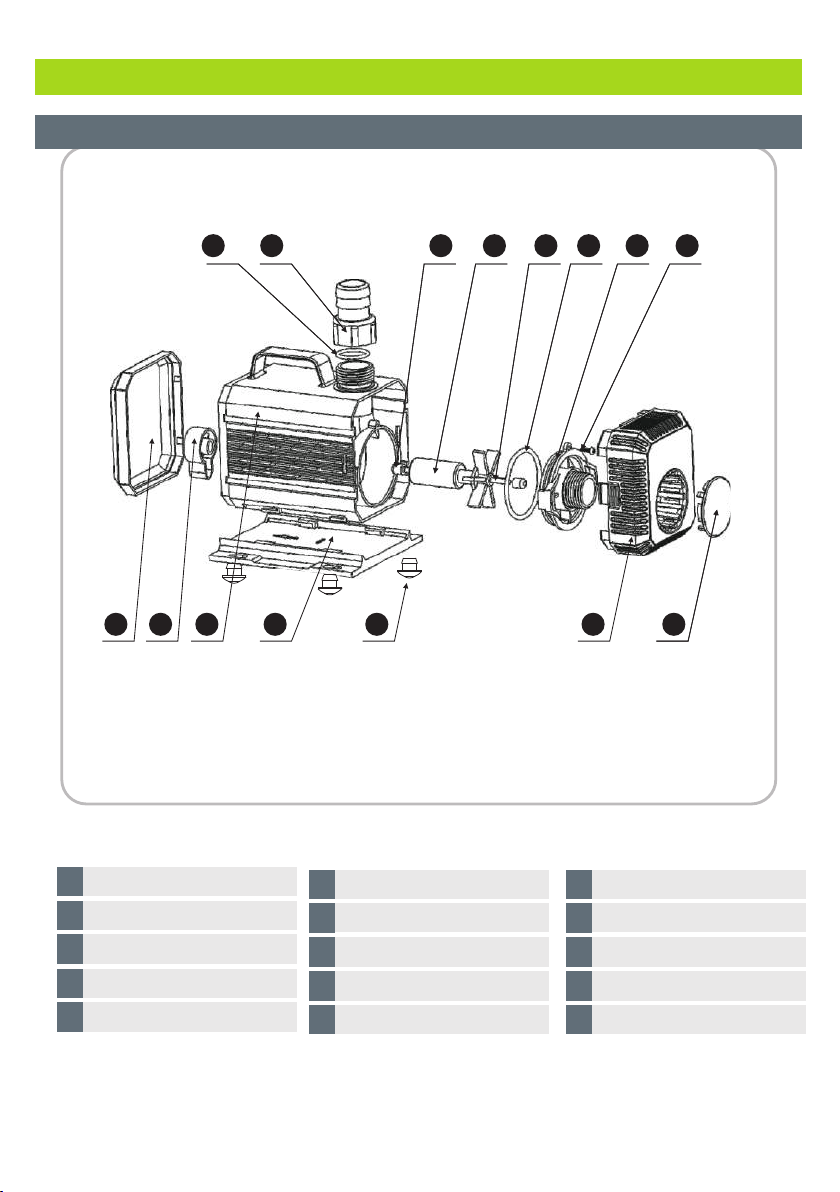

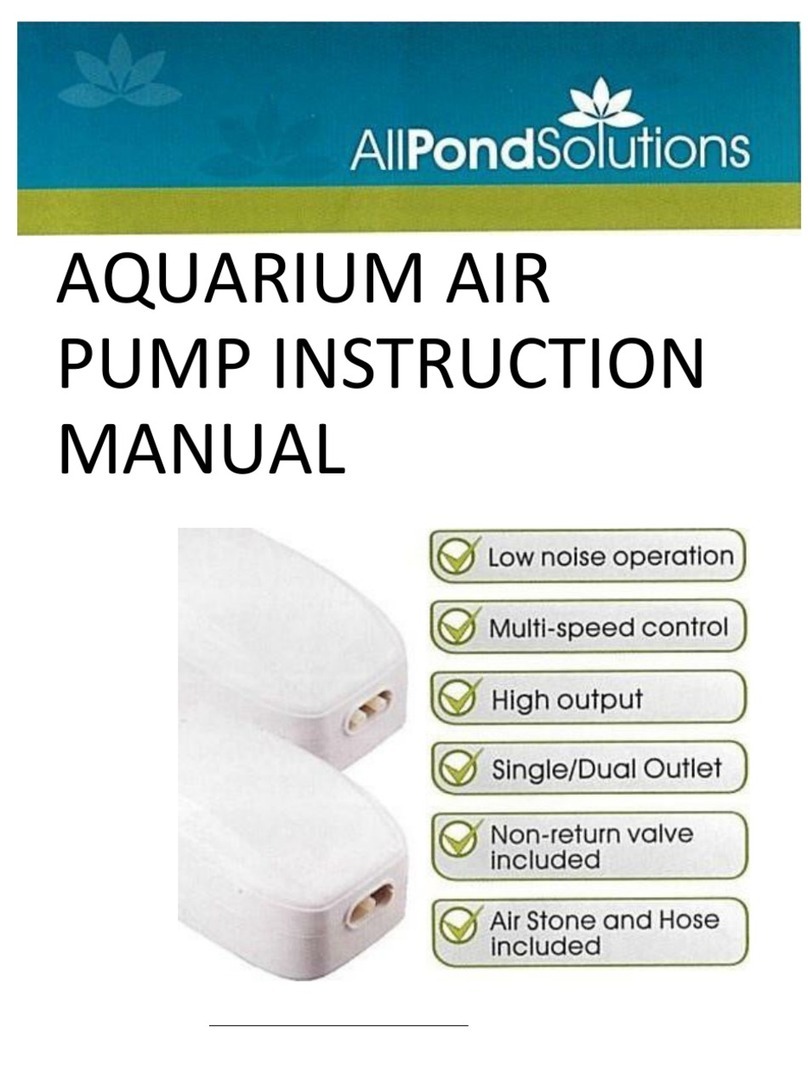

All Pond Solutions 1400PP User manual

POND & AQUARIUM

WATER PUMP

1400PP / 3000PP / 4500PP

SHAFT MADE OF QUALITY CERAMIC -

ANTI-CORROSIVE & WATERPROOF

COMPLETELY SEALED MOTOR-

EXCELLENT INSULATION

SUBMERSIBLE USE ONLY - SUITABLE

FOR FRESH AND SALT WATER

ANTI CORROSIVE AND HIGHLY

DURABLE PUMP BODY & CASING

To ensure your new pond pump is set up and running correctly, and to prevent

any accidental damage or injury, please read and follow the below instructions

carefully before using your product.

SAFETY

IMPORTANT! Disconnect the mains electricity supply before attempting any

installation / maintenance of any kind. Do not attempt to modify this unit in

any way and only use the recommended parts for replacement.

· The PP pond & aquarium pump should never be run dry as this will cause

the unit to overheat and cause permanent damage.

· All connections must be earthed.

· The power cord of this appliance cannot be replaced; if the cord is

damaged, the appliance should be discarded. Never cut the cord.

· Do not connect to any voltage other than that stated.

· Do not place in liquids other than water.

· Do not use with water above 90 F or 30 C.° °

· Do not carry or pull the unit by its electrical cable.

· Do not use this unit if it has a damaged cord, if it is malfunctioning or it is

dropped or damaged in any manner

· Do not attempt to modify this unit in any way and only use attachments and

the recommended parts for replacement recommended by the

manufacturer.

· Before installing, maintaining or handling your equipment, or before placing

your hands in your pond, ensure that the unit is disconnected from the

electricity supply.

· Always disconnect any electrical devices when not in use.

