Advanced Airport Lighting System

3

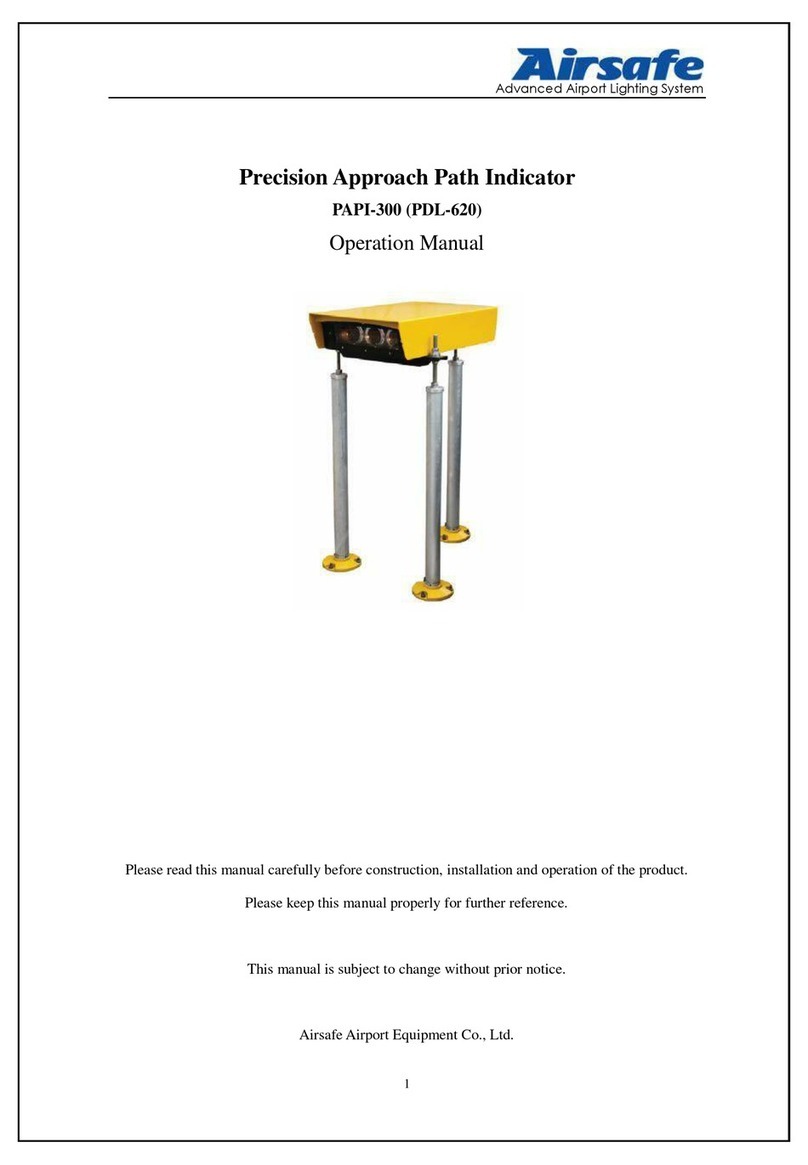

Table of Content

1.0 Foreword.......................................................................................................................................5

1.1 Illustrations and Meanings....................................................................................................6

1.2 Safety Rules and Notices ......................................................................................................7

1.3 Quality Assurance and Responsibility...................................................................................8

2.0 Introduction...................................................................................................................................9

2.1 Technical Specifications......................................................................................................10

2.2 Application Environment ....................................................................................................10

2.3 Application Scope ...............................................................................................................10

2.4 Technical Parameters...........................................................................................................11

2.5 Technical Features...............................................................................................................13

2.6 Structure..............................................................................................................................15

2.6.1 Key Components of Upper Box...............................................................................15

2.6.2 Key Components of Landing Leg Assy ...................................................................16

2.7 Interpretation of System Terminology ................................................................................17

2.7.1 Elevation ..................................................................................................................17

2.7.2 Key Buttons and Plug-ins.........................................................................................17

2.7.3 Two Working Conditions and Four Modes ..............................................................20

2.7.4 Power Supply of PAPI..............................................................................................26

3.0 Installation of Lighting Fixtures..................................................................................................28

3.1 Location of PAPI system.....................................................................................................28

3.2 Boundary Dimension ..........................................................................................................29

3.3 On-site Installation of PAPI Lighting Fixtures....................................................................30

3.3.1 Flange Fixation.........................................................................................................33

3.3.2 Installation of Legs...................................................................................................36

3.3.3 Same Height Setting of Lighting Fixtures................................................................38

3.3.4 System matched power/communication cable selection..........................................41

3.3.5 Electrical Wiring of Lighting Fixtures .....................................................................43

3.3.6 Adjustment and Setting of Lighting Fixture Elevation.............................................47

4.0 Flight Calibration Inspection and Adjustment of Lighting Fixtures ...........................................50

4.1 Disposal after Flight Calibration.........................................................................................51

5.0 Replacement of Components of Lighting Fixtures .....................................................................54

5.1 How to Replace Light Source Assembly.............................................................................55

5.2 How to Replace Main Control Board..................................................................................57

5.3 How to Replace Digital Display Panel................................................................................58

5.4 Replace Terminal Block......................................................................................................60

6.0 Maintenance of Precision Approach Path Indicator....................................................................61

6.1 Daily Inspection and Maintenance......................................................................................61

6.1.1 Daily Inspection and Maintenance Items.................................................................61

6.1.2 Troubleshooting of Common Error of Control Board..............................................63

6.1.3 Inspection Method of Elevation...............................................................................65