Page 2 of 32

Table of Contents

Table of Contents................................................................................................................ 2

Table of Figures .................................................................................................................. 3

Section 1: About this Manual ............................................................................................. 4

Who Should Attempt this Project? ................................................................................. 4

Tools You’ll Need........................................................................................................... 4

Project Overview ............................................................................................................ 5

Important Safet Notes ................................................................................................... 5

About Components ......................................................................................................... 5

Recommended Solder ..................................................................................................... 5

Section 2: Saving the Stuff that Should Be Saved.............................................................. 6

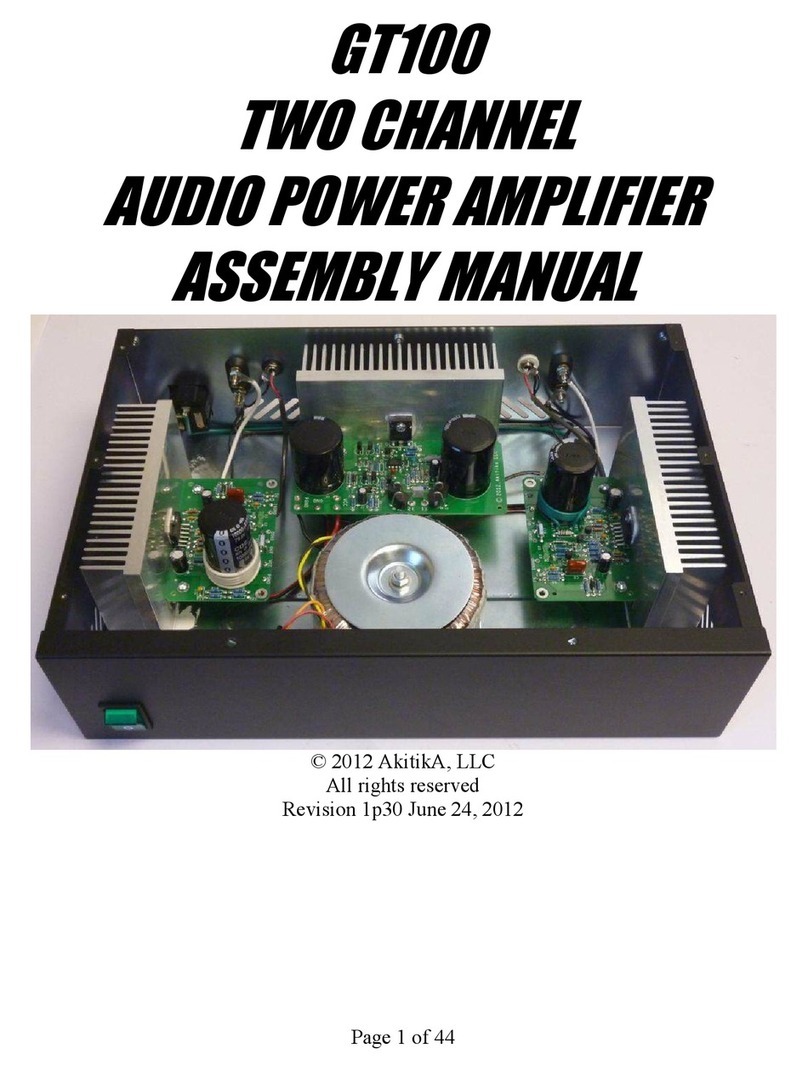

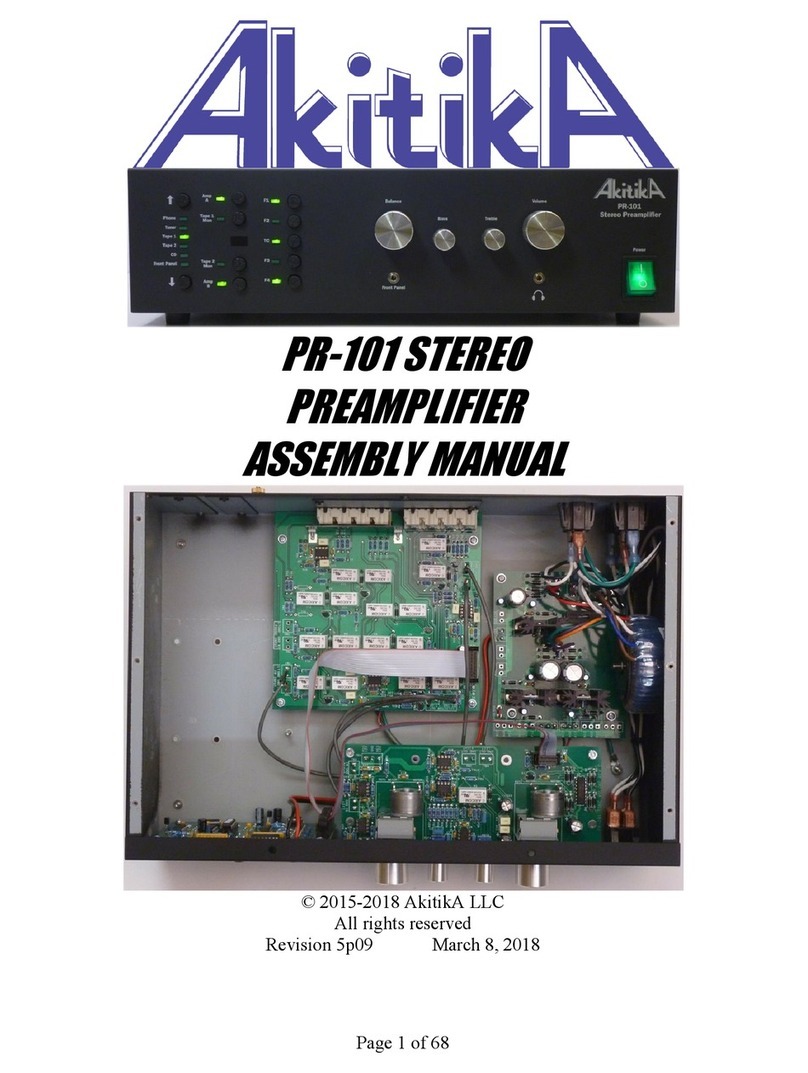

Opening the Amplifier .................................................................................................... 6

