AirTest PT9250 & CO2Application Guide 10 of 12

Calibrate You And Your Customers:

The AirTest PT 9250 is an ideal tool that can be

used to calibrate you and your customers to CO2

and ventilation. Recently a contractor was

loaned a PT9250 with the cfm/person display

function. Within two weeks the building owner

walked many of his buildings, resolved three

indoor air quality complaints and decided to

retrofit two buildings that were undergoing

renovation, with CO2based ventilation control.

A written application guide like this one can be

very useful in understanding how to use and

interpret ventilation measurements with CO2.

However, hands on experience, and seeing and

sensing what various ventilation rates and

corresponding CO2concentrations are, can take

the place of a multi-hour training course.

Here are a few suggestions on how you can

calibrate yourself to CO2and ventilation.

•Experiment with how blowing in the vicinity

of the sensor will affect its reading. How

long does it take to recover?

•Find out what outside concentrations are

typically in your area. Check it out on a few

different days and locations. Does it matter if

you are close to a highway or major

intersection, near a lake, in the suburbs, or in

the middle of the city? Are outside

concentrations different above street level?

•Carry the PT9250 around with you for a day.

Measure at home, at the office, in meetings,

in your car or in an airplane. Note the CO2

and ventilation rate and see if you can sense

areas that have more fresh air than others. If

you note the time you are in various areas,

you can download the data logged

information for the day and see what the CO2

levels where throughout the day.

•When entering a space note how CO2levels

rise and eventually stabilize in a space.

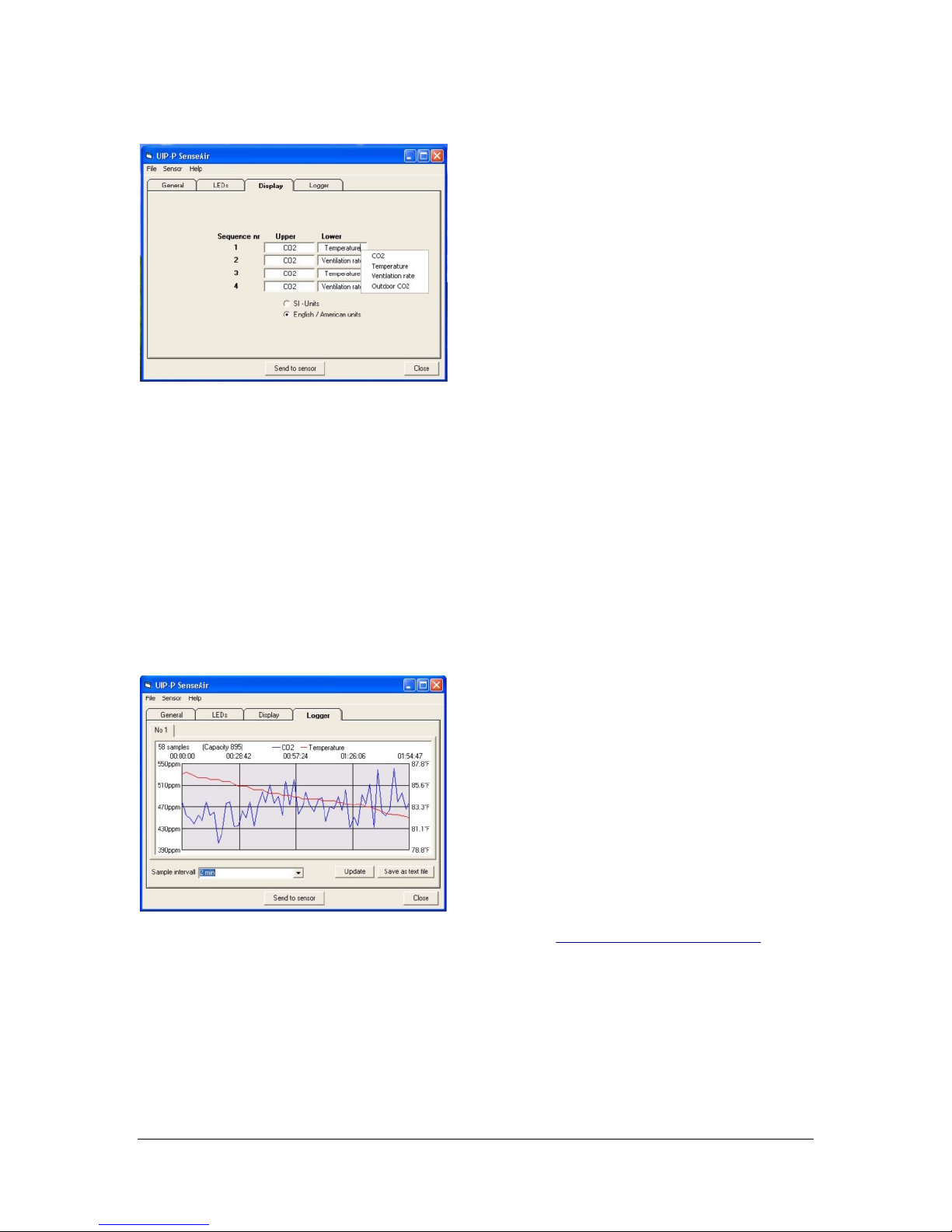

•Attach the PT9250 to your desk PC using

the software provided, and periodically press

update to view the history of CO2in the

space. You can also use this as a tool for

training others.

