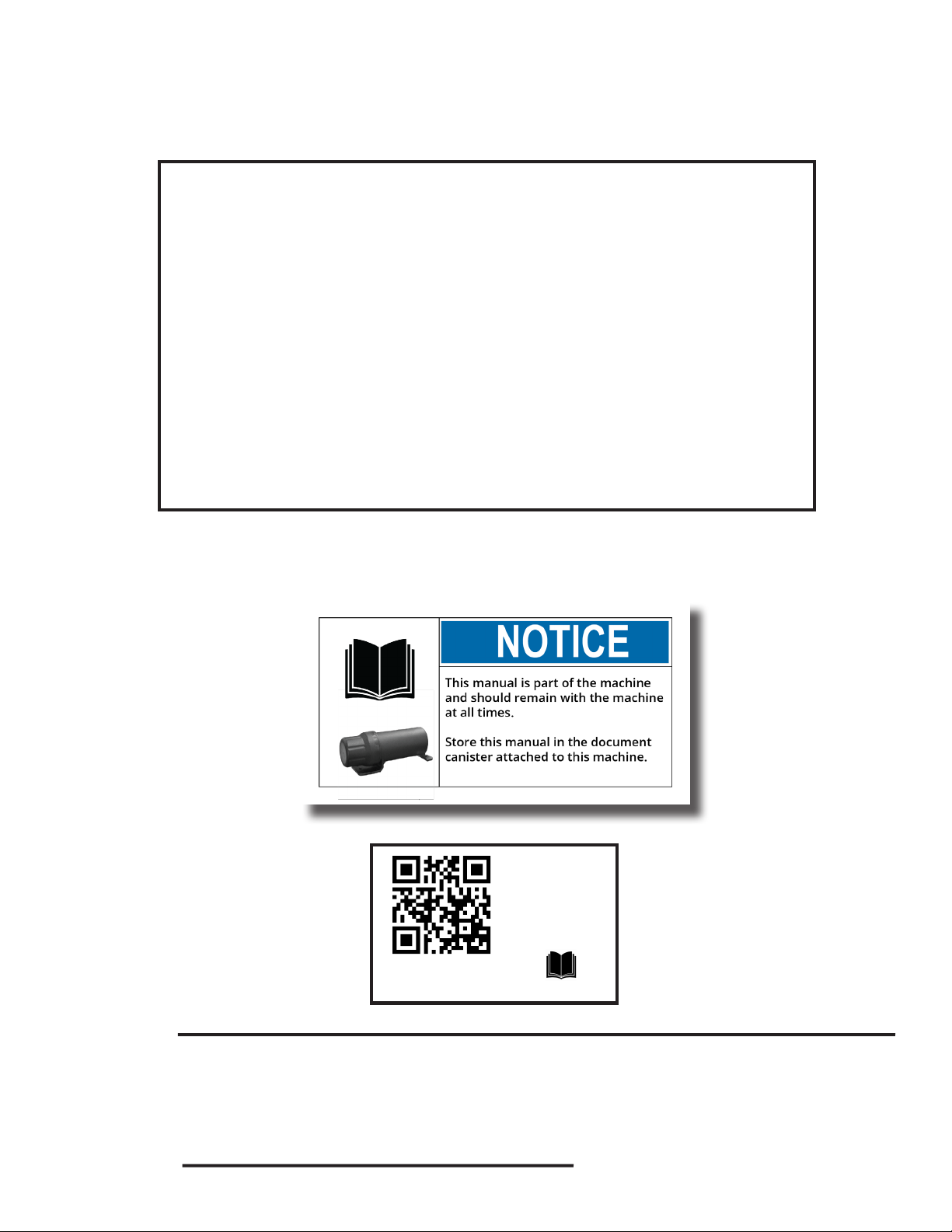

3.1 Unpacking Your Brush Cutter..................................................................................................................16

3.2 How To Connect Brush Cutter Attachment......................................................................................16-17

3.3 How To Start and Stop The Brush Cutter..........................................................................................18-19

3.4 First Time Use.......................................................................................................................................19-20

3.5 Cutting Operations..............................................................................................................................21-23

SECTION 4 MAINTENANCE PROCEDURES

4.1 Maintenance Overview...............................................................................................................................25

4.2 Maintenance Schedule...............................................................................................................................26

4.3 Storage Tips..................................................................................................................................................27

4.4 Blade Holder Removal..........................................................................................................................27-28

4.5 Blade Holder Installation............................................................................................................................28

4.6 Blade Removal Procedures........................................................................................................................29

4.7 Blade Installation Procedures.............................................................................................................30-31

4.8 Bearing Housing Maintenance...........................................................................................................31-33

4.9 Torque Specication Table........................................................................................................................33

SECTION 5 TROUBLESHOOTING

5.1 Troubleshooting Chart................................................................................................................................35

SECTION 6 SPECIFICATIONS

6.1 Specication Chart......................................................................................................................................37

SECTION 7 PARTS INFORMATION

7.1 Parts Assembly Diagrams...................................................................................................................39-42

SECTION 8 WARRANTY INFORMATION

8.1 Limited Warranty Statement....................................................................................................................44

8.2 Warranty Service Procedure.....................................................................................................................45

SAFETY ACKNOWLEDGEMENT FORMS........................................................................46-47

MAINTENACE LOG.................................................................................................................................49