OVERVIEW IMPORTANT SAFETY INFORMATION IS ENCLOSED.

Read and follow all instructions before using these vacuums. Please read them carefully since

failure to follow these precautions could result in injury. When using electrical equipment basic

safety precautions should always be followed.

Warning: The basic vacuum is designed for dry/damp pickup. Do not attempt to

pickup liquids under any condition without using an automatic shut off assembly.

When using the electrical vacuum, basic precautions should always be followed.

The following warnings should be adhered to reduce the risk of fire, electrical shock or

injury:

1. DO NOT leave vacuum when plugged in. Unplug from outlet when not in use and before

servicing.

2. Electric shock could occur if used on wet surfaces. DO NOT expose to rain. Store

indoors.

3. Use only as described in this manual. Use only Air Systems' recommended attachments

and replacement filters.

4. DO NOT use with damaged cord or plug. If vacuum is not working as it should because it

has been dropped, damaged, left outdoors, or dropped into water, return it to Air Systems

for servicing. Call 1-800-866-8100 for a return authorization number. Do not return

contaminated vacuums.

5. DO NOT pull or carry by cord or use cord as a handle. Keep cord away from heated

surfaces.

6. DO NOT unplug by pulling on cord. To unplug, grasp the plug, not the cord.

7. DO NOT handle plug or vacuum with wet hands.

8. DO NOT put any objects into motor openings. Do not use with openings blocked.

9. DO NOT vacuum up anything that is burning or smoking, such as cigarettes, matches, or

hot ashes.

