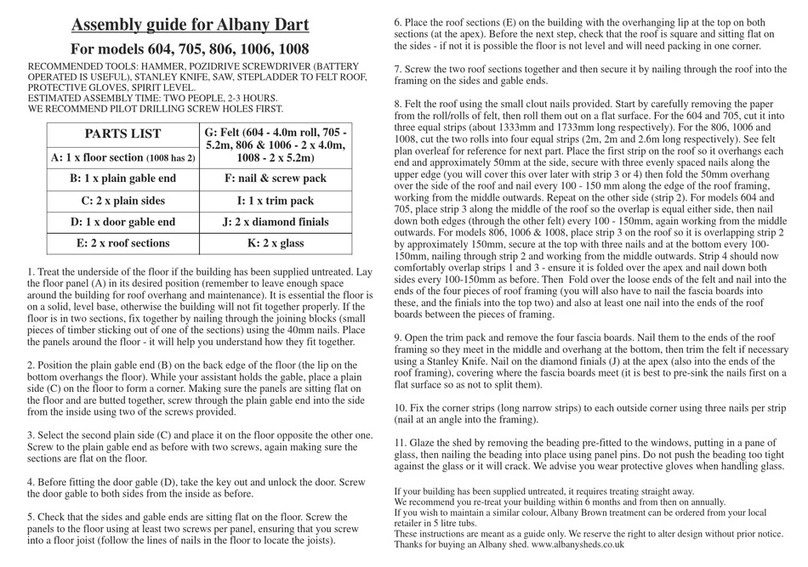

Assembly Guide For Albany Apex Sheds

1208 - 1608 Warwick & Warwick Plus.

RECOMMENDED TOOLS: HAMMER, CROSS HEAD SCREWDRIVER

(BATTERY OPERATED IF AVAILABLE), STANLEY KNIFE, SAW,

STEPLADDERS TO FELT ROOF. 10MM & 13MM SPANNER/ SOCKET

ESTIMATED ASSEMBLY TIME: TWO PEOPLE 3 - 4 HOURS.

WE RECOMMEND PILOT DRILLING SCREW HOLES FIRST.

A: 2 X FLOOR SECTIONS (3 ON 1608)

M: 1 X ROOF TRUSS (ON 1408&1608) NOT

SHOWN ON DIAGRAM

1. Lay the floor panels (A) in their desired position (remember to leave enough

space around the building for roof overhang and maintenance). It is essential the

floor is on a solid level base otherwise the building will not fit together properly

and the door may not fit flush. Fix by nailing through the floor into the joining

blocks. Place the panels around the floor - it will help you understand how they fit

together.

2. Position the plain gable (B) on the back edge of the floor (the lip on the

bottom overhangs the floor). While your assistant holds the gable place a plain

side panel (C) on the floor to form a corner. Check that the sides are sitting flat

on the floor and the panels are butted together, screw through the gable into the

side from the inside using two of the screws provided (hexagon head coach

screws). Bolt the second plain side (C) to the first using the coach bolts provided.

3. Select a window side panel (D) and place on the floor, screw to the plain

gable (E) as before with two screws, again making sure the sections are flat on

the floor. Bolt the second window panel (B) to the first as before.

4. Before fitting the door gable (E) remove the key from the inside of the door

(where supplied) and unlock the door, screw the door gable to the sides from the

inside as before.

5. On buildings supplied with a truss (M), position in the middle of the building

and secure with a nail or screw. Position the roof purlin (L) so it stands upright on

the door & plain gable. Place the roof sections (F) on the building so that the

overhang on one side of the roof meets at the apex (the roof purlin sits between

the roofs), before fixing check that the roof is sitting flat with the sides, if not it is

possible the floor is not level and will need packing in one corner.

6. With the roof square check that the sides and gables are sitting flat on the

floor. Screw the panels to the floor using two (standard) screws per panel,

ensuring that you screw into a floor joist (follow the lines of nails in the floor to

locate the joists).

7. Screw the two roof sections together (through the purlin) then secure by

nailing through the roof into the framing on the sides and gables.

8. Felt the roof using the small clout nails provided. Start by carefully removing

the paper from the first roll of felt. Place the first strip on the roof so it overhangs

each end and approximately 50mm at the side, secure with three evenly spaced

nails along the upper edge then fold the felt over the side of the roof and nail

every 100 - 150 mm along the edge roof framing working from the middle

outwards. Repeat on the other side. Place the third roll of felt just below the apex

and nail as before. Place the fourth strip on the roof dividing the overhang equally

to either side; nail down both sides every 100 - 150mm again working from the

middle outwards. Fold the ends of the felt and nail into the ends of the framing.

9. Open the trim pack and remove the four fascia boards, nail them to the ends

of the roof then trim the felt if necessary. Nail on the diamond finales (its best to

pre-sink the nails first on a flat surface so as not to split them).

10. Fix the corner strips (long narrow strips) to each outside corner using three

nails per strip (nail at an angle into the framing). Nail the cover strips (long wide

strips) on each side to cover the join where the sides meet.

11. Glaze the shed from the outside using the beading provided (pre fitted in the

window). Do not push the beading too tight against the glass or it will crack. We

advise you wear gloves when handling glass.

We recommend you re treat your building within six months and from then

on annually with a recognized brand of spirit based preservative.

Barrettine red cedar can be ordered from your local dealer in 5L cans.

These instructions are meant as a guide only we reserve the right to alter

design without prior notice.

Thank you for buying an Albany Shed.

www.albanysheds.co.uk