Contents

Introduction............................................................................................................................................................2

1Overview........................................................................................................................................................3

1.1 Ordering key..............................................................................................................................................4

2Specifications................................................................................................................................................5

2.1 Environmental conditions .......................................................................................................................7

3Safety .............................................................................................................................................................8

3.1 Safety precautions....................................................................................................................................8

3.2 Intended use..............................................................................................................................................8

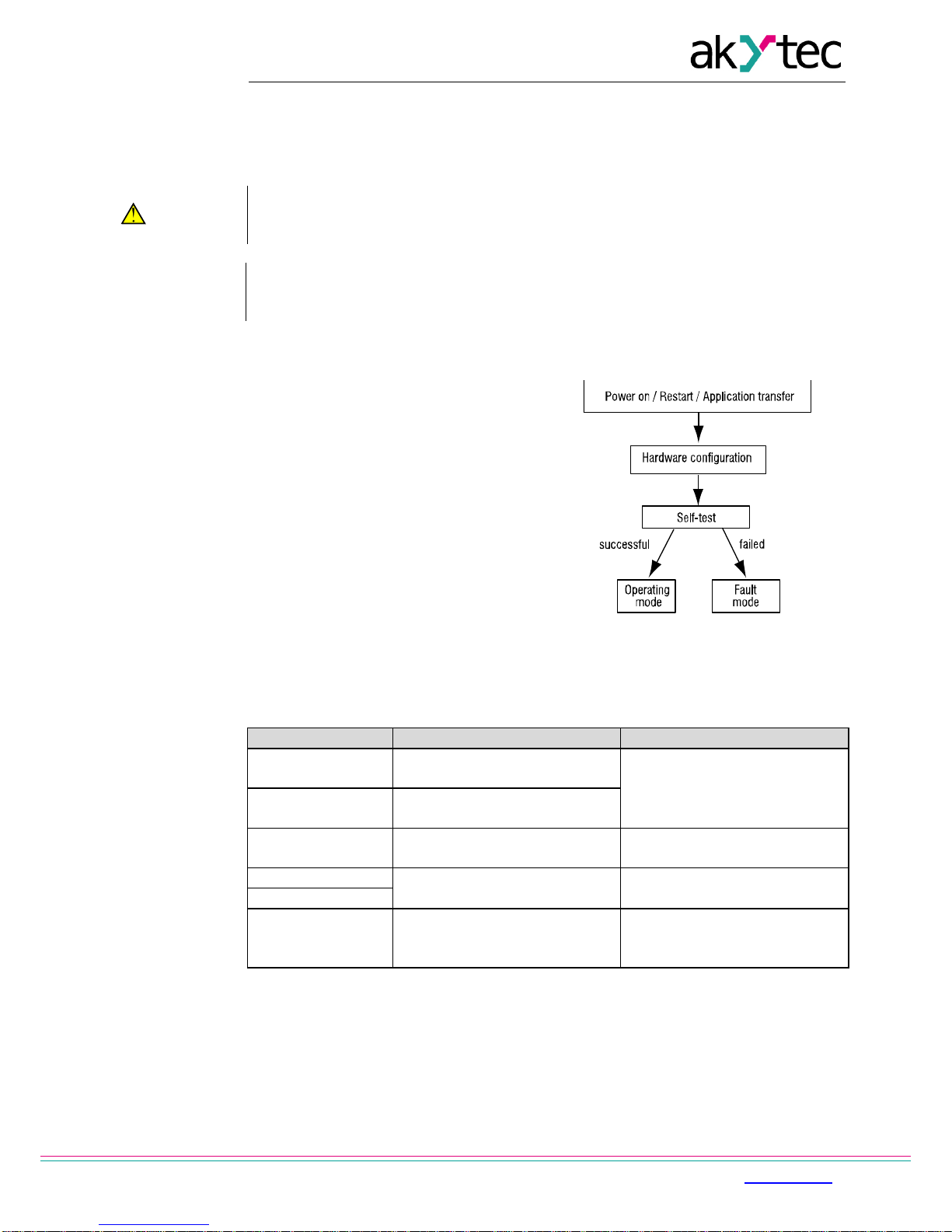

4Functioning....................................................................................................................................................9

4.1 Operating mode........................................................................................................................................9

4.2 Fault mode.................................................................................................................................................9

4.3 RS485 network interface..........................................................................................................................9

4.4 Slave mode..............................................................................................................................................10

4.5 Master mode............................................................................................................................................11

4.6 Special modes.........................................................................................................................................14

5System menu...............................................................................................................................................16

5.1 Menu navigation .....................................................................................................................................16

5.2 Menu content ..........................................................................................................................................17

6Configuration...............................................................................................................................................20

6.1 Analog inputs AI1…AI4..........................................................................................................................20

6.2 Analog outputs AO1, AO2 .....................................................................................................................23

6.3 Display elements ....................................................................................................................................23

6.4 Auto Precision ........................................................................................................................................23

7Installation ...................................................................................................................................................24

7.1 Mounting..................................................................................................................................................24

7.2 Wiring.......................................................................................................................................................24

7.3 Quick replacement..................................................................................................................................28

8Maintenance ................................................................................................................................................29

9Transportation and storage.......................................................................................................................30

10 Scope of delivery ........................................................................................................................................31

Appendix А. Dimensions ..................................................................................................................................32

Appendix B. Terminal layouts..........................................................................................................................33

Appendix C. Galvanic isolation........................................................................................................................36

Appendix D. Circuit diagrams ..........................................................................................................................38

Appendix E. Connection to PC.........................................................................................................................39

Appendix F. Calibration ....................................................................................................................................40

F.1 General ....................................................................................................................................................40

F.2 Analog input............................................................................................................................................40

F.2 Analog output 4-20 mA ..........................................................................................................................41

Appendix G. Battery replacement....................................................................................................................42

Appendix H. Interface card installation...........................................................................................................44