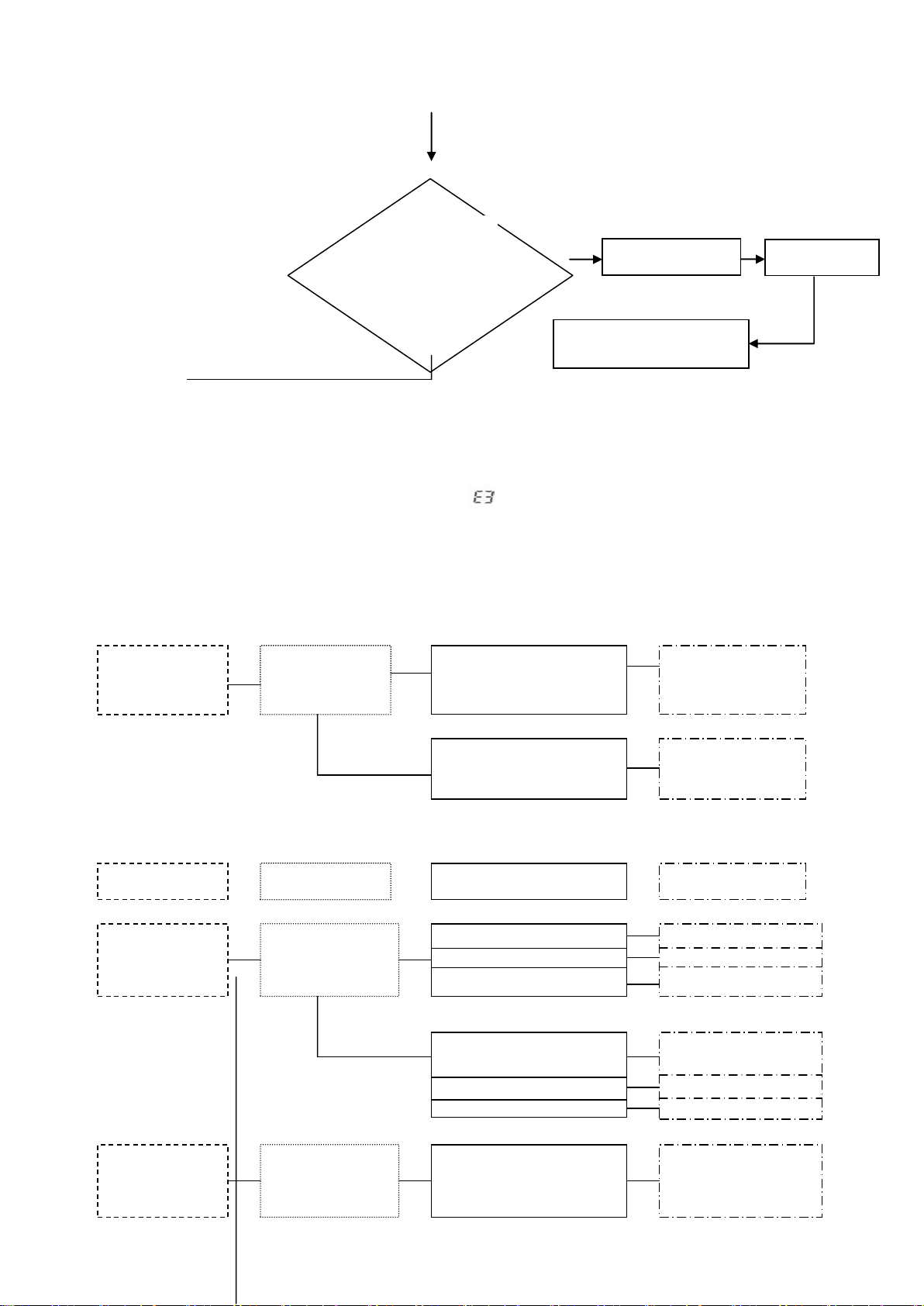

ABNORMALCONDITION

When the washer is abnormal, the washer stops as the every actions turns off, beep tone sounds

ON-0.1 second and OFF-0.1 second for 6 seconds and number window LED display abnormal

code and blink on and off. The washer judges the following six conditions as abnormal condition.

1) Abnormal condition of water supply

In supplying with water, the water level does not reach 1 level within 10 minutes or does not

reach your chosen water level within 20 minutes from the water level of 1 level.

The number window LED display abnormal code: and begin blinking on and off at the

same time and the electric buzzer sounds to indicate a problem.

