Alitrak DTRAK 300 Operating instructions

October 22, 2008 Rev.01

0–INDEX

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages2-57

October 22, 2008 Rev.01

0–INDEX

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages3-57

0INDEX

0INDEX_______________________________________________________________________3

0.1 REFERENCEDSTANDARDS_________________________________________________________5

1INTRODUCTION_______________________________________________________________8

1.1 HOWTO READTHEMANUAL: STRUCTUREAND CONSULTATION__________________________8

1.1.1 Purposeandcontentsofthemanual___________________________________________________8

1.1.2 Generalwarnings__________________________________________________________________8

1.1.3 Safetytermsandsymbolswhichwillbeusedinthemanual_________________________________8

1.1.4 Operatorsforwhomthemanualisintendedandterminologyused___________________________10

1.1.5 Searchcriteriaandconsultinginformation______________________________________________11

1.1.6 Preservationofthemanual_________________________________________________________11

1.2 HOWTO UPDATETHEMANUAL_____________________________________________________11

1.3 MANUFACTURERINFORMATION____________________________________________________12

1.4 TECHNICALASISTANCE___________________________________________________________12

1.5 Warranty_________________________________________________________________________12

2DESCRIPTION_______________________________________________________________13

2.1 GENERALMACHINEDESCRIPTION__________________________________________________13

2.1.1 Machineunits____________________________________________________________________14

2.1.1.1Frameunit______________________________________________________________________14

2.1.1.2Batteryunit______________________________________________________________________14

2.1.1.3Motorunit_______________________________________________________________________14

2.1.1.4Trayunit________________________________________________________________________14

2.1.1.5Driveunit_______________________________________________________________________14

2.1.1.6Commandconsoleunit_____________________________________________________________14

2.2 DATASHEET:CHARACTERISTICS___________________________________________________15

2.2.1 Technicalcharacteristics___________________________________________________________15

2.2.2 Characteristicsof thetransportedproduct__________________ Errore.Ilsegnalibronon èdefinito.

2.3 INTENDEDUSE___________________________________________________________________16

2.3.1 Intededuseandforeseenusageenvironments__________________________________________16

2.3.1.2Unintendeduse__________________________________________________________________16

2.3.1.3Usageenvironment_______________________________________________________________17

2.3.2 Environmentaloperatingconditions___________________________________________________17

2.3.3 Lighting_________________________________________________________________________17

2.3.4 Usageillustration_________________________________________________________________18

2.3.6 Vibrations_______________________________________________________________________19

2.3.7 Noise__________________________________________________________________________19

3TRANPORT_________________________________________________________________20

3.1 WARNINGS______________________________________________________________________20

3.2 TRANSPORINGAND LIFTINGTHEMACHINE___________________________________________20

4WORKAREAUSE____________________________________________________________22

4.1 WARNINGSANDINSTRUCTIONSFORWORKAREA USE________________________________22

4.2 REGULATIONSREGARDING THEENVIRONMENTALCONDITIONS________________________22

4.3 SPACENECESSARYDURINGFUNCTION_____________________________________________23

4.4 RECHARGINGTHEBATTERY_______________________________________________________24

4.4.1 Connectingthebatterycharger______________________________________________________25

5SAFETY____________________________________________________________________26

5.1 GENERALINFORMATION-USES -ZONES____________________________________________26

5.1.1 Generalsafetyinformationandwarnings_______________________________________________26

5.2 WORKAREA _____________________________________________________________________27

5.2.1 Workingzones, controlzones, dangerzones____________________________________________28

5.2.3 Informing,educatingandtraining operatorstousethemachine_____________________________30

5.3 INTEGRATEDSAFETYDEVICESAND OPERATINGCYCLE_______________________________30

October 22, 2008 Rev.01

0–INDEX

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages4-57

5.4 SAFETYAND CONTROLSYSTEMS___________________________________________________33

5.5 CHARACTERISTICSOFGUARDS,PROTECTIONSAND SAFETYDEVICES WHICH HAVE BEEN

EMPLOYEDTOREDUCEMECHANICALRISKS_________________________________________34

5.5.1 Fixedguards____________________________________________________________________34

5.5.2 Riskofbreakageduringfunction_____________________________________________________34

5.5.3 Riskspresentedbyedges, obstaclesandcorners________________________________________34

5.5.4 Burnrisks_______________________________________________________________________34

5.5.5 Risksanddangersofinstability______________________________________________________35

5.5.6 Residualriskspresentedbymobile(driveorworking)elements_____________________________36

5.5.7 Safetydevices___________________________________________________________________37

5.6 PROTECTIONMEASURES AGAINSTOTHERRISKS_____________________________________39

5.6.1 Protectionagainsttherisks presentedbyelectricalenergy_________________________________39

5.6.2 Protectionagainsttherisks ofexplosion_______________________________________________39

5.6.3 Protectionagainsttherisks presentedbynoiselevels_____________________________________39

5.7 SAFETYDURING MAINTENANCE,REGULATION, USAGEAND ADJUSTMENTPHASES________40

5.7.1 Prohibitionsandregulations_________________________________________________________40

5.8 SAFETYDURING CLEANING________________________________________________________40

6FIRST USE__________________________________________________________________41

6.1.1 Controls________________________________________________________________________41

6.2 STARTINGUPTHEMACHINE_______________________________________________________43

6.2.1 Uphill/downhillmaneuvering________________________________________________________44

6.2.2 Parking themachine_______________________________________________________________44

6.2.3 Intensiveandprolongeduse________________________________________________________44

6.3 DISCONNECTINGTHEENERGYSOURCES____________________________________________45

7ORDINARYMAINTENANCE____________________________________________________46

7.1 SAFETYPRECAUTIONS:PREPARINGTHEMACHINEFORMAINTENANCEAND RELATIVE

PRECAUTIONS___________________________________________________________________46

7.1.1 Preparingthemachineformaintenance________________________________________________46

7.1.2 Generalsafetyprecautions_________________________________________________________47

7.1.3 Safetydevicechecks and functionalitytesting___________________________________________47

7.1.4 Electricalsystemmaintenance_______________________________________________________48

7.2 ORDINARYMAINTENANCEACTIVITIES(GENERALINFORMATION)________________________49

7.2.1 Technicalprecautionsforpropermaintenance__________________________________________49

7.2.2 Maintenanceplan_________________________________________________________________51

7.3 ORDINARYMAINTENANCE_________________________________________________________52

7.3.1 Ordinarymaintenanceprogram______________________________________________________53

7.4 SPECIALMAINTENANCE___________________________________________________________54

8WASTEDISPOSAL___________________________________________________________55

9DISPOSALOFTHEMACHINE__________________________________________________56

10 ANNEXES___________________________________________________________________57

October 22, 2008 Rev.01

0–INDEX

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages5-57

MACHINEDATALABEL

ViaCrispi,10 –36056 TEZZESUL BRENTA(VI)–ITALIA

Tel.+390424898349–fax+390424536792

Model DTRAK300

Year ofmanufacture

xxxx

Serial number xxxxxxxxxxx

Max. capacity xxx Kg

Power input 24 volt

Motorpower 900 W

IMPORTANTNOTICE:THISMANUALISTHEPROPERTYOFALITRAK,ANYREPRODUCTION,

EVENPARTIAL, ISFORBIDDEN.

DOCUMENTTYPE: INSTRUCTIONMANUAL Rev. 01

REFERENCEDMACHINE:Mod. DTRAK300

SERIALNO.

0.1REFERENCEDSTANDARDS

The manualhasbeen drafted inconsideration ofthe indicationsprovided by:

UNI 10893 July2000;

UNI 10653 November1997;

IECEN62079 January 2002.

October 22, 2008 Rev.01

0–INDEX

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages6-57

ECStandards

Reference Title

ECDirectiveno. 98/37 Knownas"The MachinerySafetyDirective"

ECDirectiveno. 2004/108

Regarding ElectromagneticCompatibility(EMC)

ECDirectiveno. 2006/95 Regarding the LowVoltage Directive,regarding theCEmarking

ECDirectiveno. 2000/14 Environmentalacousticemissionsofmachinery and equipmentintended

forexternaluse

ECDirectiveno. 2002/44 Minimumsafetyand healthrequirementsregarding the exposureof

workerstorisksderivingfrommechanicalvibrations

Harmonizedstandards, exposuredraftsandnational technical standards

Reference Title

ISOEN12100

(2003) Safetyofmachinery --Basicconcepts, generalprinciplesfordesign

Part 1–Basicterminology, methodology(exEN292-1)

Part 2–Technical principles(exEN292-2)

EN294 (1993) SafetyofMachinery -SafetyDistancestoPreventDangerZonesBeing

Reached bythe UpperLimbs

EN349 (1994) Safetyofmachinery -Minimumgapstoavoidcrushing ofpartsofthe human

body

EN418 (1994) SafetyofMachinery.Emergency Stop Equipment,Functional Aspects-

PrinciplesforDesign

EN457 (1993) SafetyofMachinery -Auditory DangerSignals-GeneralRequirements,

Design and Testing

EN563 (2000) SafetyofMachinery -TemperaturesofTouchableSurfaces-Ergonomics

DatatoEstablishTemperatureLimitValuesforHotSurfaces

EN953 (2000) Safetyofmachinery.Guards.Generalrequirementsforthe design and

construction offixed and movableguards.

