Couriering the

Airbow® Framer

anywhere.

Airbow® Framer

is to be transported

via air travel

There is a

suspected issue

with the Airbow®

Framer onboard canister.

Before any repairs

are done to

the Airbow® Framer.

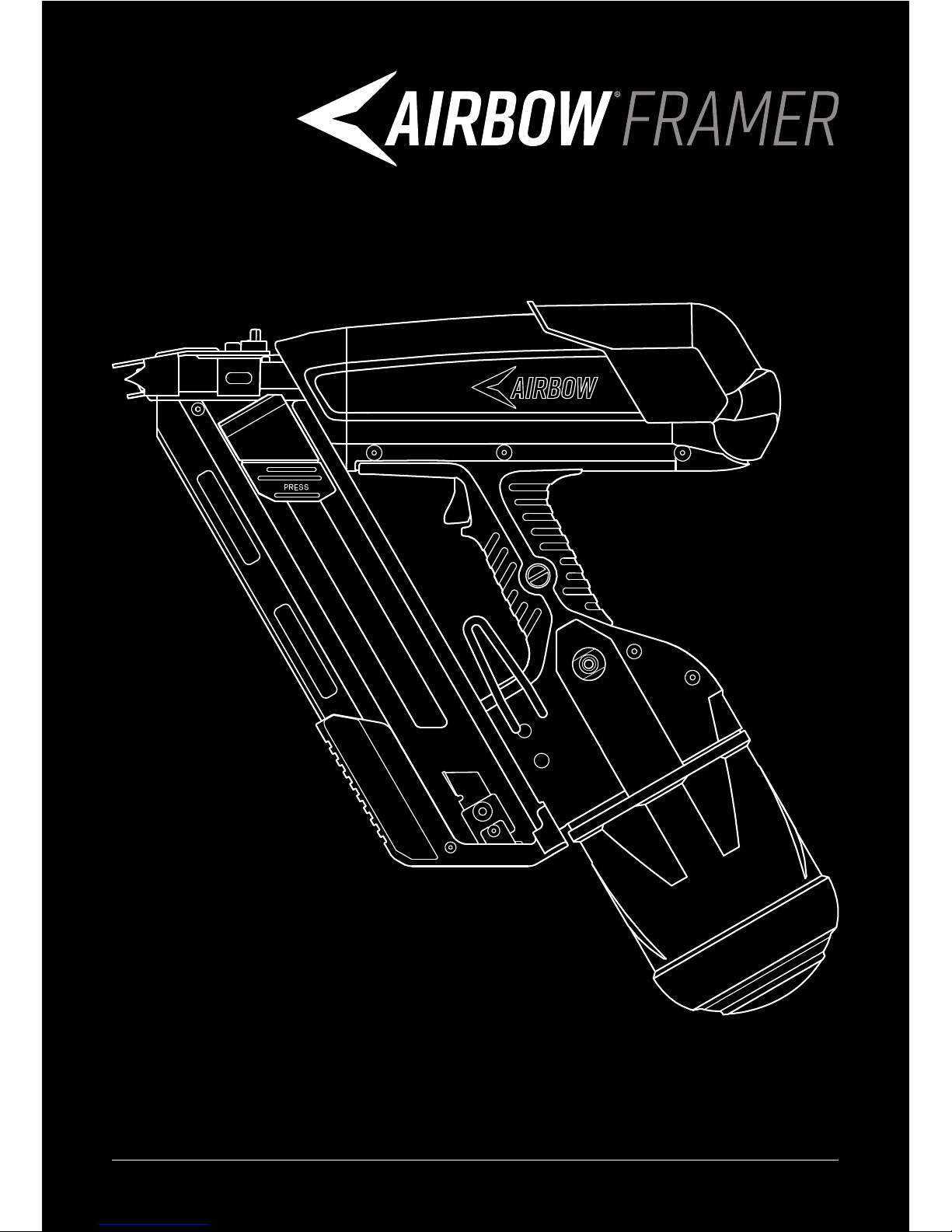

LONG TERM STORAGE BASIC TROUBLESHOOTING FOR FIRST USE:

For long term storage open

Cylinder Pressure Release

Valve to release all pressure

(listen for air release) from

the Onboard Canister. Leave

valve open until next use.

Full Troubleshooting Guide is available on-line at

www.airbowsystems.com

Important

Releasing all pressure from

the onboard canister must be

undertaken when:

General Safety:

• Always store your Airbow®

Framer in the case provided.

• Avoid leaving your Airbow®

Framer in direct sunlight for

prolonged periods. Refer to

the full Airbow® Framer Manual

for pressure related variations

relating to heat (online

at www.airbowsystems.com).

Airbow® Framer Quick Guide 1514 Airbow® Framer Quick Guide

Onboard

Canister

Firing Chamber

Open Cylinder

Pressure Release

Valve

Airbow® Framer doesn’t fire

• Check the Cylinder Pressure

Release valve is closed.

• Check your Airbow® Framer

is topped up with Air.

• Check that your high pressure

compressor is operating correctly

and that its pressure release

valve is closed.

• Check your Airbow® Framer

is Re-cocked (to charge Firing

Chamber).

• Check you have nails loaded.

You can hear air escaping from

Airbow® Framer

• Your Cylinder Release Valve may

not be closed completely.

Dry Firing (No nail driven on fire)

• Paper issue. Some paper collated

nails will deposit small amounts

of paper into the guiding

components of the magazine

during the firing process.

• If you are experiencing dry fires,

do not continue to fire the tool.

• Check to see if any paper

is visible at the top of the

magazine. If easily cleared, do so.

• If not easily cleared, remove

all nails from the magazine.

• Depress the safety relief valve

to release pressure from the

firing mechanism and then

clear any pieces of paper or glue

that have been deposited

(refer to Clearing a Nail Jam).

Nails aren’t firing home

• Check your Nose Depth

Adjustment setting.

• Check the pressure in your

Airbow® Framer.

• Check that your high pressure

compressor is operating correctly

and that its pressure release

valve is closed.

• Check Cylinder Release Valve

is closed completely (if air

is escaping the Firing Chamber

won’t refill quickly enough

with air).

• Check correct collated nails

are being used.

Note: It is safe for the Airbow®

Framer’s onboard canister to remain

under pressure during normal daily

transportation by motor vehicle

however we recommend pushing the

Safety Pressure Release button (rear

of Re-cock Lever) to depressurise

& isolate the Firing Chamber for

transportation as a safety precaution.