Introduction

This manual is a work in progress and will be continously

updated as needed. If you see an area that needs work,

contact us thru e-mail and let us know. If you have

sugestions or a different method of doing something

that pertains to the Excalibur and its components, write

us with your suggestions. We decided to place the

manual on disk for the simplicty of keeping it up to date

and to eliminate paper waste. The manual was written

in HTML so it will be compatible with well over 95% of

the computers people use in their day-to-day life. A

PDF version of this document is also included on this

disk for users who prefer to print out their own hard

copy of the manual.

The ground work for the very first ideas of the Excalibur

were laid down back in 1988 as I was working on my

apprenticeship in the family machine shop - Leads Metal

Products, Inc. Leads Metal Product’s other division,

Endeco Soldering and Desoldering, had just finished

developing an electronically-controlled power vacuum

desoldering station which used solenoids and 4-way

solenoid valves to actuate the mechanism. Endeco had

been manufacturing and selling soldering and

desoldering irons since the late fifties.

At the time of the development of the new power vacuum

desoldering station, I had developed several paintball

gun prototypes, several blow back guns, and one

pneumatic blow forward. I had an idea and added a 4-

way solenoid valve from the desoldering stations to one

of my paintball gun designs. It worked great, but the 4-

way solenoid valves at the time were far too big to make

a portable paintball gun. I continued to develop the idea

but later shelved it when I went off to college in 1990.

In October 1998, after hearing many complaints about

the electronic markers available at that time, AKALMP

decided to build a paintball gun that would hold up to

the punishment that any paintball gun endures. Most

electronic markers are based on an inexpensive blow-

back semi-auto open bolt marker which limits their

performance. The Excalibur’s(tm) (pat pend) design

makes it the most advanced integrated paintball marker

in the world. The electronics are state-of-the-art but have

been kept simple for durability and longevity. The

mechanical components of the Excalibur(tm)(pat pend)

have been designed to give many years of flawless

operation with very little maintenance. The whole marker

was designed around the “KISS” (Keep It Simple Stupid)

principal. The design is very simple and rugged but is,

at the same time, very advanced. The outside of the

Excalibur(tm)(pat pend) may not look fancy, but the

inside is what is adavnced. The Excalibur(tm)(pat pend)

is built more like a high performance tank. We leave the

decoration up to customers and airsmiths. In addition,

we wanted to provide a warranty that was simple, not

long and complicated.

With many years of design and manufacturing knowledge

outside of paintball to draw from, AKALMP, Inc. and

LEADS METAL PRODUCTS, Inc. bring the paintball

community the finest paintball products available.

AKALMP has the finest products with the highest

performance ratings which will not be compromised.

President AKALMP, Inc.

Aaron K. Alexander

Specifications

Model: Excalibur(tm)(pat pend)

Version:1300-B Caliber: .68

Action: Closed Bolt Electo-pneumatic Operation

Gas Source: Compressed air, Nitrogen or CO2

Power Supply: 9 Volt battery ROF (Cyclic Rate): 13

BPS(MAX)

Standard Barrel Length: 12.0" Javelin (Cocker Threads)

Length: 8.125 inches

Height: 8.4 inches (Top of feed tube to bottom of grip)

Width: 1.75 inches

Weight: 3. lbs (Without battery & barrel)

Operating Pressure: 140-180 PSI @ 280 FPS

(depending on paint size)

Input PSI to Sidewinder: 400-800 PSI

Pneumatics Pressure: 90-100 PSI

Features:

