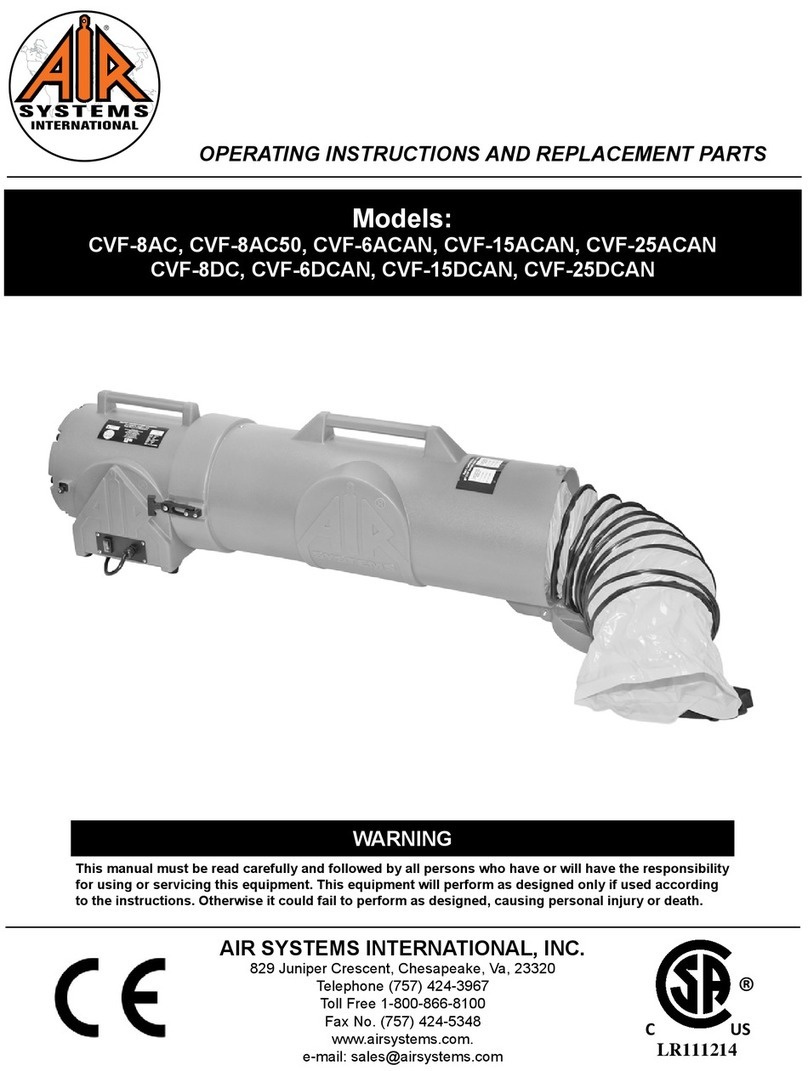

Typical Saddle Vent® Setup Procedure

Place fan or blower a minimum of

5 ft. (1.6m) from manhole opening

Blower or Fan

90° Elbow

Manhole

Opening

Manhole Lid

Universal Mount

Saddle Vent®

Select a blower or fan based on environmental

conditions and the size of the confi ned space.

For information or guidance in selecting the

proper set-up, please contact Customer Service.

STEP 1) Install 6 ft. (1.8m) duct on blower or fan

STEP 2) Install 90° elbow on top of Saddle Vent®

STEP 3) Install duct on bottom of Saddle Vent®

STEP 4) Install universal mount on Saddle Vent® and

set in place with manhole lid for support

STEP 5) Install duct from blower to 90° elbow

STEP 6) Turn on blower or fan

Warning: For explosive environments,

follow ANSI/API 2015 and 2016 procedures

The Saddle Vent® is a registered trademark of Air Systems International, Inc.

The Conductive Saddle Vent® is covered by U.S. and Foreign Patents

WARNING: HAZARDOUS LOCATION OPERATIONS

Use an explosion-proof or intrinsically safe blower or fan,

conductive ducting, and The Conductive Saddle Vent® System.

Attach all grounding wires and assure a complete circuit to the

blower or fan in order to remove static charges.

The Saddle Vent® Ventilation System

2

All ventilation procedures should comply with federal, state, and local regulations. Air quality should be tested

prior to ventilating a confi ned space. Air quality should be tested continuously during confi ned space occupancy to ensure

a stable atmosphere and worker safety as atmospheric conditions can change rapidly. Additional procedures and recom-

mendations are available from federal, state, and local agencies. DO NOT operate these fan units in a vertical

position or with the ange or guards removed.

If volatile or explosive vapors are suspected, use Air Systems’ explosion proof electric blower, Model SVB-E8EXP, explo-

sion proof in-line fan, Model SVF-10EXP, explosion proof contractors fan, Model CVF-8EXP or Air Systems’ intrinsically

safe pneumatic blower, Model SVB-A8.

Note: For confi ned space ventilation in non-hazardous locations, use Air Systems’ confi ned space ventilation kit, Model

SV-CUP. For hazardous locations use ventilation kit, Model SV-CUPCND along with one of the above explosion proof

blowers or fans.

SAFETY PRECAUTIONS

READ AND FOLLOW ALL INSTRUCTIONS BELOW

WARNING

Fan and blower models with the “EX” or “X” designation are the only models

approved for use in hazardous locations.

WARNING

Explosion proof models should be fi tted with an approved explosion proof plug.

The plug should NOT be connected or disconnected in an explosive environ-

ment when the blower is energized. The use of conductive ducting is recom-

mended when operating in potentially explosive environments. Install ground-

ing cable from blower to a grounded source.