Allducks 812/300 User manual

Assembly Instructions

812/300; 812/400; 812/400 MONO

812.03 ; 412.03pro; 812.03/400pro

Table of contents

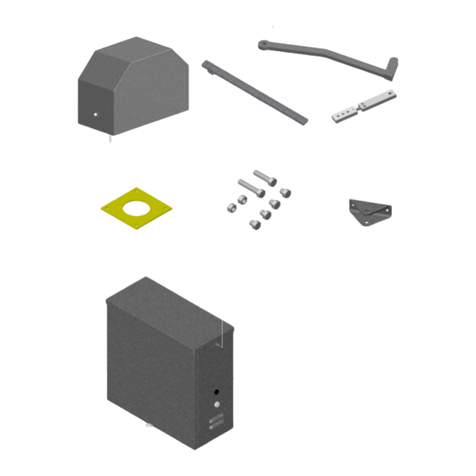

1.1 Gate operator kit

1.2 Technical features

1.3 How to operate the device

1.4 Safety recommendations

1.5 For higher safety

1.6 Emergency control

1.7 Compliance to norms

2.0 Actuators assembly to “K” plate

2.1 Front support assembly

2.2 Second actuator assembly

3.0 Wiring

3.1 Standard electric connections

3.2 Special connections

3.3 Settings

3.4 Special electric connections: photocells

3.5 Emergency battery

3.6 Key selector

3.7 Blinker

3.8 Transmitter encoding

3.9 Advanced functions

4.0 Control list: 20 points

4.1 Help ...trouble shooting

4.2 Spare parts

5.0 Guarantee

1

ALLDUCKS Srl

via Alessandro Volta,1 - 20060 Ornago (MI) Italy

Tel. +39/039/6010654 Fax +39/039/6011243

www.allducks.it

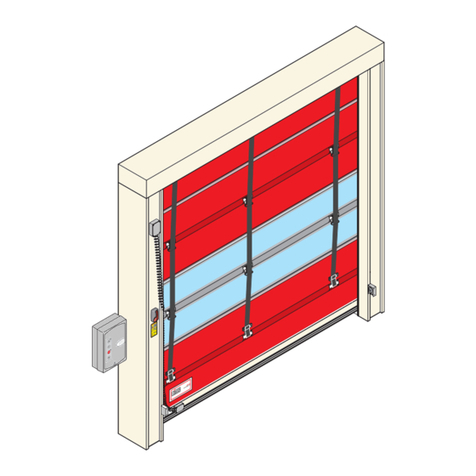

1.1 Kits composition Fig.1

HC 812.03 max 2.5 x 2 m

No. 2 12V actuators 300 mm stroke. A

No. 1 CTR42 Programmer with radio receiver. B

No. 2 remote transmitters with 12V built-in battery. C

No. 1 Key selector. D

No. 1 Unlocking key. I

No. 1 Blinker. E

HC 412.03/ 400 protop max. 3.5 m

No. 1 Actuator 12V 400 mm stroke. A

No. 1 CTR42/S Programmer with radio receiver. B (extra outputs: 12V electric lockset, pedestrian opening, temporised garden light)

No. 2 3-channel remote transmitters with 12V built-in battery. C

No. 1 Key selector. D

No. 1 Unlocking key. I

No. 1 Blinker. E

No. 1 Pair of photocells. M

No. 1 Antenna with cable. N

HC 812.03 /400 protop max 3 x 2 m

No. 2 12V actuators 400 mm stroke. A

No. 1 CTR42/S Programmer with radio receiver. B (extra outputs: 12V electric lockset, pedestrian opening, temporised garden light)

No. 2 3-channel remote transmitters with 12V built-in battery. C

No. 1 Key selector. D

No. 1 Unlocking key. I

No. 1 Blinker. E

No. 1 Pair of photocells. M

No. 1 Antenna with cable. N

All our kits are provided with accessories for the assembly

2

HC412.03/400 protop HC812.03/400 protop

HC812.03

Fig.1

3

1.2 Technical features

A: Actuators provided with triple trapezoidal screw driven by an irreversible worm screw gear motor provided

with EMERGENCY UNLOCKING SYSTEM.

12 V DC Motor

- Maximum thrust: 150N

- Piston rod speed: 1.5 cm per sec.

- Possibility of continuous work.

- Operating temperature: -15 + 45°C.

