HEK MS 3000 User manual

Table of contents

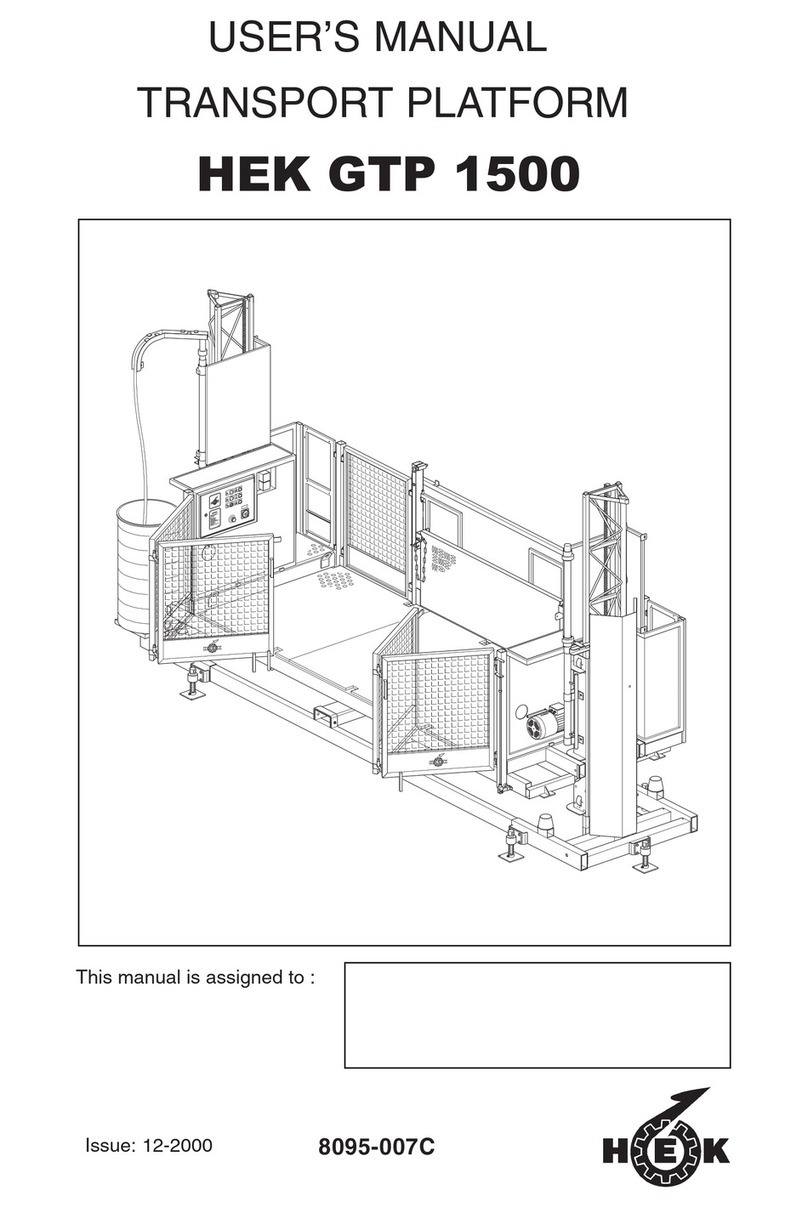

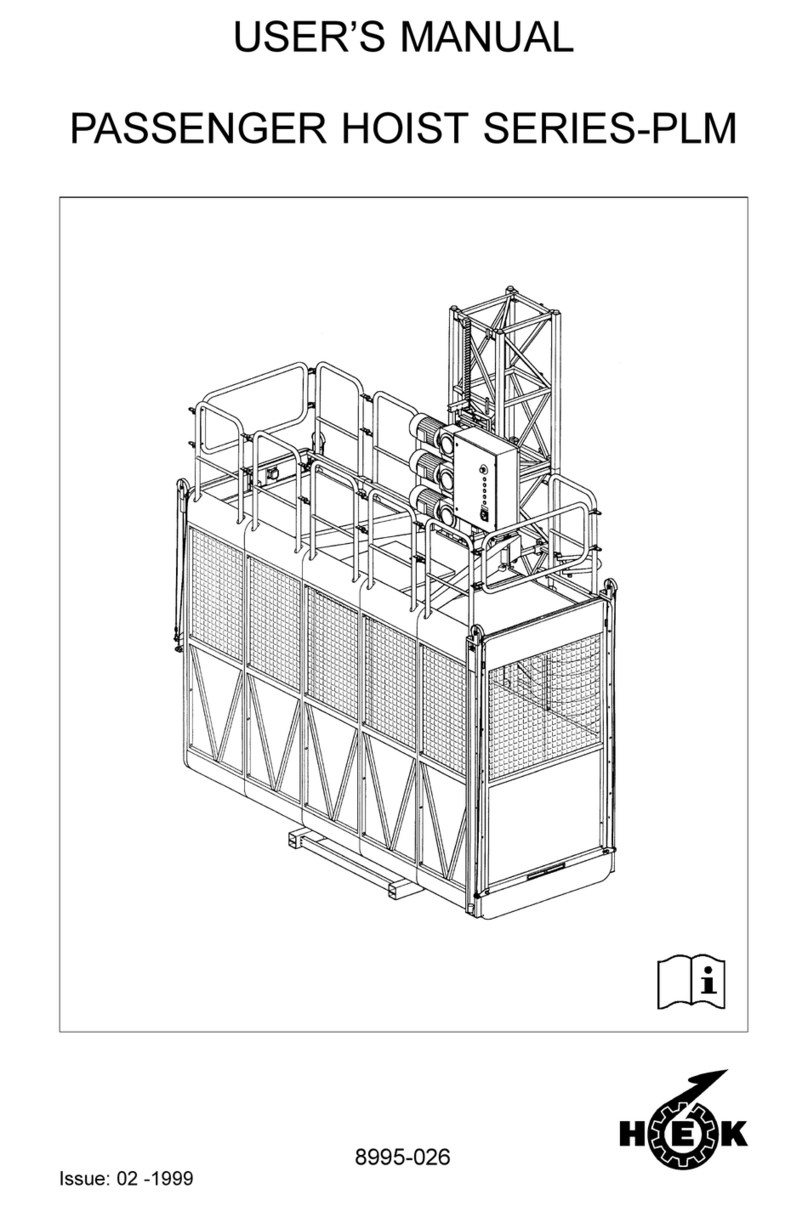

Other HEK Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Amco Veba

Amco Veba 804 WARNING, OPERATING AND MAINTENANCE MANUAL

Thern

Thern ENSIGN 500 owner's manual

UTS

UTS 700 FOLDOUT instruction manual

Reece

Reece DURA BOOT 9503545 Installation instruction

Branch Manager