2) Abnormal condition of drain

In draining, the water level does not go down below the reset level of the water level sensor

within 8 minutes.

The number window LED display abnormal code: and begin blinking on and off at the

same time and the electric buzzer sounds to indicate a problem.

3) Abnormal condition of spin-dry

•The tub switch works 3 times continuously during the program of rinse-spin or works 1 time

in the single program of spin-dry.

The number window LED display abnormal code: and begin blinking on and off at the

same time and the electric buzzer sounds to indicate a problem.

• The washer lid is opened.

The number window LED display abnormal code: and begin blinking on and off at the

same time and the electric buzzer sounds to indicate a problem.

4) Abnormal condition of wash.

The number window LED display abnormal code: and begin blinking on and off at the

same time and the electric buzzer sounds to indicate a problem.

5) Abnormal condition of water level sensor.

The water level sensor malfunctions.

The number window LED display abnormal code: and begin blinking on and off at the

same time and the electric buzzer sounds to indicate a problem.

6) Abnormal condition of load sensor.

The number window LED display abnormal code: and begin blinking on and off at the

same time and the electric buzzer sounds to indicate a problem.

XQB100-Y1066S

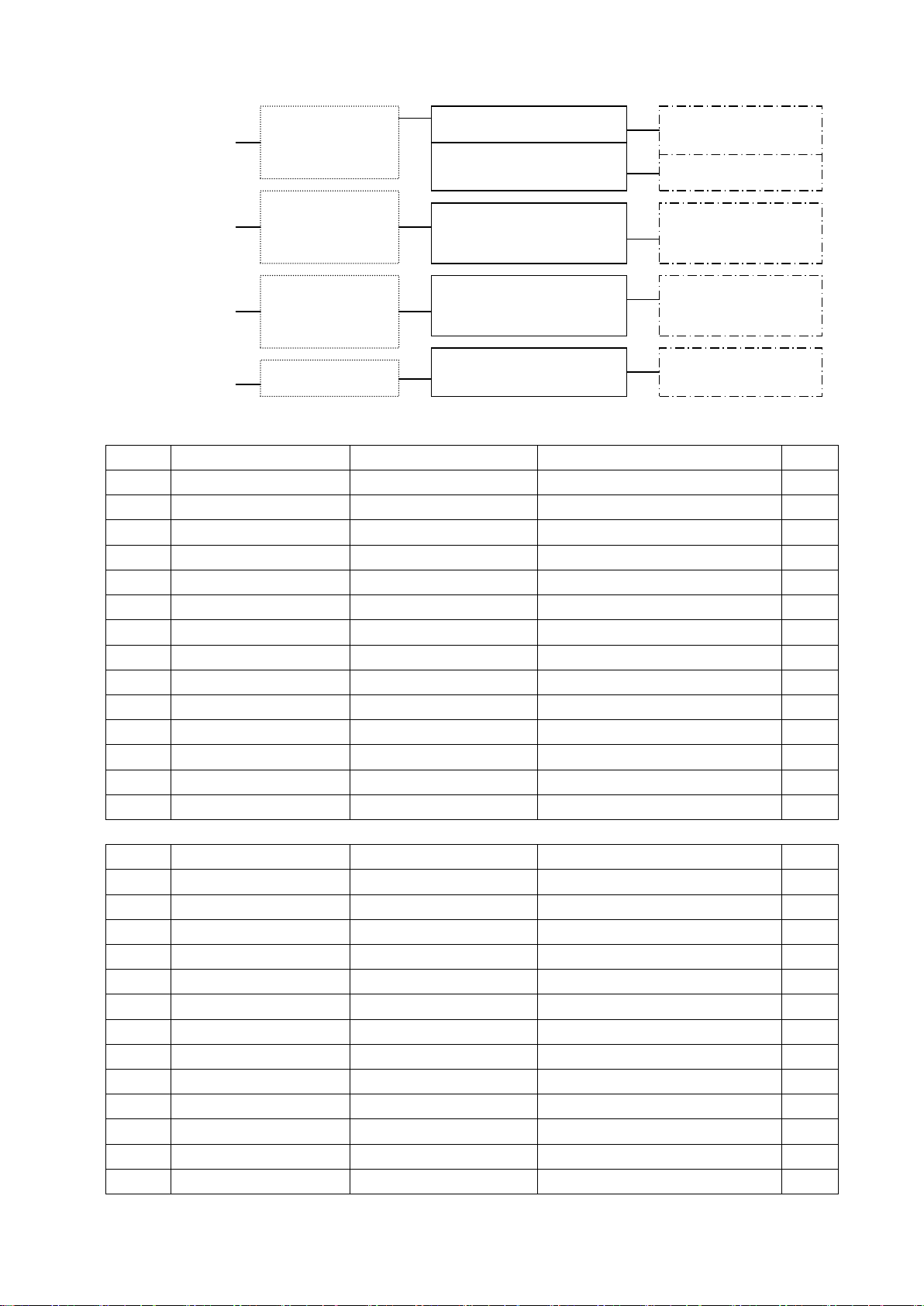

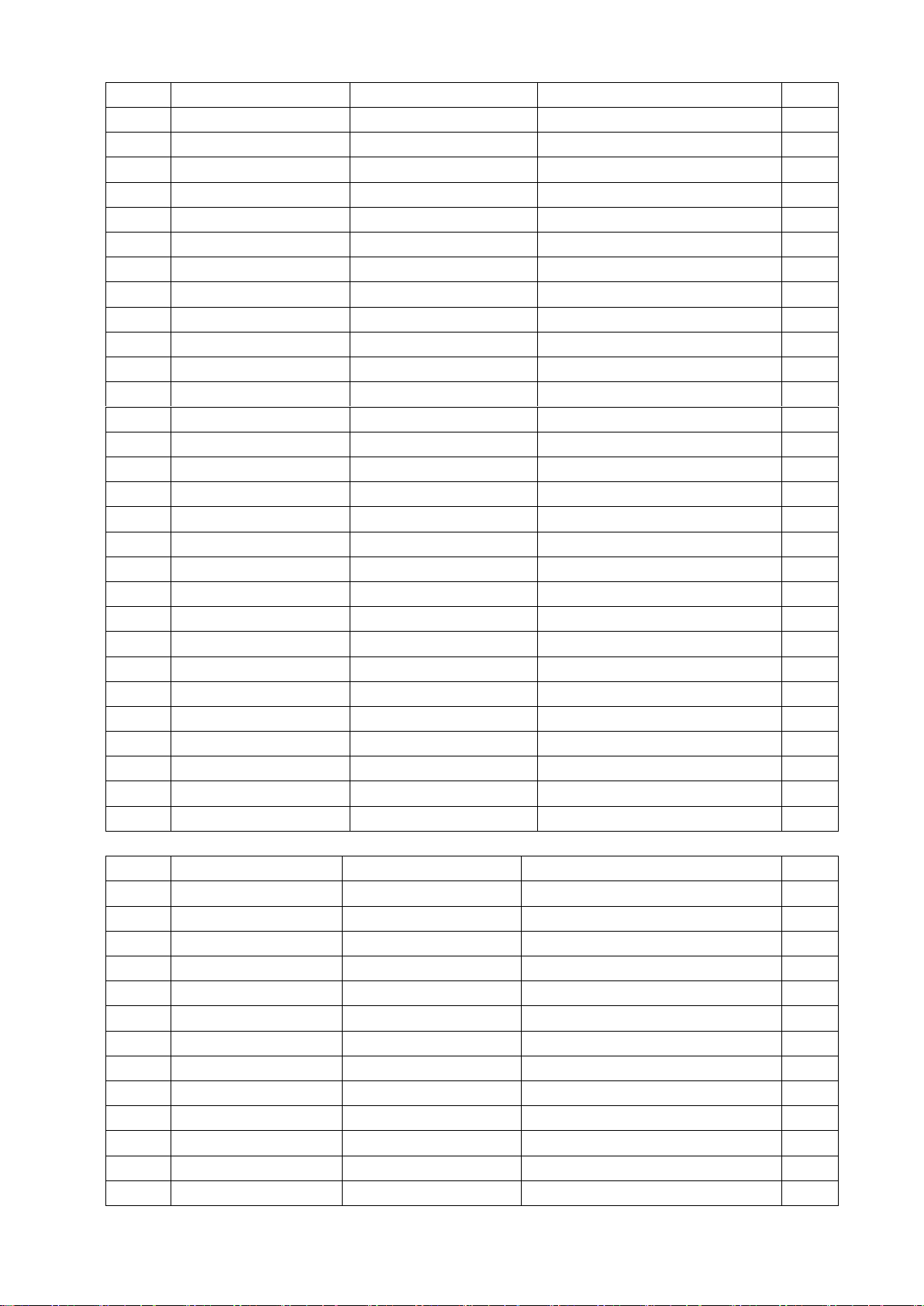

CIRCUIT DIAGRAM