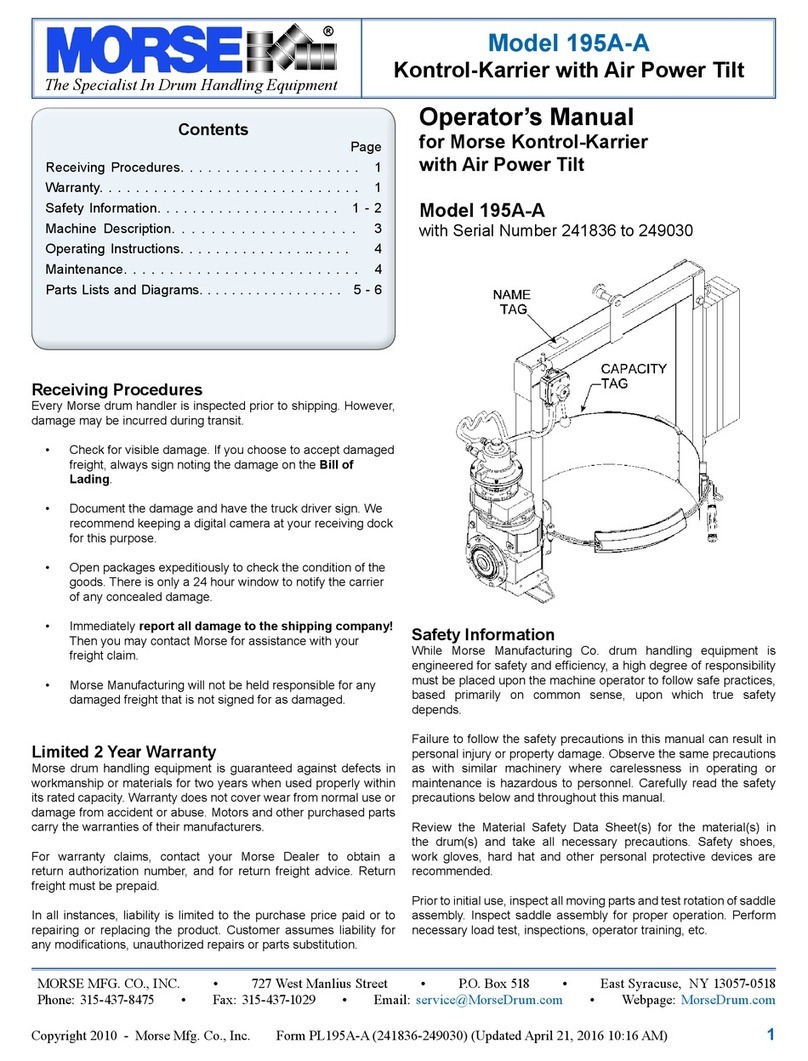

Allegri PRATIK 30 User manual

VEHICLE LIT

PRATIK 30

USE AND MAINTENANCE

CAREFULLY READ THE INSTRUCTIONS GIVEN IN

MANUAL BEFORE USING THE LIFT

1

PRATIK - Installation use and maintenance ENG-

USE AND MAINTENANCE

MANUAL

CAREFULLY READ THE INSTRUCTIONS GIVEN IN

THIS

MANUAL BEFORE USING THE LIFT

TRANSLATION OF THE ORIGINAL TEXT

EDITION: 2018-07-05

THIS

ENGLISH

TRANSLATION OF THE ORIGINAL TEXT

2

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

3

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

4

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

T

HE MACHINE DESCRIBED IN THIS MANUAL REFERS TO THE FOLLOWING SERIES:

WARRANTY

The manufacturer warrants lifts and the relevant accessories for 12 months after purchase date. This warranty

consists in the repair or replacement

Manufacturer's Technical Service, tu

rn out to be faulty from origin. All electrical parts are excluded. Warranty is

limited to material defects, and becomes null and void if the returned parts are tampered with or disassembled by

unauthorized

staff. Any liability for direct and indirect inju

malfunction are excluded from warranty. The expenses deriving from lubricants replacement, transport charges, and

any customs duty, VAT and any other expense not specified in the supply contract

replacement and repair of parts under warranty, anyway, do not extend warranty terms. The

nevertheless be entitled to assert its rights on warranty, specified in the supply contract. Should the parties not

willing to submit any dispute arising from the supply contract to arbitration, or in any other case where the judgement

of a body of the ordinary competent court is required, the Court of Vicenza will be the only competent court on the

territory.

DISCLAIMER

Upon delivery, please check that the product has not been damaged during transportation, and that the accessories

coming with it are intact and complete. Any complaint shall be filed within 8 days after lift delivery date. Besides the

cases envisaged by the supply

contract, the warranty becomes null and void:

• In case of a man oeuvre

error caused by the operator.

• If the damage is caused by poor maintenance.

• If the envisaged capacity is exceeded.

• If the machine has been somehow modified, and the damage has been caused by such a modification, due to repair

operations by the user without the

authorization

• If the instructions described in this

user's manual are not complied with.