- Protection degree: IP44.

B: System control equipment.

- Plastic casing with IP44 protection degree, provided with No. 3+2 fairleads.

- Control card CTR42 and/or CTR42/S .

- 20 amp. relays

- 433.92 MHz radioreceiver in compliance with European norms I.ETS 300 220

- 12 V AC power supply input ; 12 V DC outputs.

- Double working program: Step-to-step/Automatic.

- Amps safety control system.

- Power supply warning LED.

- Toroidal transformer - CE - 230/12V -50Hz 110/12V -60 Hz 100W.

C: 433.92 MHz quartz remote transmitters in compliance with norms I-ETS 300 220, EEC approvals.

D: Key selector with built-in force-proof system.

E: Blinker:

- Plastic casing with IP44 protection degree provided with fairlead.

- Lamp holder.

- 12V 10W max bulb

F/H/L/K: Adjustable fixation system

I: Unlocking key.

M: Pair of 12V photocells. Protop models

N: Antenna with cable. Protop models

Protop

Protop

Fig.1/a

1.3 How to operate the device Fig.2

The pulse is sent to the remote transmitter “C” and is received by the electronic programmer “B” which provides to

supply the energy to motors “A” which drive the gate wings. Two operating modes are available: step-to-step and auto-

matic.

STEP TO STEP OPERATION

OPENING STEP

A pulse open the wings.

During the operation, one can always stop the movement by giving a pulse, while a further pulse (after 3-4 seconds

from the stop) leads to closing.

CLOSING STEP

A pulse closes the wings.

During the movement one can always stop the movement by giving a pulse, while a further pulse (after 3-4 seconds

from the stop) reopens the gate.

AUTOMATIC OPERATION

OPENING STEP

A pulse opens the wings.

During the operation, one cannot stop the movement by giving a pulse.

CLOSING STEP

After the opening the gate will automatically close, after a pause time that can be set as desired through the program-

mer. During the pause, the system does not accept closing pulses.

During closing a pulse reverses the movement (reopening).

The blinker “E” will warn the wings are moving.

The system is designed to last many years and NO MAINTENANCE is needed.

At intervals wash the actuators with water and soap.

The actuator piston rod made of stainless steel has NEVER to be lubricated.

1.4 Safety recommendations

The system is provided with a crushing-proof electronic safety device controlled by microprocessor. Check the perfect

alignment of the gate hinge pivots for a correct adjustment.

1.5 For higher safety Fig. 16/16a

We advise to install one or two pair of photocells. They shall provide for the reopening of the wings in case an object

obstructs their way.

We also advise to comply with norms on automation in force in the various countries.

1.6 Emergency control Fig. 3

In case the system fails, the gate can be manually opened.

Insert the triangular key inside the triangular slot positioned over the motors, then turn counter-clockwise till the stop.

Motors will unlock. The inverse operation restores the gate automation.

4

Fig.2

Fig.3

5

2.0 Actuators assembly to “K” plate Fig.4

ssemble the adjustable “K” plate and fix it to the wall. This operation is extremely important as it shall determine the following parameters:

1. Gate opening speed

2. Actuator thrust strength

Fundamental elements to make this choice are the following:

3. The gate size (weight/length)

4. Pillar size

You will find a series of sizes to determine the positioning of K plate with respect to the gate “V” rotation axis (hinge pivot). Fig.6-7-8

- F7 300mm STROKE ACTUATORS

- F8 400mm STROKE ACTUATORS

- For gates whose length is longer than cm 150, consider “B” measures higher than 10 cm.

- The “A” measure is actually ininfluent in the choice therefore it can be determined only by the size of the pillar.

- Some standard advised measures are (for 300 mm stroke actuators):

Gates not exceeding 150 cm: A=10 cm / B= 10 cm

Gates exceeding 150 cm: A= 14 cm / B= 12 cm

- Remind the higher is “B” measure, the slower the gate will open.

Caution: :maximum thrust strength allowed: 150 N

In order to be sure not to exceed 15 Kg of thrust strength, do not use measures shown in the blackened boxes of Fig. 7. In case it were necessary to use those measures, it is mandatory

to install a double pair of safety photocells. Fig.16 (Ref. 7012)

2.1 Front support assembly

After the “K” plate fixation, install the actuator through the pivot. ( Fig.1/a element F).

IMPORTANT: Then provide for the “STOPS” installation on the ground.