Cutting the wires on the old amplifier modules.............................................................. 6

Removing the LEFT channel module......................................................................... 6

Removing the RIGHT channel module ...................................................................... 7

Removing C7 RIGHT ............................................................................................... 10

Removing C7 LEFT.................................................................................................. 10

Removing the Output Zobel Networks ..................................................................... 10

Salvaging the Heat Sinks from the Amplifier Modules................................................ 12

Section 3: Checking the Stereo 120 Power Suppl .......................................................... 12

Prepare and Connect the Test Load .............................................................................. 12

Test the Power Suppl .................................................................................................. 13

The Voltage is Much More than 75.6 volts .................................................................. 13

The Voltage is Much Less than 68.4 volts.................................................................... 13

There’s No Voltage at All............................................................................................. 14

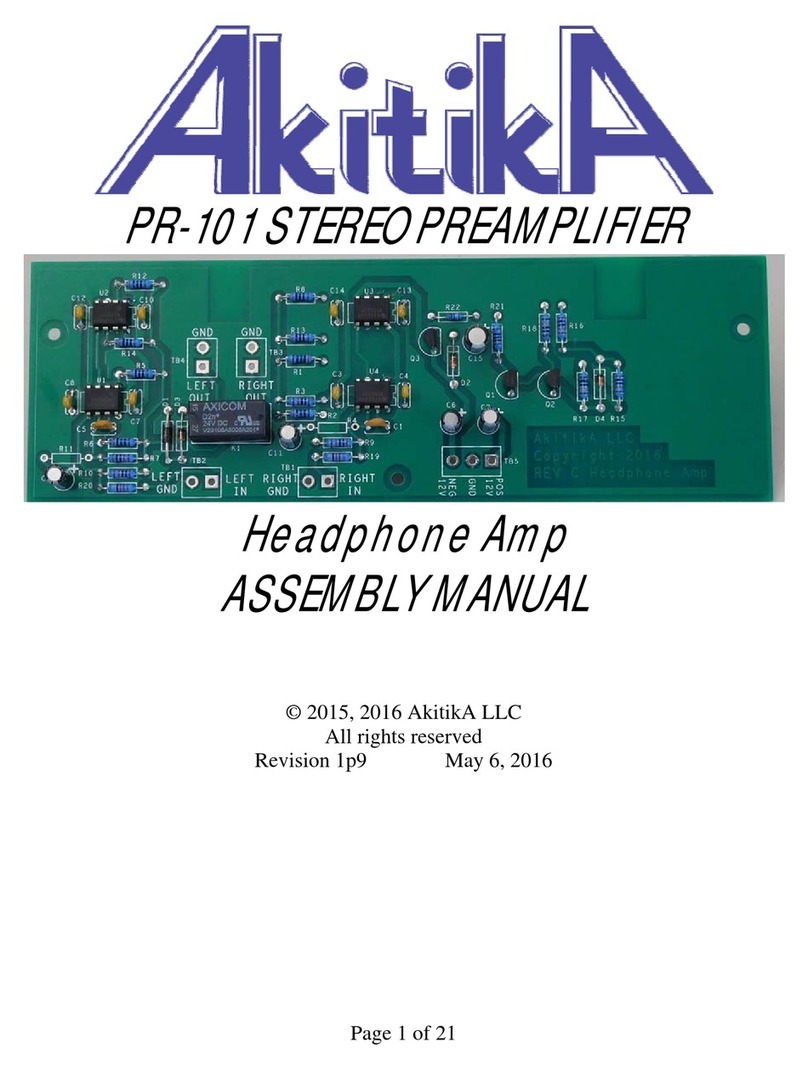

Section 4: Assembling the Amplifier Circuit Boards ....................................................... 14

Install the Resistors ....................................................................................................... 15

Install the Small Capacitors and the Diodes ................................................................. 17

Last Capacitors and the Transistors .............................................................................. 18

Winding the Output Inductor ........................................................................................ 19

Solder the LM3886 into the Board ............................................................................... 20

Final Inspection of the Circuit Board............................................................................ 22

Mounting the Updated Amplifier Board to the Heat Sink............................................ 23

Section 5: Wiring In the Updated Amplifier Modules...................................................... 24

Revise the Grounding S stem....................................................................................... 24

Revise the Power S stem.............................................................................................. 25

Complete the Ground S stem ....................................................................................... 26

Wiring the Inputs .......................................................................................................... 26

Wiring the Outputs........................................................................................................ 27

Connecting the Left Channel Amplifier Module .......................................................... 27

Connecting the Right Channel Amplifier Module........................................................ 28

Making the Speaker Binding Posts User Friendl ........................................................ 29

Section 6: Testing the Completed Amplifier .................................................................... 29

Test #1........................................................................................................................... 29

Test #2........................................................................................................................... 30