ToolKitRC ST8 User manual

@ToolkitRC 2019

1

ST8

Manual V1.0

2019.09

www.toolkitrc.com

ToolkitRC Technology (Shenzhen) Co.. Ltd.

@ToolkitRC 2019

2

Thanks

Thank you for purchasing the ST8 Multi-function

servo tester. Please read this manual carefully before

use.

Key Points

Tips

Important

Information

Further Information

To ensure you have a more enjoyable experience,

please use WeChat to scan the QR code below and use

it to get the usage details, video teaching and latest

information. Or visit www.toolkitrc.com.

WeChat QR Code

@ToolkitRC 2019

3

Safety Precautions

1, The ST8 allows input voltage of 7-28V. To ensure that

the power supply voltage is consistent, pay attention to

the positive and negative polarity of the power supply

when connecting.

2, The S1-S4,S4 Ext. signal ports only support a

maximum of 2A current. For a larger current servo,

connect the output main port to prevent the internal

circuit from being burned out.

3, The S1-S4 signal port can only output up to 8.4V, for

higher voltage uses the main port.

4, Do not use this product in heat, humidity, flammable

or explosive atmosphere.

5, Do not leave this product unattended while in use to

prevent accidents.

6, Please unplug the input power when not use this

product.

@ToolkitRC 2019

4

Contents

Thanks...................................................................2

Key Points.............................................................2

Further Information..............................................2

Contents................................................................4

First start............................................................... 7

Main interface.......................................................8

Pause interface.................................................. 10

Channel setting.................................................. 11

1,Signal source setting............................... 11

2,P1 source setting......................................11

3,S5 source setting..................................... 12

4,Internal source setting............................14

5,Key setting................................................ 16

6,S 1 source setting.................................... 16

7,Output source setting.............................17

System setting....................................................17

@ToolkitRC 2019

5

Product overview

The ST8 is a product for testing servos, with up to 28V

voltage output, 8-channel signal output, current

measurement, curve display and other functions.

4 channels of programmable independent signal, 8

channels of signal output, accuracy of 1 ms.

4 independent current acquisition, respectively,

curve display.

Multiple measurement modes (speed, count, step,

linear).

output PWM signals with a period of 33 to 1000 Hz.

A variety of signal trigger sources (internal, buttons,

knobs, external sources).

Measure the response speed of the steering gear

with an accuracy of 1 millisecond.

The external input signal supports PWM/ PPM/

SBUS with an accuracy of 1 ms.

The external input signal supports PWM/ PPM/

SBUS with an accuracy of 1 ms.

Drive the servo with a maximum load of 100W.

Multi-language system, you can upgrade the

language you need.

The device is simulated as a USB flash drive, and

the upgrade file is copied to implement product

firmware upgrade.

@ToolkitRC 2019

6

ST8 Layout

Front

Back

Display

Exit

USB port

P1 knob

(press,lock)

Input

Output

S4 Ext. port

Knob(OK)

S1-S4 port

S5 port

@ToolkitRC 2019

7

First start

1, the 7-28V power supply is connected to the input port

on the back of the ST8

2, the display shows the boot logo and stays for 2

seconds

3, accompanied by do-re-mi boot sound

4, the boot is completed, the display enters the main

interface as shown below:

5, Press [Exit] to start the PWM signal output and test.

6, Rotate [Knob], move the cursor to select different

channels, press [OK] to confirm, pop up the setting

options of the selected channel, and set the input and

output signals of the channel.

7, Press and hold [OK] to enter the system setup menu.

8, Press [Exit] to end the modification or return to the

main interface.

@ToolkitRC 2019

8

=================================

1, Short press 1 [Knob], to determine the key function.

2, Press and hold [Knob] for 2 seconds to set the

function for entering the system.

3, Short press 1 [Exit], pause, start, exit function.

4, Successfully operate any key, have didi prompt

tone.

===================================

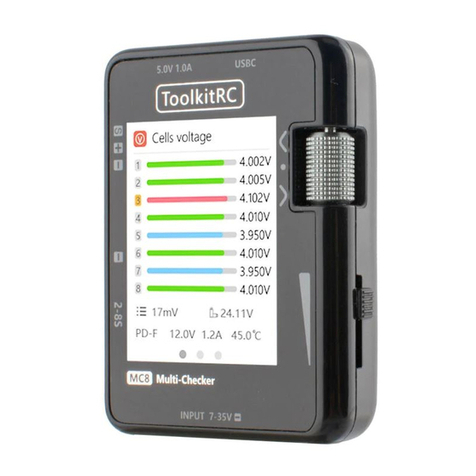

Main interface

After pressing the [Exit] button after powering on,

the system shows the main interface, as shown below:

The top 5.0V is the output voltage of the main port

or PWM output port. When the main port voltage is off,

the voltage of the PWM output port will be displayed in

black. When the main port voltage is turned on, the

main port voltage will be displayed in red. The output

20.0ms/50Hz is the PWM output frequency and period.

Input 9.7V is the input voltage. Below the minimum

input voltage set by the system, it will alarm and flash

@ToolkitRC 2019

9

red. 41 ° C is the motherboard temperature, higher than

the safe temperature set by the system will alarm and

flash red.

The right side S1, S2, S3, and S4 are independent

4-channel PWM signals, which are distinguished by

different colors and graphically display the pulse width

value.

The middle grid is a curve display of 4 PWM output

current, which is easily distinguished by the

corresponding color display on the right side.

Below is the output bar, which outputs the

maximum current, speed, and count of each channel in

real time.

The PS, PC and PE buttons are in the lower right

corner. When the button source mode is selected, the

buttons will become selectable.

