TABLE OF CONTENTS

SPECIFICATIONS ..............................................................................................................................................................

TABLE OF CONTENTS ......................................................................................................................................................

SERVICING NOTICES ON CHECKING .............................................................................................................................

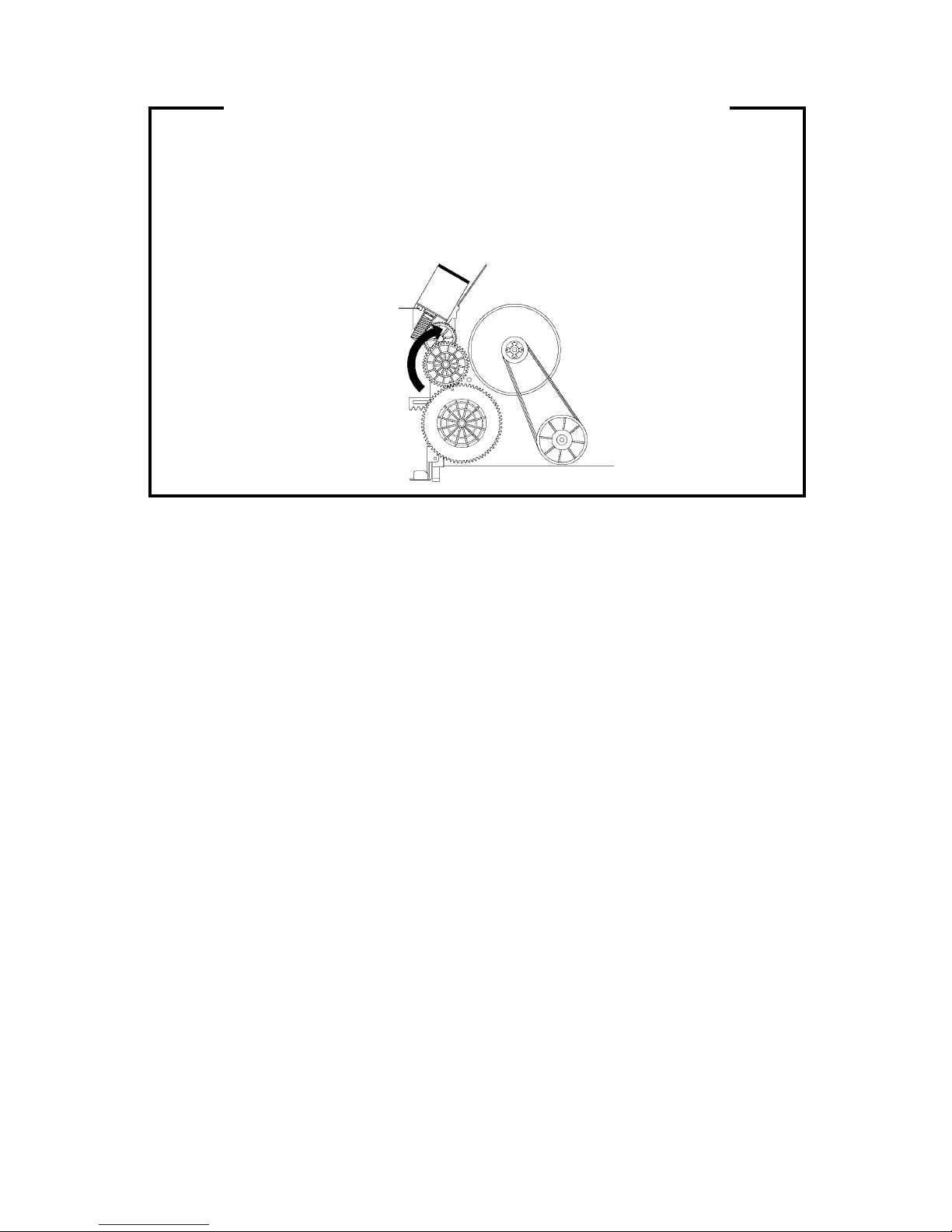

TAPE REMOVAL METHOD AT NO POWER SUPPLY......................................................................................................