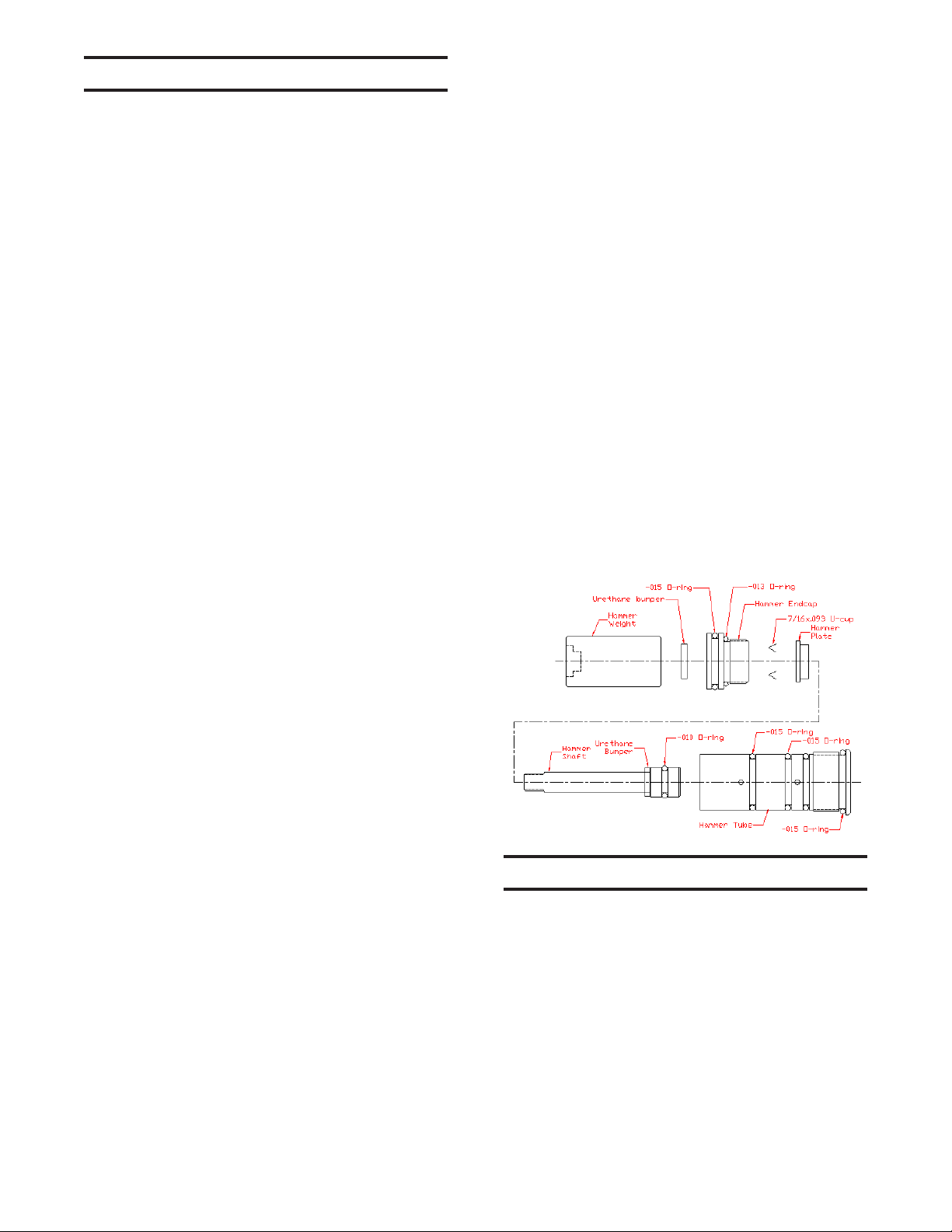

Tornado(tm)(Pat# 5791328) Valve Low Pressure, High

Efficiency Lightning(tm) Bolt(delrin) with Quick Release

Pin Javelin (tm) Barrel 45 Grip Ball Detent Built-In Vertical

Mount Sidewinder(tm)(pat pend) Vertical Pressure Reg.

Threaded Vertical Feed Adjustable Trigger (3 adjustment

points) Adjustable operating software, includes,

hammer drive, hammer release, bolt drive, bolt release,

Adjustable ROF, Warp feed drive, Ball drop sensor

optional, plus more. Adjustable Low Pressure

Pneumatics Reg. Pull Through Cleaning Easy

Disassembly & Low Maintenance Rugged Design Barrel

Plug Carrying Case