EN954-1 (1998) Safetyofmachinery.Safetyrelated partsofcontrolsystems.Part1:general

principlesfordesign.

ENISO13849-

2

(2003) Safetyofmachinery -Safety-related partsofcontrolsystems-Part2:

Validation (EN954-2)

EN1037(1997) Safetyofmachinery -Prevention of unexpected start-up

EN1050 (1998) Safetyof Machinery -PrinciplesforRiskAssessment

October 22, 2008 Rev.01

0–INDEX

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages7-57

Reference Title

EN1070 (2000) Safetyofmachinery.Terminology

EN60204-1 (1998) Safetyofmachinery -Electricalequipmentofmachines-Part1:general

requirements

EN60445 (1992) Basicand safetyprinciplesforman-machine interface,marking and

identification -Identification ofequipmentterminalsand ofterminationsof

certaindesignated conductors,including general rulesforan alphanumeric

system

EN60447 (1997) Man-machine interface(MMI)-Actuating principles

EN60529 (1977) Degreesofprotection provided byenclosures(IPCode)

EN61082-1 (1993) Preparation of documentsused inelectrotechnology-Part 1: rules

EN61310-1 (1996) Safetyofmachinery -Indication,marking and actuation-Part 1: requirements

forvisual, acousticand tactilesignals

EN61310-2 (1996) Safetyofmachinery -Indication,marking and actuation-Part 2: requirements

formarking

EN61310-3 (2000) Safetyofmachinery -Indication,marking and actuation-Part 3: requirements

forthe location and operation ofactuators

UNI 10653 (1997) Technicaldocumentation -Qualityofproducttechnical documentation

UNI 10893 (2000) Technicaldocumentation ofproduct-Instructionsforuse-Articulation and

exposition of the content

CEI 64-8 (2003) Electricalsystemswithnominaltension valuesnotsuperiorto1000 Vin

alternatecurrent and 1500 Vindirectcurrent–Parts1through 7

EN1175-1 (1999) Safetyofindustrialtrucks.Electricalrequirements.Part1:general

requirementsforbattery powered trucks.

EN474-1 (1997) Earth-movingmachinery.Safety. Part 1: general requirements

EN474-6 (1997) Earth-movingmachinery -Safety-Part 6: requirementsfordumpers

ENISO 3450 (1997)

Earth-movingmachinery.Brakingsystemsofrubber-tired machines.Systems

and performancerequirementsand test procedures.

ISO6393 (1985) Acoustics-Measurementofairborne noiseemitted byearth-moving

machinery -Method fordetermining compliancewithlimitsforexteriornoise-

Stationary test conditions

ISO5349-2 (2004) Mechanicalvibration -Measurementand evaluation ofhuman exposureto

hand-transmitted vibration -Part 2: practicalguidanceformeasurementinthe

workplace

22 ottobre 2008 Rev.01

1–INTRODUZIONE

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages8-57

1INTRODUCTION

1.1HOW TO READTHEMANUAL:STRUCTUREAND CONSULTATION

1.1.1Purpose and contentsofthemanual

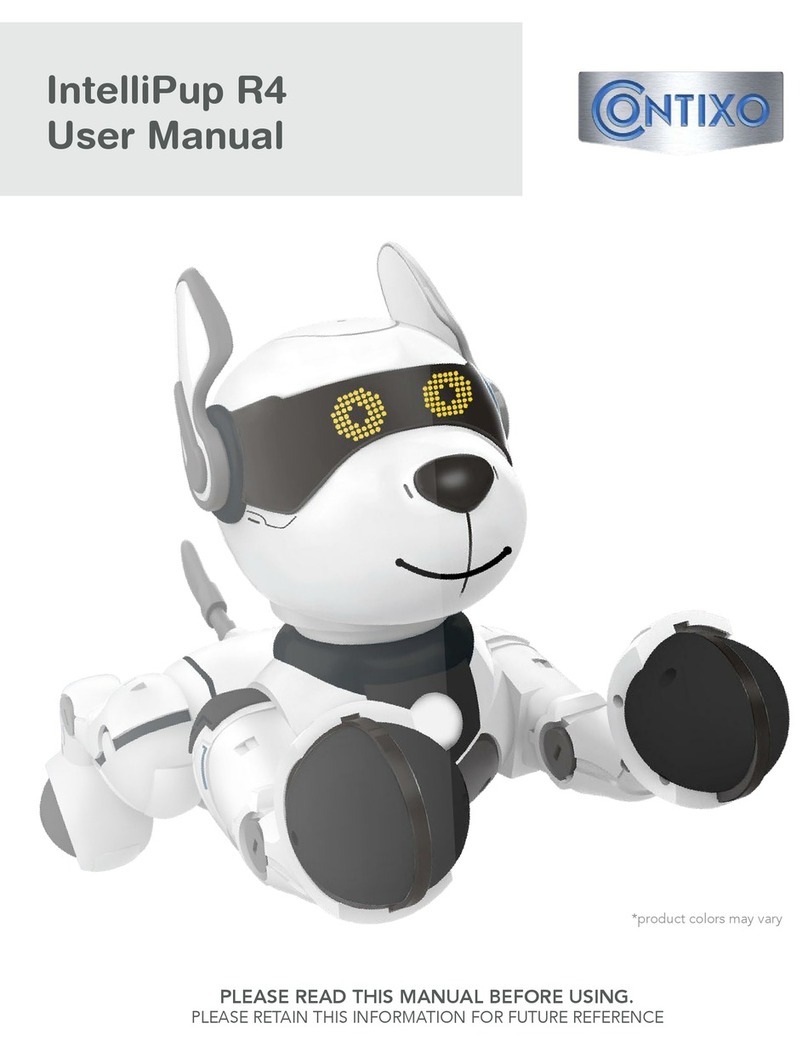

Thismanual describesthe DTRAK 300 machine.

The machine can be used forworking withproductswhichhavethe characteristicsdescribed inthe

datasheet (see chapter2).

Hereafterinthe manual,the DTRAK 300 machine willbesimplyreferred toasthe “machine”.

The manualiswritten insuchawaysoastoinformitsoperatorabout:

-problemsregarding themachineand the productsbeing worked with;

-safeoperation.

Therefore,withinthe manualthe operatorwillfinduserinstructionsand propermaintenance

procedures, togetherwithsafetyand accidentprevention regulations.

1.1.2Generalwarnings

WARNING:BEFOREPERFORMINGANYOPERATIONupon themachine,ITS

OPERATORSAND QUALIFIEDTECHNICIANSMUSTCAREFULLYREAD THE

INSTRUCTIONSCONTAINEDINTHEPRESENTDOCUMENT(and relative annexes)AND

FOLLOWTHEMWHENPERFORMINGANYOPERATIONS.

The generalwarningscontainimportantinformation regarding:

-the safetyofthe personnelassigned tothe machine’suse, operation and maintenance;

-the safetyand the efficiency of the machine;

-work quality.

WARNING:USEOFTHEMACHINEISNOTTOBEPERMITTEDIF THEREAREANY

DOUBTSREGARDINGTHECORRECTINTERPRETATIONOFTHEINSTRUCTIONS.

REQUESTANYNECESSARYCLARIFICATIONSFROMTHEMANUFACTURERORFROM

AN AUTHORIZEDASSITANCECENTRE.

The manufactureriswilling toprovide training coursesatitsfacilitiesorelseatthe facilitiesofthe

machine’sdistributor.

Availability, times,costsand methodsmust be agreed upon beforehand.

1.1.3Safetyterms andsymbolswhichwillbeusedin themanual

-DANGERZONE:zone withinornearthe machine whichconstitutesahealthand safetyriskforany

person exposed tothe zone.

-EXPOSEDPERSON:aperson located entirelyorpartiallywithinadangerzone.

-OPERATORS:peopleincharge ofinstalling,operating,adjusting,maintaining orcleaning the

machine, eachwithinthe limitsofthe responsibilitiesassigned tothem.

Risk:The combinationofprobabilityand severityofpossiblepersonalinjuryorhealth

risksindangeroussituations.

Residualrisk:Anyriskremaining afterhaving adopted the appropriatesafetymeasures;

Danger:Sourcesofpossiblepersonalinjury.

22 ottobre 2008 Rev.01

1–INTRODUZIONE

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages9-57

NOTE:Theresponsibilities ofthevariousoperators willbedefinedwithinthemanual.

