G-2 H-093630_EN • 00

Table of ConTenTs

General InformatIon ...................................... G-3

Liabilities of the Manufacturer, the Installer and the

End user....................................................................G-3

About this Manual.....................................................G-4

Appliance Naming.....................................................G-5

Appliance Marking ....................................................G-5

Safety Instructions ....................................................G-6

Package Contents ...................................................G-7

Product descrIPtIon ..................................... G-8

TEXAS 99 - 230.........................................................G-8

General Description............................................................ G-8

Frost Protection.................................................................. G-8

Safety Devices ................................................................... G-8

Optional equipment............................................................ G-8

Control Panel and Main Functions..........................G-12

Symbols and Messages on the Control Panel .......G-13

technIcal sPecIfIcatIons .............................. G-14

Dimensions ............................................................G-14

Clearances ..............................................................G-15

Performance and Eciency Data ...........................G-16

ErP Data..................................................................G-16

Electrical Data.........................................................G-16

Hydraulic Data ........................................................G-16

Combustion Data....................................................G-17

Gas Data .................................................................G-18

InstructIons for the user............................ u-19

Safety Instructions for the User ..............................U-19

Disposal of the Product at the End of Service Life .U-20

Periodic checks .....................................................U-20

Starting the Appliance ............................................U-21

Stopping the Appliance ..........................................U-21

What to Do if... ........................................................ U-21

Operating the Controller - End User Level..............U-22

Basic Settings .........................................................U-24

Product InstallatIon ................................... u-26

Safety Instructions for the Installation ....................U-26

Unpacking the Product.............................................I-27

Handling the Product................................................I-27

Installing and Preparing the Appliance .....................I-28

Opening and Closing the Front Door and Access Panels . I-29

Inverting the Opening Side of the Front Door...........I-30

Requirements for the Hydraulic Circuits ...................I-31

Safety Instructions for the DHW Circuit....................I-34

Typical Hydraulic Connections - DHW Circuit ..........I-35

Safety Instructions for the Chimney Connections ....I-36

Chimney Connection ................................................I-38

Engineering the Chimney System.............................I-41

Accessories...............................................................I-41

Safety Instructions for the Gas Connection..............I-42

Gas Conversion ........................................................I-43

Preparing the Appliance for Gas Conversion ...................... I-44

Adjustment of Fan Speeds ................................................. I-45

Combustion Adjustment for Gas Conversion ....................... I-46

Safety Instructions for the Electrical

Connections..............................................................I-48

Cables.......................................................................I-48

Routing the Cables ...................................................I-48

Accessing the Electronic Board and Low and High

Voltage Terminal strips..............................................I-49

Wiring Diagram - TEXAS 99......................................I-50

Wiring Diagram - TEXAS 230....................................I-52

commIssIonInG ...............................................I-54

Safety Instructions Before Start-up ..........................I-54

Filling the Water Heater.............................................I-54

Start-up and Commissioning....................................I-55

Combustion Adjustment ...........................................I-55

Commissioning Wizard .............................................I-56

General Structure of the Commissioning Wizard................. I-57

maIntenance..................................................I-60

Safety Instructions for Maintenance .........................I-60

Maintenance Requirements ......................................I-61

Shutting Down for Maintenance ...............................I-62

Draining the Circuit ...................................................I-62

Restarting after Maintenance....................................I-62

Checking the Flue Gas (FPS) and Air (APS) Pressure

Switches operation ...................................................I-63

Removing, Cleaning and Installing the Condensate Trap ... I-64

Removing and Installing the Ignition and Ionisation

Electrodes .................................................................I-66

Removing and Installing the Fan, Venturi and Gas

Valve (TEXAS 99).......................................................I-68

Removing and Installing the Fan, Venturi and Gas

Valve Assembly (TEXAS 230) ....................................I-70

Removing and Installing the Burner..........................I-72

Removing and Installing the Burner Plate.................I-74

Checking and Cleaning the Combustion Chamber ..I-76

Checking the Scaling in the Appliance and Descaling I-77

Appliance Settings for the Installer ...........................I-78

Access Levels .................................................................... I-78

Menus and Settings ........................................................... I-78

Structure of Menus for the Installer ..........................I-79

Error Codes and Solutions........................................I-81

Troubleshooting ........................................................I-84

Maintenance Messages ............................................I-85

Installation Checklist .................................................I-86

Combustion Parameters - Log Sheet .......................I-89

Water Parameters - Log Sheet .................................I-90

declaratIon of conformIty ............................I-91

INDEX OF ILLUSTRATIONS

Fig. 1. Data Plate - Typical .............................................................. G-5

