TROUBLESHOOTING

Backer rod is breaking during operation

•Note:Not all backer rod is spooledcorrectly. Finding a

spool of backer rod without overlap and tangles is essential

for smooth operations. When using 1/4" backer rod a 2,000'

spool can be more user friendly than the 3,200' and 4,000'

footspools.

•Check backer rod spoolfor tangles and overlap. To correct,

place Rover handle into wind and remove backerrod until

tangles and overlaps are chased out. Carefullyrewindbacker

rod back onto spool.

• Do not push Rover too fast. Start out slow and increase toa

normal walking speed. This becomes increasingly important

as the backer rod spool diameter decreases.

•It iscritical the joints are cleanand ready for sealant before

backer rod is applied. Any rocks, sand, concrete dust, or

debris can eect the performance of this machine. Joint

preparation and cleaning must be done prior tobacker rod

installation.

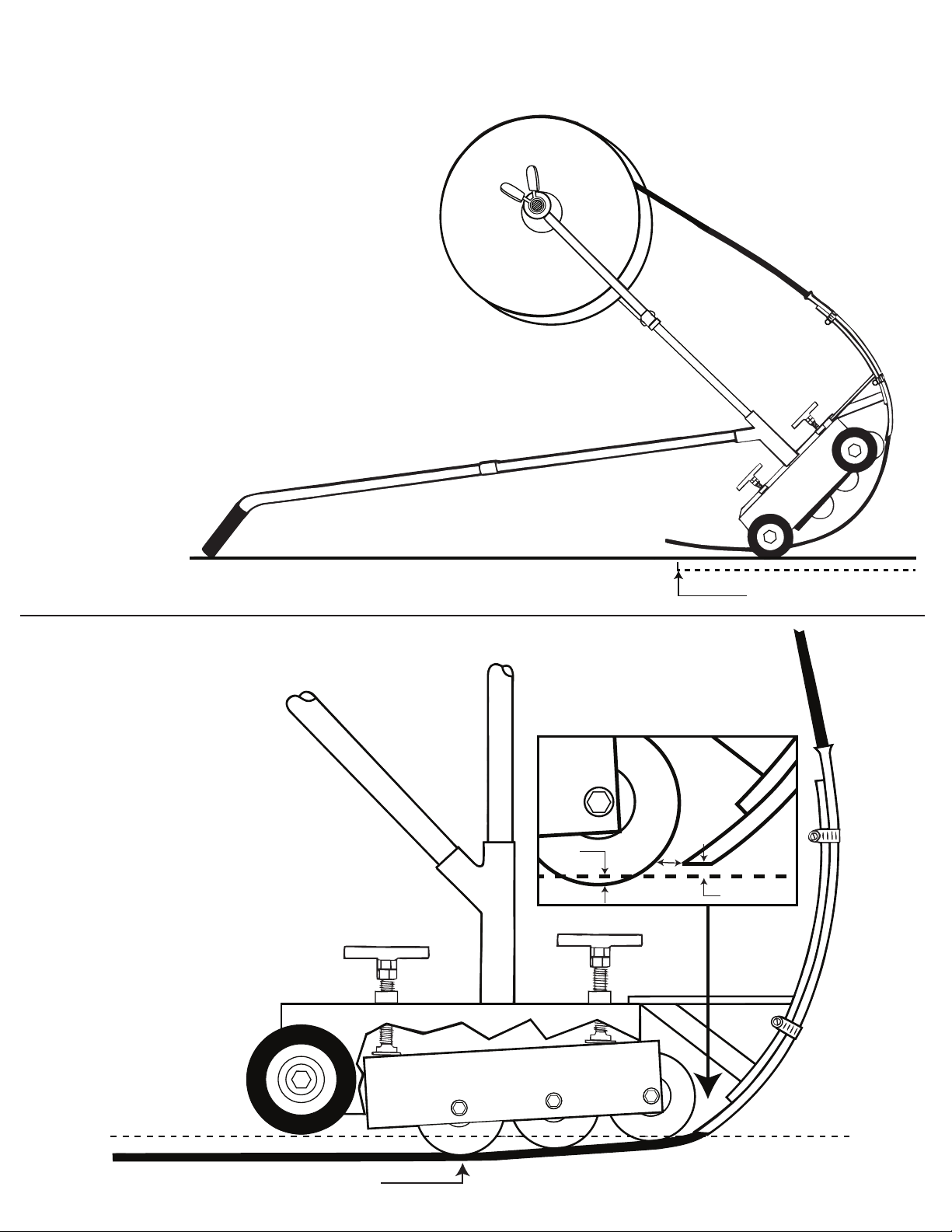

•Move the spool carriage to its forward position to maintain a

smooth entry angle into the entry point of guide tube.

(see gure 6)

•Check for clearance between spool retainers and backer rod

spool. The spool axle should not be spinning with the backer

rod spool. Spool must rotate freely without friction.

•Ensure backer rod passes freely through guide tube

without friction.

•Check backer rod guide tube for burr on exit end.

Backer rod is too largefor guide tube

Backer rod is punctured or cut at entry points of the joint

• Adjust front insertion wheel upwards. Approximately 1/8"

shouldbe inside the joint.

Backer rod does not roll into joint when Rover is

pushed forward

• Make sure front insertion wheel is not set too deep.

• Wiggle handle slightly while pushing Rover forward to

help start backer rod into the joint.

•Checkbacker rod guide tube alignment.

• Step on the backer rod "tail" while pushing Rover forward.

Backer rod is too shallow in the joint

• Adjust the rearinsertion wheel down.

• For extremely tight joints or joints requiring adeep sealant

bed, asecond passwithout dispensing additional backer rod

may be necessary. Setting the insertions wheelsdeeper for a

second dry pass can provide an acceptable depth.

• For custom applications requiring backer rod depth deeper

than 3/4" contact Albion Engineering.

• Make sure saw cutiswide enough for the insertion wheels

out and re-cut to proper width.

• The joint can be silted with debris and may require

additionalcleaning.

page 8

OR VISIT WWW.ALBIONENG.COM

QUESTIONS? CALL 856.235.6688

•Make sure backer rod size matches the guide tube and

insertion wheelsizes.

• Backerrod can swellslightly when stored in extreme heat or

become elliptical during the forming process. In most cases it

is faster to replace the backerrod instead of changing the

guide tube.

179