-QUALIFIEDOPERATOR:

The useofthe machine mustbe permitted exclusivelytoadequatelytrained,qualified personnel.

Thispersonnelmustbe capableofoperating the machine through the useofthe appropriate

controls,of managing alloperationalproceduresand ofperforming the start-up orwork recovery

phasesfollowing anyinterruptions.

-SPECIALIZEDMAINTENANCEMECHANIC:

Aqualified technician capableofoperating the machine innormalconditions,ofoperating the

machine withthe safetydevicesdisabled and ofperforming allofthe necessary adjustments,

maintenanceoperationsand repairwork upon the mechanic, pneumaticand hydraulicparts.

WARNING:SPECIALIZEDMAINTENANCEMECHANICSARENOT AUTHORIZEDTO

WORKONLIVE ELECTRICSYSTEMS.

-SPECIALIZEDMAINTENANCEELECTRICIANS:

Qualified technicianscapableofoperating the machineinnormalconditionsand ofoperating the

machine withthe safetydevicesdisabled;areincharge ofthe performing adjustments,

maintenanceoperationsand repairwork upon the machine’selectrical components.

Thesetechniciansshall be capableofworking on the liveelectricalsystemswithinthe appropriate

cabinetsand boxes.

-MANUFACTURERSPECIALIZEDTECHNICIANS:

Specialized personnel,employed bythe Manufacturerorbyan authorized assistancecentre,

appropriatelytrained and authorized toperformspecialmaintenanceorrepairwork whichrequire

specialized knowledge ofthe machine, of howthe machine works, ofthe safetydevicesand of the

mannerinwhichsafetydevicesinterveneduring the machine’sfunction.

Symbolsused forsafetywarningsinordertofacilitatethe reading and comprehension of the text:

ATTENTION:Indicatesdangeroussituationsforpersonnelandinjury prevention

standardsfortheoperators.

NOTICE: Indicatesdangeroussituationsforthemachineand/oritscomponentsand/or

theproductbeingworkedwith.

CAUTION:Additionalnoticesand/orregulationsregardingsafetyissuesduring the

currentoperation.

NOTE:Provides usefulinformation.

IMPORTANT NOTICE: Provides particularlyusefulorimportantinformation.

22 ottobre 2008 Rev.01

1–INTRODUZIONE

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages10 -57

1.1.4Operators forwhomthemanualisintended andterminologyused

The manualisintended for:

-personnelincharge ofoperating the machine (hereafterreferredtointhe manual simplyas

“operators”);

-technicalpersonnelincharge of ordinary maintenance(hereafterreferred tointhe manualsimplyas

“maintenancepersonnel“), eachwithregardstotheirownspecialty(mechanicalorelectrical);

-maintenancemechanics:personnelwhichhasbeentrained and authorized formaintaining the

mechanical parts, the pneumaticsystems, and the hydraulicsystems;

-maintenanceelectricians:personnelwhichhasbeen trained and authorized formaintaining electric

and/orelectronicpartsand systems;

-qualified technicians(employed bythe manufacturerorbyan authorized assistancecentre),in

charge of specialmaintenanceaswell ascomplexand/orspecialized operations.

NOTE:Thismanual shall definetheduties, theresponsibilities and theoperationallimitsofthe

variousoperators.

ATTENTION:Itisforbidden forthemachine’soperatorsto perform operationswhich are

reservedforthequalifiedmaintenance ortechnicalpersonnel. TheManufacturer bears

noresponsibilityfordamagesderived fromfailure toobserve thisprohibition.

NOTICE: Some activities(suchasopening thepackaging, assemblyand setup, initial

calibration and adjustments, repairwork, servicing and movementand/ordismantling of

themachine)require thepresence ofqualifiedtechniciansemployedbythe

Manufacturer orbyanauthorizedassistance centre.

Inordertofullyunderstand the instructions(textand illustrations),the machine’soperatorsmusthave

(ormust acquirebymeansofadequateeducation and training)atleast the following characteristics:

-generaleducation and technical knowledge atalevelwhichissufficienttobe abletoread and

understand the partsofthe manual’scontentswhichapplytothemand tobe abletoproperly

interpretthe drawingsand figures;

-the capabilityofunderstanding and interpreting thesymbols,the pictogramsand the visual

messages;

-knowledge ofthe mainhygiene,injury prevention and technological standards;

-knowledge ofthe location of the machine withinthe workplace;

-knowledge ofwhattodo incaseofemergency,wheretofind the personalprotection devicesand

howtousethemproperly.

The maintenancepersonnel,inaddition tothe abovecharacteristics,mustalsopossessthe

appropriatetechnicaleducation,acquired bymeansofadiploma,aprofessionalqualification and/or

adequate,relevantwork experience.Moreover,theymustpossessthe necessary,specificand

specialized technicalknowledge (mechanical orelectrical)forthe responsibilitiesforeseen inthe

manual.

22 ottobre 2008 Rev.01

1–INTRODUZIONE

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages11 -57

ATTENTION:Some importantregulationsprescribedbytheEuropeanDirectiveson

safetyin theworkplace are listed below.

THEPERSONINCHARGEOF WORKPLACESAFETYmust:

-verifythattheemployeesactuallypossesstheknowledgenecessaryforreading and

fullyunderstandingthemanual;

-provideadequatepracticaltrainingandmake sure,eventhroughtesting,thatthe

operatorsare capableofoperatingthemachineinasafeand proper manner,bothin

normaloperating situationsaswell asin emergencysituations.

1.1.5Search criteriaand consultinginformation

The information and the instructionswithinthe manual areorganized bychaptersandbyparagraphs

and can be easilyfound byconsulting the systematicindexat the beginning of the manual.

Page and figurenumbering.

The chaptertowhicheachpage belongsisprovided at the top of the page.

Paragraphsarenumbered using twoormorenumbersseparated byperiods.The firstnumber

indicatesthe chapterandthe numberswhichfollowindicatethe paragraphandsub-paragraph

numbersinlogical order(example: 1.1.5indicateschapter1, paragraph 1,sub-paragraph 5).

Figuresarenumbered using twonumbersseparated byadash. The first numberindicatesthe chapter

whilethe second numberindicatesthe figure(example: fig. 2-23 indicatesfigure23 inchapter2).

ATTENTION:PAYPARTICULAR ATTENTIONWHENREADINGCHAPTER5“SAFETY”

ASIT CONTAINSIMPORTANTAND DETAILEDSAFETYINFORMATIONAND WARNINGS.

1.1.6Preservation ofthemanual

THEPRESENTMANUALand all ofitsannexesMUSTBE PRESERVEDINAPLACEWHICH IS

EASILYACCESSIBLE,NEARTHEMACHINEAND KNOWNTOALL OF THEMACHINE’SUSERS

(OPERATORSASWELL ASPERSONNELINCHARGEOFITSMAINTENANCE).

The operatorsand maintenancepersonnelmust be able toquicklyconsult the manualinanysituation.

FORSAFETYPURPOSES,THEMANUALISTOBECONSIDEREDANINTEGRALPARTOFTHE

MACHINE.

Therefore:

-It must bekept entire(inallofitsparts);

-It mustbe keptwiththe machine untilthe machine isdisposed of(aswell asincasesoftransfer,

sale, rent, etc.ofthe machine itself);

-IT MUSTBEKEPTUPTODATEAND NOTEANYEVENTUALMODIFICATIONSWHICH HAVE

BEENMADETOTHEMACHINE.

1.2HOW TO UPDATETHEMANUAL

Ifthe machine shouldbe subjected tosubstantial modifications,the manufacturershallarrange forthe

Customertobe provided withacorrect and updated version of the presentmanual.

Upon receiving the newmanual,the usermusttakecaretosubstituteall existing copiesofthe

previousone inordertoensurecongruitybetween the manual and the systembeing utilized.

22 ottobre 2008 Rev.01

1–INTRODUZIONE

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages12 -57

1.3MANUFACTURERINFORMATION

Manufacturer:ALITRAKs.r.l.

Via, Crispin°10

CAP 36056 TEZZESUL BRENTA(VI)Italy

Tel.: +39 0424 -898349

Fax:+39 0424 –536792

e-mail: info@alitrak.com

website: www.alitrak.com

1.4TECHNICAL ASSISTANCE

Ourcustomerassistanceisat the Customer’sdisposalfor:

-clarificationsand information;

-requesting specialized technicalpersonnelforinterventionson site, atthe customer’sfacilities;

-requesting spareparts.

Requestsforspecialmaintenancecan be faxed eitherdirectlytothe Manufacturerortoaqualified

assistancecentre.

