DVH550/600 5

Par. Title page

3.3.9 Change V-belt for the .........................

hydraulic pump ................................... 29

3.3.10 Lubricate the vibration shaft ............... 30

3.3.11 Adjust, clean the scraper .................... 30

3.4 Operating materials and fill levels .. 31

4 Faults in operation ........................... 32

4.1 General .............................................. 32

4.2 Troubleshooting ............................... 32

4.3 Hydraulic system diagram ............. . 33

5 Winter storage .................................. 34

5.1 Measures prior to storage ............... 34

5.2 Start-up after

storage .............................................. 35

6 Contact addresses for .....................

W E B E R ..........................................

Maschinentechnik GmbH ................ 36

Para. Title Page

Introduction ...................................... 3

General safety guidelines ................ 4

Table of contents ............................. 5

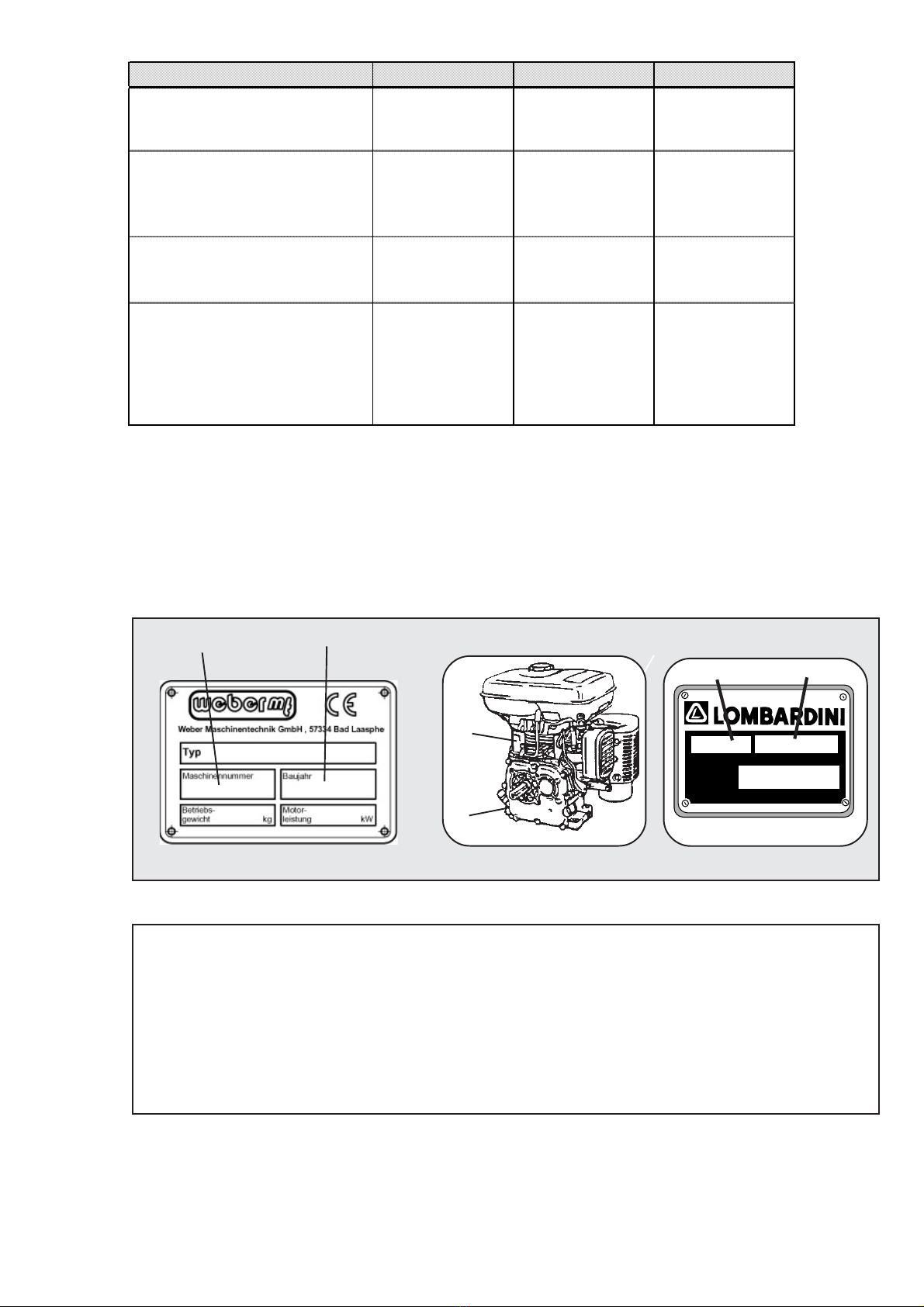

1 Technical description ...................... 6

1.1 Graphic presentation ....................... 6

1.2 Device description ........................... 7

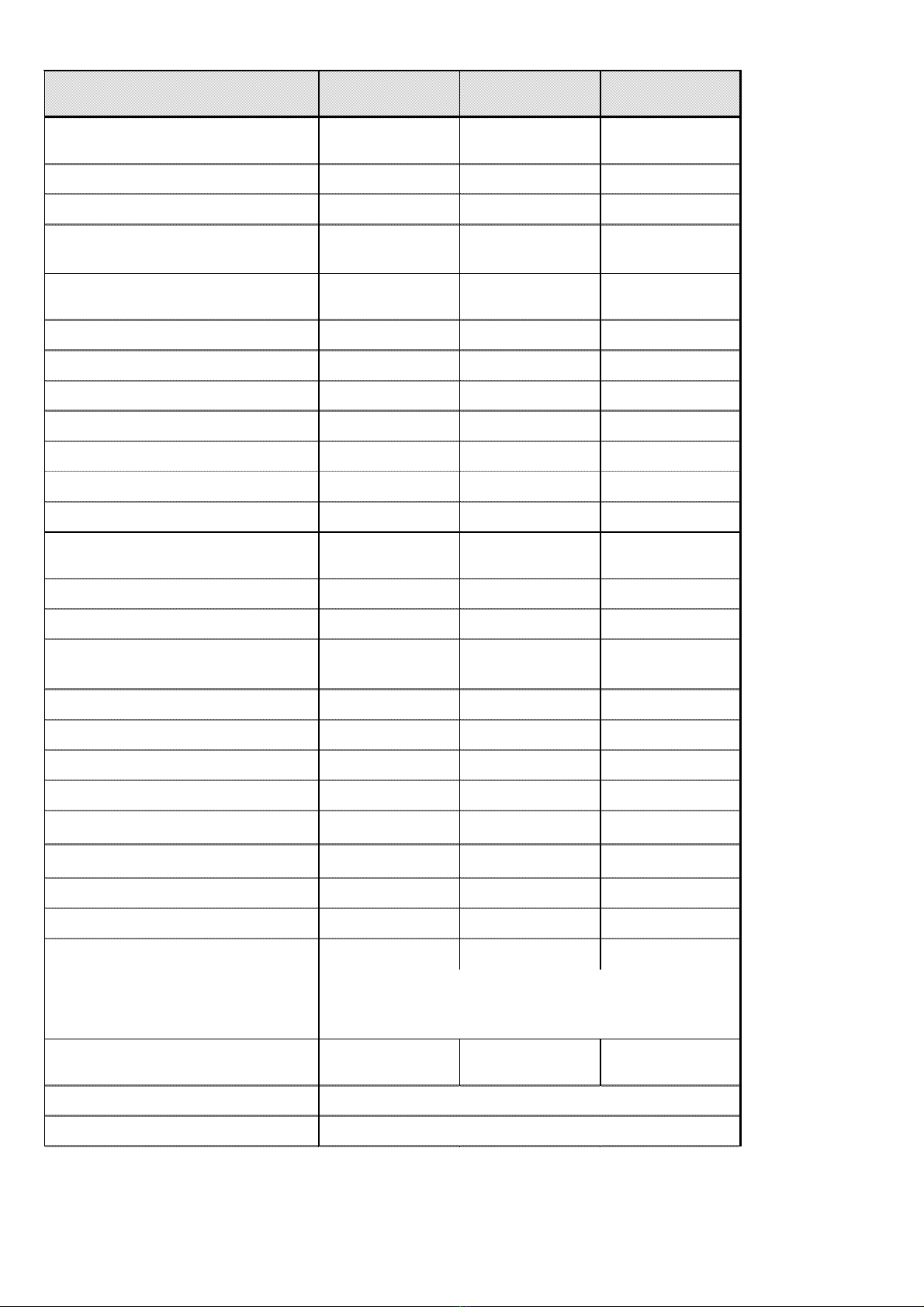

1.3 Technical data .................................. 8

2 Operation .......................................... 10

2.1 Safety guidelines

for operation ..................................... 10

2.2 Transport .......................................... 11