•Hold the PT9250 near the exhaust of a car

or truck. How much CO2is produced?

•Open a couple of carbonated drinks in a

closed room and see what happens.

•If CO2levels are high in the space, see how

quickly levels change when you open a

window or a door.

Dealing With IAQ Complaints:

Many symptoms related to indoor air quality

(IAQ) complaints can also be associated with

other physical ailments, stress, or emotional

issues related to the individual. If you are

involved in investigating a suspect IAQ problem

you can use the PT9250 to determine if

ventilation is a factor in the complaint or concern.

Most buildings by code must be provided with 15

to 20 cfm/person of outside air to ensure

adequate air quality. You can use the PT9250 to

benchmark your building to ensure you meet

these or other code required levels.

One school maintenance person keeps a number

of PT9250 sensors on hand to loan to teachers if

they have a concern with the ventilation rate in

their classroom. If by measuring over a few days

the teacher finds reduced ventilation rates, the

maintenance people can adjust air delivery to the

space. More often than not, the maintenance

person has found the ventilation is sufficient and

that use of the PT9250 convinces the teacher

that lack of fresh air is not the problem.

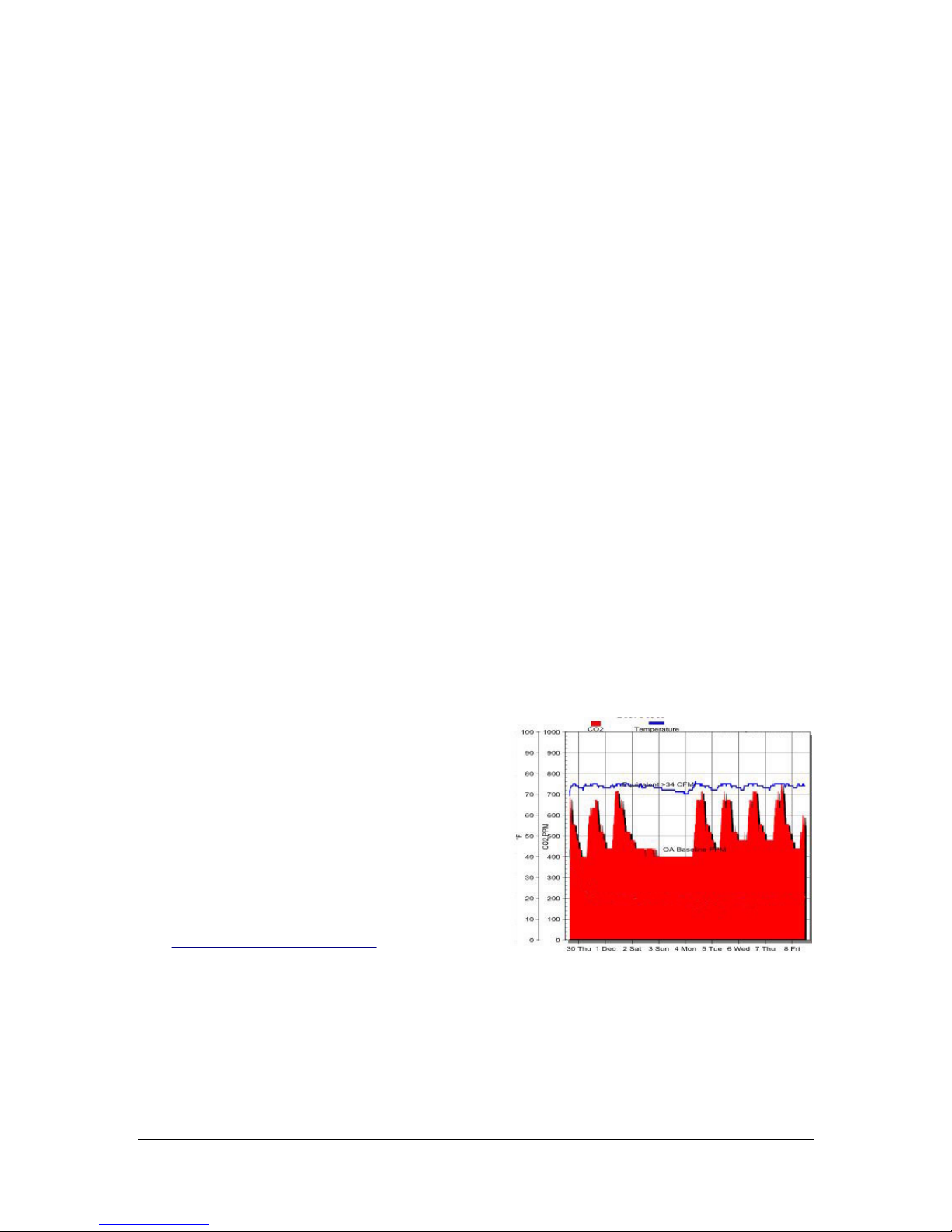

