www.ako.com

HOJA TÉCNICA 1301H201 Edición 01 (01 de 02)

Thermometers, thermostats and temperature electronic controllers for 58 x 25,4 mm panel cut-out pattern

GB

Small dimensions unit range, designed to monitoring, control and regulating

refrigerating generators (with manual or automatic defrost programmed by

stopping the compressor) or heating generators.

Index:

1-Versions and references 6- Parameters description and messages

2-Technical data 7- Parameters transfer

3-Installation 8- Relay operation and control

4-Front panel functions 9- Maintenance

5-Adjustment and configuration 10- Warnings

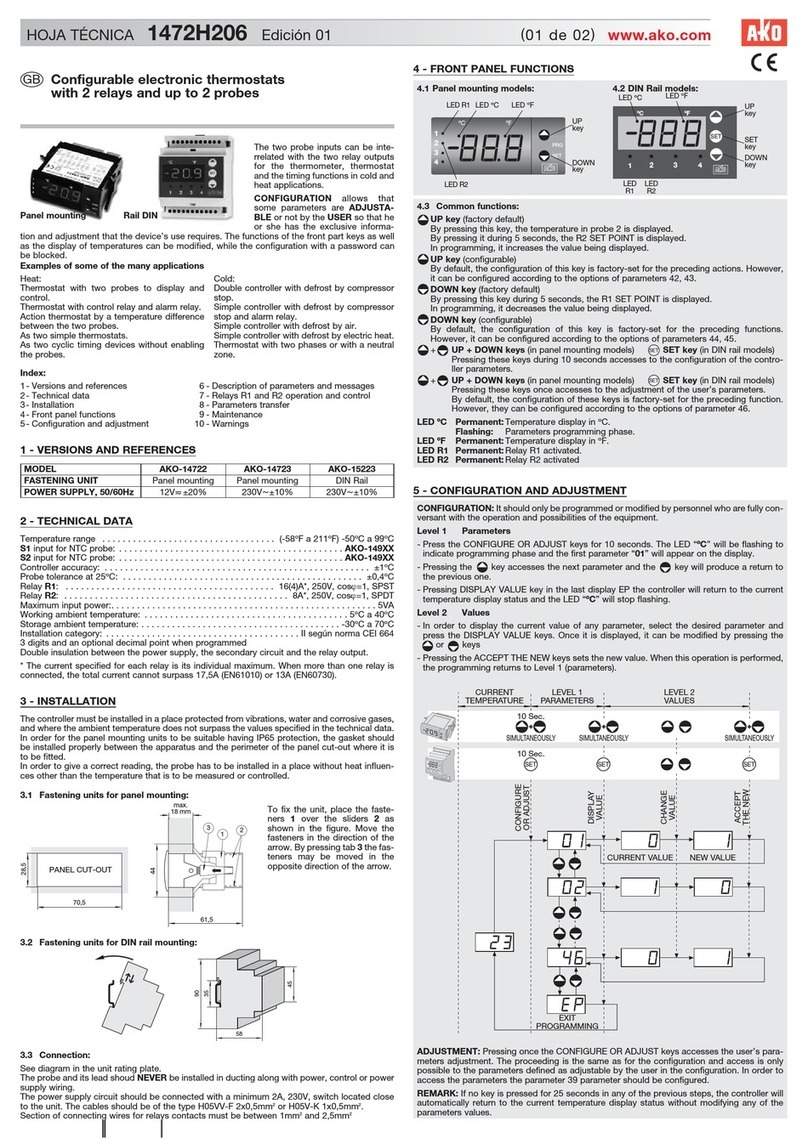

1- VERSIONS AND REFERENCES

MODEL FUNCTION RELAY

POWER SUPPLY, 50/60 Hz

AKO-13012 Thermometer - 12 V ±20%

AKO-13020 Thermometer - 120 V ~ +8% -12%

AKO-13023 Thermometer - 230 V ~ ±10%

AKO-13112 Thermostat

16(4) A, 250 V, cos ϕ=1, SPST

12 V ±20%

AKO-13120 Thermostat

16(4) A, 250 V, cos ϕ=1, SPST

120 V ~ +8% -12%

AKO-13123 Thermostat

16(4) A, 250 V, cos ϕ=1, SPST

230 V ~ ±10%

2- TECHNICAL DATA

Temperature range: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -50 ºC a 99 ºC

Resolution, Set Point and differential: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 ºC

Input for NTC probe: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AKO-149XX

Controller accuracy: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1ºC

Probe tolerance at 25 ºC: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0,4 ºC

Maximum input power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 VA

Working ambient temperature: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 ºC a 40 ºC

Storage ambient temperature: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -30 ºC a 70 ºC

Voltage pulse assigned: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 V

Pressure ball test temperature

- Accessible parts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 ºC

- Active elements positioning parts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 ºC

CEM emission voltage test: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207 V

CEM emission current test: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 mA

Control device classification: Independent mounting, with characteristic of

automatic operation action Type 1.B, to be used in clean situation, logical

medium (software) class A.