· To avoid injury, do not touch hot or moving parts such as, but not limited to

UV bulbs or impellers.

· During maintenance ensure all O-rings are present and intact.

· If the appliance shows any signs of water leakage or the RCD unit switches

off, disconnect the unit from the power supply and consult the retailer

where you purchased the unit.

· Do not install or store this unit where it will be exposed to temperatures

near to 0°C / 32°F. In freezing conditions, remove and store the unit in a

sheltered area ensuring all water has been drained from it.

· Do not bury the cord for this unit. Ensure it does not cause a trip hazard or it

at risk from damage from lawn mowers, strimmers or other garden

equipment.

· This is a submersible product - do not operate the product if not fully

submerged.

Please note – this appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental capabilities or lack

of experience and knowledge, provided they are given supervision and

instruction concerning use of the appliance and understand the hazards

involved. Children must not play with the appliance. Any maintenance must not

be made by children without supervision.

ELECTRIC

This unit comes complete with a generous supply of 3 core cable, however

should any additional cable be required, the use of an approved waterproof

cable connector with a proper rating is essential. A cord rated for less amperes

or watts than the appliance rating may overheat.

Please Ensure:

· The power supply must be earthed and fused at 3amps.

· You regularly inspect the cable for damage and deterioration.

· Do not connect to any voltage other than that stated.

· You consult a qualified electrician if in doubt about any aspects of

wiring.

· A residential current device (RCD) is used for additional safety

· You have complied with Local Electricity Authority regulations if

permanently installing to the mains supply.