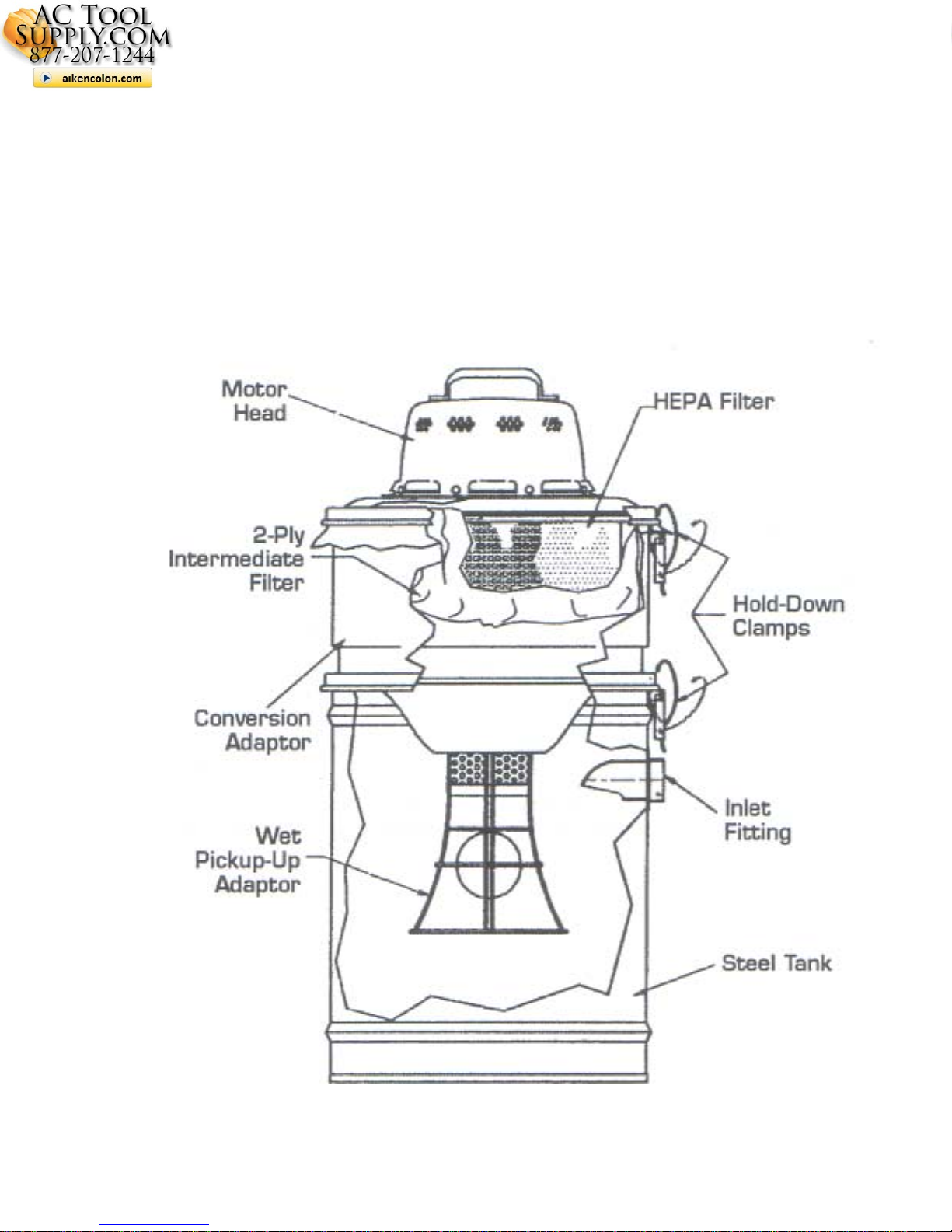

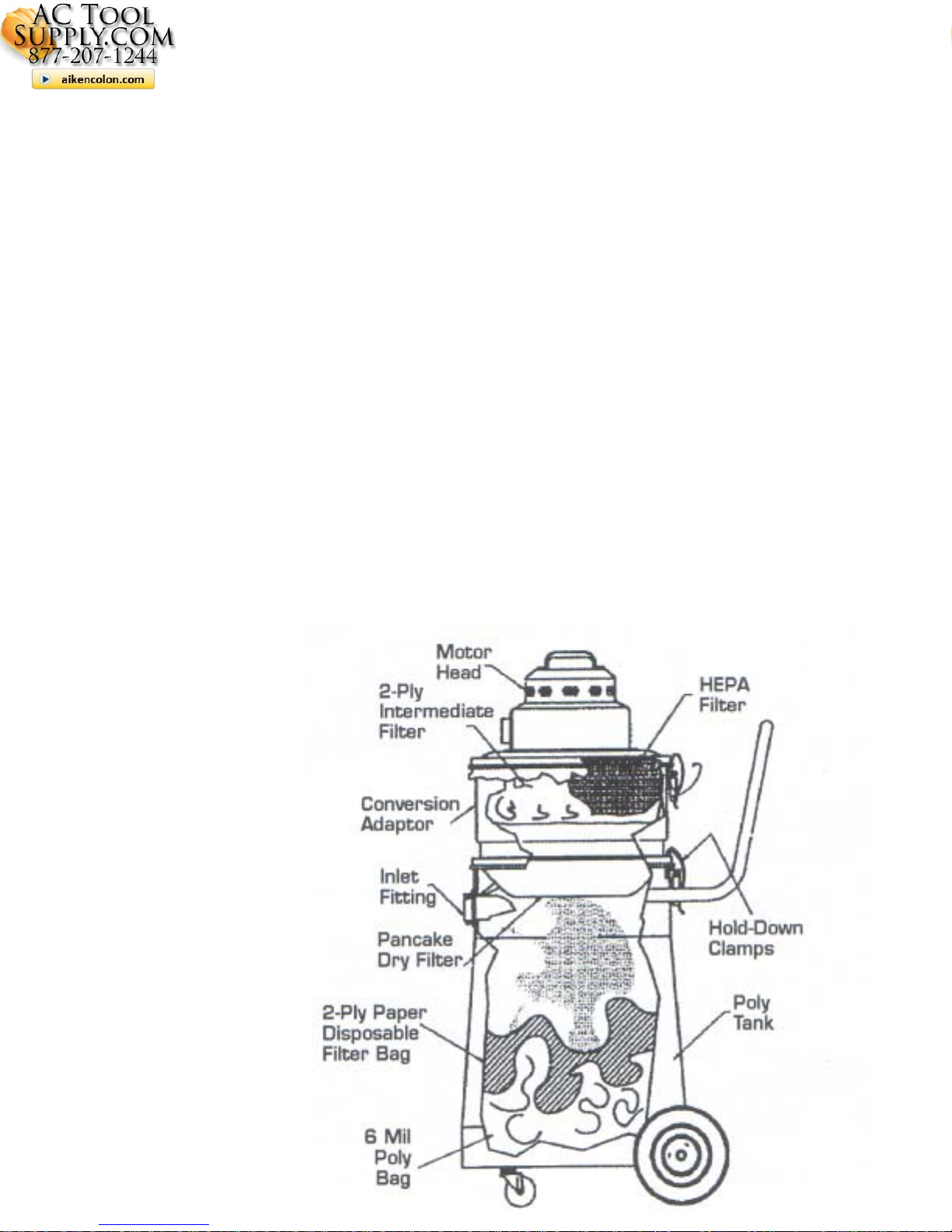

10. For toxic dusts, do not use without paper filter bag, intermediate filter, and HEPA filter

properly installed.

11. DO NOT use in areas where flammable or combustible liquids, such as gasoline, may be

present.

12. DO NOT use where oxygen or anesthetic gases are used.

13. DO NOT use an extension cord unless absolutely necessary. If an extension cord is used,

then wire size must be 14/3 or larger and should not exceed 50 feet in length. Extension

cord must be a three-wire type to insure "grounding" protection.

14. Replace damaged or worn parts immediately with genuine original equipment parts to

maintain safety and to protect your limited warranty.

Note: Absolute HEPA filtered vacuums meet ANSI Standard Z9.2-1979 with UL-586

tested and labeled HEPA filter.