2.2.1 Loading with crane ............................. 11

2.3 First start-up ..................................... 11

2.4 Activities prior to starting work ...... 11

2.4.1 Check the fuel level ............................ 12

2.4.2 Check the engine oil level ................... 12

2.4.3 Check the hydraulic fluid level ............ 13

2.5 Starting.............................................. 14

2.5.1 Normal start DVH 550 L/ 600 L .......... 14

2.5.2 Normal start DVH 550 R ..................... 15

2.6 Driving and compacting .................. 16

2.7 Shutdown .......................................... 17

3 Maintenance ..................................... 18

3.1 Safety guidelines

for maintenance ............................... 18

3.2 Maintenance overview ..................... 19

3.2.1 Initial maintenance ............................. 19

3.2.2 Regular maintenance ......................... 20

3.3 Description of

maintenance tasks ........................... 22

3.3.1 Change engine oil .............................. 22

3.3.2 Change engine oil filter ....................... 22

3.3.3 Clean/change air filter cartridge .......... 23

3.3.4 Clean/change fuel filter ....................... 24

3.3.5 Check & change the vibration V-belt .. 25/

........................................................... 26

3.3.6 Lubricate, tension, or replace the .......

drive chains ........................................ 27

3.3.7 Change hydraulic fluid ........................ 28

3.3.8 Change hydraulic fluid filter ................ 28

Table of contents