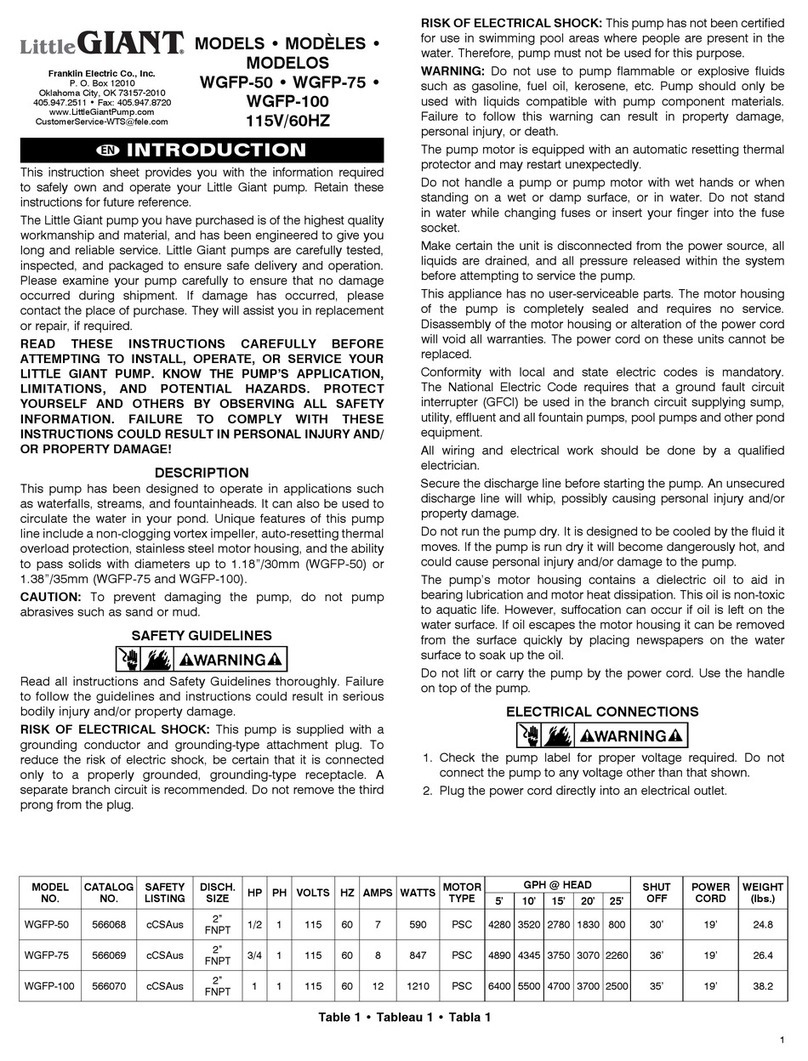

PARTS DIAGRAM

1400PP

BACK CASE

BACK COVER

SUCTION CUPS

1

2

3

MAIN BODY

5

SHAFT

7

IMPELLER COVER

FRONT COVER

8

9

COVER CAP

10

5IMPELLER

6

BASE PLATE

4

RUBBER BEARING

12

NUT

OUTLET

13

14

O-RING

15

5O-RING

11

12345678910

11

12

13

14

15

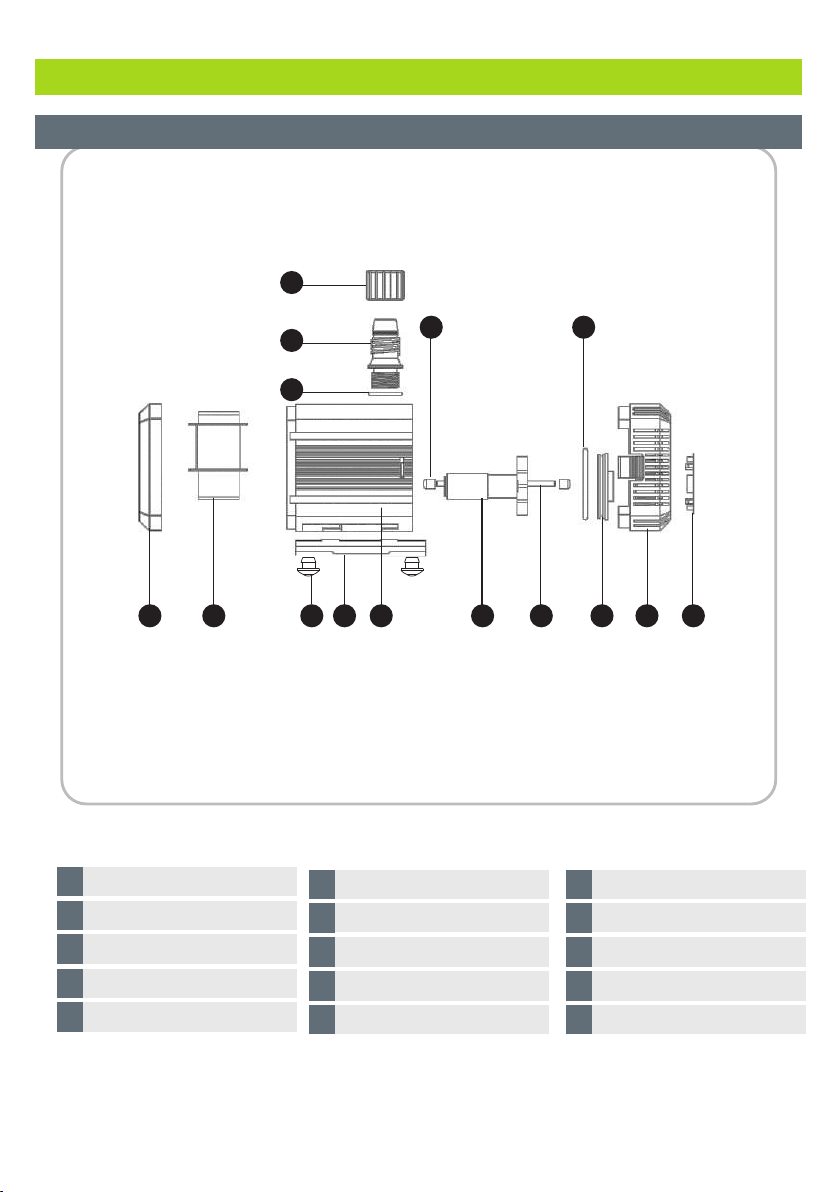

PARTS DIAGRAM

3000PP / 4500PP

12 3 45678

9

10

11

12

13

14

15

OUTLET

O-RING

RUBBER BEARING

1

2

3

SHAFT

5

IMPELLER COVER

7

SCREW

COVER CAP

8

9

FRONT COVER

10

5O-RING

6

IMPELLER

4

BASE PLATE

12

MAIN BODY

BACK CASE

13

14

BACK COVER

15

5SUCTION CUPS

11

The All Pond Solutions PP pump range can be used to circulate water, pump to

and from a separate filtration system or water features using suitable flexible

hose (flexible hosing sold separately).

Please read the below instructions carefully before beginning to set up your

pump. DO NOT CONNECT THE UNIT TO THE MAINS UNTIL SET UP IS

COMPLETE AND UNIT IS FILLED WITH WATER.

1. Connect the required attachments - make sure

the O-rings is added to the outlet hosetail (see image

on the right for reference). This will prevent leakage.

2. Connect your outlet pipe to either your filter, water

feature or alternative location. Secure the outlet pipe

using the included nut and ensure this is tight and

secure.

INSTALLATION & USE

You can add filter foam (sold separately) to the inlet of

the PP. This may slow down your flow rate but will

ensure you pick up larger dirt particles before this

enters your pump/filter system.

3. If you need to connect the inlet pipe you can

remove the front case cap before attaching the hose.

4. Position the unit - fully submerge your PP unit.

Place it on a level and sturdy surface at the bottom of

your pond, this is to avoid silt entering the pump

causing excessive wear and increasing pump cage

cleaning. If you have a pond liner, use the provided

suction cups.

5. Connect your PP pump to the mains - Connect the unit to the mains using a

residual current device (RCD) for additional safety.

6. Switch on your unit at the mains - turn on the operation by switching on the