CAREFULLY READ THE INSTRUCTIONS

GIVEN IN THIS MANUAL BEFORE USING THE LIFT

THIS USER'S MANUAL IS WRITTEN IN THE

LANGUAGES. IN CASE OF COMPLAINT, FOR LEGAL PURPOSES, THE VERSION IN ITALIAN LANGUAGE ONLY WILL

APPLY. THE MANUFACTURER DISCLAIMS ANY LIABILITY FOR DIRECT AND/OR INDIRECT DAMAGES CAUSED BY

POOR TRANSLATION OR

WRONG TEXT INTERPRETATION.

5

PRATIK - Installation use and maintenance ENG-

HE MACHINE DESCRIBED IN THIS MANUAL REFERS TO THE FOLLOWING SERIES:

PRATIK.

The manufacturer warrants lifts and the relevant accessories for 12 months after purchase date. This warranty

consists in the repair or replacement

- free of charge -

of those parts that, after a careful analysis by the

rn out to be faulty from origin. All electrical parts are excluded. Warranty is

limited to material defects, and becomes null and void if the returned parts are tampered with or disassembled by

staff. Any liability for direct and indirect inju

ries to people, animals or property due to machine failure or

malfunction are excluded from warranty. The expenses deriving from lubricants replacement, transport charges, and

any customs duty, VAT and any other expense not specified in the supply contract

are at the purchaser's charge. The

replacement and repair of parts under warranty, anyway, do not extend warranty terms. The

nevertheless be entitled to assert its rights on warranty, specified in the supply contract. Should the parties not

willing to submit any dispute arising from the supply contract to arbitration, or in any other case where the judgement

of a body of the ordinary competent court is required, the Court of Vicenza will be the only competent court on the

Upon delivery, please check that the product has not been damaged during transportation, and that the accessories

coming with it are intact and complete. Any complaint shall be filed within 8 days after lift delivery date. Besides the

contract, the warranty becomes null and void:

error caused by the operator.

• If the damage is caused by poor maintenance.

• If the envisaged capacity is exceeded.

• If the machine has been somehow modified, and the damage has been caused by such a modification, due to repair

authorization

of the manufacturer or after fitting non-

original spare parts.

user's manual are not complied with.

CAREFULLY READ THE INSTRUCTIONS

GIVEN IN THIS MANUAL BEFORE USING THE LIFT

THIS USER'S MANUAL IS WRITTEN IN THE

MANUFACTURER'S LANGUAGE, AND IN OTHER COMMUNITY

LANGUAGES. IN CASE OF COMPLAINT, FOR LEGAL PURPOSES, THE VERSION IN ITALIAN LANGUAGE ONLY WILL

APPLY. THE MANUFACTURER DISCLAIMS ANY LIABILITY FOR DIRECT AND/OR INDIRECT DAMAGES CAUSED BY

WRONG TEXT INTERPRETATION.

EDITION: 2018-07-05

The manufacturer warrants lifts and the relevant accessories for 12 months after purchase date. This warranty

of those parts that, after a careful analysis by the

rn out to be faulty from origin. All electrical parts are excluded. Warranty is

limited to material defects, and becomes null and void if the returned parts are tampered with or disassembled by

ries to people, animals or property due to machine failure or

malfunction are excluded from warranty. The expenses deriving from lubricants replacement, transport charges, and

are at the purchaser's charge. The

replacement and repair of parts under warranty, anyway, do not extend warranty terms. The

purchaser will

nevertheless be entitled to assert its rights on warranty, specified in the supply contract. Should the parties not

be

willing to submit any dispute arising from the supply contract to arbitration, or in any other case where the judgement

of a body of the ordinary competent court is required, the Court of Vicenza will be the only competent court on the

Upon delivery, please check that the product has not been damaged during transportation, and that the accessories

coming with it are intact and complete. Any complaint shall be filed within 8 days after lift delivery date. Besides the

• If the machine has been somehow modified, and the damage has been caused by such a modification, due to repair

original spare parts.

