General Set-Up and Operation

For CVF-8AC, CVF-8AC50, and CVF-8DC Models

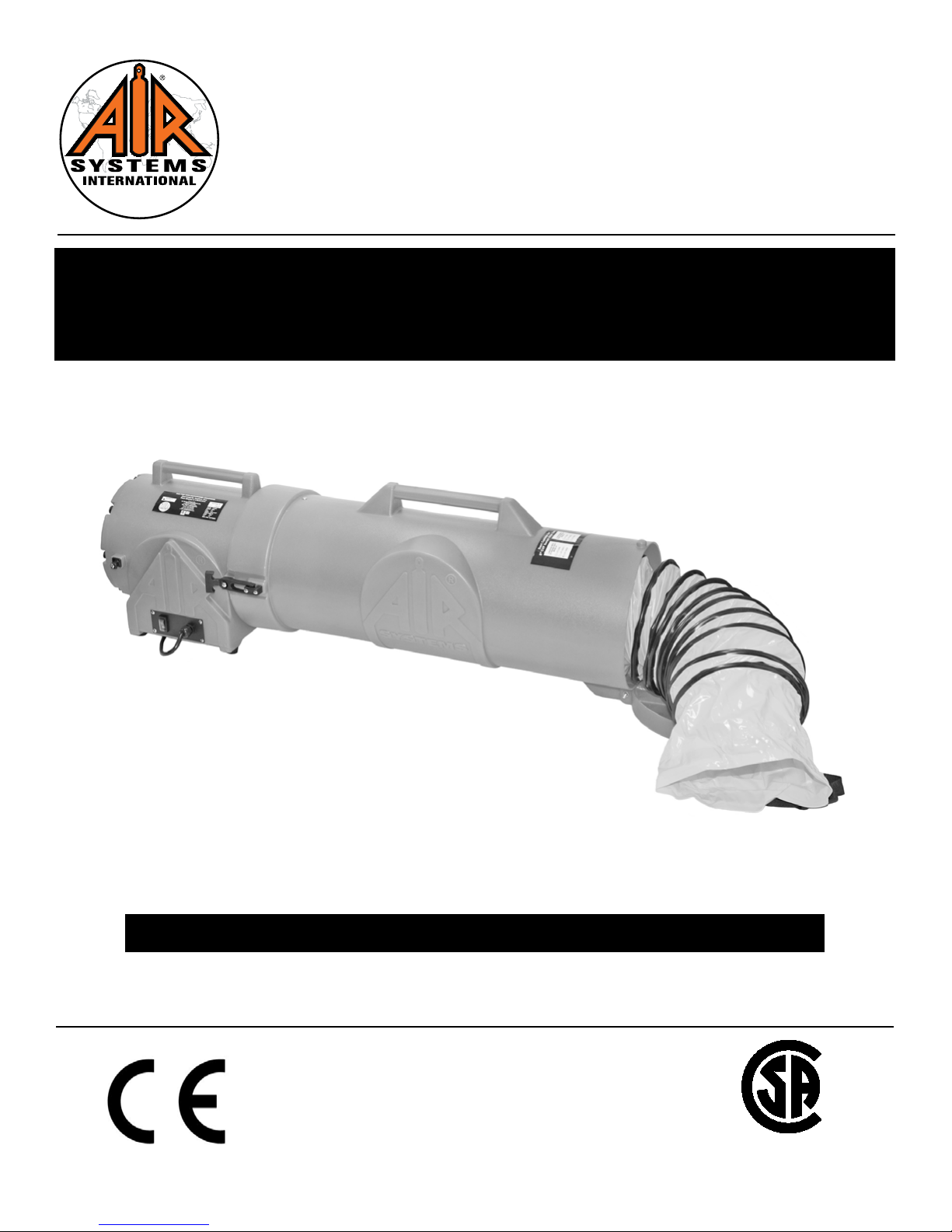

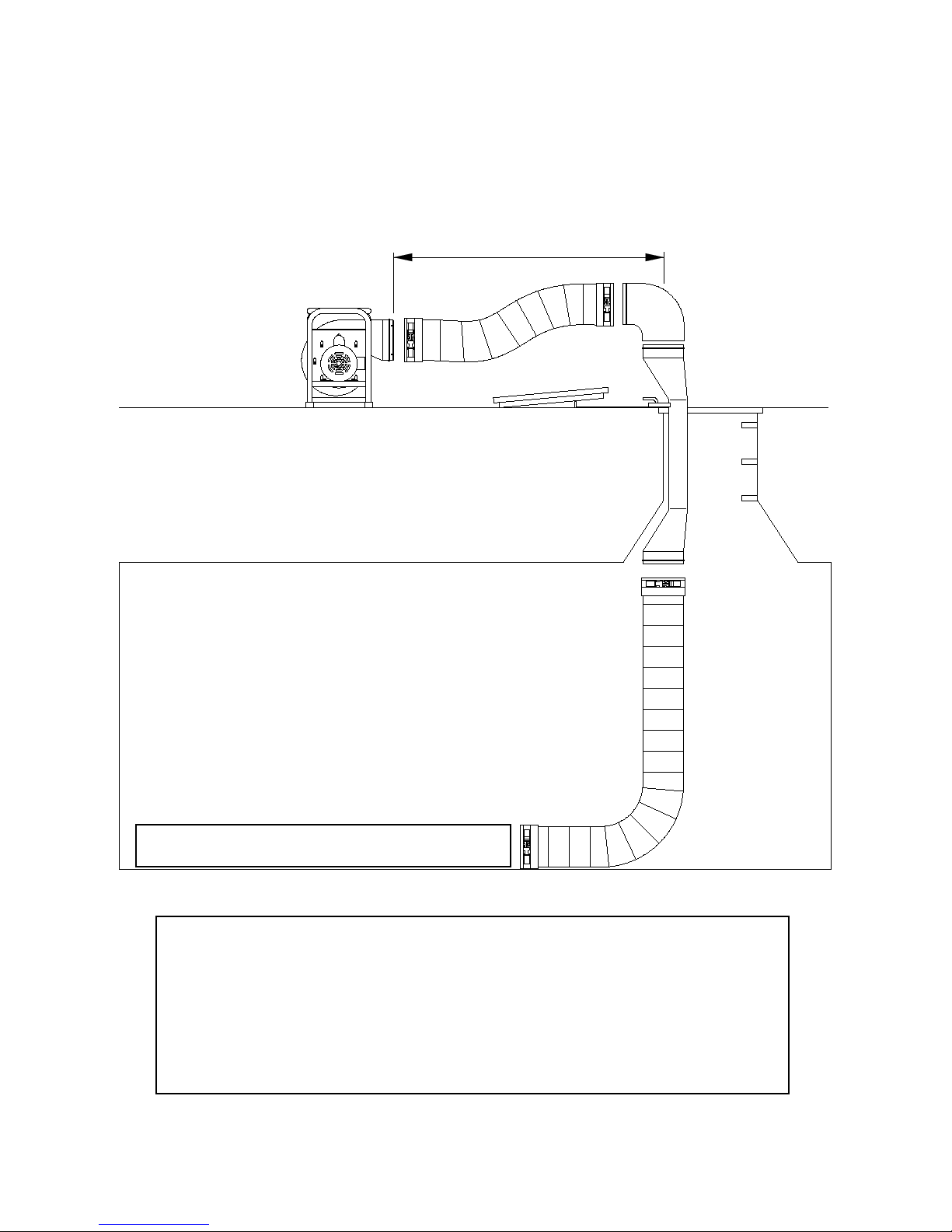

1) Place fan in a clean fresh air environment.

2) Air quality of the conned space should be tested prior to ventilation. If air quality of the conned space is

unacceptable, consult a trained professional.