Fig.4 Fig.5

V

K

H

Fig.6

6

Fig.7 Fig.8

- Open the gate wing till the desired position is reached

Now the “H” front plate can be fixed following this scheme.

- You have to unlocked the actuator by means of the key through the plug. Fig.3

1. Open the wing till the STOP is reached.

2. Lay the actuator on the gate with the rod COMPLETELY INSIDE (position perfectly horizontal).

3. Fit the “H” plate.

4. Then fix the H plate to the gate by means of screws or by welding it to the gate.

It is advisable to check the good operation of the movement by opening the gate wings manually.

2.2 Second actuator assembly

Repeat the operation for the other gate wing, following the same steps 2.0 and 2.1.

Caution: Fixation measures of the second actuator shall absolutely be the same as the first ones.

7

3.0 Wiring Fig. 9

AC: AC line input

A: 12 V electromechanical pistons

B: Electronic control equipment Fig.14

D: Key selector

E: 12V max 10W blinker

1: Connection cable motor M1 - Bipolar cable 1.5 mm_ cross section

2: Connection cable motor M2 - Bipolar cable 1.5 mm_ cross section

3: Blinker connection cable (not supplied)

4: Key selector connection cable (not supplied)

5: Connector block (not supplied). Minimum height above ground 40 cm.

6: Underground cable duct (not supplied)

Mark and drill the pillar in the anchoring point of the control unit. Position the unit at a minimum distance of 1 m from the motor.

3

4

Fig.9

B

Fig.10

Fig.11

Fig.12 Fig.13

230V 50Hz

110V 60Hz

Fig.12a

8

3.1 Standard electric connections Fig.14

Unscrew the protection of the control unit Fig.14a and carry out the following connections according to the following:

1. Connect the M1 motor to terminals

M1 (16 blue 17 brown) in case of 1 motor. First motor with delayed start in closing

And/or

M2 (14 blue and 15 brown) in case of 2 motors. Second motor with delayed start in opening

!!Caution: in the one-wing kit (HC412.03/400 protop) the motor shall be connected to M1 terminals (16 blue and 17 brown) and

the switch YP1 (fig.14) moved to 1 position.

2. Connect the power supply line to transformer terminals. Fig.12/12a.

Caution: Check the good anchoring of actuators and the sliding movement of the gate by moving it manually after having unlocked

the actuators by turning the unlocking key counter-clockwise, see Fig. 3. Then close the wings and lock motors.

- In case photocells were not used, connect terminals 4-5 with a jumper (operations already carried out in the workshop).

3. The green LED will go on.

TEST!

By pressing the T1 left hand button of the remote transmitter, Fig.20, the gate shall open and stop in the wide open position.

By further pressing the same key, the gate shall close.

“You can then open your gate automatically!”

Fig.14

Fig.14a

Connections:

1 – antenna pole

2 – antenna sheath

3 - start

4 - photocell

5 - start/photocell common

9 - pedestrian start (only CTR42/S)

10 – photocells power supply positive

11 - photocells power supply negative

12 – blinker

13 – blinker

14 – motor 2 blue

15 – motor 2 brown

16 – motor 1 blue

17 – motor 1 brown

18 – courtesy light (only CTR42/S)

19 – courtesy light (only CTR42/S)

20 – electric lockset (only CTR42/S)

21 - electric lockset (only CTR42/S)

RV1) motor 1 power

RV2) motor 2 power

RV3) pause

LV) green led

LR) red led

P1) remote transmitter encoding

P2) non pressure

Fuse) 10A protection fuse

yp1) 1/2 wings operation switch

Batt+) positive battery input

Batt-) negative battery input

V12/V0) transformer input

9

Fig.14

3.2 Special connections only for CTR42/S Fig.14

Caution : only for the following references:

HC412.03/400 protop and 812.03/400 protop professional automation

CTR42/S programmer version

It will be possible to:

1. Connect an electric lockset

2. Another garden lights output

3. Open only one wing to allow the pedestrian crossing

How to proceed:

1. carry out all the connections, see paragraph 3.1 and possibly photocells paragraph 3.4.

2. Connect the terminals:

18-19 to a low voltage relay which is, on its turn, connected to garden lights

20-21 to a 12V electric lockset to be connected to the gate and which shall be activated at each movement

5-9 to a push-button that will activate the only pedestrian crossing.