ATTENTIONremember that:

-TheCustomer isobligedtopurchase exclusivelyoriginalspare partsorelse those

whichhave been expresslyauthorized inwritingbytheManufacturer;

-Theinstallationandremovalofspare partsmustbeperformedbyqualified

techniciansandcarriedoutin accordance with theManufacturer’sinstructions;

-Theuse ofnon-originalspare partsand/orincorrectinstallationofspare partsshall

exoneratetheManufacturer fromanyresponsibility.

Authorized assistancecentre:ALITRAKs.r.l.

Via, Crispin°10

CAP 36056 TEZZESUL BRENTA(VI)Italy

Tel.: +39 0424 -898349

Fax:+39 0424 –536792

e-mail: info@alitrak.com

website: www.alitrak.com

1.5WARRANTY

ALITRAKguaranteesthatthe machine referred tointhe presentmanualhasbeen designed and

manufactured inaccordancewiththe currentstandards,particularlywiththoseregarding operator

healthand safety;the machine hasbeen inspected and approved (see attached certificate).

The productisguaranteed for12 months; electricalpartsareexcluded fromtheguarantee.

Consumption materialsarealsoexcluded fromthe guarantee.

The purchaserisexclusivelyentitled tothe substitution ofanydefectiveparts.Anytransportcosts

shall be atthe Purchaser’sexpense.

Anydamage deriving fromthe pooroperation ofthe machine,fromfailuretoobservethe maintenance

standardsaswell asfromincorrect manoeuvring on behalf of the operatorshall be excluded fromthe

guarantee.

Anytampering withthe machine, especiallywiththe safetydevices, shall nullifythe GUARANTEEand

exoneratethe Manufacturerfromanyresponsibility.

No refundsshall be granted forreasonsoflackofmachine use.

October 22, 2008 Rev.01

2-DESCRIPTION

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages13 -57

2DESCRIPTION

2.1GENERAL MACHINEDESCRIPTION

Foreword

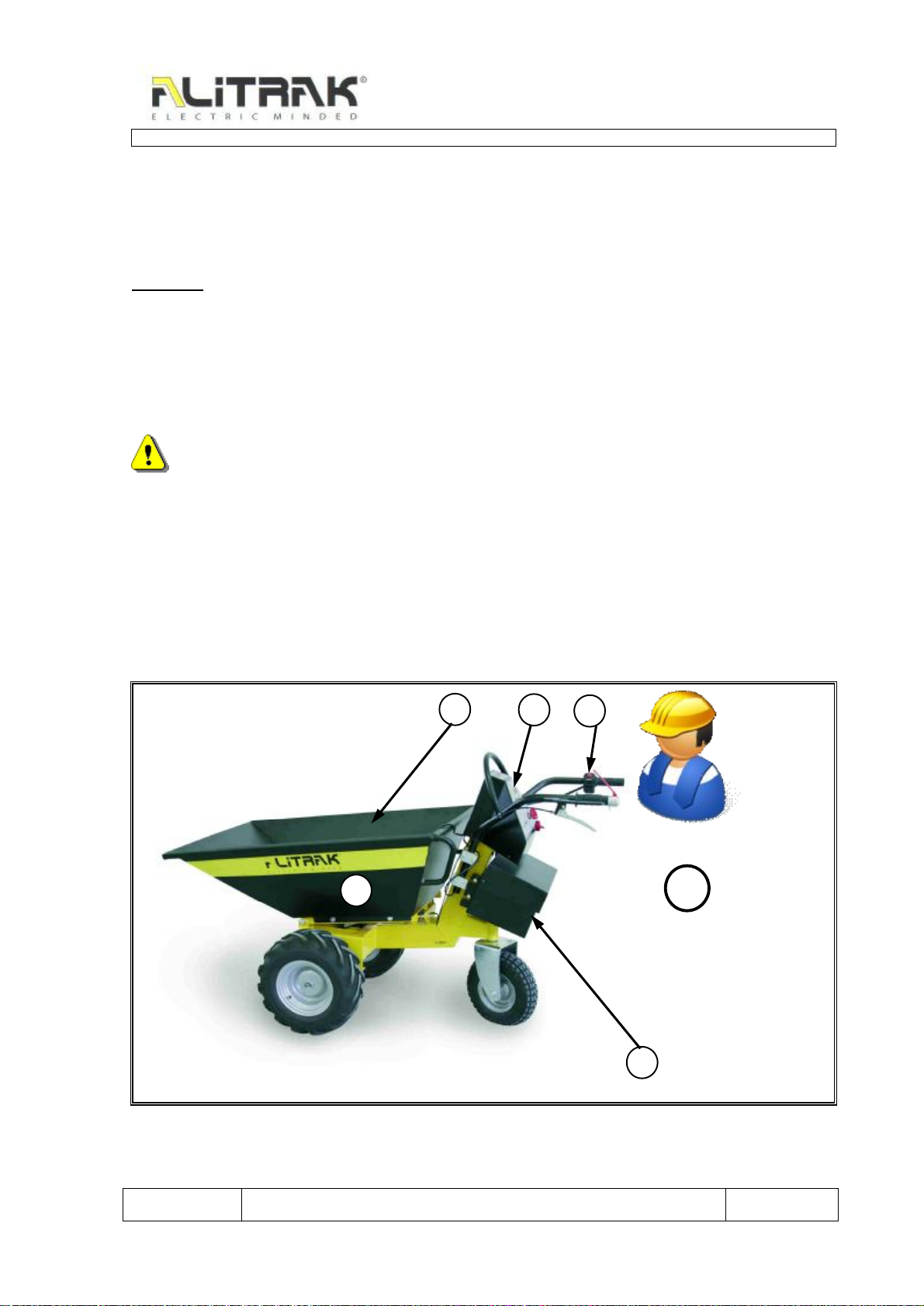

The DTRAK300 machine (no.1infig.2-1)hasametallicframewhosebaserestsupon three

wheels,twofortraction and one forturning.Anelectricmotor,powered bya24 voltbattery,is

located withinthe basicframe.The manualdumpertray(no.2),inwhichthe materialtobe

transported shall be placed,ispositioned abovethe frame.The battery lodging (no.3)islocated at

the front, abovewhichcan be found the controlpanel (no.4)whichisconnected tothe plough-stilt

drivesystem(no.5)withitsrelativemanualcontrols.The position fromwhichthe operatorshall

conduct the machine isshownwithpoint(A)infig. 2-1.

ATTENTION:some ofthemanual’sillustrationsshow themachine,orpartsofit, without

itsguardsorwithitsprotective devicesremoved.Thishas beendoneexclusivelyfor

explanatory purposes.USE OF THEMACHINEWITHOUTITSGUARDSORWITHTHE

PROTECTIVE DEVICES DEACTIVATEDISALWAYSFORBIDDEN.

FAILURETOOBSERVE THISOBLIGATIONCAN LEAD TOSERIOUSACCIDENTS.

The description ofthe machine hasbeenperformed in aconcisemannersothatthe OPERATORS

and the MAINTENANCEPERSONNELmayacquire:

-an initial knowledge ofthe machine and the partsof whichit iscomposed;

-aknowledge ofthe termsand the nameswhichshall beused withinthe manual.

Theseelementsareessentialtounderstanding the instructionsand the warningswhicharecontained

inthefollowing paragraphs.