Branch Manager T1001 OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Peri

Peri SKYDECK Instructions for assembly and use

morse

morse 201BVS-1 Operator's manual

DeWalt

DeWalt D25980-XE instruction manual

Zoomlion

Zoomlion ZCC2600CR Operator's manual

Manitowoc

Manitowoc National Crane NBT50 Series Operator's manual

Norton

Norton Clipper CRP21 Translation of the original instructions

Dexter Laundry

Dexter Laundry HCM450B Safety instructions

HIAB

HIAB L-HiPro 145 Operator's manual

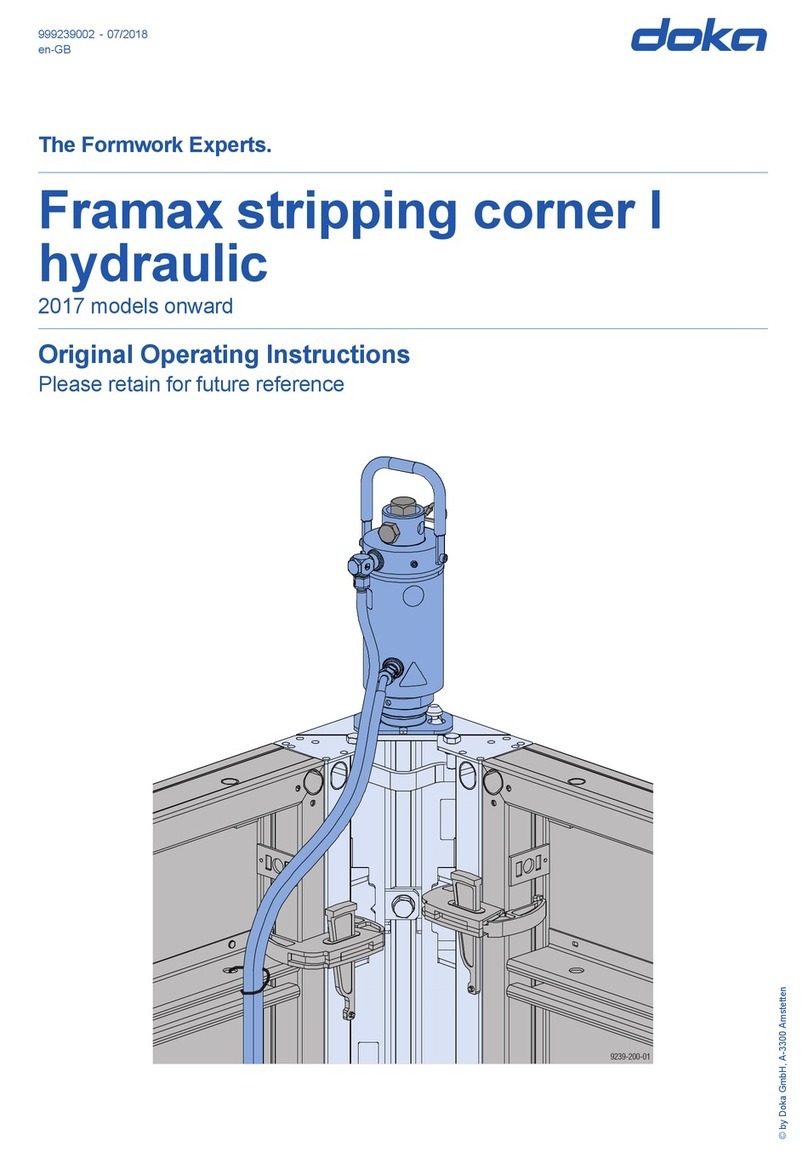

Doka

Doka Framax stripping corner I Series Original operating instructions

TUBESCA-COMABI

TUBESCA-COMABI SPYDER Assembly manual

Dynaset

Dynaset HPW-DUST operating instructions

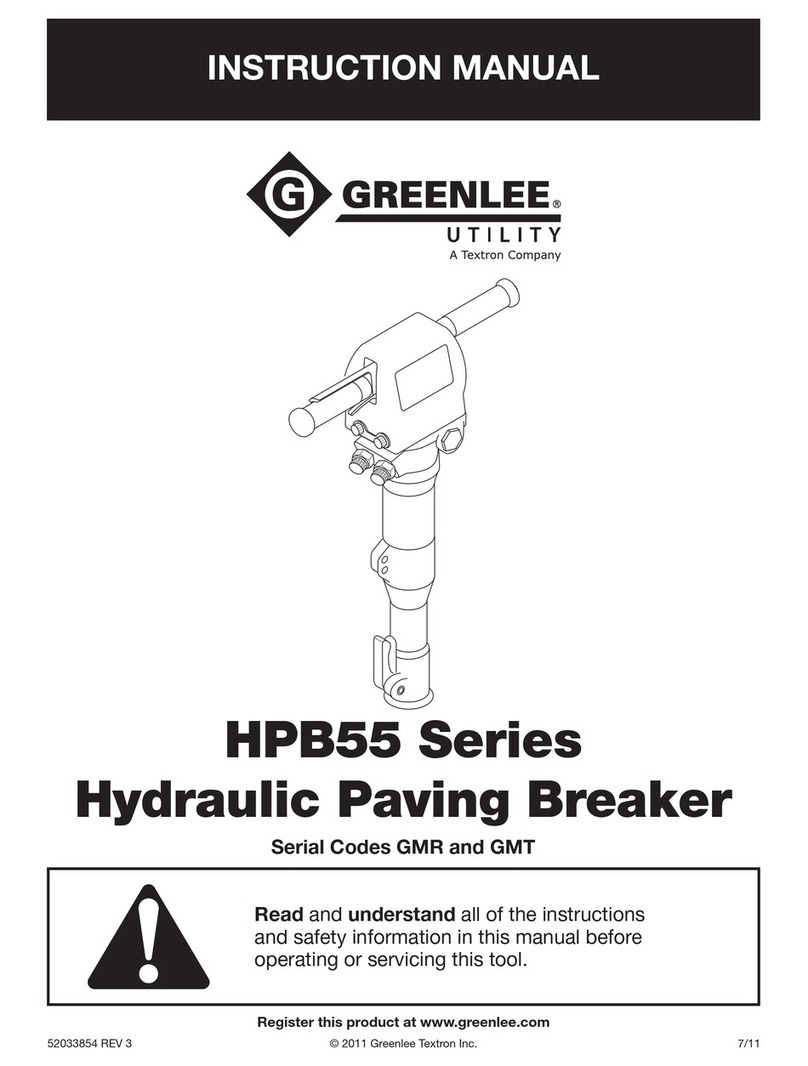

Textron

Textron Greenlee HPB55 Series instruction manual

SUNWARD

SUNWARD SWTC5D Operation & maintenance manual