unit at the

mains.

WATER HOSETAIL

OUTLET SETUP

WATER HOSETAIL INLET

& OUTLET SETUP

MAINTENANCE

To ensure optimal performance and that your unit functions correctly, regular

maintenance is essential. Failure to do so may result in damage to your unit and

may invalidate your warranty.

We recommend that a regular cleaning and maintenance schedule is followed

to ensure responsible fishkeeping. Depending on water volume and stocking

levels, regular cleaning of the impeller and inlet/outlet pipework will help

ensure that the product works efficiently and your pond remains healthy.

1 MONTH

3 MONTHS

6 MONTHS

ANNUALLY

All Pipework

Clean & Inspect

Hosing

Clean & Inspect

O-Rings

Clean & Inspect

Lubricate &

Clean

Replace

Pump Maintenance

IMPORTANT! Failure to carry out routine maintenance and/or leaving the pump

with reduced/no flow rate for long periods will result in a shorter pump life and

will invalidate the warranty.

It is recommended to disconnect your pump and clean the impeller and

pipework monthly. Pipework will become blocked with waste and protein slime

over time, so regular cleaning is important for optimal performance.

The frequency of how often you will need to clean and inspect your unit of

course will depend on a lot of factors like how dirty the water is when you first

start using your pump, your pond volume and also how many fish you have.

How often you feed your fish and seasonal light levels will also affect how

quickly your pond water gets dirty and will need to be taken into consideration

when planning how often to clean your PP unit.

Front cover - can be removed by gently depressing

the push clips located on either side. Wash through

the cover to remove any debris.

It is vital that O-rings are regularly inspected and replaced as the rubber

watertight seal will perish over time, which may cause your unit to leak. Before

replacing your o-rings, ensure they are well lubricated to ensure the seal is

kept water tight.

O-rings

Impeller - unscrew a single screw fixing located on

top of the impeller cover. Turn it anti-clockwise and

pull away from the body.