Caution: giving a pulse on the button connected to terminals 5-9 NO (normally open) the wing will open corresponding to the first

motor M1. Also in this case one can program the operation in step-to-step or automatic mode.

3.3 Settings Fig.14

1.Motor 1 RV1 trimmer and motor 2 RV2 trimmer ampere set-

ting or safety setting: it shall be set as to ensure safety in case

of obstacle, however with enough power to move wings. Turn

the trimmer clock-wise to increase the power.

Caution: during winter months or when a strong wind blows,

the settin

2.PROGRAM: RV3 trimmer allows to manage two operating

modes:

A: Step-to-Step, by setting the trimmer to “0” ZERO, by com-

pletely turning counter-clockwise (each step is controlled by a

single pulse)

B:Automatic with closing after a set time: to set the pause time

between opening and closing, turn the trimmer clockwise till

the desired time is set. (Warning: turn _ revolution at least)

(During the opening and pause the equipment shall not accept

other signals, while during closing a pulse will reverse the

movement)

Caution: ALL THE SETTINGS SHALL BE PERFORMED WITH

THE WINGS CLOSED: in addition, they will be stored only at a

cycle start, therefore they shall be effective only starting from

the next cycle.

10

3.4 Special electric connections : photocells (optional for HC812.03)

The protection system by means of photocells is composed of one or more PAIRS of devices, one of them is the TRANSMITTER and the other is the RECEIVER. Fig.16-17

The first transmits an invisible infrared beam picked up by the receiver; in case the beam were interrupted the equipment will open a relay which shall transmit a signal to the programmer

that shall provide to invert the motors operation direction during the wings closing.

Caution: Carry out connections according to Fig.16. In case photocells were more than ONE pair, carry out connection SERIES. Fig. 16a. Provide for a digging in the ground suitable to lay a

cable duct crossing the gate width.

1. Cable having a minimum cross section of 0.5 mm_ SHALL BE PROTECTED BY A PROPER SHEATH.

2. In case of double safety device, provide for a DOUBLE PASSAGE.

3. Position the receiver in front of the transmitter at the same height (40/60 cm).

4. The red led off indicates a perfect alignment.

5. Install the photocells cables far from cable ducts to avoid interference.

6. Never assemble the receiver in front of the sun.

7. In case of double safety device, alternate a receiver with a transmitter Fig. 16a

Accessories installation, see paragraph 3.1 Connections.

Fig.16 Fig.16/a

Fig.17 Fig.17/a

11

10 cm

12 cm

12V

5 cm

5 cm

Fig.18 Fig.19

3.5 Emergency battery and C/M/BATT battery charger (optional) Fig. 12

The system can also operate AUTOMATICALLY, that is without power supply coming from the mains supply.

By installing a 12V 6,3 Amp. battery, it will be possible to carry out approx. 30 emergency operations without power supply.

The battery can be fit in the proper space inside the plastic casing containing the control unit. The automatic device C/M/BATT able to keep the battery charged. Provide for the connection

of ter the automatic device C/M/BATT to the Fig. 14 terminals Before using the system with the battery only, it shall be first charged for at least 24 h.

The optional battery charger Ref. C/M/BATT shall be purchased.

3.6 Key selector assembly Fig.18

The key selector allows to start the operation by turning the control key clockwise. Avoid to use the remote transmitter at the same time.

The selector can operate the gate according to the set program. The contact is Normally Open (N.O). In case more than one selector or possibly a switch were to be fitted, carry out parallel

connections.

It is equipped with a FORCE-PROOF device and therefore it cannot be opened without the key.

Caution: for a higher force-proof safety, we advise to make the connection cable pass inside a walled cable duct.

3.7 Blinker Fig.19

This device is foreseen by all safety EEC norms, and it has to be installed in a visible position.

Size and light features are in compliance with norms in force. The device operates at LOW VOLTAGE and is provided with a lamp holder and a 12V 10W bulb.

Caution: Never exceed this power as there might be the risk of damaging circuits.

- Operation: the intermittent signal comes from the control unit.

- The activation starts 2 seconds before each operation.

- The blinking is fast when the gate opens and slower when the gate closes.

Caution: Firmly fix the device as vibrations may reduce the bulb lifetime.

12

3.8 Transmitter and receiver encoding

The newly designed remote transmitter ref. 6203 is standard PRE-CODED in the factory, fig.20a.