Fig. 2. TEXAS Water Heater Packaged for Transport.................... G-7

Fig. 3. TEXAS 99 - 230 Components - Front views ...................... G-9

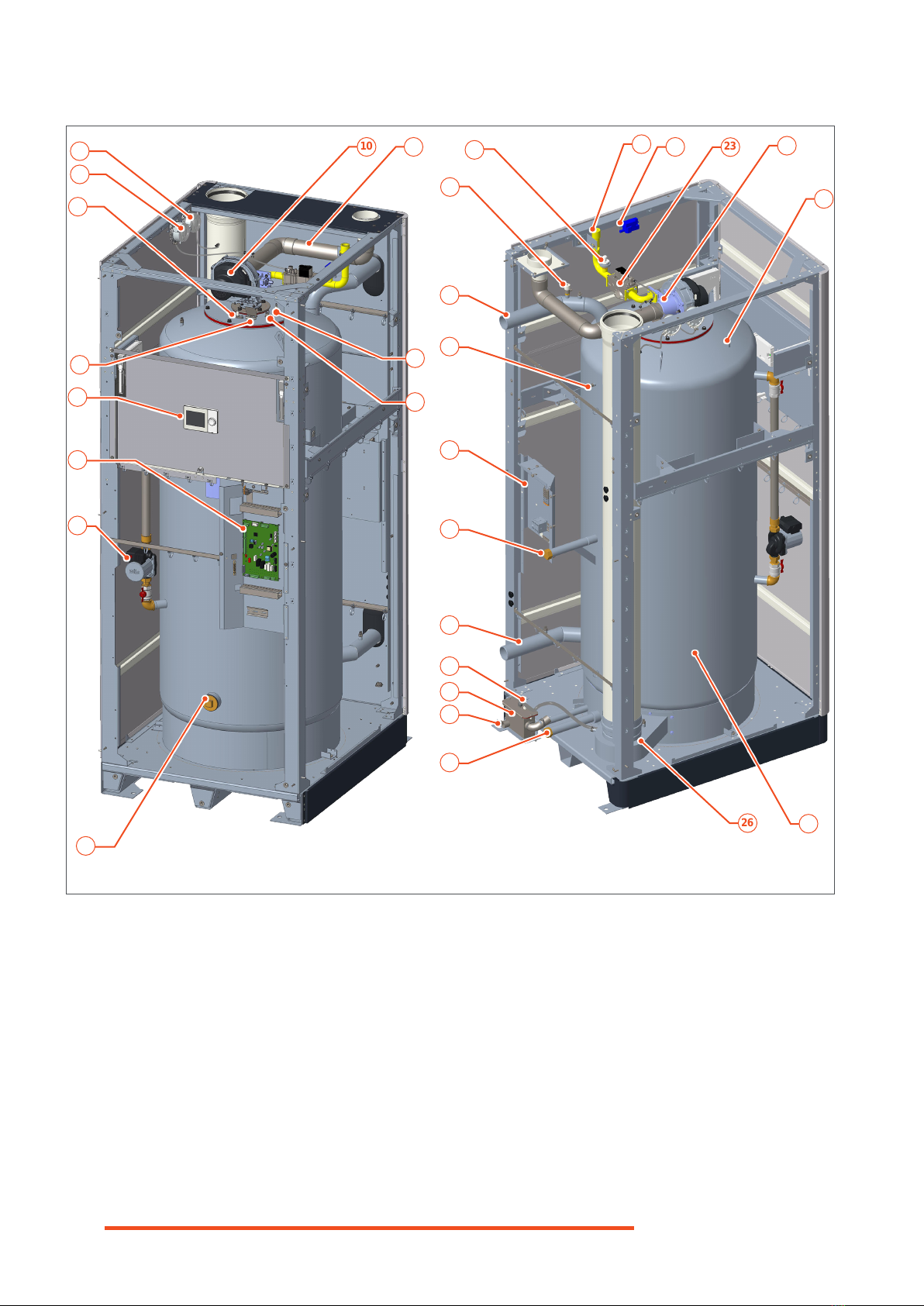

Fig. 4. TEXAS 99 - Inner Components - Front & rear views........ G-10

Fig. 5. TEXAS 230 - Inner Components - Front & rear views ..... G-11

Fig. 6. Control Panel...................................................................... G-12

Fig. 7. Typical Display.................................................................... G-13

Fig. 8. Single Appliance Clearances - View from the Top ........... G-15

Fig. 9. Appliance Transport and Installation................................... I-27

Fig. 10. Installing the Air Inlet Silencer........................................................... I-28

Fig. 11. Opening and Closing the Access Door and Panels........... I-29

Fig. 12. Inverting the Door Opening Side......................................... I-30

Fig. 13. Typical DHW Circuit ............................................................. I-35

Fig. 14. TEXAS 99 Gas Valve ........................................................... I-42

Fig. 15. TEXAS 230 Gas Valve......................................................... I-42

Fig. 16. TEXAS 99 - Shutter Pre-adjustment for Propane............... I-44

Fig. 17. TEXAS 230 - Shutter Pre-adjustment for Propane ............ I-44

Fig. 18. Fan Speed Adjustment - Typical Screen ............................ I-45

Fig. 19. Combustion Adjustment - Control Panel............................ I-46

Fig. 20. Combustion Adjustment on Gas Valves ............................. I-47

Fig. 21. Routing the Electrical Cables .............................................. I-48

Fig. 22. Accessing the Electronic Board and High & Low voltage

Terminal Strips...................................................................... I-49

Fig. 23. Filling the Water Heater - Typical......................................... I-54

Fig. 24. Combustion Adjustment on Gas Valves ............................. I-55

Fig. 25. Draining the Appliance - Typical.......................................... I-62

Fig. 26. Testing the Air Pressure Switch and Flue Pressure SwitchI-63

Fig. 27. Cleaning the Condensate Pipe and Trap............................ I-65

Fig. 28. Removing and Installing the Electrodes ............................. I-67

Fig. 29. TEXAS 99 - Removing and Installing the Fan/Venturi

Assembly and Gas Valve ..................................................... I-69

Fig. 30. TEXAS 230 - Removing and Installing the Fan/venturi/

Gas Valve Assembly............................................................. I-71

Fig. 31. Removing and Installing the Burner.................................... I-73

Fig. 32. Removing the Burner Plate.................................................. I-75

Fig. 33. Cleaning the Combustion Chamber ................................... I-76

Fig. 34. Descaling the Water Heater................................................. I-77