MANUFACTURER'S LANGUAGE, AND IN OTHER COMMUNITY

LANGUAGES. IN CASE OF COMPLAINT, FOR LEGAL PURPOSES, THE VERSION IN ITALIAN LANGUAGE ONLY WILL

APPLY. THE MANUFACTURER DISCLAIMS ANY LIABILITY FOR DIRECT AND/OR INDIRECT DAMAGES CAUSED BY

6

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

CONTENT

1. 0. TECHNICAL DATA

1.1 DESCRIPTION OF THE LIFT

1.2 OVERALL DIMENSIONS

1.2.1 FOUNDATIONS SCHEME

1.2.2 FOUNDATIONS SCHEME INSIDE THE FLOOR

1.3 LOAD DISTRIBUTION

1.4 PICTOGRAMS

1.5 PICTOGRAMS APPLICATION DIAGRAM

1.6 HAZARDOUS AREAS

2. INTRODUCTION

2.1 EC CERTIFICATION

2.1.1 TESTING

3. GENERAL SAFETY AND ACCIDENT-PREVENTION PULES

3.1 SET-UP AND CLOTHING

3.2 ENVIRONMENT AND POLLUTION

3.3 LIFT DISPOSAL

3.4 DANGER LEVELS

3.5 HAZARDOUS AREAS

3.6 LIFT IDENTIFICATION AND PICTOGRAMS DESCRIPTION

3.7 INTENDED USE

4. INSTRUCTIONS FOR USE

4.1 PUSH-BUTTON PANEL

4.1.1 LIFT RISING

4.1.2 LIFT LOWERING

4.2 VEHICLE LIFTING PROCEDURE

4.3 VEHICLE LOWERING AND UNLOADING PROCEDURE

4.4 SAFETY DEVICES

4.5 EMERGENCY LOWERING

5. HANDLING AND INSTALLATION

5.1 TRANSPORT AND UNLOADING

5.2 FOUNDATIONS

5.3 LIFT POSITIONING

5.4 CONNECTING HYDRAULIC PIPES

5.5 ELECTRICAL CONNECTIONS

5.6 HYDRAULIC SYSTEM FILLING

5.6.1 FIRST INSTALLATION

5.7 COMPLETING THE INSTALLATION

5.7.1 DEFINITION OF DANGER AREA

5.7.2 AREAS AT RISK

5.8 OVERALL DIMENSIONS

5.9 HYDRAULIC CONNECTIONS WITH CONTROL UNIT POSITIONED RIGHT

5.9.1 HYDRAULIC CONNECTIONS WITH CONTROL UNIT POSITIONED LEFT

5.9.2 FIXING THE LIFT TO THE FLOOR

6. MAINTENANCE

6.1 SAFETY DEVICES CHECK

6.1.1 EMERGENCY DISCONNECTOR / OFF

6.1.2 VOLTAGE WARNING LIGHT

6.1.3 AUTOMATIC ALIGNMENT AND AIR BLEEDING

6.1.4 RUBBER PADS

6.2 PERIODICAL MAINTENANCE

6.2.1 EVERY WEEK

6.2.2 EVERY MONTH

6.2.3 EVERY 200 OPERATING HOURS OR EVERY 5 YEARS, AT LEAST

7. TROUBLESHOOTING

7.1 SPARE PARTS

8. HYDRAULIC SCHEME

8.1 WIRING DIAGRAM 230/400 V 3PH

8.3 CONTROL PANEL SCHEME

9. RESERVED TO THE TECHNICIAN INSTALLER

9.1 RESERVED TO THE USER

SPARE PARTS LIST

7

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

1.0 TECHNICAL DATA

PRATIK30

Max. capacity Kg 3000

Raising time sec. . 38

Lowering time sec. . 46

Min.useful htight \ 120

Max. useful height mm 2000

platform size with closed arms mm 1525 x 270

platform size with extended arms mm 2130 x 270

Long lift to the ground C mod./ L mod. mm 2210 / 3720

Total width lift mm 2060

4-pole three-phase electric motor Volt-Hz-Amp

Volt- Hz-Amp

230 / 400 - 50 - 12.8 / 7.4

230 / 400 - 60 - 10.5 / 7.1

Three-phase motor power kW / HP 2,6 / 3,5

Motore elettrico 4 poli monofase Volt- Hz-Amp

230 - 50 - 15.9

4-pole single-phase electric motor KW / HP 2,2 / 3

Maximum Operating Pressure bar (MPa) 240 / 24

control circuit voltage Volt 24

Weight of a base - complete platform Kg 360

Total weight of the lift Kg 720

Weight of a control unit Kg 40

Recommended Hydraulic Oil ESSO NUTO H32 or equivalent (ISO

VG32)

Quantity hydraulics oil l 10

Ground fixing screw anchors TIPO HILTI HLC-H 10x80 or equivalent (8

PIECES)