The impeller can then be gently pulled away from the housing and inspected

for damage. Clear the fittings and parts of any waste build-up.

Reassemble the unit. Ensure the O-rings are in place to avoid leakage.

1400PP 3000PP 4500PP

SPECIFICATIONS

1400PP

180

120 x 95 x 95

18mm Flexible Hose

OUTLET FITS:

DIMENSIONS (mm):

MAX HEIGHT (cm)

1400 L/H

MAX FLOW RATE:

MODEL: 3000PP

350

153 x 105 x 125

22mm Flexible Hose

3000 L/H

24w

WATTAGE: 85w

10m10m

220-240V

VOLTAGE: 220-240V

4500PP

450

175 x 112 x 133

22mm Flexible Hose

4500 L/H

100w

10m

220-240V

CABLE LENGTH

(Plug not included):

20mm Flexible Hose

INLET FITS: 27mm Flexible Hose 27mm Flexible Hose

TROUBLESHOOTING

Slow Flow RateSlow Flow Rate

1. For optimum function of the unit, we highly recommend the pump is

positioned on a brick, so it is not resting directly on the bottom on the pond. This

is to prevent large clumps of debris blocking the inlets and restricting the flow.

2. Follow the maintenance section. Ensure pipe work is not blocked, leaking or

is laid so that it gets crushed or kinked.

3. Locate the impeller and shaft in the pump and inspect for damage and clear

the fittings and parts of any waste build-up.

No Flow From Pump

1. Check power supply is on.

2. Check fuse and cable for any damage.

3. Follow the slow flow rate guide (see above) and keep any hose fittings to a

minimum. This helps to remove frictional loss of flow and so increases pump

flow rates.

My Unit is Cutting Out

1. For optimum function of the unit, we highly recommend the pump is

positioned on a brick, so it is not resting directly on the bottom on the pond. This

is to prevent large clumps of debris blocking the inlets and restricting the flow.

2. Ensure that all O-rings are in place and well lubricated.

3. Locate the impeller and shaft in the pump and inspect for damage and clear

the fittings and parts of any waste build-up.

If none of the above resolves your issue, or you require spare parts for your

pump, please contact the supplier of your unit.

The All Pond Solutions PP pump range is guaranteed against defects in material

or workmanship under normal pond usage and comes with 12 months warranty

for all electrical parts. The warranty period commences from the date of

purchase.

If you require support on how to use your unit, replacement parts or if your

pump develops a fault during the warranty period, please contact the supplier

of your unit.

Non-replaceable, non-perishable and non-serviceable parts will be repaired or

replaced free of charge, once the unit is returned with all components along

with a valid proof of purchase and postage paid. We reserve the right to replace

or repair the unit at our discretion.

Please be aware that perishable parts that are subject to normal wear and tear,

such as impellers, impeller covers and motor seals are not covered by your

warranty and a charge may be required for replacements of these.

This warranty does not apply to any unit that has been subjected to misuse,

accidental damage, negligence, tampering or customisation. It does not apply

to units which have been assembled incorrectly, improperly maintained, or

where the instructions and safety information in this manual has not been

followed correctly.

No liability is assumed with respect to loss or damage to livestock or personal

property irrespective of the cause thereof.

Please ensure that only genuine All Pond Solutions components are used when

completing a replacement or repair. Spare parts are available at our official

website or from your local supplier.

Before returning your unit under warranty terms, check that all setup and

maintenance instructions have been correctly followed. If you are in doubt,

please contact your local aquatic retailer for further advice before returning the

product.

This does not affect your statutory rights.