The pre-set codes will be transmitted by pressing T1-T2-T3 keys Fig.20

T1 Gate operator

T2 Garage operator

T3 (T1+T2 at the same time) other

- To set a new code in the remote transmitter follow this procedure:

1. Press the remote transmitter T1 and T2 keys at the same time (Fig.20) until the Led goes on with fixed light.

2. Release the keys, the Led goes off. Now the remote transmitter is in the programming function.

3. Press and release the key corresponding to the channel to be programmed (ex. T1, T2 or T3), the Led goes on for approx. one second.

4. Press T1 ( OFF ) and T2 (ON) keys for 12 times composing your 12-pulse personal coding string you had previously marked. After each pulse wait until the led goes on and then off.

Example: if you pressed T1-T2-T1-T2- you programmed: OFF-ON-OFF-ON etc. up to 12.

!! If you have not entered all the set 12 codes, the remote transmitter will stay in the "programming". ALL THE 12 CODES HAVE NECESSARILY TO BE ENTERED ALSO IN CASE OF

ERROR DURING PROGRAMMING.

To carry out a new programming repeat the instruction from point 1.

5. After having reached the thirteenth pulse, the remote transmitter will blink various times, which means the new programming has been accepted. If this would not occur, repeat the ope -

ration from point 1.

!Important : we recommend to copy the numbers string you coded using the scheme fig.20b.

How to set the new remote transmitter code in the programmer: "SELF-LEARNING" function

Caution: clear the pre-coded standard code by pressing the P1 key for 10 seconds until the red led blinks.

Then:

1. Press the programmer P1 key (one time only!) the red Led will go on

2. Press the key of the previously set channel on the remote transmitter (T1 - T2 - T3) for some seconds. When the red led goes off for one second and then turns on, it means the code

has been accepted. The receiver is programmed!

Fig. 20

T1

off

T2

on

T3

20a

1 2 3 4 5 6 7 8 9 10 11 12

ON

OFF

1 2 3 4 5 6 7 8 9 10 11 12

ON

OFF

1 2 3 4 5 6 7 8 9 10 11 12

ON

OFF

T1

T3

T2

1 2 3 4 5 6 7 8 9 10 11 12

ON

OFF

1 2 3 4 5 6 7 8 9 10 11 12

ON

OFF

1 2 3 4 5 6 7 8 9 10 11 12

ON

OFF

T1

T3

T2

20b

13

3.9 Advanced functions

1) Function of opening one wing only with the remote transmitter.

Proceed as follows:

a) ON THE REMOTE TRANSMITTER:

- select a new key (T1, T2 or T3) different from the one used to open the two wings and code the remote transmitter with a NEW CODE (see paragraph 3.8)

b) ON THE PROGRAMMER Fig.14:

- Press the P1 key TWICE, let 1 second elapse from one pressing to the other

- Press the key of the chosen channel (T1, T2 and T3) of the remote transmitter to transmit the code to the programmer

Caution: the receiver will accept a code that allows this further function only if different from the code previously set for the basic functions and only if set on a different key.

2) Function to enable or disable the non pressure of wings, CTR42 and CTR42/S:

to disable the function:

a) press the P1 key of the programmer Fig. 14 for 1 second. The red led will go on.

b) Press the P2 key for 1 second

To enable the function repeat the procedure at points a and b

Fig.14

14

4.0 Control list: 20 points

We suggest to check the following points in order to be absolutely sure to have

made a correct assembly:

1. The dimensions of the gate shall not exceed the maximum limits detailed.

Paragraph 1.1

2. The gate wings shall be able to move correctly by hand with little effort.

3. Actuators shall be fixed in a TOUGH way and shall be perfectly symmetrical.

4. Electric connections shall be carried out with care and attention.

5. In case no photocells were used, connect the terminal No.4 to terminal No.5

through a jumper.

6. In case one or more fuses burnt due to assembly fault, replace them with

others of the same type.

7. Set the power to a value sufficient to move wings. Do not exceed. In case of

strong wind or during the winter season, increase the power – RV1 and RV2-

(paragraph 3.3).

8. Test the safety device, it must be able to promptly intervene and stop the

wings movement.

