Page 6 / 24

WARNING ! SAFETY INSTRUCTIONS

Please read this manual carefully before using the device.

•This air conditioner is designed exclusively for domestic use.

•It is suitable for indoor use only.

•Please only use the accessories provided by the manufacturer of the air

conditioner. Otherwise, it could be damaged.

•This air conditioner can be used by children aged 8 years and over and people with

reduced physical, sensory or mental abilities or lack of experience and knowledge, if

they are supervised or have received instructions for using the air conditioner.

appliance in a safe manner and understand the risks involved.

•Children should not play with this air conditioner.

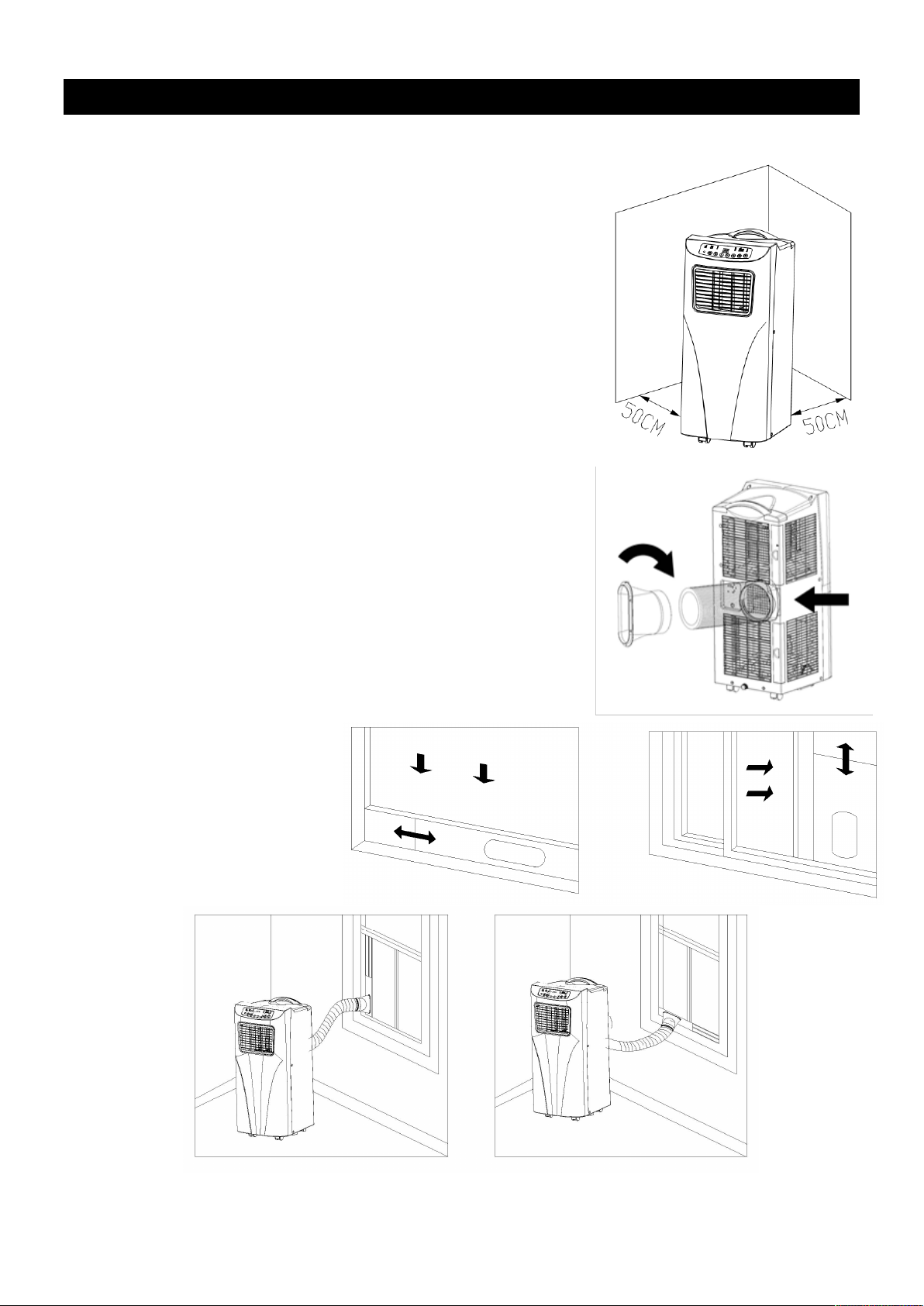

•Make sure that the air conditioner is always placed on a flat, dry and stable surface.

•The air conditioner should be placed away from heat sources and out of direct sunlight.

•Do not install the air conditioner in a place exposed to water or any other liquid.

Make sure that water or any other liquid cannot enter the air conditioner.

•Do not use the air conditioner in the presence of explosive or flammable vapors.

•Never leave the air conditioner running unattended.

•Do not insert your fingers or other objects into the vent outlet.

•Regularly check the power cable. Do not use in case of damage to the power

cable, electrical outlet or air conditioner.

•If the cable or flexible outer cord of this air conditioner is damaged, it must be

replaced exclusively by the manufacturer or its service agent or a person of

equivalent qualification, in order to avoid any risk.

•The voltage of the electrical outlet must comply with the requirements. Any damage

resulting from incorrect power supply is not covered by the warranty.

•When unplugging the power cord, always pull it by the plug, do not pull on the

cord itself.

•An extension cord can be used if the power cable is too short. Be careful not to

place the cord in places where it could be torn off.

•Do not handle the plug or the air conditioner with wet hands.

•Cleaning and user maintenance shall not be made by children without

supervision.

•Follow the instructions in this manual for cleaning the air conditioner.

•Always unplug the air conditioner from the electrical outlet when the air

conditioner is not in use, before moving it or cleaning it.

•Do not use chemicals or abrasive detergents for cleaning, which could easily

damage or deform your air conditioner.

•Never attempt to disassemble or repair the air conditioner yourself. Any possible

risk incurred due to maintenance by an inexperienced person would constitute a

violation of the provisions of the guarantee.