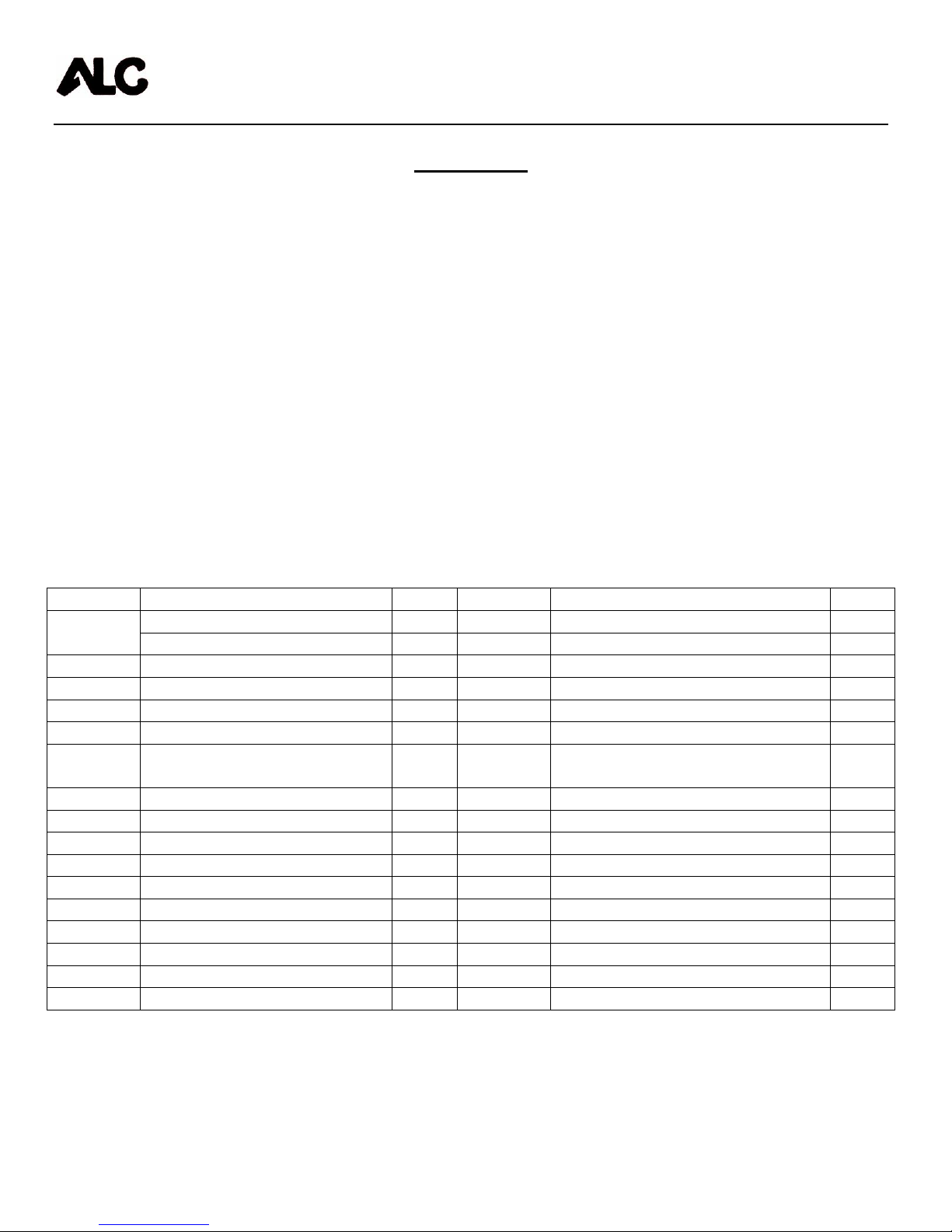

40392 Assembly Instructions

Page 2

WARNING!

Do not use an ALC Cabinet Blaster until you have read this manual and you understand its

contents and warnings. These warnings are included for the health and safety of the

operator and those in the immediate vicinity. Keep this manual for future reference.

Dust created by power sanding, sawing, grinding, drilling, and other construction activities

may contain chemicals known to cause cancer, birth defects or other reproductive harm and

respiratory illnesses. Some examples of the chemicals include:

Lead from lead based paints

Crystalline silica from bricks, cement and other masonry products

Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: Work in a ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

Abrasive blasting produces harmful dust. Everyone in the blasting area must wear a

properly fitted and properly maintained NIOSH approved air supplied respirator.

SILICOSIS AND OTHER DUST WARNINGS:

Breathing dust from silica sand may cause silicosis, a fatal lung disease. Breathing dust

during blasting operations may also cause asbestosis and/or other serious or fatal diseases.

A NIOSH-approved, well maintained air supplied abrasive blasting respirator must be used by

anyone blasting, anyone handling or using media containing toxic substances or media with

more than point one percent (.001) free crystalline silica and anyone in the area of the dust.

Harmful dust can remain suspended in the air for long periods of time after blasting has

ceased, causing serious injury or death.

Before removing respirator, use an air monitoring instrument to determine if atmosphere is

safe to breathe. Contact local OHSA or NIOSH office to determine the proper respirator for

your particular application.

Air supplied respirators do not remove or protect against carbon monoxide (CO) or any other

toxic gas. Use a carbon monoxide removal device and monitoring device with the respirator

to ensure grade D quality air. Follow all applicable OSHA standards and OSHA regulation

1910.134 (d).