Double insulation between the power supply, the secondary circuit and the relay output.

3- INSTALLATION

The controller must be installed in a place protected from vibrations, water

and corrosive gases, and where the ambient temperature does not surpass

the value specified in the technical data.

In order the controllers be suitable having IP65 protection, the gasket should

be installed properly between the apparatus and the perimeter of the panel

cut-out where it is to be fitted.

In order to give a correct reading, the probe has to be installed in a place

without heat influences other than the temperature that is to be measured or

controlled.

3.1 Fastening:

To fix the unit, place the

fasteners 1over the sli-

ders 2as shown in the

figure. Move the faste-

ners in the direction of

the arrow. By pressing

tab 3the fasteners may

be moved in the opposi-

te direction of the arrow.

3.2 Connection:

See diagram in the unit rating plate.

The probe and its lead should NEVER be installed in ducting along with

power, control or power supply wiring.

The power supply circuit should be connected with a minimum 2 A, 230 V,

switch located close to the unit. The cables should be of the type H05VV-F

2x0,75 mm2or H05V-K 0,75 mm2.

Section of connecting wires for relays contacts must be between 1,5 mm2

and 2,5 mm2

LED 1

UP

key

ON

LED 2

DOWN

key

SET

key

4- FRONT PANEL FUNCTIONS

UP key

When pressed for at least 5 seconds,

a manual defrost is started with pro-

grammed duration, (in thermostats

function).

In programming, it increases the dis-

played value.

DOWN key

In programming, it reduces the dis-

played value.

SET key

When pressed for at least 5 seconds, it displays the SET POINT tem-

perature value, (in thermostats function).

In programming, accept the programmed new value.

LED 1: Defrost in operation indicator. (in thermostats function)

LED 2: Relay ON indicator. (in thermostats function)

LED 2 flashing: Programming phase.

5- ADJUSTMENT AND CONFIGURATION

It should only be programmed or modified by personnel who are fully con-

versant with operation and possibilities of the equipment.

5.1 Set Point temperature.

The factory SET POINT default value is 0 ºC.

-Press key for at least 5 seconds to DISPLAY SET POINT. It displays the

CURRENT SET POINT value and LED “2” start flashing.

-Press or keys for CHANGE SET POINT to the required value.

-Press key to ACCEPT THE NEW SET POINT. The display returns to the

current temperature display status and the LED “2” stop flashing.

When PA appears in display, PASSWORD programmed in L5 parameter

should be enter for accede to the CURRENT SET POINT.

-Press key. 0will be displayed to ENTER PASSWORD.

-Press or keys to CHANGE NUMBER and DISPLAY PASSWORD.

-Press key to ACCEPT PASSWORD. The CURRENT SET POINT value

will be displayed and possible to be modified.

REMARK: If no key is pressed for 25 seconds in either of the previous steps,

the controller will automatically return to the current temperature display sta-

tus without modifying any of the parameters values.

5.2 Parameters configuration

Level 1 Parameters

-Press + keys simultaneously for at least 10 seconds. The LED “2” will

be flashing, we are in the LEVEL 1 PARAMETERS and in the display appe-

ar the first parameter “C0”.

-Press key to access the next parameter and key to return to the pre-

vious one.

-Pressing the key in the last parameter EP, the controller returns to the

current temperature display status and the LED “2” will stop flashing.

When PA appears in display, PASSWORD programmed in L5 parameter

should be enter for accede to programming LEVEL 1 PARAMETERS.

-Press key. 0will be displayed to ENTER PASSWORD.

-Press or keys to CHANGE NUMBER and DISPLAY PASSWORD.

-Press key to ACCEPT PASSWORD. The first parameter “C0” will be dis-

played.

Level 2 Values

-To DISPLAY CURRENT VALUE of any parameter, select the required one

and press key. Once it is displayed, you can CHANGE VALUE pressing

or key.

-Press key to ACCEPT THE NEW VALUE. The programming returns to

LEVEL 1 PARAMETERS.