Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC/EU Declaration of Conformity .................................................................. 5

2. Safety .................................................................................................... 6

2.1. Important information ............................................................................. 6

2.2. Warning signs ..................................................................................... 6

3. Introduction ............................................................................................ 7

3.1. Introduction ........................................................................................ 7

3.2. Intended Use ...................................................................................... 8

3.3. Patents and Trademarks ......................................................................... 8

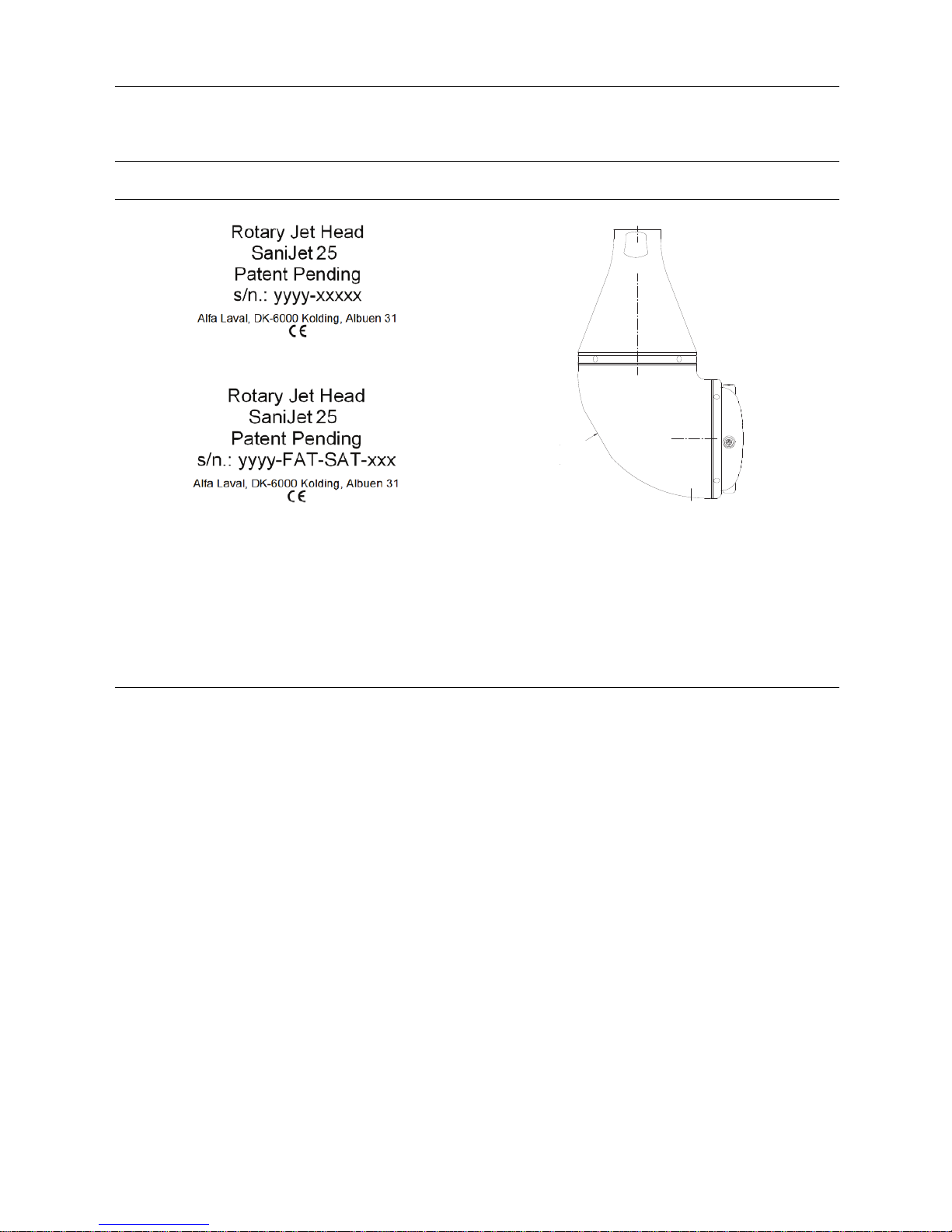

3.4. Marking ............................................................................................ 9

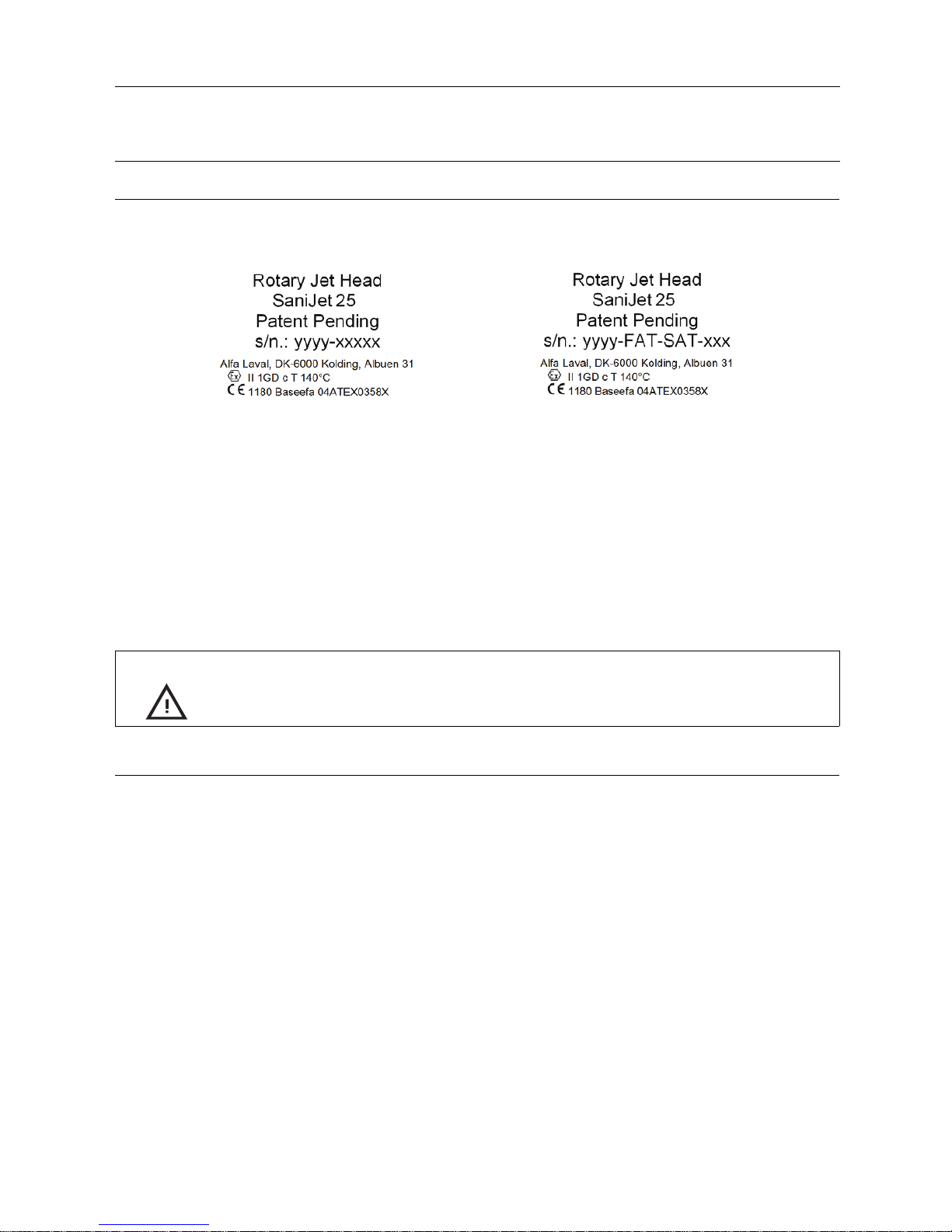

3.5. ATEX Marking ..................................................................................... 10

4. Installation .............................................................................................. 11

4.1. General description ............................................................................... 11

4.2. Quality system .................................................................................... 11