sound level EN ISO 3746

acoustic pressure weighted average LpAm dB(A) 63,6

Sound pressure at operator LpA dB(A) 64,6

LwA sound power dB(A) 81,6

8

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

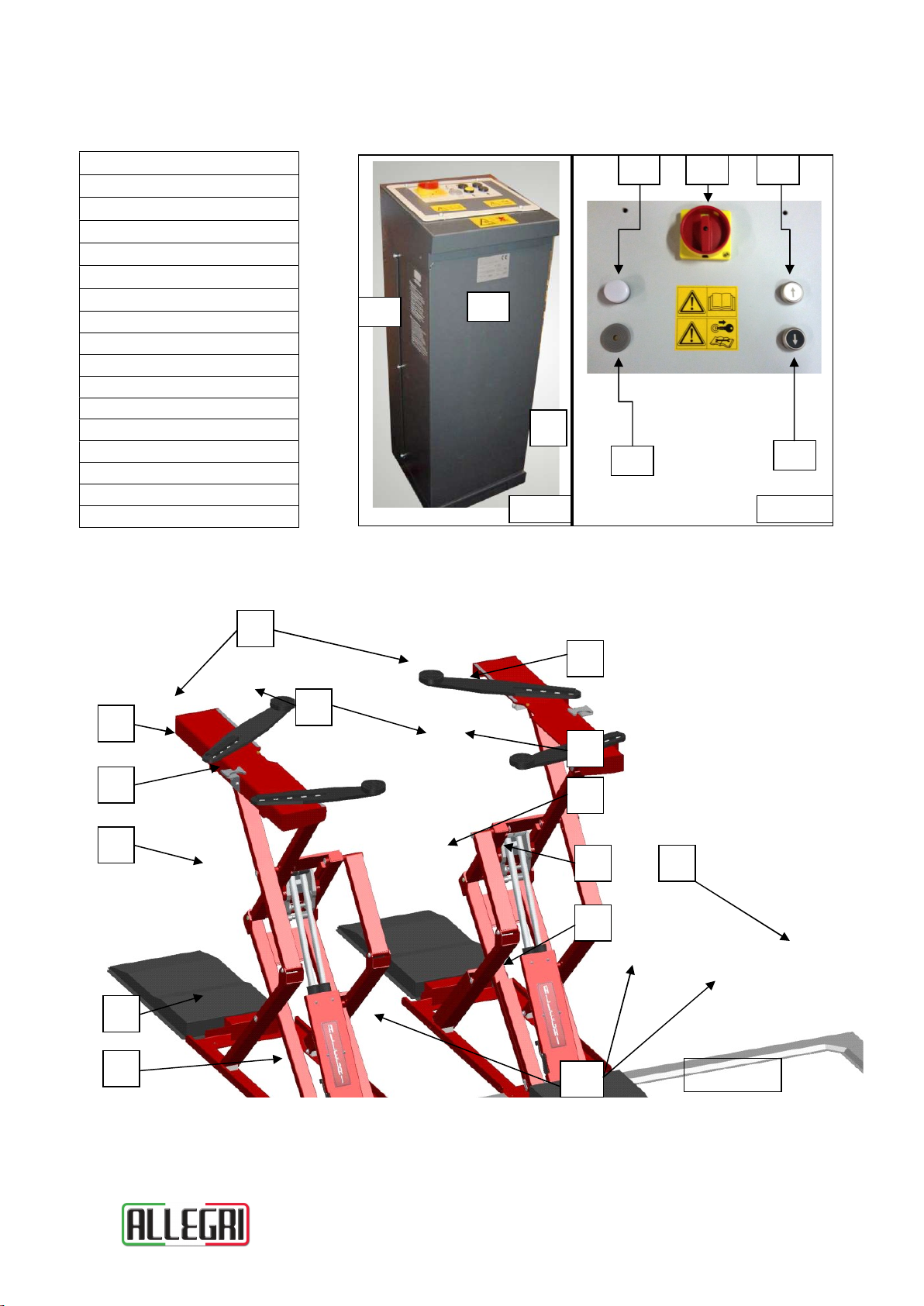

1.1 DESCRIPTION OF THE LIFT

1

-

base

2

-

p

latform

3

parallelogram

4

-

arms

5

-

arms

6

-

rubber pads

7

-

ramps

8

-

hydraulic

cylinders

9

-

control panel

10

-

switch / emergency

11

-

up button

12

-

down button

13

-

lamp voltage presence

14

-

buzzer

15

-

identification plate

16

-

label instructions

17

-

pipe covers

1

2

3

4

5

6

7

8

9

9

3

13

11

12

14

10