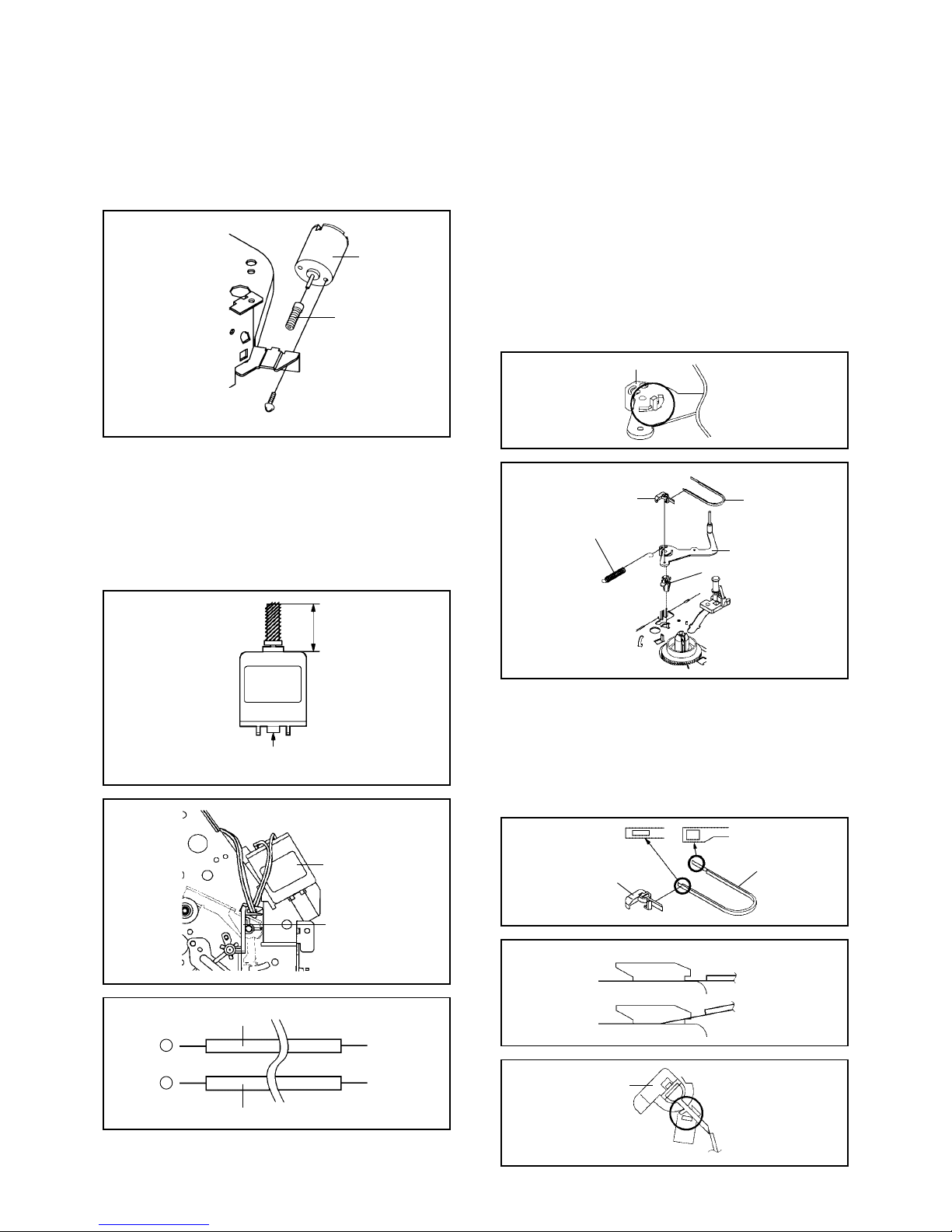

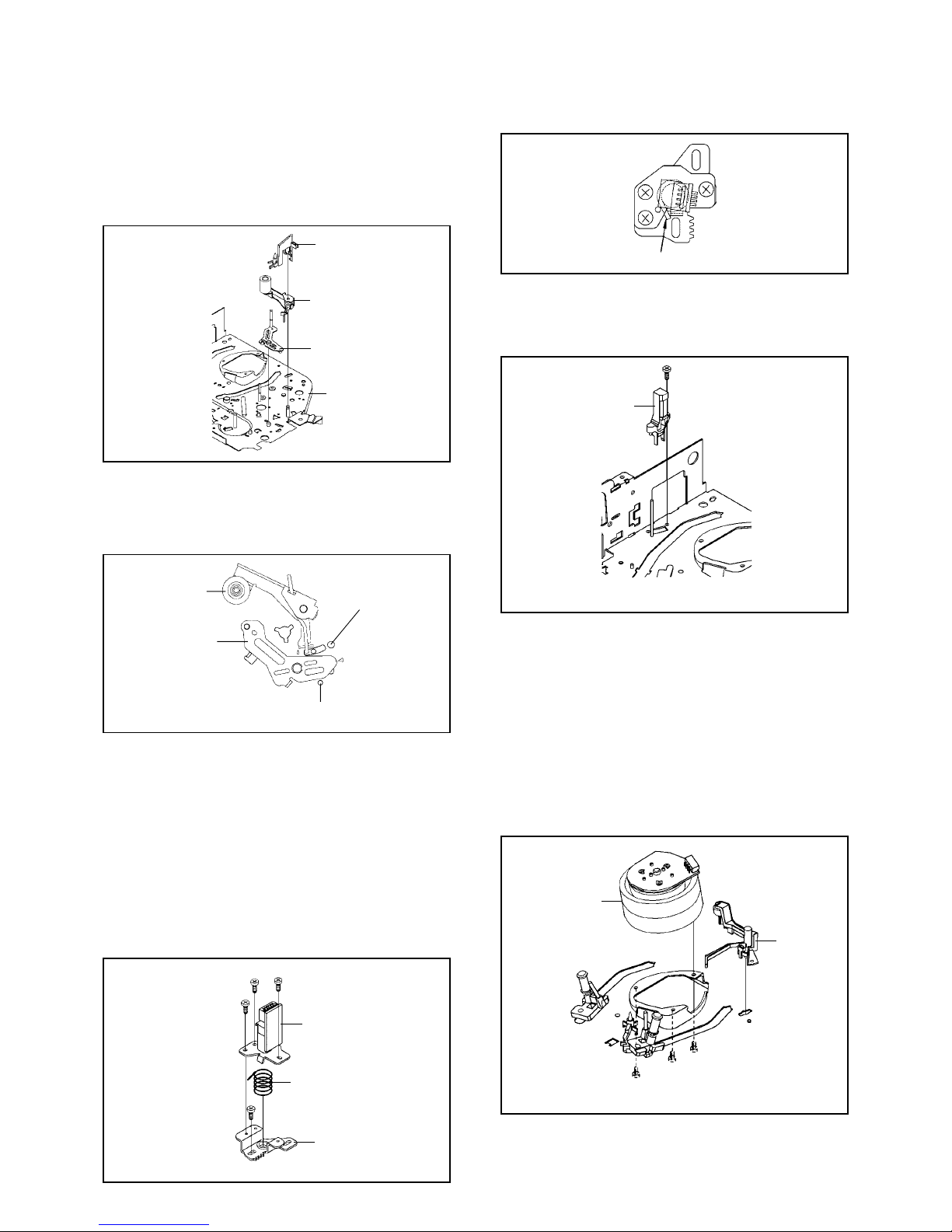