Fig. 2-1Machinelay-out

A

1

4

5

3

2

October 22, 2008 Rev.01

2-DESCRIPTION

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages14 -57

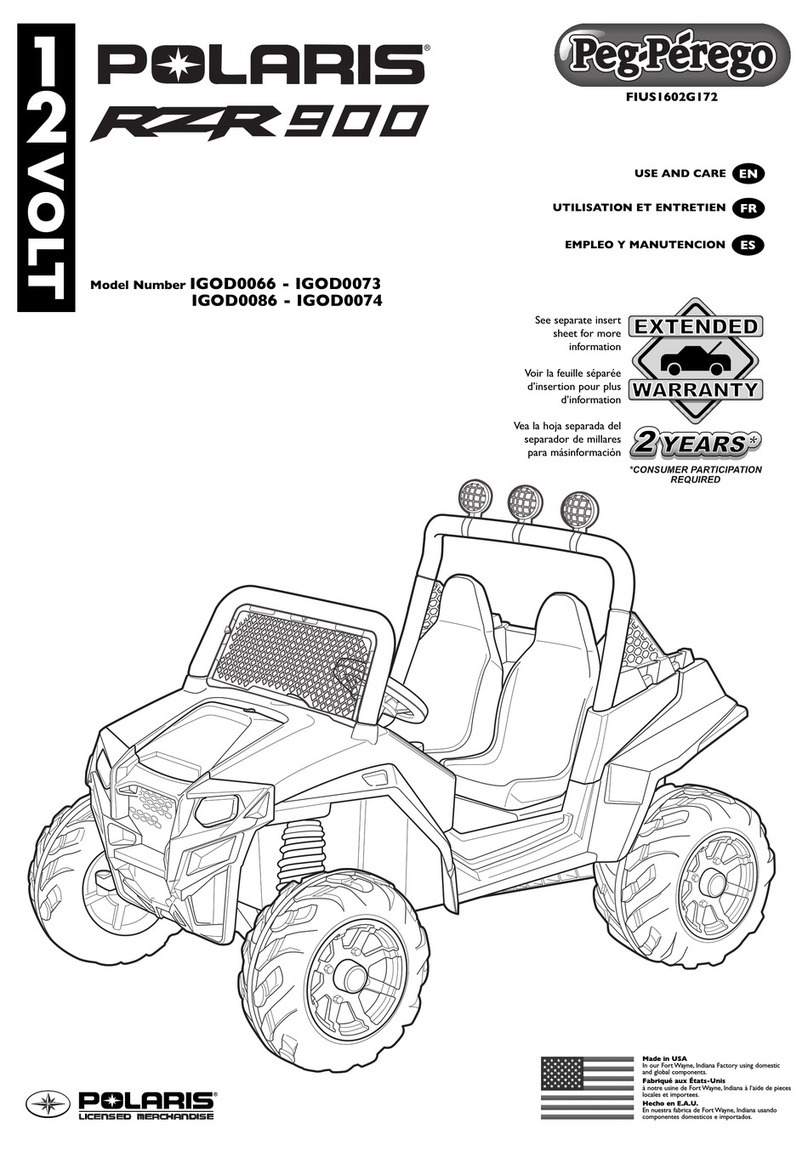

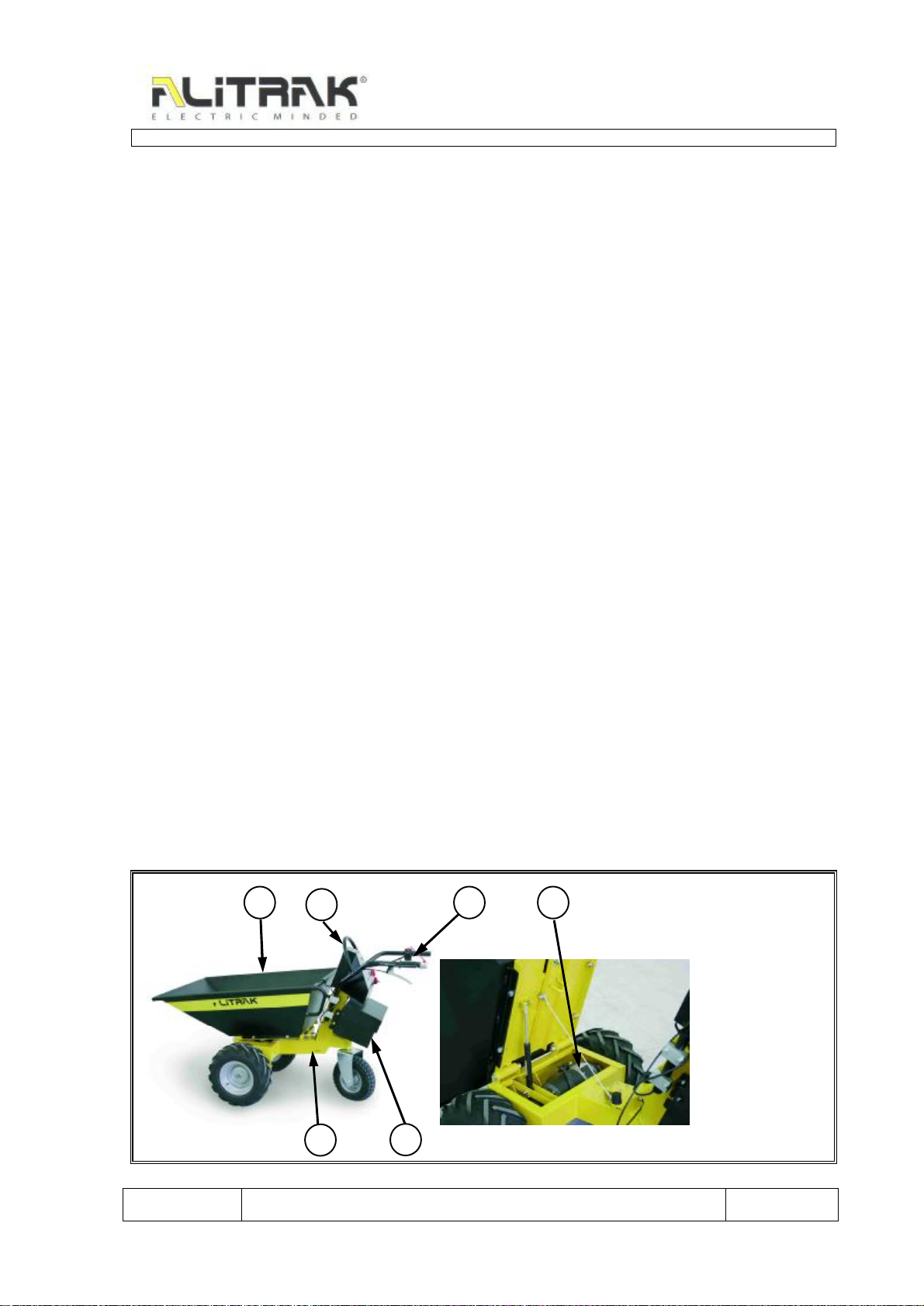

2.1.1Machineunits

The machine isconstituted bythe following unitsasindicated infig. 2-2;

1)frameunit;

2)battery unit;

3)motorunit;

4)trayunit;

5)driveunit;

6)commandconsoleunit.

2.1.1.6 Commandconsoleunit

2.1.1.1Frame unit

The frameunitisconstituted byiron barswhichhavebeen welded togetherinsuchawaysoasto

formthe load-bearing partofthe machine.The motorhousing,withitsrelativeconnectionstothe

traction wheels,islocated upon the frame.Onthe frontalportion ofthe framearelocated:the turning

wheels, the batterylodging,the command consolelodging and the plough-stilt drivesystem.

2.1.1.2Battery unit

The battery unit, located underneaththe command console,iscomposed of a60ah battery whichhas

acharge-lifeof approximately4hours. The machine comesequipped withan externalbattery charger.

2.1.1.3Motorunit

The motorunit,located initsappropriatelodging underneaththe tray,ispowered bythe battery

through acontrol unit positioned withinthe command console.

2.1.1.4Tray unit

The steeltrayunitisattached tothe framewithhingeswhichallowthe operatortoeasilyemptythe

trayof product being transported.

2.1.1.5Drive unit

The driveunitiscomposed ofaplough-stiltdrivesystemwhichisattached tothe frame.The

movement and stopping commandscan be found upon the driveunit.

2.1.1.6Commandconsoleunit

The command consoleunit, located infrontofthe operator'sdriving position,allowstheoperatorto

check the battery’scharge and toturnthe machine on oroff withthe ignition key.The battery release,

formaintenanceoperations, can be found nexttothe console.