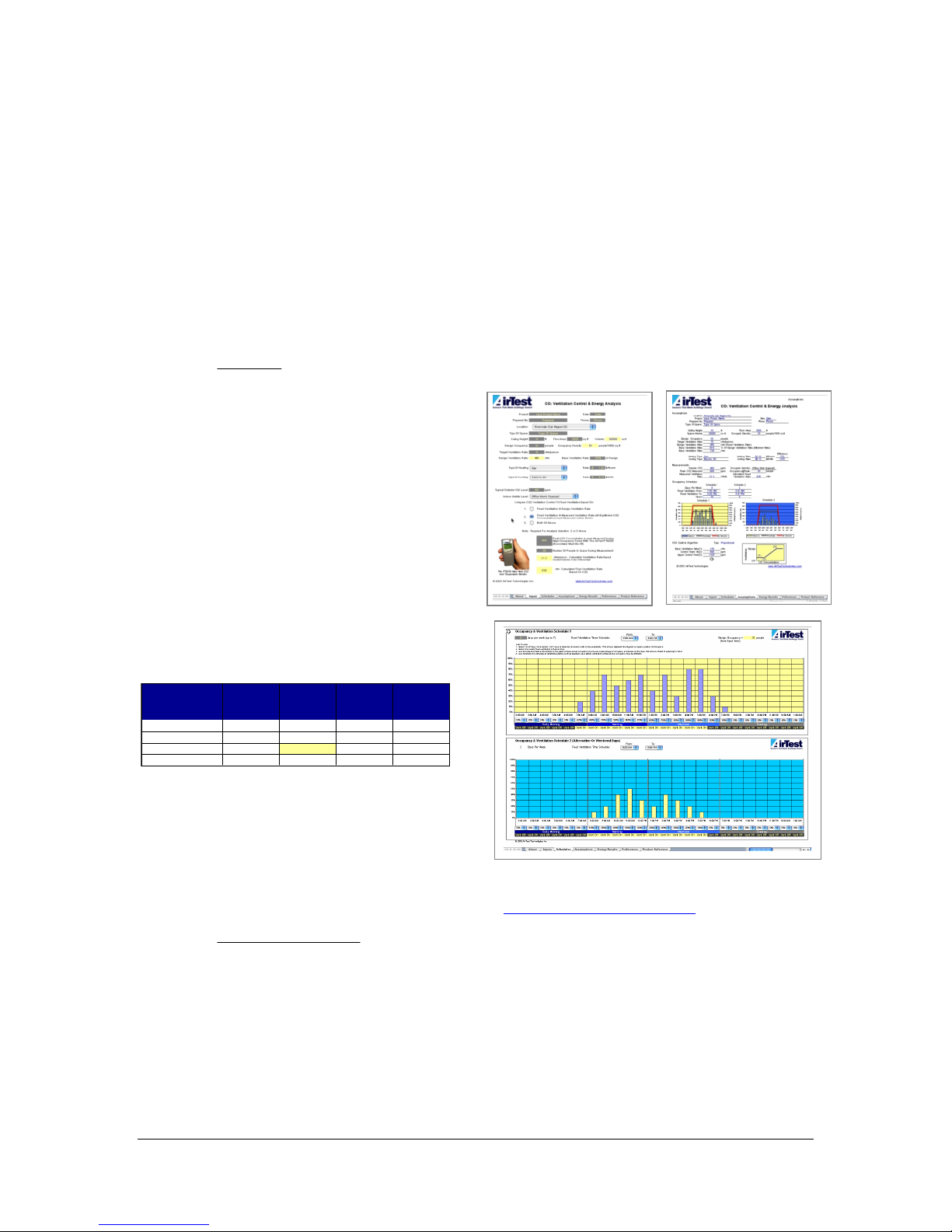

Baseline Monitoring As A Business:

Many building owners are now looking to third

parties to inspect and monitor their buildings to

ensure they are providing a good environment for

their tenants.

A number of contracting and consulting firms are

using the PT9250 to benchmark various areas of

a building several times per year. The data-

logging feature is ideal for providing a clearly

documented report on building operating status

as it relates to ventilation.

This process can provide peace of mind to

building owners and occupants and can also be

used to quickly identify potential problems with air

intakes or the mechanical systems within a

building.

I Smell Combustion Fumes:

While people produce CO2, it also is one of the

major components of combustion fumes (8 to

11% by volume). As a point of comparison, a

medium sized, residential high-efficiency furnace

produces as much CO2as about 160 people. If

CO2levels in a space seem excessively high

(e.g. over 4,000 ppm) unwanted combustion

fumes may be present. Here are some examples

of how elevated CO2concentrations can be used

as a diagnostic for combustion fumes:

•Check areas around building air intakes to

see if idling vehicles are venting into the

building (especially an issue with schools).