2

Operation and Maintenance Manual

Preamble

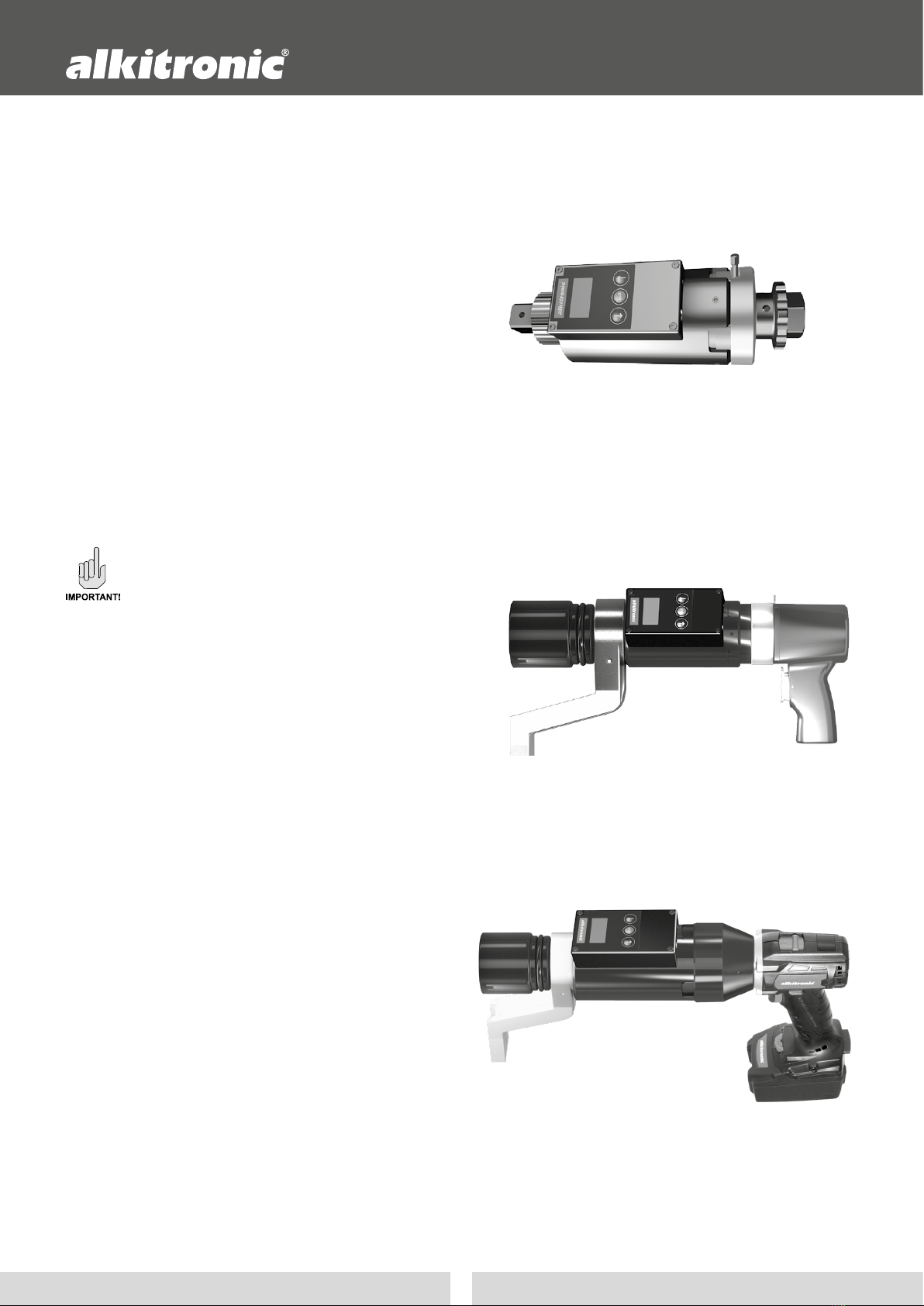

Congratulations on the purchase of a torque multiplier

from the alkitronic® MDS (mounting documentation sys-

tems) product range.You have chosen a premium quality

product that sets new standards, both in safety as well as

in international quality standards. In order to ensure the

high quality of this product it is recommended that it is

regularly serviced and maintained. We therefore request

that you read these operating and maintenance instruc-

tions carefully, paying particular attention to the follow-

ing: the manually operated alkitronic® HSD, the air

driven

alkitronic® CLSD and the battery-operated alkitronic®

EASD

as well as the battery charger unit included in the delivery

may only be serviced and repaired by employees of alki

TECHNIK GmbH, or specialist trained and qualied by alki

TECHNIK GmbH or sta of a certied and approved third

party company.

Improper maintenance or operation poses a risk of injury

or health hazards and material damages to devices or

machinery; in addition, this will render any warranty or

guarantee null and void.

When using an alkitronic® MDS product the respective

product-specification standard operating and mainte-

nance instructions must be observed.The alkitronic® MDS

operating instructions contain information and instruc-

tions required to be observed for the settings and the

operation of the mounting documentation. Both manuals

must therefore be read by the operators before starting

use of the device. The manuals must at all times be avail-

able for reference at the location where the alkitronic®

tools / devices are used.

These operating instructions refer exclusively to the prod-

ucts of the alkitronic® MDS range.

At all times ensure that the safety instructions listed in the

section “Notices and descriptions” as well as, according

to the situation, all other pertinent general regulations,

notices, recommendations and instructions.

Notices and descriptions

Safety notice to prevent hazards to life and

limb of persons.

Safety notices to prevent damages to alkitronic®

tools, devices, their functions, and the environ-

ment.

Notices to ensure proper and safe operation.

Recommendations to make work easier.

Content Page

A Incoming inspection and packaging 3

B General description 3

B1 Model descriptions 3

1. General technical data 4

2. Safety notices 4

2.1 Proper and correct use 4

2.2 User obligations 4

2.3 Hazard information 5

2.4 Prevention of data loss 5

2.5 Mechanical operation and miscellaneous 5

3. MDS Operation interface sensor electronics 6

3.1 Menu guide / functions (HSD) 6

4. Program preparation / settings 7

4.1 Parameter table alkitronic® MDS torque tools 7

4.2 Starting Sensor electronics 7

4.2.1 Updating / synchronisation of time zones, date

and time settings (alkitronic® APP) 7

4.2.2 Operation Sensor electronics 7

5. Bolting programs (Overview) 7

5.1 Bolting program 1 7

5.2 Bolting program 2 8

5.3 Bolting program 3 9

5.4 Bolting program 4 10

5.5 Bolting program 5 11

6. Technical details 12

7. Function test, storage, maintenance 12

8. Data communication 13

8.1 alkitronic®APP 13

8.2 alkitronic®APP - screens 14

8.2.1 „Device“ screens 15

8.2.2 „Setting“ screens 15

8.2.3 „Info“ screen 15

8.3 CSV Data set 15