Fig. 2-2Machineunits

1

2

3

4

5

6

October 22, 2008 Rev.01

2-DESCRIPTION

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages15 -57

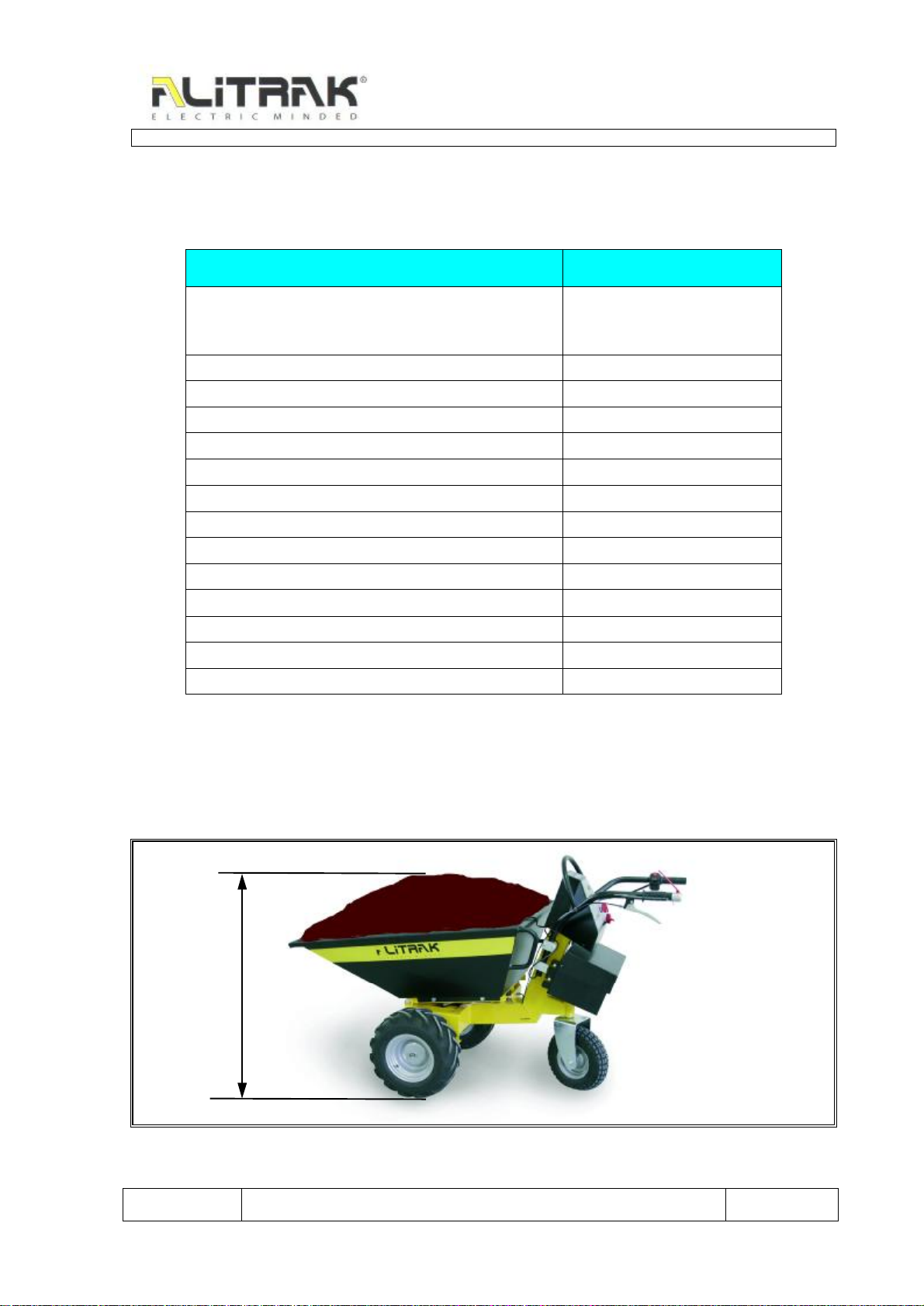

2.2DATASHEET:CHARACTERISTICS

2.2.1Technical characteristics

DESRIPTION DTRAK300

Machinedimensions

(mm)

Length=1325

Width=775

Height =1060

Weightempty (Kg) 152

Weighttransportableonalevelsurface (Kg) 300

Maximumweight at20%incline (Kg) 300

Motorpower (W) 900

Batteries (Ah) 80

Powersupply (V) 24

Autonomy (h) 8

Rechargetime (h) 8

Forwardspeed (Km/h) 5

Reversespeed (Km/h) 2,5

Maxinclineforwardandreverse (%) 20

Pivotingtirepressure Bar 2,0

Tractiontirepressure Bar 1,9

Table2-1machinetechnicaldata

2.2.2Characteristics ofthetransportedproduct

The machine hasbeen designed totransportinertmaterialssuchasgravel,soiland sand inthe

quantitiesindicated intable2-1. Refertofig.2-3formaximumload height.

Fig. 2-3Characteristics ofthetransportedproduct

900mm

October 22, 2008 Rev.01

2-DESCRIPTION

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages16 -57

2.3INTENDEDUSE

2.3.1Intendeduse andforeseen usageenvironments

2.3.1.1Foreseen use

The DTRAK 300 isan ecologicalvehiclewithground drivecontroland electrictraction whichcanbe

used fortransporting inert materialsinaccordancewiththe product datacontained withinthismanual’s

datasheet. The DTRAK 300,withthe characteristicsshown intable2-1of thismanual, issuitablefor

indoorand outdooruse.The machine maynotbe used inacidicorexplosiveenvironmentsnorinany

otherenvironmentwhichhasnot been expresslyapproved bythe manufacturer.

Allofthe operating proceduressuchasloading and unloading can be performed byasingleoperator.

The machine and itsaccessoriesaredesigned andmanufactured forsafeoperation underthe

following conditions:

-usage withinthe prescribed limits;

-the operatorsmustfollowthe proceduresdescribed inthe instruction manual;

-the operatorsmust respect the foreseen working conditions, paying special attention to:

-the totaloperationallimits;

-the servicecoefficient(working hourspershift);

-environmental conditions(dust, temperatureand humidityinthe workplace).

2.3.1.2Unintendeduse

It if FORBIDDENtousethe machine fortransporting:

a)liquidsofanykind,explosives,flammablematerials, corrosivematerials, etc.;

b)explosivematerials, dynamite,fireworksetc. ;

c) people, animals;

It isFORBIDDENtousethe machine inenvironmental conditionssuchas:

a)inthepresenceofsnoworice;

b)lowvisibility;

c) slippery surfaces;

d)surfaceswithinclinessuperiortothosewhichareprescribed on the datalabellocated on every

side of the machine;

e)constant wind;

f)rainand stormswithrisksoflightning.

ATTENTION:UNFORSEENAND/ORIMPROPERAND/ORINCORRECT USE.

Using themachinewithdifferentmaterialsorforthepurposeofobtaining production

valuessuperiortothosewhich are indicatedisconsidered “IMPROPERUSE”.

Anyulterioremploymentofthe machine mustbe authorized beforehand inwriting bythe

manufacturer.Withoutauthorization,suchemploymentistobe considered “improperuse”and

therefore,insuchcases,the Manufacturershallbearno responsibilityforanyeventualdamagesto

peopleorobjectsand shall considerevery type ofwarrantyforthe machine and forthe devices

furnished asnullified.

October 22, 2008 Rev.01

2-DESCRIPTION

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages17 -57

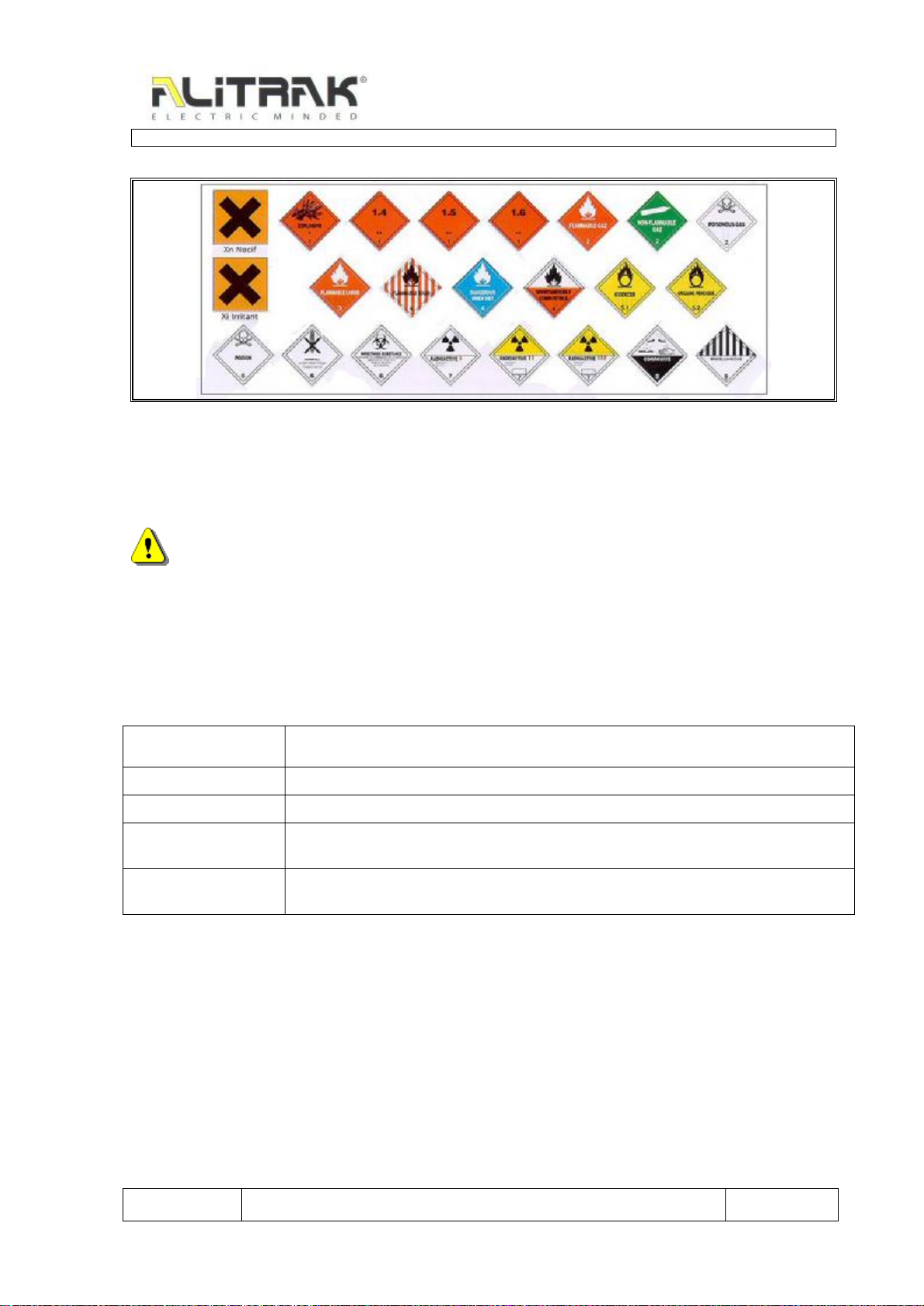

Fig. 2-4Tableoftoxicandharmfulproductsforwhich transportisFORBIDDEN

2.3.1.3Usageenvironment

ATTENTION:EXPLOSIVE ATMOSPHERE.