4.3. Functionality ....................................................................................... 12

4.4. General Safety and Installation Instructions .................................................... 13

4.5. Specific Conditions for Safe Use in accordance with ATEX Certification .................... 15

5. Operation ............................................................................................... 16

5.1. Normal operation ................................................................................. 16

5.2. Safety Precautions ................................................................................ 17

6. Maintenance ........................................................................................... 18

6.1. Preventive Maintenance .......................................................................... 18

6.2. Service and Repair of ATEX Certified Machines ............................................... 18

6.3. Service and repair of machines ordered with Q-doc and with Q-doc + FAT-SAT .......... 19

6.4. Maintenance Intervals and Service Kits ......................................................... 20

7. Trouble Shooting Guide .............................................................................. 23

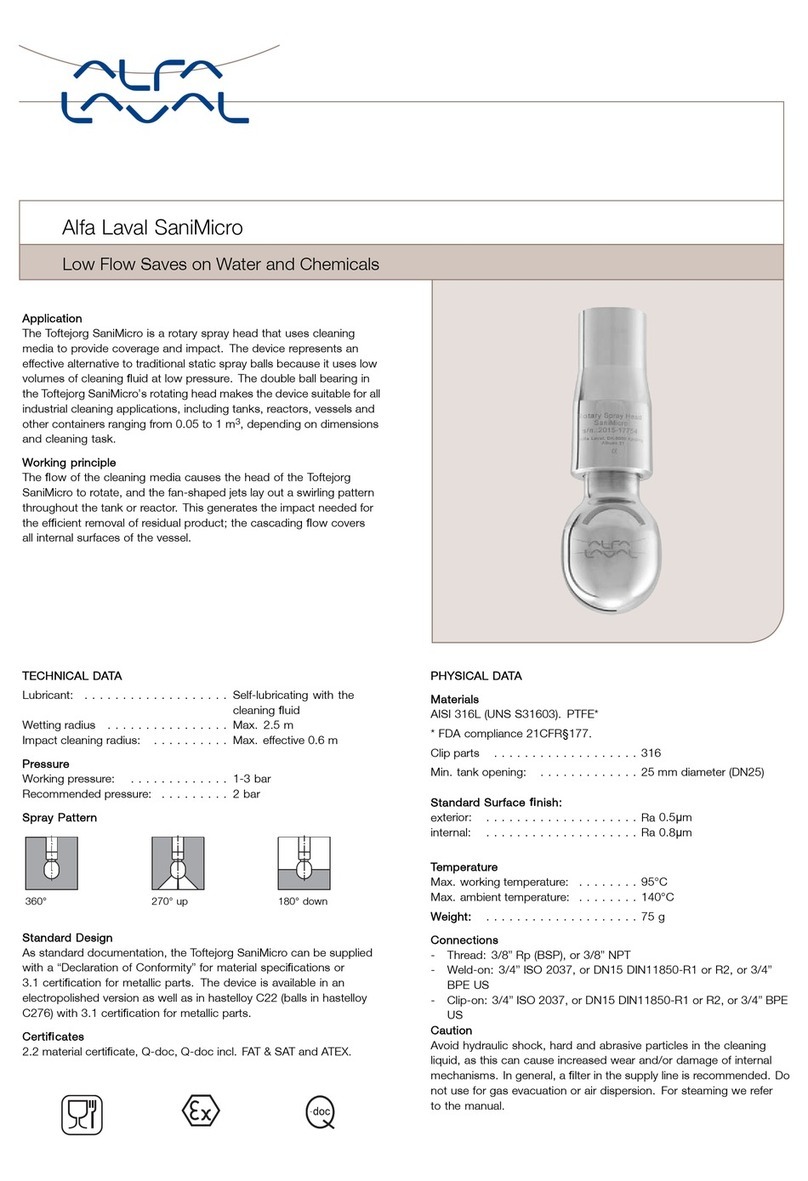

8. Technical Data ......................................................................................... 24

9. Product program ...................................................................................... 26

9.1. Standard configurations .......................................................................... 26

9.2. Available documentation add-ons .............................................................. 26

9.3. Available add-ons for Spare parts ............................................................... 27

10. Part List Drawing and Lists, Service Kits and Tools ............................................. 28

10.1.Part List Drawing .................................................................................. 28

10.2.For machines with -0x and -7x (after August 2012) ........................................... 29

10.3.For machines with -5x, -6x, -8x and -9x (after August 2012) ................................ 30

10.4.Tool kit and tools for assembly and disassembly .............................................. 31

11. Disassembly ............................................................................................ 32

11.1.Disassembly into main subassemblies ......................................................... 32

11.2.Disassembly of lower parts (Hub) ............................................................... 38

11.3.Disassembly of top parts (Cone and Turbine) .................................................. 41

11.4.Disassembly of Impeller Shaft Assembly ....................................................... 46

11.5.Disassembly of gear ring (bearing for body – Pos. 13.3) ..................................... 47

11.6.Disassembly of planet gear (bushing – Pos. 11.1) ............................................ 48

3