9. Do not carry out the assembly when children or pets are around.

10. Do not assemble when it rains.

11. The cable ducts shall be well underground: minimum at 40 cm depth.

12. All the clamping screws shall be well tightened.

13. Use cable terminals for electric connections.

14. Address to qualified personnel to have the plant connected to the 230V

mains supply. Provide for a safety magneto-thermal switch of min. 5 Amp. for

the AC supply line. Class II plant, the earthing is not necessary.

15. No maintenance is required, do not oil pistons.

16. Every 3 / 4 months, check the good operation of the manual unlock.

17. Use electric cables for outdoor installation type HO7RNF and nothing else.

18. In case of emergency battery use, possibly choose a well-known brand (2

years average lifetime).

19. Change remote transmitters batteries every 12 months.

20. Use exclusively original spare parts.

Caution: The gate automation is a device with a high technological content both

for the high level of the software used and for the mechanical components

manufactured to achieve a long lifetime. We advise to follow these instructions

with attention and if in doubt, address to our assistance points.

4.1 HELP.... TROUBLE SHOOTING (S = PROBLEM, C = CAUSE R = REMEDY)

S-The gate does not open when a pulse is given

C- 1. Remote transmitter battery discharged 2. 230V power supply missing

3. Remote transmitter code different from the one of the control unit.

R- 1. Replace the remote transmitter battery or temporarily use the key selector

2. Check the 230V power supply switch or the fuse of the transformer A.0.8.

3. Code the remote transmitter as detailed in paragraph 3.8

S- A motor opens and the other closes

C- 1. M1/M2 wrong connection

R- 1.Invert the connection cables to motors, see Fig.14

S-Motors stops immediately

C- 1.Incorrect power

R- 1. Set power acting on RV1 and RV2 trimmers

S- The gate does not close after opening

C- 1. Photocells jumper, and or photocells alignment. Fuses.

2. START contact closed

R- 1. If no photocells are installed connect the terminal 3 with terminal 4. Align photocells. Check

fuse 5A.

2. Close the gate giving a START pulse. Then try again.

3. START contact permanently active. Check.

S- The blinker does not work

C- 1. Bulb fault

R- 1. Check the 12 V max. 10W bulb.

2. Check 5A fuse.

S- The key selector does not work

C- 1. Connection fault

R- 1. Check electric connections. Fig.14

S- Motors works slowly after some years

C-1. Brushes fault

R-1. Replace electric brushes. Art. R/70

S- 10 amp. Fuse burnt

C- 1. Transformer burnt

2. Short circuit in the motors supply

R- 1. Check the transformer isolation

2. Check motors cables

S- 10 amp. Fuse burnt

C- 1. Blinker fault

2. Photocells fault

R- Check there are no short circuits in the supply of:

1. Blinker 2. Photocells S-Green LED off

C- 1. AC 230 V power supply R- 1. Check 0.8 T Amp. fuse.

2. Check the AC 230V power supply connection

15

R3

R4/R28

R11 R14

R13

R15 R37

R76

R73

HC412

HC312

CTR42/S

CTR42

4.2 Spare parts:

REF. DESCRIPTION

R1 Stainless steel tube with clevis and nut screw, 300 mm

R1/400 Stainless steel tube with clevis and nut screw, 400 mm

R2 Screw provided with ball bearing, gear and unlocking system, 300 mm

R2/400 Screw provided with ball bearing, gear and unlocking system, 400 mm

R3 Unlock pivot

R4/R28 Complete Reduction gear casing

R8 Accessory set for the K + H plates assembly + screws

R9 Trapezoidal anodised aluminium tube, 300 mm

R9/400 Trapezoidal anodised aluminium tube, 400 mm

R11 Fixation pivots

R13 Fixation elastic rings

R14 Unlock plug

R15 Unlock key

R37 Front guide

R39 Rotor provided with manifold and winding

R71/R72 Plastic casing for electronic equipment with cover and 230/12V transformer

R73 Fairleads

CTR42 Programmer card

CRT42/S Programmer card for professional models

HC 312 12V motor, 300 mm stroke with tie rods (R38)

HC 412 12V motor, 400 mm stroke with tie rods (R38/400)