15

16

FIG: 1B

5

4

1

FIG.1

FIG.1A

17

9

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

1.2 OVERALL DIMENSIONS (model C)

650

675

675

900

2000

350

2210

3000 MAX

FIG. 2

10

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

1.2 OVERALL DIMENSIONS (model L)

650

675

675

3720

2000

350

900

3000 MAX

FIG. 3

11

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

1.2 OVERALL DIMENSIONS (model I)

FIG. 4

12

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

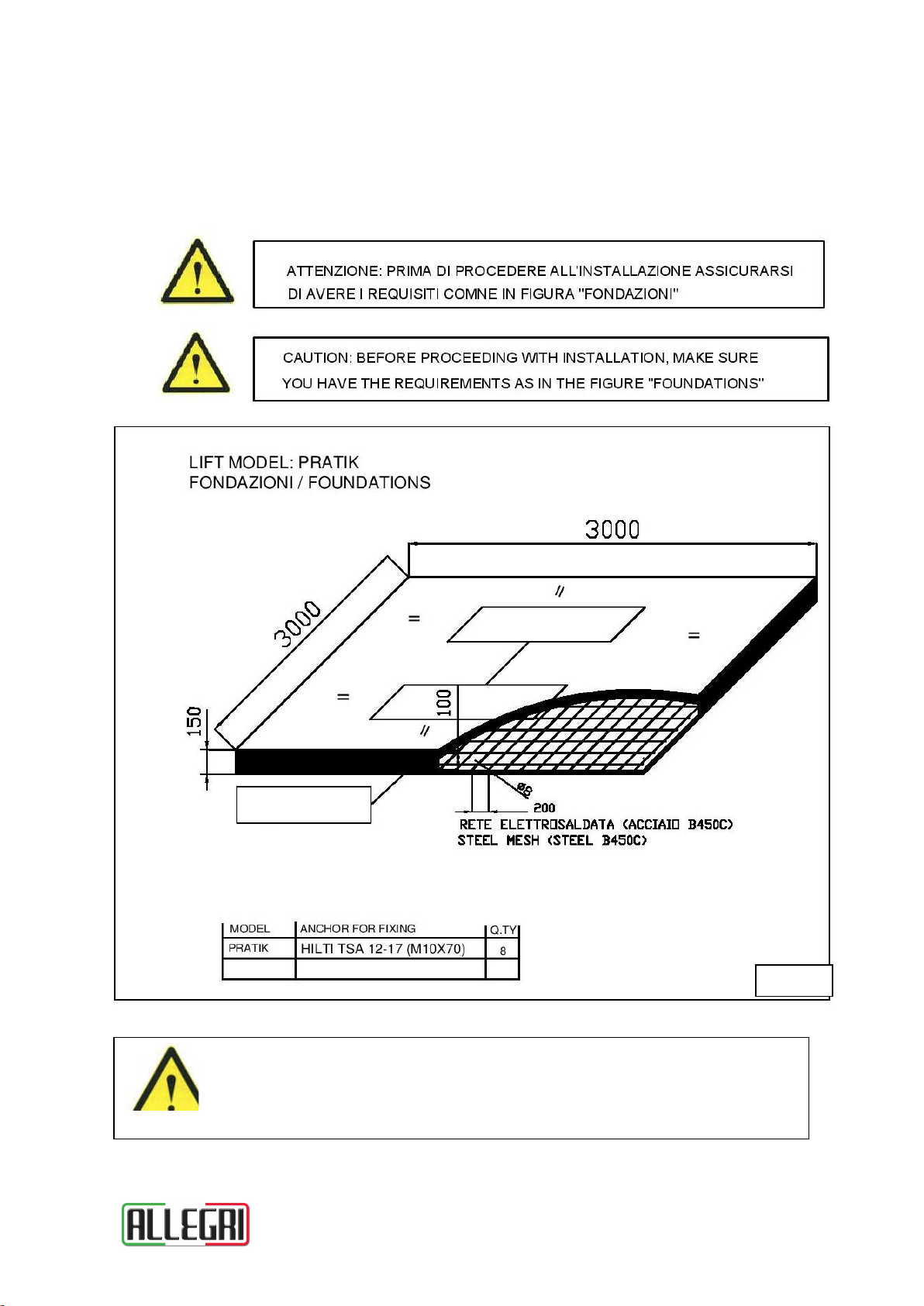

1.2.1 FOUNDATIONS SCHEME (INSTALLATION ON THE FLOOR)

ATTENTION: WITHOUT THE REQUIREMENTS IN FIG. 5 or 5A, NOT

STARTED WITH INSTALLATION OF