DISASSEMBLY INSTRUCTIONS

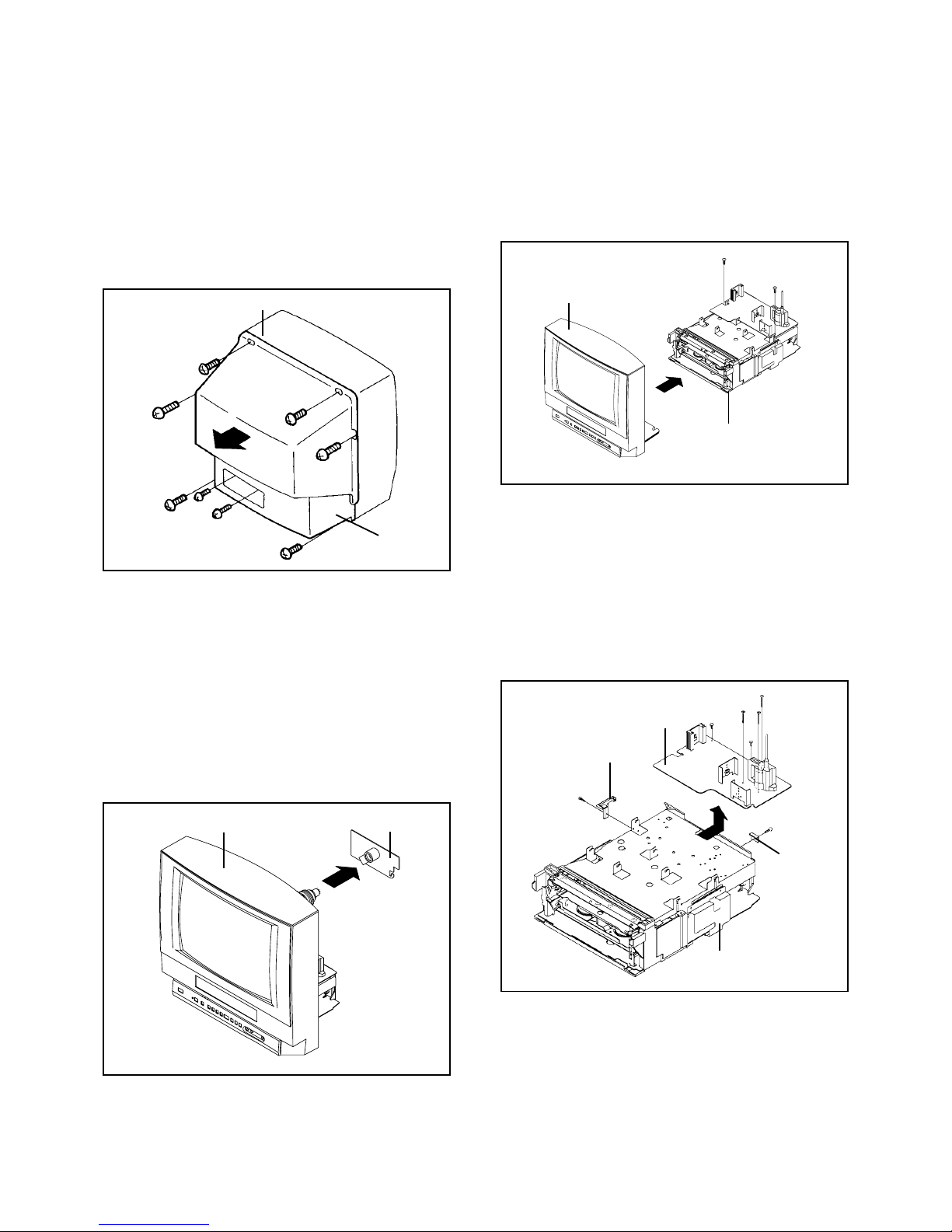