R76 12V Motor (R22 ball bearing for drive shaft type 6002zz-R26 type, motor body

with magnetos – R39 complete rotor- R40 motor cap with brush-holder –R68 608 zz –R70

driving shaft ball bearing – R70 pair of brushes) with ring and plate

4.3 Original accessories

7012 Pair of safety photocells

5000 Key selector

7500 Blinker

6025 Antenna with cable

6500 Clavier universal keyboard

6203 3-channel remote transmitter

6040 Outdoor separate receiver

918 Pair of columns for photocells

12/M/BATT 12V 6.3 A emergency battery

C/M/BATT Emergency battery charger

16

5.0 Guarantee

This product is guaranteed for 24 months from purchase date, for manufacture or material

defects. In case of repair, the product shall be returned to the reseller where the product was

purchased or to one of our authorised after-sale centres. The authorised technical assistance

centres are the only acknowledged assistance suitable to carry out repairs under guarantee

(see addresses in the last page). In case of difficulties, please address to:

Allducks srl

Via volta,1 20060 Ornago (MI) ITALIA

Tel. +39/039/6010654

Fax +39/039/6011243

Guarantee conditions

1.The guarantee is accepted only in case the guarantee certificate is completely filled in and

presented with the invoice or coupon proving the purchase; no alteration or cancellation shall

be on the certificate.

2.Allducks obligations are limited to the repair or, at its own discretion, to the defective parts

replacement.

3.The product guarantee shall immediately decay if the product is modified and adapted to

technical and safety norms different from the ones in force in the country the product was

conceived and manufactured for. No refund is foreseen for damages deriving from the above-

mentioned modifications.

4.The guarantee does not cover:

a) Periodical checks, maintenance, repairs or replacement of worn out parts.

b) Transport, handling or installation costs relating to this product.

c) Improper use, mistakes in the operation and incorrect installation.

d) Damages caused by fire, water, natural phenomena, storms, incorrect power supply, or any

other cause not depending on the manufacturer.

5.This guarantee neither influence the rights of the customers envisaged by law, according to

the national applicable laws, nor the rights of the customer towards the reseller deriving from

the purchase contract. In case there were no national applicable laws, this guarantee shall be

the only safeguard for the customer and neither the manufacturer nor his distributor will be lia -

ble for accidental or indirect damage to their own products deriving from the infringement of

guarantee conditions.

For after sale information, please contact :

Allducks srl

Via volta,1 20060 Ornago (MI) ITALIA

Tel. +39/039/6010654

Fax +39/039/6011243

5.1 Compliance certificate and norms

CE CONGFORMITY DECLARATION

WE DECLARE THAT:

The wing gates operator: Models No. HC812/300-812/400 bi or mono; HC412.03 protop–

HC812.03- HC812.03/400 protop, 812/300 AND 812/400,

when installed and used according to the Manufacturer instructions, are in compliance with

the directive 89/392/EEC and all its amendments.

THE MENTIONED ITEMS

are in compliance with the norms EN55014, EN61000-3, EN60529, ETS 300 683, EN60555,

& EN60335-1, EN60034 according to the European Directives: R&TTE 99/05/CE,73/23/CEE,

89/336/CEE, 98/37/CE;

EN 55014;EN61000-3; EN60529; ETS300 683; EN60555; EN60335-1;EN60034; EN13241-1;

EN12453;EN12445

products are in compliance with RoHS rules

6203 remote transmitter: 433 Mhz 12 Bit - CE 0681- FCC ID OLS137925764

I, the undersigned, hereby declare that the above mentioned products and all their accesso -

ries detailed in the manual are in compliance with the above mentioned directives and stan -

dards.

january 2007

Allducks srl

Via volta,1 20060 Ornago (MI) ITALIA

Tel. +39/039/6010654

Fax +39/039/6011243

A.Toutberidze

The Chairman

This manual suits for next models

5

Table of contents

Popular Gate Opener manuals by other brands

BFT

BFT PHOBOS N Installation and user manual

Aprimatic

Aprimatic XT2500 INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER

Brookfield Industries

Brookfield Industries NB-4120-1 Series Operator's manual

Centsys

Centsys D10 Turbo installation guide

Apollo

Apollo 3500 Operator's manual

Merlin

Merlin Slide 600 Quick reference guide

Beninca

Beninca DU.350NL instructions

Life

Life Optimo OP3 Instructions and warnings for installation, use and maintenance

Nice

Nice 4024 Instructions and warnings for installation and use

DITEC

DITEC TRAFFIC C Installation manual, maintenance, use

Beninca

Beninca RI.6SF Operating instructions and spare parts catalogue

Tormatic

Tormatic NovoSwing Mounting and operating instructions