ThismachineISNOT AVAILABLEINAN ANTI-EXPLOSIONCONFIGURATION, butisonly

availableinastandardconfiguration.

ITSUSE ISTHEREFOREFORBIDDENINWORKPLACES WHERETHECONCENTRATION

OF EXPLOSIVESUBSTANCESMAYEXCEDETHEMAXIMUMLIMITSAND CREATEAN

ATMOSPHEREAT RISKOFEXPLOSION.

2.3.2Environmentaloperatingconditions

The properfunction,the reliabilityand the workinglifeofthe machine and itscomponentsare

guaranteed ifthe environmentalconditionsarewithinthelimitslisted below.

Temperature Environmentalairtemperaturebetween+5°Cand +40°C–Average

environmental airtemperaturenotinexcess of +35°Cforperiodsof 24 hours.

Relativehumidity% Max. 95% withoutcondensation

Altitude Max. 1000mabovesea levelif not otherwisespecified

Transport Transporttemperaturebetween -25°Cand +55°Cwithvariationsup to70°Cfor

amaximumtimeof 24 hours.

Storage Storage temperaturebetween -25°Cand +55°Cwithvariationsup to70°Cfora

maximumtimeof24 hours.

2.3.3Lighting

The working environmentmustbe sufficientlyilluminated withnaturallighting and be equipped with

adequateartificialillumination devicesforthe safeguarding ofhealthand safetyinaccordancewiththe

European Directive89/654/EEC(workplaces).

The illumination of the workplacemust conformtothe current lawsofthe countryinwhichthe machine

isinstalled and must, inall cases,beuniformand guarantee good visibilityforevery partofthe

machine,mustnotcausedangerousreflectionsand mustallowforthe command panelstobe read

clearlyand forthe emergencybuttonstobe identified.

The illumination mustallowforthe safeexecution ofanymaintenanceoperationsforeseen bythe

manual.Useadequatelighting sourcesformaintenanceoperationsinspecificzones(suchasinthe

internal partsofthe machine).

The workplacelighting devicesmust notconstituterisksofdanger.

October 22, 2008 Rev.01

2-DESCRIPTION

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages18 -57

2.3.4Usageillustration

ATTENTION:UNFORSEENAND/ORIMPROPERAND/ORINCORRECT USE.

Using themachineanditsunitswithdifferentmaterialsorforthepurposeofobtaining

productionvaluessuperiortothosewhichare indicatedisconsidered“IMPROPER

USE”.

The usage illustration showninfig. 2-5isdescribed below.

The producttobe transported isloaded intothe tray(no.1)and unloaded manuallybythe operatorby

meansofthe twohandles(no.2)located on the sidesofthe tray. The plough-stilt driving position,from

whichthe operatorconductsthe machine withagoodvisibilityofthe necessary commands,isgiven

bythe letterA.

Fig. 2-5Usageillustration

1

A

2

October 22, 2008 Rev.01

2-DESCRIPTION

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages19 -57

2.3.6Vibrations

The machineisequipped withthree vibration-absorbing wheelswhichwill nottransmitanyvibrations

whichcouldcompromisestability.The machine,beingpowered byan electricmotor,emitsvibration

levelsinferiorto2.5m/sec2.

Anyanomalousvibrationsmaycausemechanicalproblems(suchasflange and beltloosening, etc.). If

suchphenomena persist, consultthe Manufactureroryourlocalreseller’sassistancecentre,indicated

inthefirst pagesofthe manual.

2.3.7Noise

The machine isdesigned and builtinsuchawaysoastoreducenoiselevelsattheirsource.The

noiselevelsindicated areemission levelsand do notnecessarilyrepresentsafeoperativelevels.

Although thereisarelationshipbetween emission levelsand exposurelevels,thisrelationshipcannot

be utilized inareliablemannerinordertoestablishwhetherulteriorprecautionsarenecessary.The

factorswhichdetermine the exposurelevelstowhichthe operatorisexposedarethe duration of

exposure, the characteristicsofthe workplaceand othernoisesources(numberofmachines, adjacent

processes, etc.). Moreover, the maximumallowed exposurelevelscan vary fromcountry tocountry.In

anycase,the information provided willallowthe machine’suserbetterevaluateanyeventualdanger

orrisks.

ATTENTIONChanging thetypologyoftheproductbeingworkedwithand changingthe

operatingconditionswillalso changethenoiselevels.

Anyeventualanomalousnoisescancausemechanicalproblems(suchasbeltorchainloosening,

etc.).Performanynecessary maintenanceoperationsasdescribed inthe instructions(see chapter7

“Maintenance”).Ifsuchphenomena persist, consultthe Manufactureroryourlocalreseller’s

assistancecentre, indicated inthe first pagesof the manual.

October 22, 2008 Rev.01

3-TRANSPORT

FY310.doc ThismanualisthepropertyofALITRAK

Anyreproduction,evenpartial, isforbidden. Pages20 -57

3TRANSPORT

3.1WARNINGS

ATTENTION:Thelifting, handling, transportingandunpacking ofthemachineandits

componentsmustbeperformedunder thefollowing conditions:

-theseoperationsmustbeentrustedexclusivelytoqualifiedpersonnel(slingers,crane

operators, forkliftoperators, signalmen).

Theoperatorsmustalso be:

-informedasto thenature oftheloadsto belifted, astotheoperationstobecarriedout

and astotheproceduresforeseen bythemanual;

-authorized;

-assisted byemployeesofthemanufacturer (oroftheauthorized assistance centre)who

have agood knowledgeofthemachineanditsmanual;

-operatein accordance withtheproceduresindicated in themanualitself.

ATTENTION:Duringtheseoperationstheoperatorsinvolvedmustwear personal

protection gear suchas:helmets,gloves,safetyshoes,work coverallsand anyother

meansrequiredbythecurrentstandardsbasedon thenature oftheoperationstobe

performed.

ATTENTION:Theoperatorsmustrespecttheregulationsandprohibitionsprescribedby

thecurrentstandardsforliftingandtransportoperations;amongstthese,thefollowing

generaloperative rulesare tobekeptin mind:

-stand back fromtheloadsbefore performing lifting andlowering manoeuvres;

-donotstandunderneath suspendedloads;

-accessto unauthorizedpersonnelistobeprohibited;

-keep asafedistance fromthesuspendedmachineduringanymanoeuvres.

ATTENTION:Failure toobserve theabove warningscanleadtoseriousinjury and/or

accidentswith consequentmachinery damageandpersonal injury.

InthemostseriouscasestheseaccidentsCAN CAUSE THEDEATHOF THE

OPERATORSINVOLVED.

3.2TRANSPORTING AND LIFTING THEMACHINE

The machine isshipped completelyassembled and packaged inacardboardboxattached toapallet.

Upon arrival,verifythatthe machine hasnotbeen damaged during transportand thatall ofthe parts

indicated inthe packing listarepresent, including the instruction manual.

ATTENTION:Anymeansusedforhandlingmustbesuitableforliftingthemachine,

keeping in mind:

-theshapeand size;

-themass (weight)and itsdistribution (centre ofgravity);

-theforeseen liftingconnectionpoints.

NOTICE: Arrangethelifting apparatusin suchaway soastoavoid collisionsand/or

pressure uponprotruding parts(especiallythecommand panel, etc.).

ATTENTION:Appropriatelytrainedpersonnelshouldbeassignedtotheseoperations

(slingers,craneoperators,forklift operators,etc).Arrangeforaperson tobein charge

ofsignalling astheencumbrance ofthemachineanditspackaging canimpede

sufficientvisibilityfortheoperatorsperformingthemanoeuvres.