FIG.5

Clk

class: 20

-

25

13

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

1.2.2 FOUNDATIONS SCHEME (INSTALLATION ON THE FLOOR)

FIG.5

A

VEHICLE ENTRANCE

Clk class: 20

-

25

14

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

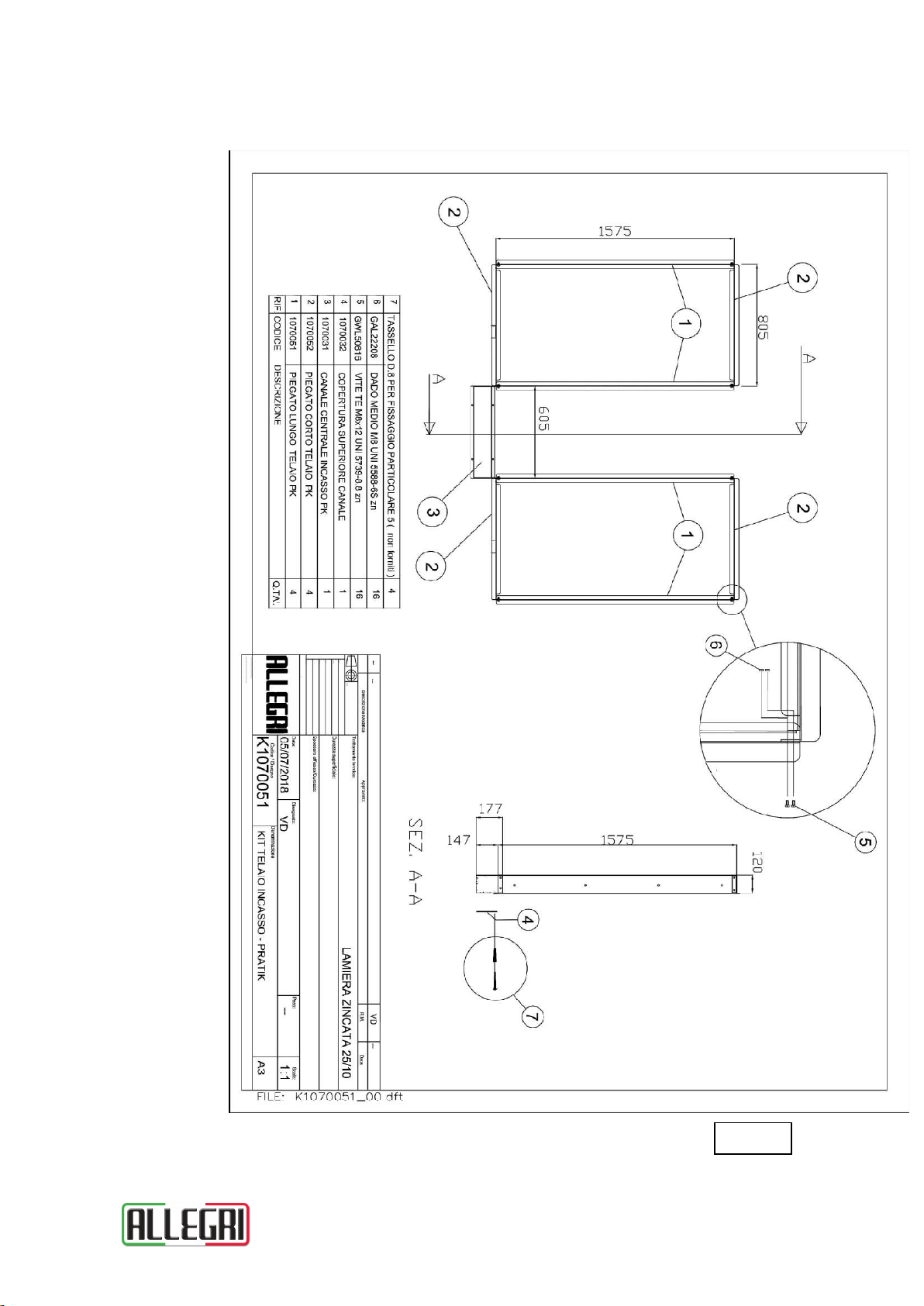

1.2.3 FOUNDATIONS SCHEME (INSTALLATION ON THE FLOOR (WITH FRAME)

FIG.5

B

15

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

1.3 LOAD DISTRIBUTION

LOAD DISTRIBUTION: 3/5 – 2/5 di Q

Q= CAPACITY 3000 KG - Q1= 1800KG (3/5 DI Q) Q2= 1200KG (2/5 DI Q)

Q2 MAX= 1200KG (2/5 DI Q) Q1 MAX= 1800KG (3/5 DI Q)

Q1 MAX= 1800KG (3/5 DI Q) Q2 MAX= 1200KG (2/5 DI Q)