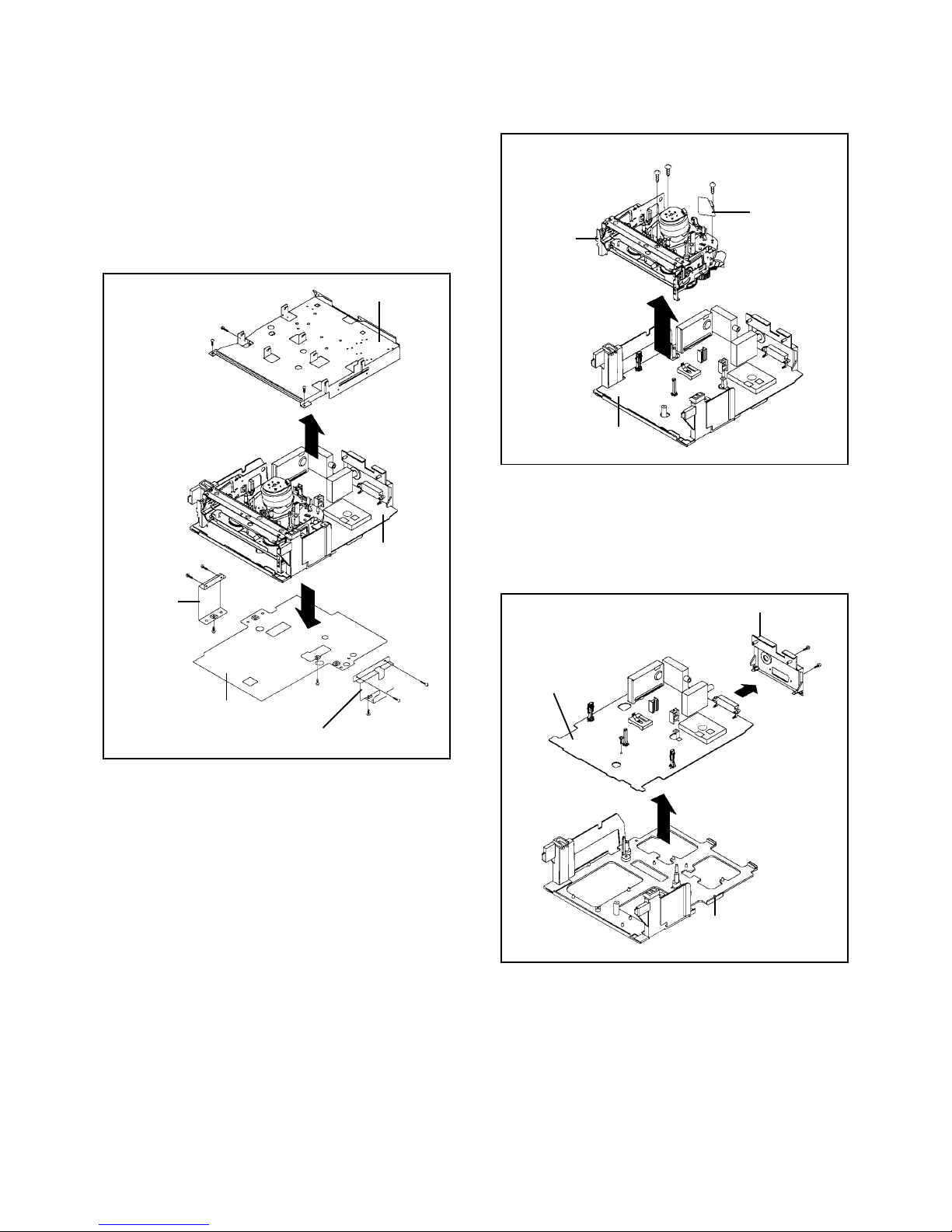

REMOVAL OF MECHANICAL PARTS AND P.W. Boards ..............................................................................................

