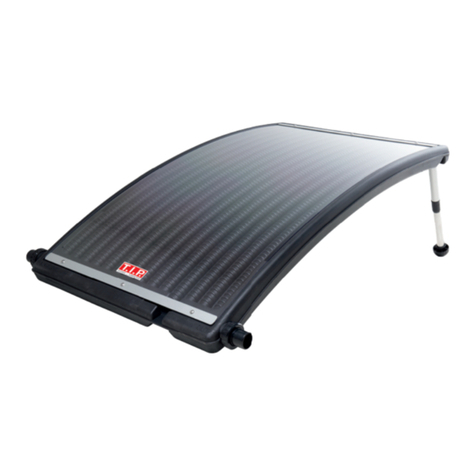

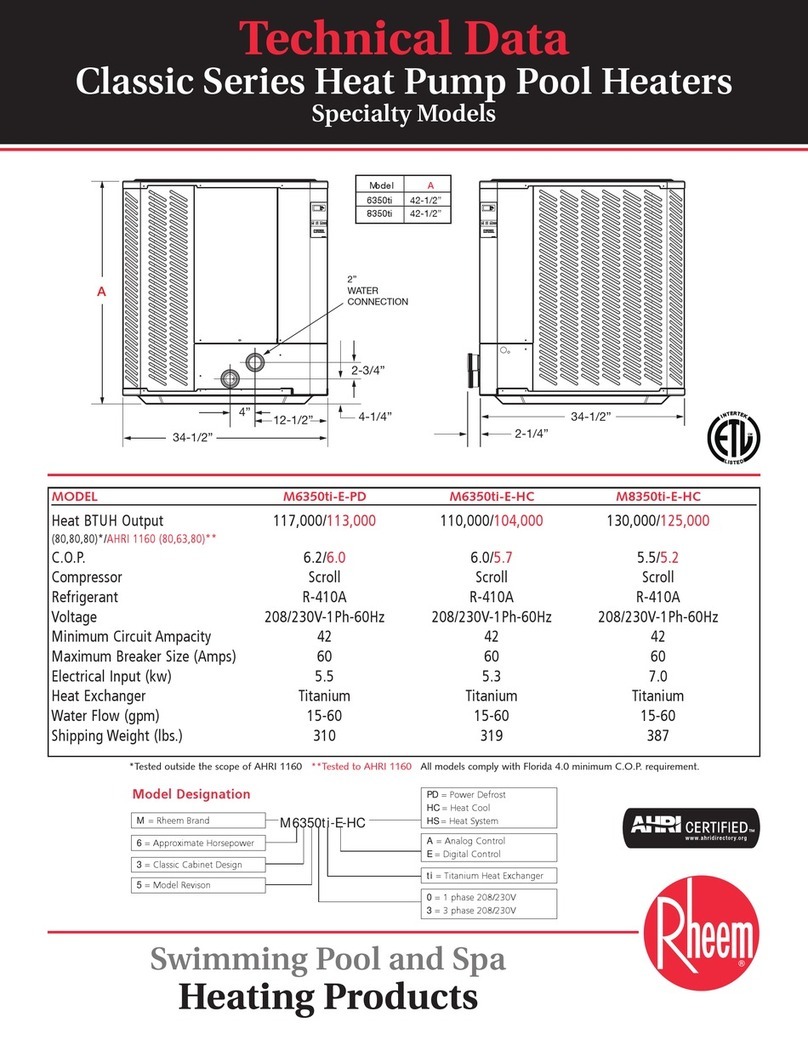

HPPH Control Display

The HPPH display is viewable from outside of the

heater. All operation and settings of the HPPH control

are accomplished through the use of the 3 buttons of

the user interface. These buttons are labeled as fol-

lows:

• MENU/SET – Scroll through available menus

and set changed values (MENU)

• U – Increase values in the Adjust menu

• DOWN – Decrease values in the Adjust menu

The display uses a 2-line, 16-character backlit Liquid

Crystal isplay (LC ) as the method for supplying

information. The backlight is normally off. The back-

light is on for 15 minutes after Power-Up and for 15

minutes after any button press. Use the LC to setup

and monitor the operation of your heater.

If the membrane switch remains inactive for 180 sec-

onds (3 minutes), the screen will revert to the current

view.

On HEAT/COOL models, the options available by

pressing the MENU/SET (MENU) button are POOL

HEAT, POOL COOL, POOL AUTO, SPA, TIME SPA

and OFF. The cooling setpoint can be adjusted in the

range of 50F to the Cooling eadband value below the

Heating setpoint. This allows use in Plunge Pools.

Adjust the cooling setpoint accordingly.

The control board is equipped with a red status LE

on the back of the board which flashes at a “heartbeat”

of 2Hz while operating normally. The control board is

also equipped with a green LE (next to the commu-

nications jack) on the back of the board which will

flicker to indicate active communications when con-

nected to another system.

Upon initial application of power, the HPPH control

briefly sets all segments on the LC at power-up. On

a normal power-up, the control displays the current

software revision and the model type configuration

(HEAT ONLY, POWER EFROST or HEAT/COOL) on

the LC for 2 seconds and then resumes the user

selected mode it was in before power was interrupted.

The configuration for these units should be

HEAT/COOL.

Setpoints are read from non-volatile memory. If the

self diagnostic check indicates corrupted values,

“EEPROM Fault” is displayed on the LC and opera-

tion is prohibited until setpoints are manually set.

If unit type has not been set (like during the replace-

ment of the HPPH control), the control prompts the

user to set the model type (HEAT ONLY, POWER

EFROST, or HEAT/COOL) before any device opera-

tion is enabled. Installation in these models requires a

model type of HEAT/COOL to be selected.

Upon initial installation, there are several items that

must be defined and programmed depending on the

configuration and accessories intended to be con-

trolled by the HPPH control. These include: (1) 3-way

valve control (Yes or No), (2) Pump control (Yes or No

and then what type of control – 4-speed control or vari-

able speed control), and (3) Auxiliary control (Yes or

No and then what type – External Heat, Auxiliary

Output or Remote Output).

Once these choices are made, then additional infor-

mation relating to the establishing of pump periods,

pump speeds during each period and Return/Suction

Valve positions during each period must be deter-

mined and set in the control.

The options for the control can be very simple or very

detailed, depending upon each installation desires.

Once programming is completed, the control is ready

for operation.

WARNING: Install a check valve and/or a Hartford

loop AFTER the heat pump pool heater and

BEFORE any chlorinating devices. Install any auto-

matic chemical feeders AFTER the heat pump pool

heater. Improper installation of any type of auto-

matic chemical feeders can result in serious

damage to, or premature failure of, the heat

pump pool heater and will void the heat pump

pool heater warranty.

Fig. 4: H H Control Display

10