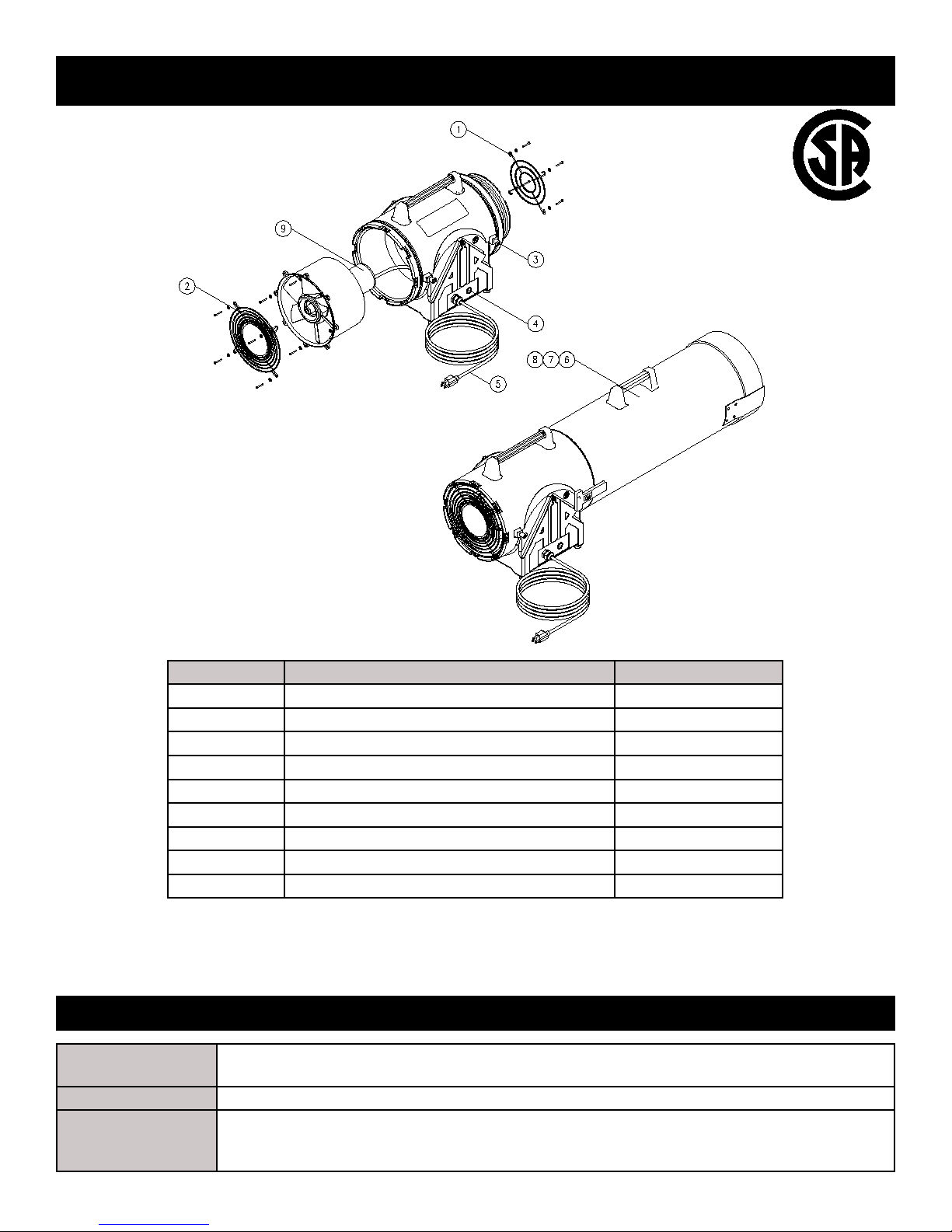

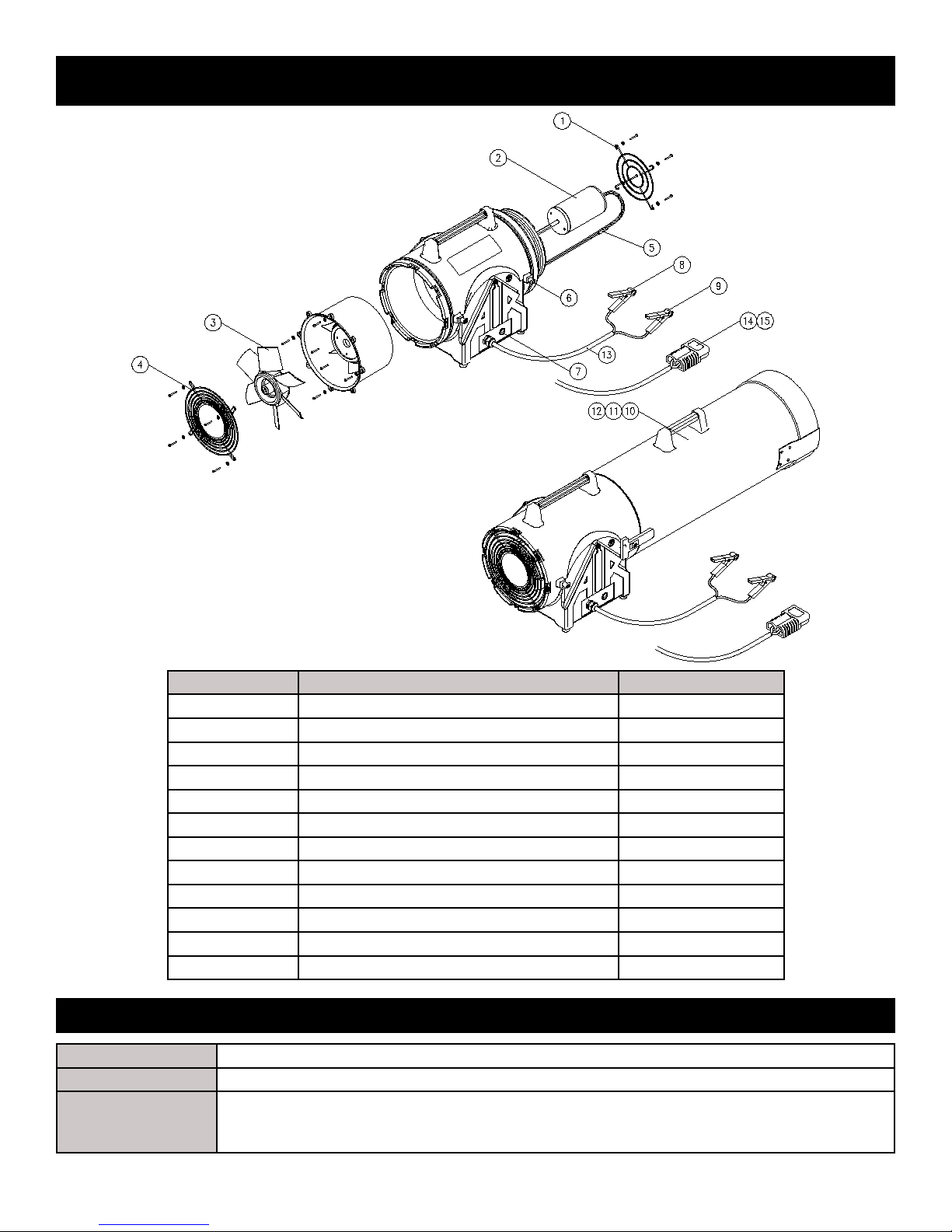

3) Inspect fan for damaged or worn parts and ducting for air leaks prior to fan operation.

4) Install duct cuff to exhaust ange and secure. Keep bends and kinks in ducting to a minimum to maximimize

air ow. If canister model is used, secure canister with connect straps, open lid and pull out ducting. Inspect

for air leaks.

5) Set fan upwind from the work location and a minimum of 5 ft. from the manhole opening.

6) Connect fan to power source.

AC versions require 115 VAC/60Hz, 15 amp service or 220 VAC/50Hz.

Note: If an extension cord is required, the minimum recommended size is 14 AWG up to

25 ft. For further information refer to the National Electric Code Tables, Article 400.

7) Push ON/OFF switch to “I” position on CVF-8AC and CVF-8DC models.