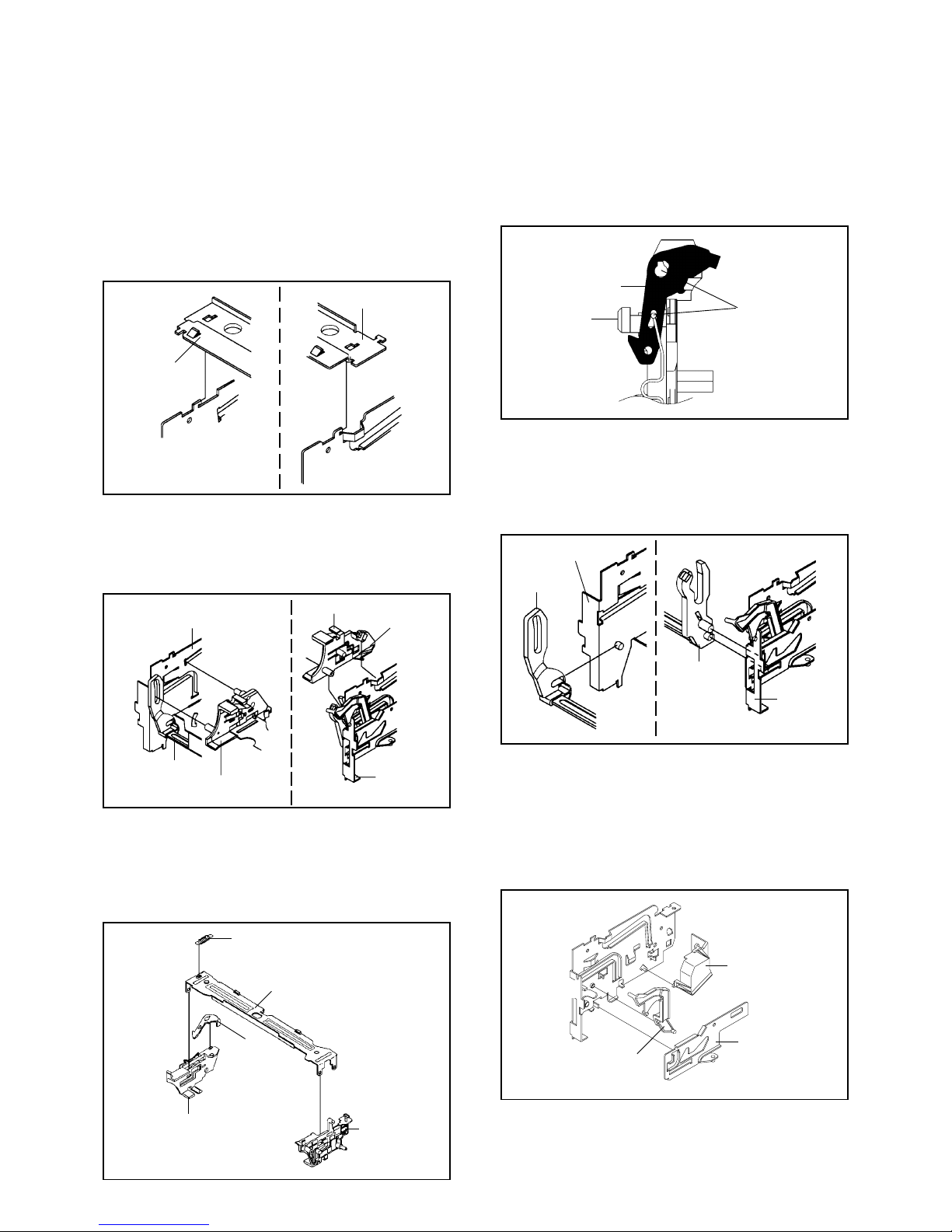

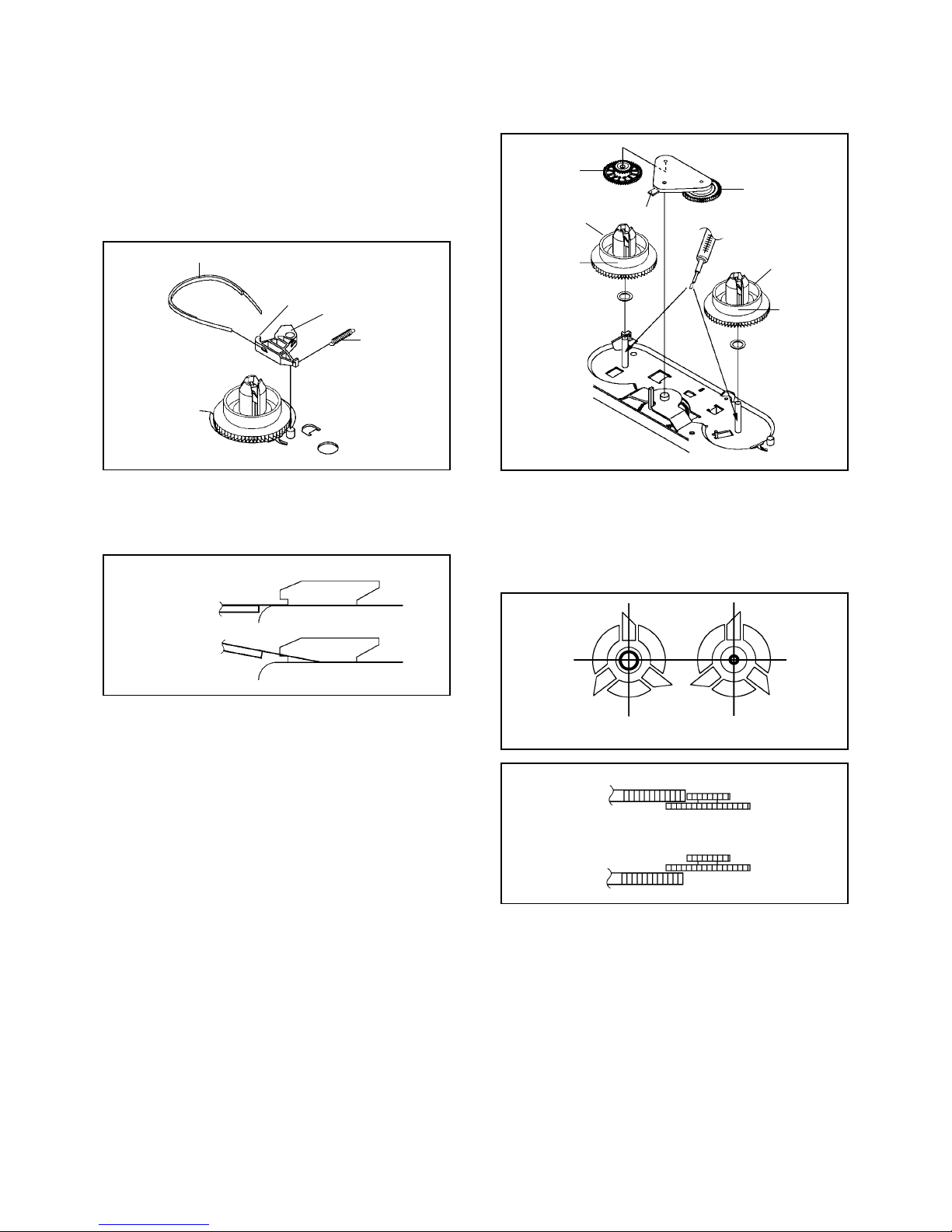

REMOVAL OF DECK PARTS .........................................................................................................................................

REMOVAL OF ANODE CAP ...........................................................................................................................................

REMOVAL AND INSTALLATION OF FLAT PACKAGE IC .............................................................................................

KEY TO ABBREVIATIONS .................................................................................................................................................

SERVICE MODE LIST ........................................................................................................................................................

PREVENTIVE CHECKS AND SERVICE INTERVALS .......................................................................................................

WHEN REPLACING EEPROM (MEMORY) IC ..................................................................................................................

SERVICING FIXTURES AND TOOLS................................................................................................................................

PREPARATION FOR SERVICING .....................................................................................................................................

VCR TEST TAPE INTERCHANGEABILITY TABLE ...........................................................................................................