@ToolkitRC 2019

10

Pause interface

After booting up or pressing [Exit] on the main

interface, you can enter the pause interface, as shown

below:

When paused, the current curve is paused and the

PWM signal is maintained at a fixed value. Rotate [Knob]

to adjust the timeline to view the saved current curve.

Press [Exit] to exit the pause interface.

@ToolkitRC 2019

11

Channel setting

After selecting a channel in the main interface, press

[OK] to pop up the setting options of the selected

channel, and the following interface is displayed.

1,Signal source setting

Rotate the [Knob], move the cursor to the [Input] [P1]

position, press [OK] to modify the source setting.

Channel 1 can be set to P1, S5, internal signal, button,

and 4 sources. Channels 2-4 can be set to P1, S5,

internal signals, buttons, channels 1, and 5 sources. After

selecting the appropriate source. Short press [OK] and

[Exit] to take effect.

2,P1 source setting

@ToolkitRC 2019

12

When the P1 source is selected, the PWM output

can be controlled by the P1 knob and the position of the

knob can be displayed. As shown below:

3,S5 source setting

When S5 is selected as the signal source, PWM,

PPM, and SBUS signals can be selected. By inputting the

corresponding signal on the S5 interface, the received

signal value can be displayed and the PWM output can

be controlled.

When the PWM signal is selected, as shown below:

@ToolkitRC 2019

13

When the PPM signal is selected, the channel can

be set from CH0 to CH7, as shown below:

When the SBUS signal is selected, the channel can

be set from CH0 to CH15. As showed below:

@ToolkitRC 2019

14

4,Internal source setting

When the signal source selects the internal signal, it

can be set to linear and phase modes. These two modes

are mainly used for the aging servo test, which will

generate a count and will stop working when the set

value is reached. It can be turned off in the system

settings.

When the linear mode is selected, you need to set

the step value and speed value. The step value ranges

from 1 microsecond to 10 microseconds, and the speed

value ranges from 1 millisecond to 10 milliseconds.

Taking 1 respectively means adding 1 microsecond

or 1 microsecond each time in the range of the PWM

signal output at a speed of 1 ms. As showed below:

@ToolkitRC 2019

15

When the phase mode is selected, if the PC point is

not enabled, it is the second-order mode, which jumps

between the two values of PS and PE at 1 second. If the

PC point is enabled, it is the third-order mode, which

jumps between the three values of PS, PC and PE at 1

second. This mode allows you to measure the response

speed of the steering gear. As shown below:

@ToolkitRC 2019

16

5,Key setting

When the signal source selects the button, the main

interface will display PS, PC, PE buttons, you can move

the cursor to the buttons on the main interface and

short press [OK] to output the corresponding PWM

value. The time to turn the angle can be measured and

displayed. As shown below:

6,S1 source setting

When S2, S3, S4 signal source selects S1, it will

follow the S1 setting and output S1 with the same PWM

value.As shown below:

@ToolkitRC 2019

17

7,Output source setting

Move the cursor to the [Output] position to set the

range of the PWM output signal with an accuracy of 1

microsecond. If you are in the button source and internal

source stage modes, you need to set the PC value.

System setting

Press [OK] on the main interface for 2 seconds to

@ToolkitRC 2019

18

enter the system setting interface, and rotate [Knob] to

switch the corresponding settings, as shown below:

Cycle: Output the period of the PWM signal, ranging

from 1 millisecond to 30 milliseconds.

VoltageOutput : The output voltage of the main port has

11 gears, including turnoff, 5V, 6V, 7.4V, 8.4V, 12V, 14V, 15V,

16V, 18V, 24V, 28V. When it is turnoff, the main port does

not output voltage, the PWM output port voltage is 5V,

and the load power is 15W. If the load power exceeds

the load, it will prompt “Please turn on the main port

power”. For 5.0V-8.4V, the main port and PWM output

ports are 5.0V-8.4V. For 12V-28V, the main port output

voltage is 12V-28V, and the PWM output port is 5V,

which can drive large servos.

CycleCount: When using the internal signal source, a

count will be generated, and when the set number of

work times is reached, the operation will stop.

LowestInput: Below this voltage, the device will stop the

@ToolkitRC 2019

19

main port output.

SafeTemperature: Above this temperature, the device

will stop the main port output.

Backlight: The backlight brightness level of the display

can be set to 1-10.

Buzzer: The tone of the buzzer can be set to off.

Language: The system displays the language. English

and Chinese can be selected.

ThemeStyle: The color style displayed by the system

interface. It is divided into bright and dark colors.

KNOB Calibration: Jump the P1 knob to the calibration of

the maximum and minimum implementation knobs.

CycleCountClear: Clear the count under the internal

source.

Default : Restore all settings to factory defaults.

Other functions

Firmware upgrade:

@ToolkitRC 2019

20

After connecting the ST8 to the computer via the

USB cable in the box. the computer will recognize the

USB flash drive named Toolkit. Download the upgrade

file app.upg on the official website to overwrite the

files in the USB flash drive to upgrade the firmware.

Specification

Input voltage

7-28V@MAX 10A

Main output port

5.0V-28.0V@MAX 10A

Signal port

Output voltage

5.0V-8.4V@MAX 4A/S1-S4

5.0V-8.4V@MAX 4A/S4 Ext.

Output signal

100us-2900us@33-1000Hz @S1-S4

PWM 500us-2500us@S5

PPM 8CH@S5 SBUS 16CH@S5

P1 rotation range

1000us-2000us@P1

MicroUSB

LCD display

2.4 inch TFT RGB 320*240 resolution

Product

Size

99mm*68mm*26mm

Weight

120g

packing

Size

105mm*80mm*45mm

Weight

200g

Table of contents

Other ToolKitRC Test Equipment manuals