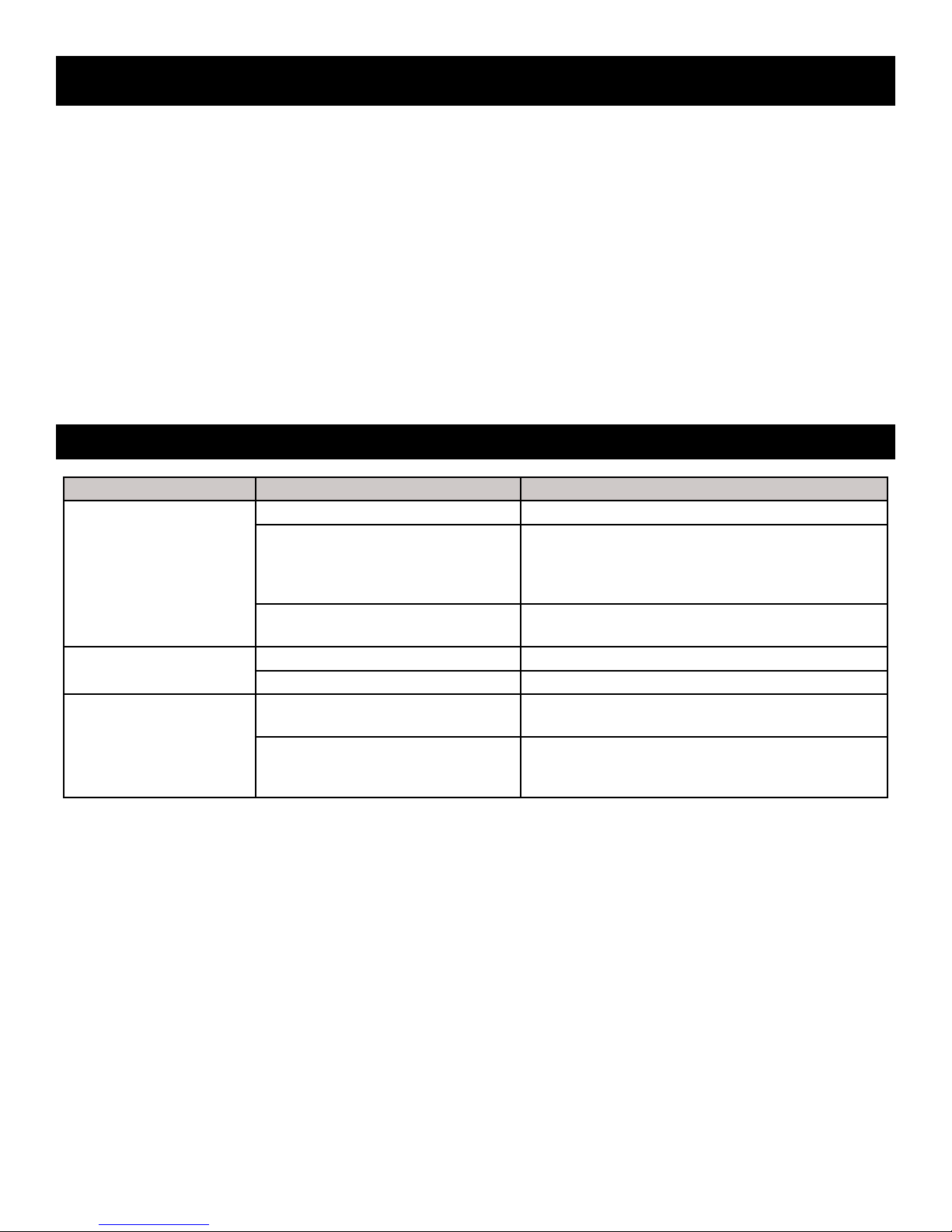

PROBLEM POSSIBLE CAUSE SOLUTION

Excessive vibration

Air intake blocked Turn fan off and clear debris from intake.

Possible internal damage

Turn off and inspect fan blades, shaft, and housing

for debris, damage, and loose screws.

Note: Never run fan for extended periods without

installing duct on the exhaust ange.

Possible external damage Turn fan off and inspect for loose guards, broken

welds, etc.

Circuit breaker trips

CVF-8AC series only

Voltage output insuf cient Test outlet with volt meter.

Extension cord improperly sized Use 14 AWG extension cord up to 25 ft.

Fan will not run

CVF-8DC only

Blown fuse (DC version only) Check and replace. Use only a 20A/32 VDC slow

blow fuse.

Battery connection

Ensure proper connection from battery clips to bat-

tery terminal posts. On battery pack units, recharge

battery.

4

Troubleshooting