WARRANTY

www.allpondsolutions.co.uk

All Pet Solutions Limited Trading as All Pond Solutions

Unit 203 Riverside Way, Uxbridge, Middlesex,

England, UB8 2YF

This manual suits for next models

2

Table of contents

Other All Pond Solutions Water Pump manuals

All Pond Solutions

All Pond Solutions AP-IS-KIT User manual

All Pond Solutions

All Pond Solutions FPP-3500 User manual

All Pond Solutions

All Pond Solutions AP-1.5-KIT User manual

All Pond Solutions

All Pond Solutions FPP-600 User manual

All Pond Solutions

All Pond Solutions 8000PP User manual

All Pond Solutions

All Pond Solutions ACP-500 User manual

Popular Water Pump manuals by other brands

Walrus

Walrus TPH50T5KF instruction manual

Oase

Oase ProMax MudDrain 25000 Commissioning

GORMAN-RUPP

GORMAN-RUPP GHC Series Installation, operation and maintenance manual

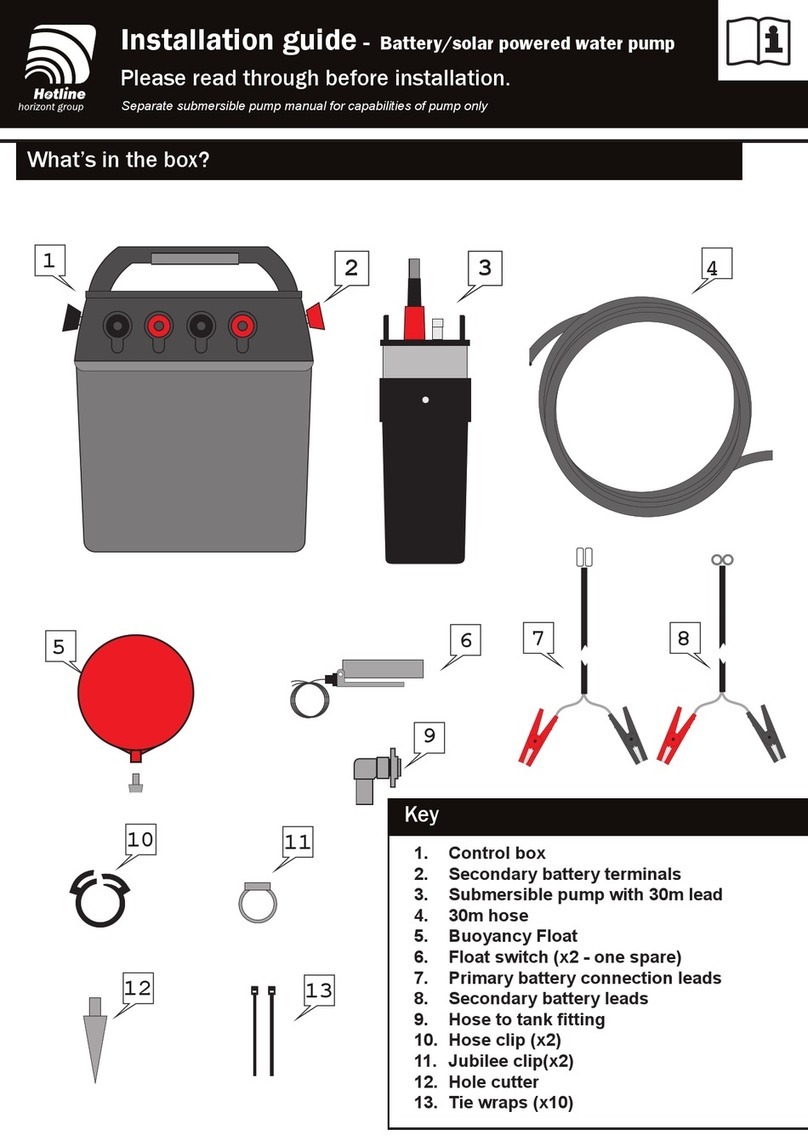

Horizont

Horizont Hotline 47SPK60-300 installation guide

Sealey

Sealey TP98.v2 quick start guide

SFA

SFA SANIPUMP ZFS 71 Series Operation manual