MOTOR TYPE 1.0 HP (.75 kw) electric, 115 VAC, 60 Hz, 8.3 amps, Single Speed, 3450 RPM, Thermally

Protected, Max. Ambient Temperature: 122° Fahrenheit (50°Celcius)

OUTLET SIZE 12” Diameter (305mm)

FLOW RATES

Free Air: 1866 cfm (3170 cmh)

15 ft. duct with one 90° bend: 1497 cfm (2458 cmh)

15 ft. duct with two 90° bends: 1282 cfm (2178 cmh)

4

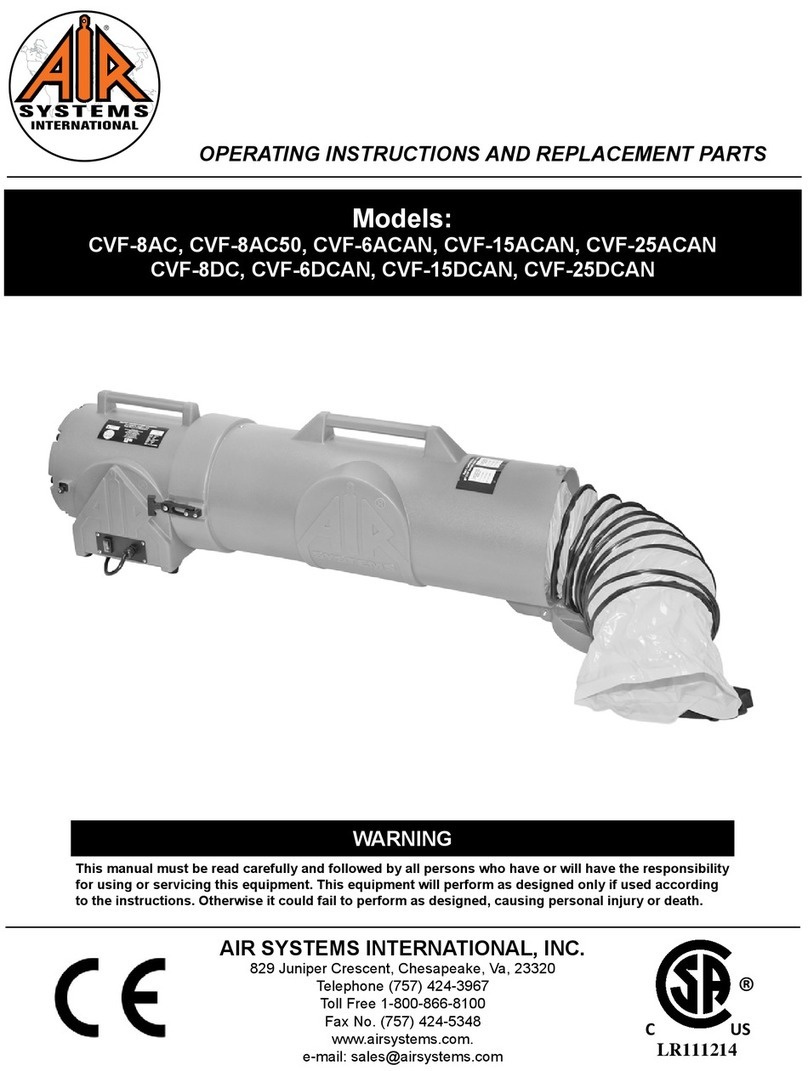

1) Place fan in a clean fresh air environment. Do not operate this fan in the vertical position.

2) Air quality of the conned space should be tested prior to ventilation. If air quality of the conned space is

unacceptable, consult a trained professional.

3) Inspect fan for damaged or worn parts and ducting for air leaks prior to fan operation.

4) Install duct cuff to exhaust ange and secure. Keep bends and kinks in ducting to a minimum to maximimize

air ow. If canister model is used, secure canister with rubber connect straps, open lid and pull out ducting. Inspect

for air leaks.

5) Set fan upwind from the work location and a minimum of 5 ft. (1.5m) from the manhole opening.

6) Connect CVF-12AC to power source, 115 VAC / 60 Hz / 15 amp. Use only GFCI protected receptacles.

Connect CVF-12AC50 to power source, 220 VAC / 50 Hz / 15 amp.

7) Push ON/OFF switch to “I” position to start.

PROBLEM POSSIBLE CAUSE SOLUTION

Excessive vibration

Air intake blocked Turn fan off and clear debris from intake.

Possible internal damage

Turn off and inspect fan blades, shaft, and housing

for debris, damage, and loose screws.

Note: Never run fan for extended periods without

installing duct on the exhaust ange.

Possible external damage Turn fan off and inspect for loose guards, broken

welds, etc.

Circuit breaker trips Voltage output insuf cient Test outlet with volt meter.

Motor Overheated Once motor cools, it will restart automatically

1) Remove the rubber isolation feet and screws from the metal inserts.

2) Install a threaded stud (male/male thread) into the 4 metal inserts.

3) Afx the fan to a location that will allow nuts to be installed on the threaded studs.

4) Put a threaded nut on each stud and tighten. The fan is now stationary.

General Set-Up And Operation

To Convert The Ventilation Fan To A Stationary Ventilator

Follow The Steps Below:

Troubleshooting

Specications - Model: CVF-12AC

Specications - Model: CVF-12AC50

MOTOR TYPE 1.0 HP (.75 kw) electric, 220 VAC, 50 Hz, 6.9 amps, Single Speed, 2875 RPM, Thermally

Protected, Max. Ambient Temperature: 122° Fahrenheit (50°Celcius)

OUTLET SIZE 12” Diameter (305mm)

FLOW RATES

Free Air: 1555 cfm (2642 cmh)

15 ft. duct with one 90° bend: 1248 cfm (2120 cmh)

15 ft. duct with two 90° bends: 1068 cfm (1815 cmh)