RECOMMENDED LOADS POSITIONING

POSSIBLE LOADS POSITIONING

Q2

Q1

Q2

Q1

FIG. 6A

FIG. 6

16

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

1.4 PICTOGRAMS

1.5 PICTOGRAMS APPLICATION DIAGRAM

P1

P

2

SOLLEVATORE PER VEICOLI

MODELLO: PRATIK

MARTRICOLA: xxxxxxxx VOLT: xxx

PRESSIONE BAR

xxx A: xx

2

10

9

8

10

8

3

2

1

10

7

7

4

3

4

FIG. 7A

FIG. 7

4

1

3

5

9

6

7

5

5

17

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

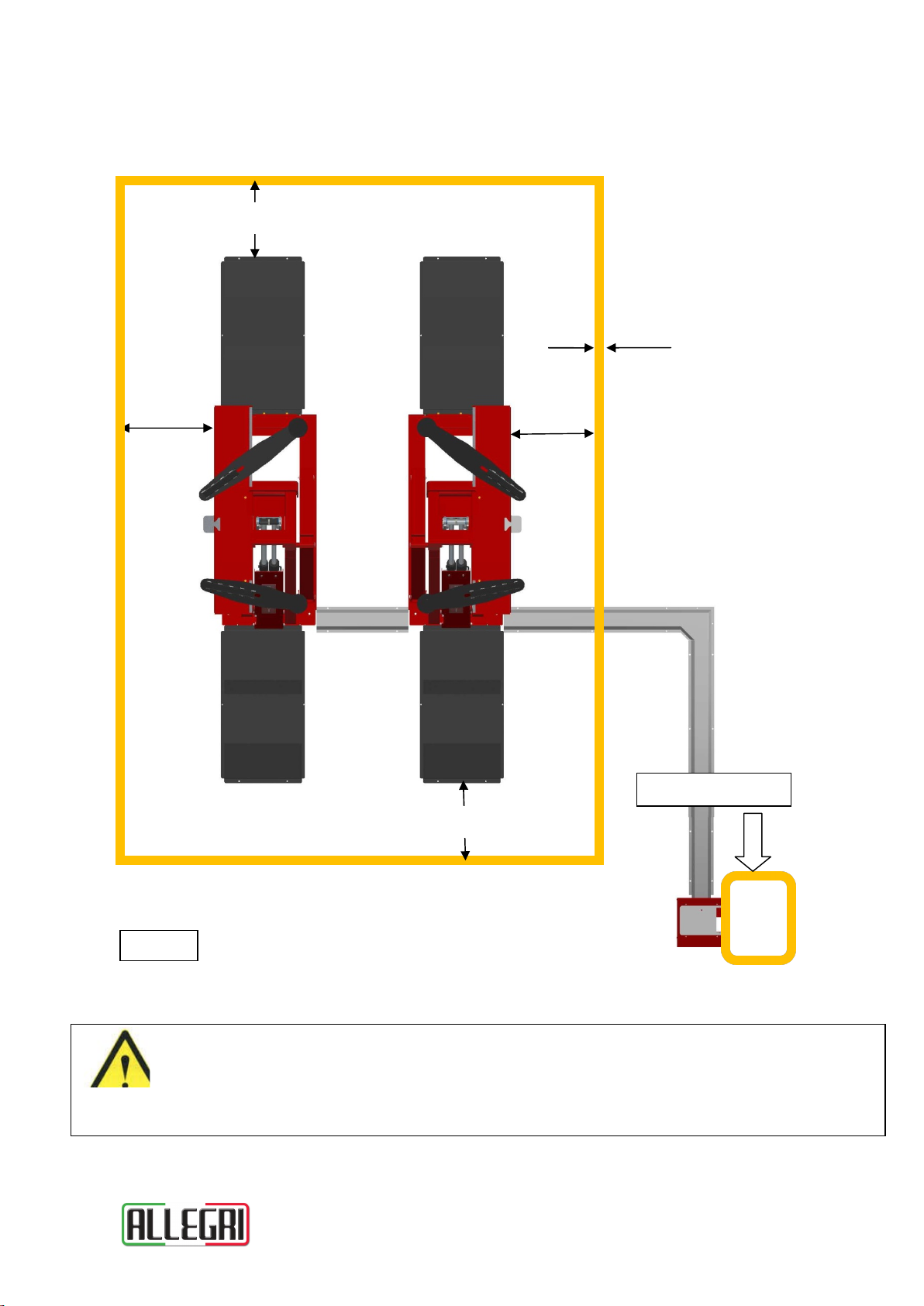

1.6 HAZARDOUS AREAS

WARNING: STRICTLY FORBIDDEN ACCESS INSIDE THE HAZARD ZONE, MARKED BY

YELLOW LINE DURING THE UP AND DOWN MOVEMENT OF THE LIFT

OPERATOR AREA

500

5

00

500

500

1

00

FIG.

8

18

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

2. INTRODUCTION

This manual includes the instructions relating to the installation, use and maintenance of the lift system called

“Vehicle Lift". The vehicle lifts described in this manual are designed and built solely to lift vehicles for repair,

maintenance and inspection purposes. Lift operation, economy and duration depend on the compliance with the

instructions given in this manual. The parts that can be supplied also as spare parts are listed in the last section of the

manual. To make instructions reading easier, this vehicle lift will be hereinafter simply called "the lift".

2.1 EC CERTIFICATION

2006/42/EC Directive, commonly known as the "Machines Directive" specifies the conditions to be respected before a

machine can be put into the market. This Directive provides that all machines can be marketed and commissioned

only if they do not jeopardise people, pets or property safety and health. To certify lift compliance with Directive

provisions, before marketing, the manufacturer subjected a machine specimen to the audit of a notified body.

Lift, manufactured in compliance with 2006/42/EC Directive provisions, and can thus be marketed without

jeopardising user's safety.

Lift is thus delivered to the customer with:

• EC Declaration of Conformity

• CE Marking

• Instructions for use

• Inspection records

2.1.1 TESTING

The lift has undergone static and dynamic tests based on the procedures included in the EN 1493:2010.

Concerning lift testing, please refer to the relevant section in the Inspection records.

The instructions given in this manual shall be compulsorily respected: the Manufacturer will not be held responsible

under any circumstances arising from negligence, from noncompliance with the instructions and from an improper

or inconsiderate use of the lift.

Failure to comply with the instructions given in the manual makes the warranty directly become null and void.

The Company also disclaims any liability for damages caused by lift improper use and/or due to changes made

without the manufacturer’s authorisation.

19

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

3. GENERAL SAFETY AND ACCIDENT-PREVENTION RULES

FOR A SAFE USE OF THE VEHICLE LIFT DESCRIBED IN THIS MANUAL

THE FOLLOWING IS ALLOWED:

• Using the lift only to lift vehicles for inspection, maintenance and/or repair operations.

