9

DOUBLE MITRE SAW T200P - T200M

2.2 General Safety Norms

- The user guarantees the machine is operated only

by trained operators.

- The user must prevent access to the machine by

non-authorized people.

2.2.1 Clothing

- Use only proper clothing. Avoid wearing clothes that

could get stuck in the moving parts. Long hair has to

be tied up. The operator must not keep any pointed

tools in their pockets.

- It is required when performing maintenance and

repair, you use protective clothes such as: cut

resistent gloves and safety shoes which have a slip

resistent sole & crush resistent tops.

2.2.2 Ecology & Pollution

CAUTION

- In paragraph «1.5 Noise Emissions» all the values

related to the noise measured on the machine are

listed. The user has the responsibility to inform the

operators of the machine, the dangers caused by

the noise, and has to respect the current safetyrules

related to this specific subject.

- All the products used for cleaning have to be discarded

in conformity with the laws of the country in which the

machine is used.

- The waste, the residual parts of the packing, & the

scrap work materials have to be given to special

companies for disposal.

- In case of the disposal of the machine, it is necessary

to conform to the anti pollution norms of the country

in which the machine is used.

2.2.3 Safety Procedures

DANGER

- It is absolutely prohibited to let people run and

operate the machine, who have not read and

understood what is described in this handbook, or by

incompetent persons, or persons that are not in good

psychological or physical condition.

- Before connecting the machine to power and running

it, verify that all safeties work properly.

- Before starting to use the machine, get used to using

the new control devices.

- It is forbidden to remove or change the safety

devices.

- The area in which the machine is used, has to be

considered as a <<dangerous area>>, especially for

the persons not trained to use it.

- Before starting the machine, verify that there no

unauthorized persons or animals in the work area.

- When a person is inside the dangerous area, the

operator has has to stop the machine immediatly.

- Do not put your hands close to the blades when the

machine is running.

- It is forbidden to leave the working area when the

machine on.

- It is forbidden to touch any of the moving parts.

2.2.4 Maintenance Procedures

WARNING

- Before starting any kind of maintenance on the

machine, disconnect the power, then disconnect the

pneumatic system and wait until every moving part is

completely stopped.

- Verify periodically the integrity of the machine and it’s

security devices.

- During the maintenance and repair of the saw, it is

required to use protective clothes such as: cut

resistent gloves and safety shoes which have a slip

resistent sole and crush resistent tops.

- Only use original spare parts.

- Do not start any maintenance or cleaning operstions,

if the machine has not been disconnected from the

power supplies; (electric & pneumatic).

- To maintain the machine, strictly follow the

descriptions in this handbook. The parts have to be

replaced only by specialized persons.

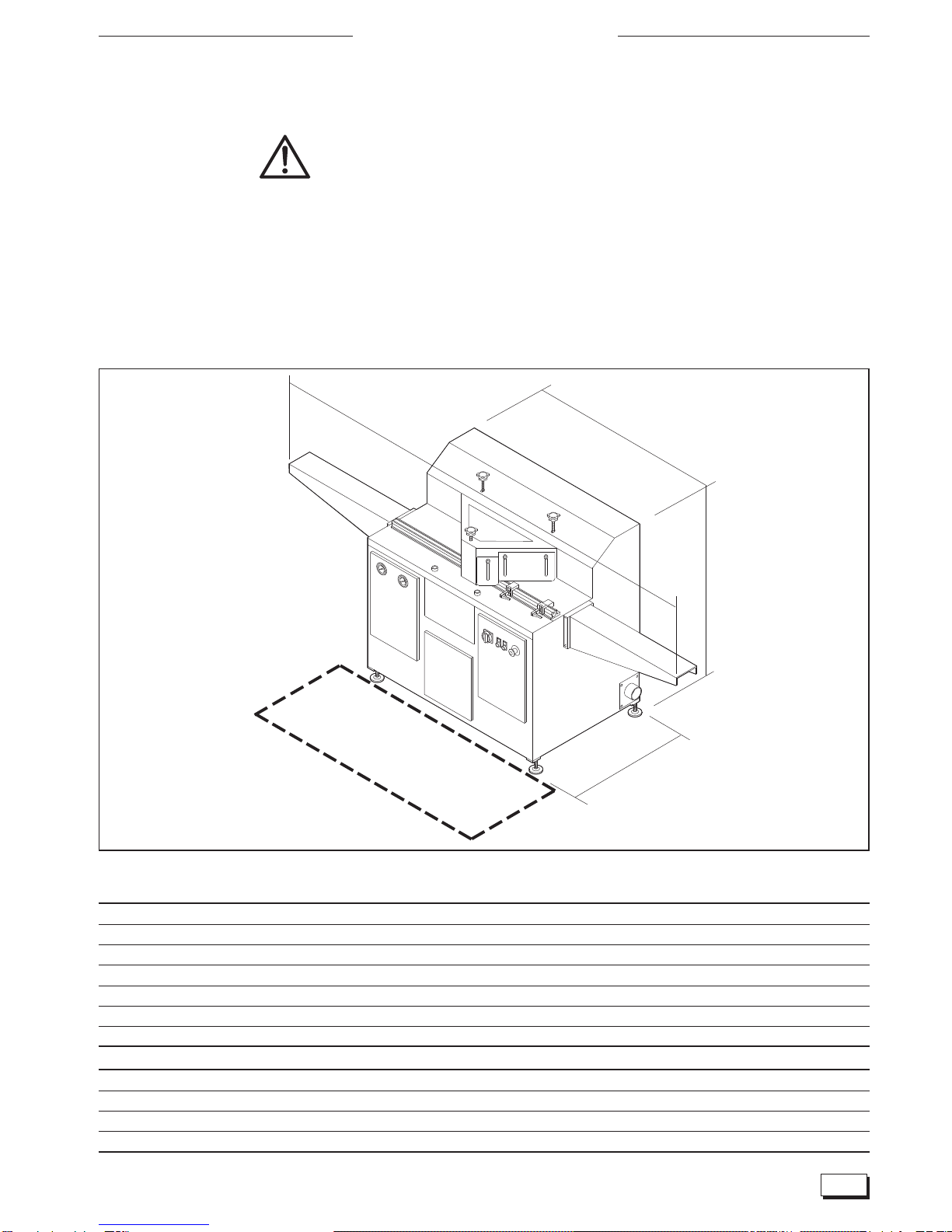

2.3 Safety Labels

The machine has been designed adopting all the

possible security norms, in order to protect the persons

that operate it. In spite of this, there can exist residual

risks that are shown on the machine by adhesive

signs. These signs (pictograms) described in Pic. 3,

are placed on the machine to show all the various

situations of unsafe and dangerous areas.

Keep the safety labels clean, and replace them

immediately when worn out.