Table of contents

Popular Motorized Toy Car manuals by other brands

Little Tikes

Little Tikes RC WHEELZ Bumper Cars manual

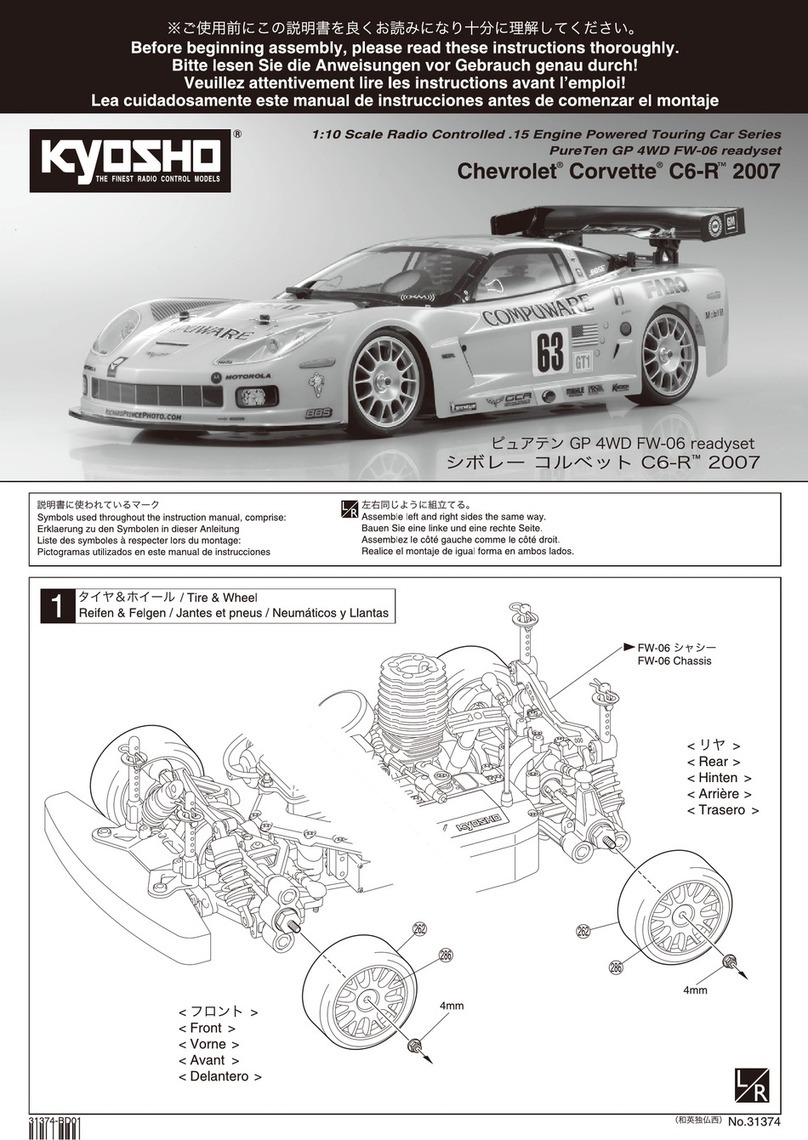

Kyosho

Kyosho Pure Ten GP 4WD FW-06 readyset instruction sheet

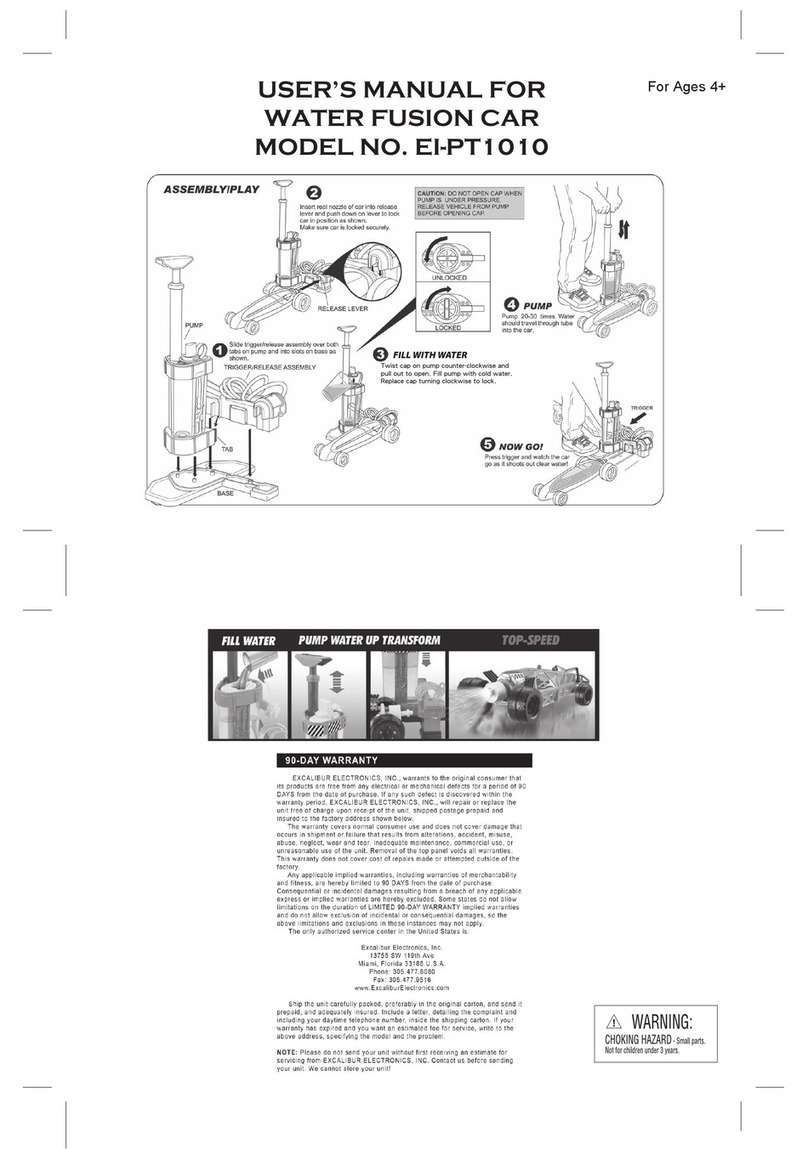

Excalibur

Excalibur Water Fusion Car EI-PT1010 user manual

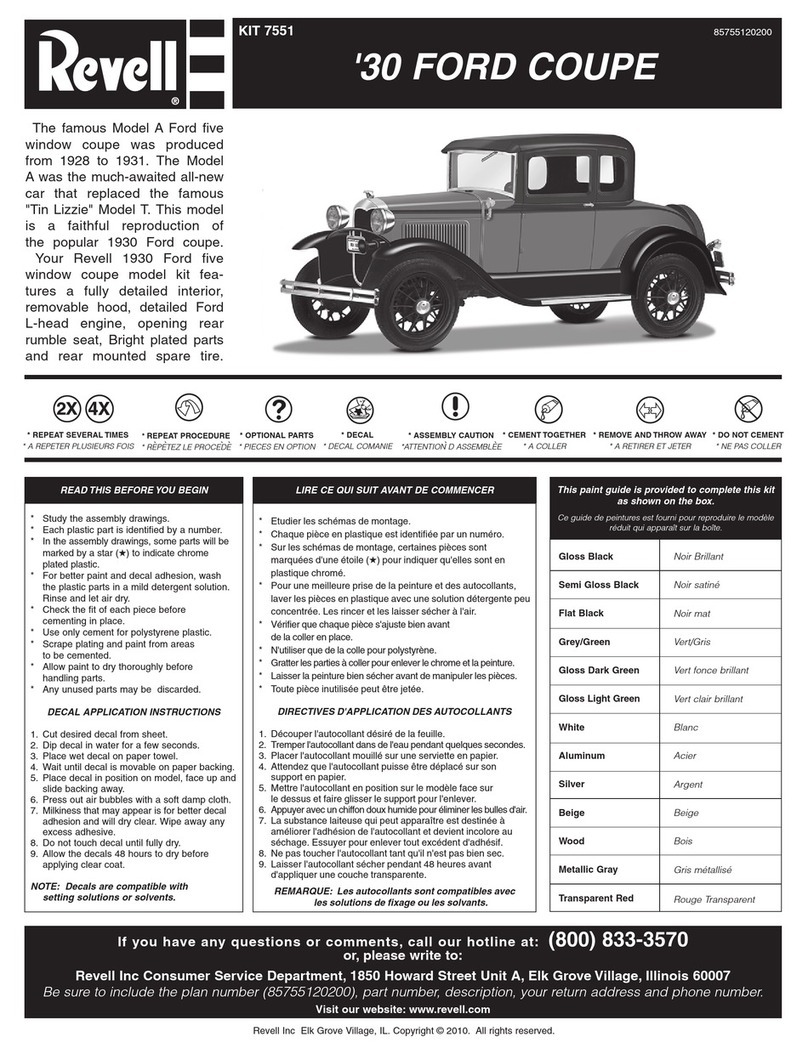

REVELL

REVELL KIT 7551 Assembly manual

REVELL

REVELL FORD F-150 SVT RAPTOR manual

Carson

Carson X10ET-XL Beat Warrior instruction manual