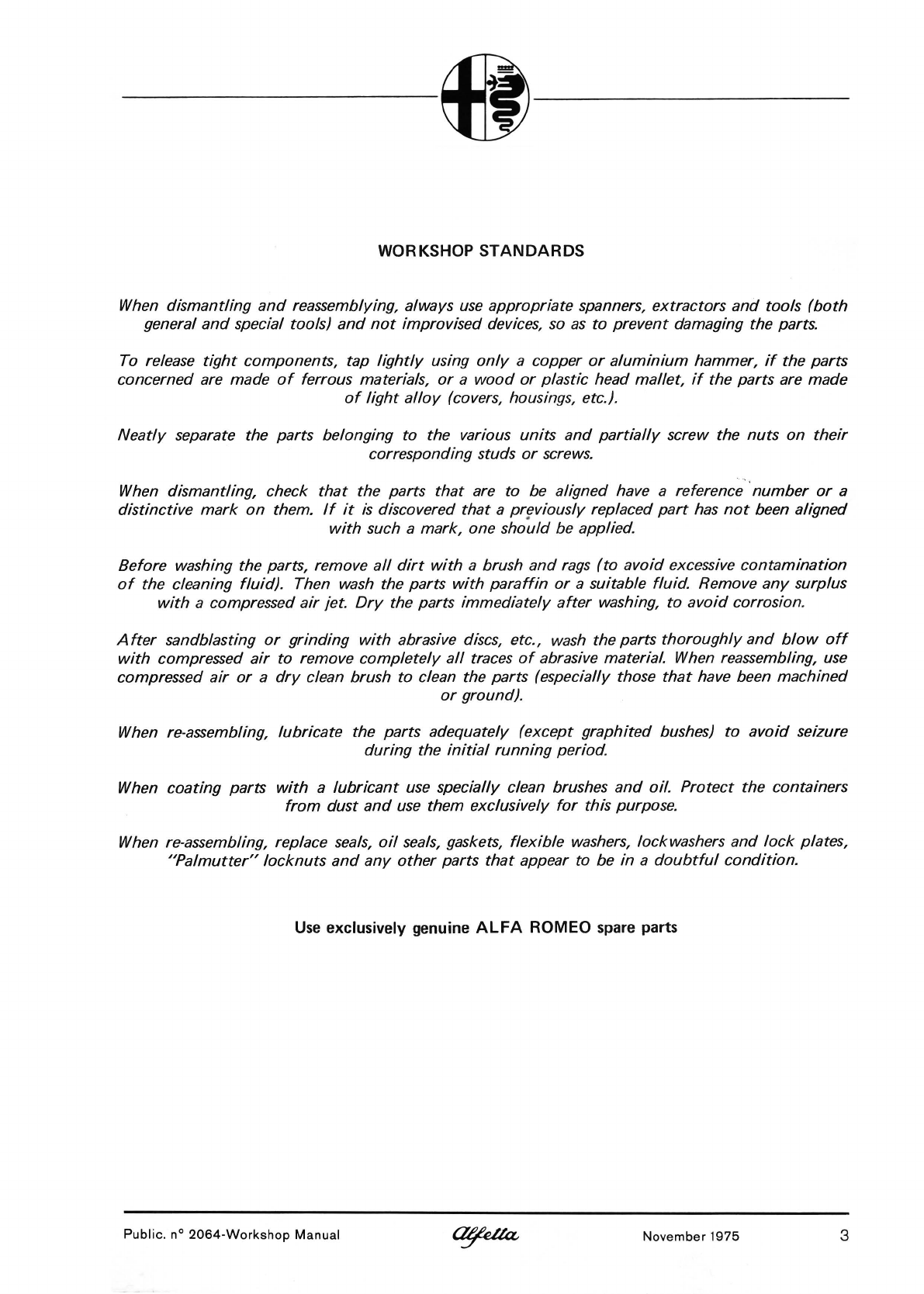

Alfa Romeo Alfetta Instruction manual

Other Alfa Romeo Automobile manuals

Alfa Romeo

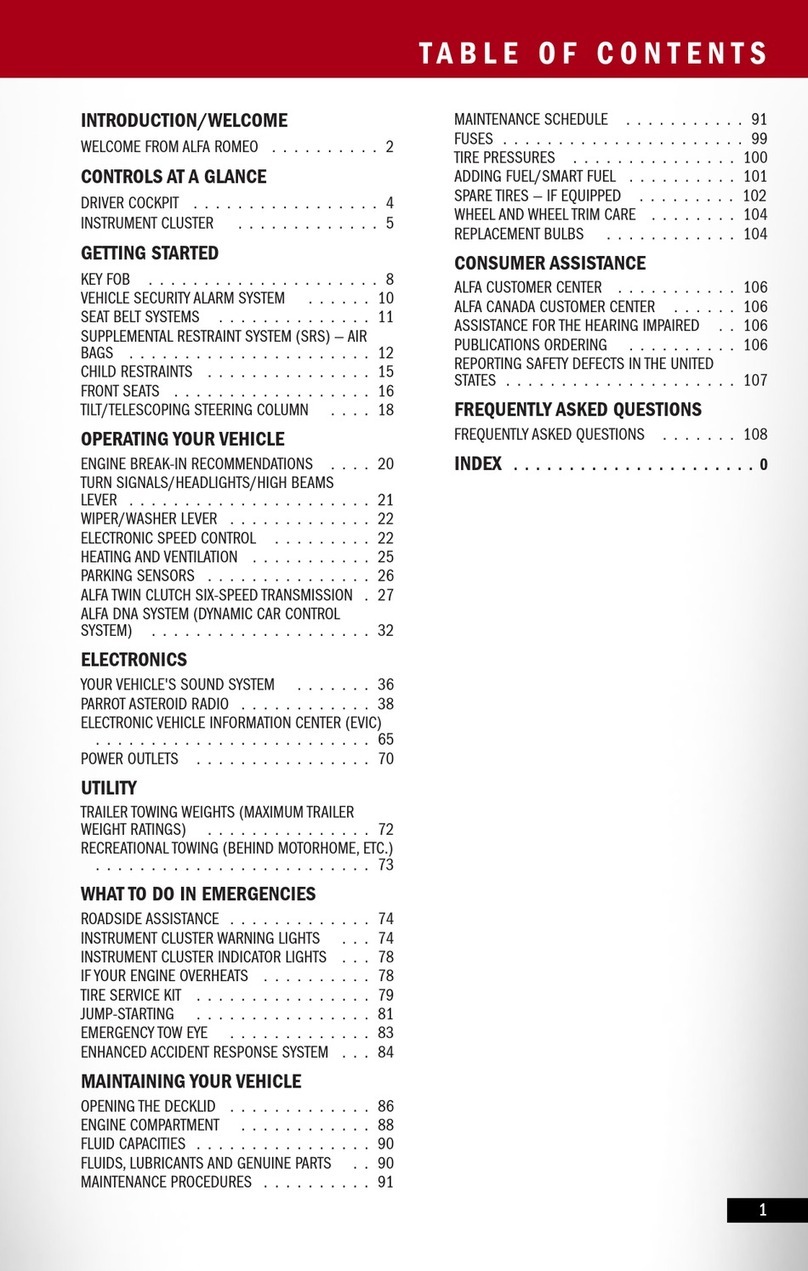

Alfa Romeo Giulia 952 D-SEDAN 2016 User guide

Alfa Romeo

Alfa Romeo 4C Spider 2015 User manual

Alfa Romeo

Alfa Romeo STELVIO 2020 User manual

Alfa Romeo

Alfa Romeo 1750 Berlina User manual

Alfa Romeo

Alfa Romeo MITO User manual

Alfa Romeo

Alfa Romeo 4C 2016 User manual

Alfa Romeo

Alfa Romeo Alfa GT User manual

Alfa Romeo

Alfa Romeo MiTo 2013 User guide

Alfa Romeo

Alfa Romeo MiTo 2015 User guide

Alfa Romeo

Alfa Romeo Giulia 2024 User guide

Alfa Romeo

Alfa Romeo Tonale 2024 User manual

Alfa Romeo

Alfa Romeo giulia 1600 T1 Install guide

Alfa Romeo

Alfa Romeo Giulietta 2010 User manual

Alfa Romeo

Alfa Romeo 1966 to 1994 Spider Installation guide

Alfa Romeo

Alfa Romeo Giulia Quadrifoglio 2017 User manual

Alfa Romeo

Alfa Romeo Tonale User manual

Alfa Romeo

Alfa Romeo Giulia 952 2017 User guide

Alfa Romeo

Alfa Romeo Giulietta 2010 User manual

Alfa Romeo

Alfa Romeo 4C Spider 2015 User guide

Alfa Romeo

Alfa Romeo Giulia 2020 User manual