• Using the lift only to lift vehicles respecting capacity limits and loads distribution indicated in this manual.

• Only authorised personnel, in good health conditions, responsible and duly trained on the allowed uses and risks

originated by lift use may operate the lift.

• The operator is allowed to use the vehicle lift only after he has thoroughly read, understood and assimilated the

contents of this manual.

• Using the lift only inside closed premises, protected against atmospheric agents such as: rain, snow, wind, etc.

IT IS COMPULSORY:

• Lift installation and maintenance operations shall be compulsorily carried out by qualified personnel only, and in full

compliance with the instructions given in this manual.

• Before installing the lift, you shall compulsorily check that the premises where you wish to position it are well

aerated and correctly lighted. (Avoid blinding light sources).

• You shall compulsorily check that the floor where you wish to install lift is solid, flat, and perfectly levelled in all

directions.

• You shall compulsorily check that the floor has been constructed to withstand the max. allowed loads, including the

lift, on lift resting areas.

• The lift shall be compulsorily positioned far from heat sources or devices that could generate electromagnetic

radiation.

• The lift shall be compulsorily positioned so that, during standard operation, with the vehicle loaded on it, it does not

interfere with or bump into any nearby fixed or moving part. Take special care to power supply, water and gas

systems.

• The lifting or handling operations of the lift or of any lift parts shall be compulsorily carried out under full safety

conditions with suitable lifting equipment, as envisaged by the National prevailing regulations.

• Lift shall be compulsorily secured to the floor only using anchors and screws of the type recommended by the

manufacturer (for lifts, where envisaged).

• Before using the lift, the wholeness of lifting elements shall be compulsorily checked.

• Before using the lift, you shall compulsorily check that safety devices are perfectly installed and in good operating

conditions.

• Vehicles shall be compulsorily positioned as shown in the table of the manual and/or the table attached to the lift.

• The vehicle shall be compulsorily lifted from the resting points specified by the vehicle manufacturer.

• When moving vehicle up, after the first 200 mm and before continuing the raising, load stability shall be

compulsorily checked in all directions.

20

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

• During the whole raising movement, load stability and lift correct and linear movement shall be compulsorily

checked.

• Before accessing the working area, the lift shall be compulsorily put in mechanical safety position with the special

command (where applicable).

• Before accessing the working area, the lift shall be compulsorily disconnected from power sources by turning to 0

(zero) the lockable rotating disconnector positioned onto the control panel.

• You shall compulsorily check that the disassembling of some of the parts of the vehicle positioned onto the lift does

not originate any load unbalance.

• Before starting lift lowering, you shall compulsorily check that no people, animals or things that could interfere with

the moving parts are under and around the working area.

• During lowering, you shall compulsorily and constantly check the lift and the lift load movement. In case of failure,

immediately turn the emergency disconnector.

• In case of irregular noise or operating failures, you shall compulsorily stop all lift operations, and check the cause of

such irregularity. In case of doubt, contact the manufacturer’s service department.

• Power supply shall be compulsorily interrupted whenever adjustment, repair or maintenance operations have to be

carried out on the equipment.

• All danger signalling stickers present onto the lift shall be compulsorily cleaned regularly or changed.

• The lift shall be compulsorily cleaned and all oil spots on the floor cleaned out, as they are very dangerous.

• All ordinary and extraordinary maintenance operations shall be compulsorily and thoroughly carried out, as

indicated in this manual; also periodical checks to be recorded on the special "inspection records" coming with the lift

shall be compulsorily carried out.

• You shall always compulsorily use only the manufacture’s original spare parts.

IT IS FORBIDDEN:

• It is forbidden to misuse the lift as well as to use it in any other manner not specified in the "INTENDED USE" section

of this manual

• It is forbidden to lift loads with just some of the lift parts (one runway only, or two arms only).

• It is forbidden to install the lift in hazardous premises containing inflammable and/or explosive substances, or where

inflammable gases or vapours can be created.

• It is forbidden to install the lift inside premises exposed to atmospheric agents.

• It is forbidden to install the lift in premises where washing or sandblasting operations are carried out, or in very

dusty premises

.

• It is forbidden to install the lift on vehicles or watercrafts.

• It is forbidden to use the lift in presence of strong magnetic fields.

• It is forbidden to use the lift to lift objects other than the specified ones (cases, containers or pallets) or to use it as a

hoist.

• It is forbidden to use the lift to lift people or animals.

Table of contents

Popular Lifting System manuals by other brands

Extreme Max

Extreme Max Boat Lift Boss 3005.7216 installation instructions

Sealey

Sealey MC450 instructions

WITTUR

WITTUR servogearless WSG-S2.3 Operating instruction

Elebia

Elebia NEO50 user manual

Oshkosh Corporation

Oshkosh Corporation JLG 830P Operation and safety manual

Ravaglioli

Ravaglioli RAV4352 manual