MECHANICAL ADJUSTMENTS

CONFIRMATION AND ADJUSTMENT ...........................................................................................................................

CONFIRMATION AND ADJUSTMENT OF TAPE RUNNING MECHANISM ..................................................................

MECHANISM ADJUSTMENT PARTS LOCATION GUIDE .............................................................................................

ELECTRICAL ADJUSTMENTS

ADJUSTMENT PROCEDURE.........................................................................................................................................

BASIC ADJUSTMENTS ..................................................................................................................................................

PURITY AND CONVERGENCE ADJUSTMENTS ..........................................................................................................

ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE .............................................................................................

TROUBLESHOOTING GUIDES .........................................................................................................................................

IC DESCRIPTIONS ............................................................................................................................................................

SERVO TIMING CHART ....................................................................................................................................................

SYSTEM SWITCH MODE ..................................................................................................................................................

SEMICONDUCTOR BASE CONNECTIONS......................................................................................................................

BLOCK DIAGRAMS

TV ....................................................................................................................................................................................

Y/C/AUDIO/HEAD AMP...................................................................................................................................................

MICON/POWER ..............................................................................................................................................................

IF/21PIN/IN/OUT .............................................................................................................................................................

T'TEXT.............................................................................................................................................................................

PRINTED WIRING BOARDS (SYSCON) ...........................................................................................................................

Y/C/AUDIO/HEAD AMP SCHEMATIC DIAGRAM ..............................................................................................................

MICON SCHEMATIC DIAGRAM ........................................................................................................................................

POWER SCHEMATIC DIAGRAM ......................................................................................................................................

21PIN/IN/OUT SCHEMATIC DIAGRAM .............................................................................................................................

CHROMA/IF SCHEMATIC DIAGRAM ................................................................................................................................

SOUND AMP SCHEMATIC DIAGRAM ..............................................................................................................................

SECAM CHROMA/HI-FI .....................................................................................................................................................

REGULATOR SCHEMATIC DIAGRAM.............................................................................................................................

T'TEXT SCHEMATIC DIAGRAM ........................................................................................................................................

PRINTED WIRING BOARDS (MAIN/CRT/POWER SW./IF) ..............................................................................................

TV POWER SCHEMATIC DIAGRAM .................................................................................................................................

DEFLECTION SCHEMATIC DIAGRAM .............................................................................................................................

CRT SCHEMATIC DIAGRAM.............................................................................................................................................

IF SCHEMATIC DIAGRAM ................................................................................................................................................

INTERCONNECTION DIAGRAM .......................................................................................................................................

WAVEFORMS ....................................................................................................................................................................

MECHANICAL EXPLODED VIEW......................................................................................................................................

MECHANICAL REPLACEMENT PARTS LIST ...................................................................................................................

ACCESSORY REPLACEMENT PARTS LIST ....................................................................................................................

CHASSIS EXPLODED VIEW (TOP VIEW) ........................................................................................................................

CHASSIS EXPLODED VIEW (BOTTOM VIEW) ................................................................................................................

CHASSIS REPLACEMENT PARTS LIST...........................................................................................................................

ELECTRICAL REPLACEMENT PARTS LIST ....................................................................................................................

A1-1

COVER

A1-1

A2-1

A2-2

B1-1, B1-2

B2-1~B2-6

B3-1

B4-1, B4-2

C1-1, C1-2

C2-1

C3-1, C3-2

C4-1

D1-1

D1-2

D1-3

D2-1, D2-2

D2-2, D2-3

D2-4

D3-1

D3-1~D3-4

D3-5

D3-6

E-1~E-27

F1-1~F1-3

F2-1

F2-2

G-1

H-1

H-2

H-3

H-4

H-5

I-1~I-3

I-4

I-5

I-6

I-7

I-8

I-9

I-10

I-11

I-12

I-13~I-15

I-16

I-17

I-18

I-19

I-20

J-1, J-2

K1-1, K1-2

K1-3

K1-3

K2-1

K2-2

K2-3

K3-1~K3-4