WARNING! Ensure that you read, understand and apply the

safety instructions before use.

WARNING! DO NOT attempt to overload the lift.

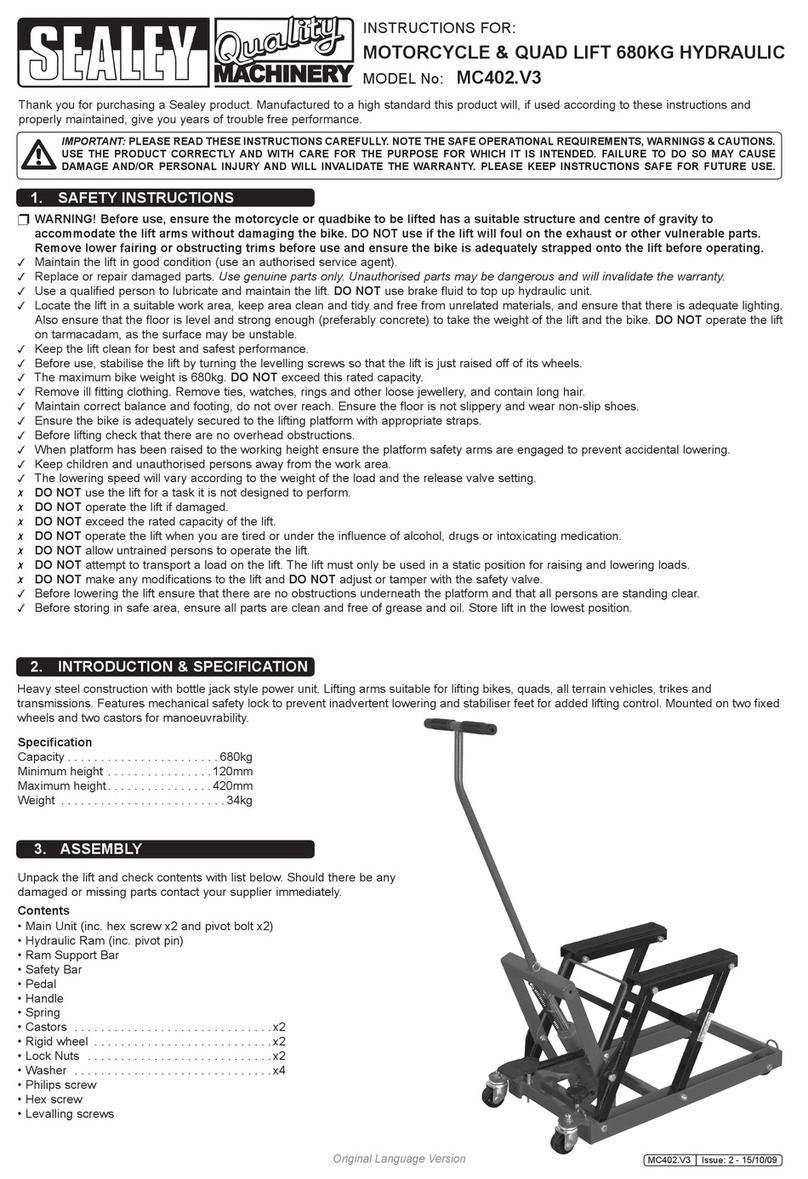

5.1 Position the lift in a suitable area, checking that the surface on

which the lift will stand is solid and flat (preferably concrete).

Bleeding the system: Whilst removing the oil ller plug from

the ram the lift must have the safety locking locking bar

engaged. Remove the locking bar pin shown in g.6B. Using the

main foot pedal (see g.2A), raise the platform until the locking

bar rides over the rst locking bar stop (see g.6). Press the

slow descent pedal (see g.2B) and allow the locking bar to

settle fully against the stop.

5.2.1 Remove the oil ller cap from the side of the ram as shown in

g.2D.

5.2.2 Raise the lift slightly so that the locking bar is no longer under

pressure. Using the locking bar lever (see g.6C) raise the

locking bar to the horizontal position and insert the locking bar

pin. Press the slow descent foot pedal (see g.2B) and allow

the lift to settle to its lowest position so that the ram is fully

retracted.

5.2.3 Fully open the release valve by depressing and holding down

the fast descent pedal (see g.2C). Now pump the main foot

pedal 6 to 8 strokes. This will help release any pressurised air

which may be trapped within the reservoir.

5.2.4 Raise the platform again, engage the safety locking bar and

reinstall the oil ller plug.

5.2.5 Check to ensure that the pump operates smoothly before

putting into service. Lubricate as instructed in the Maintenance

Section.

5.2.6 Inspect before each use. Do not use if any components are

bent, broken or cracked. components are noted.

5. OPERATING INSTRUCTIONS

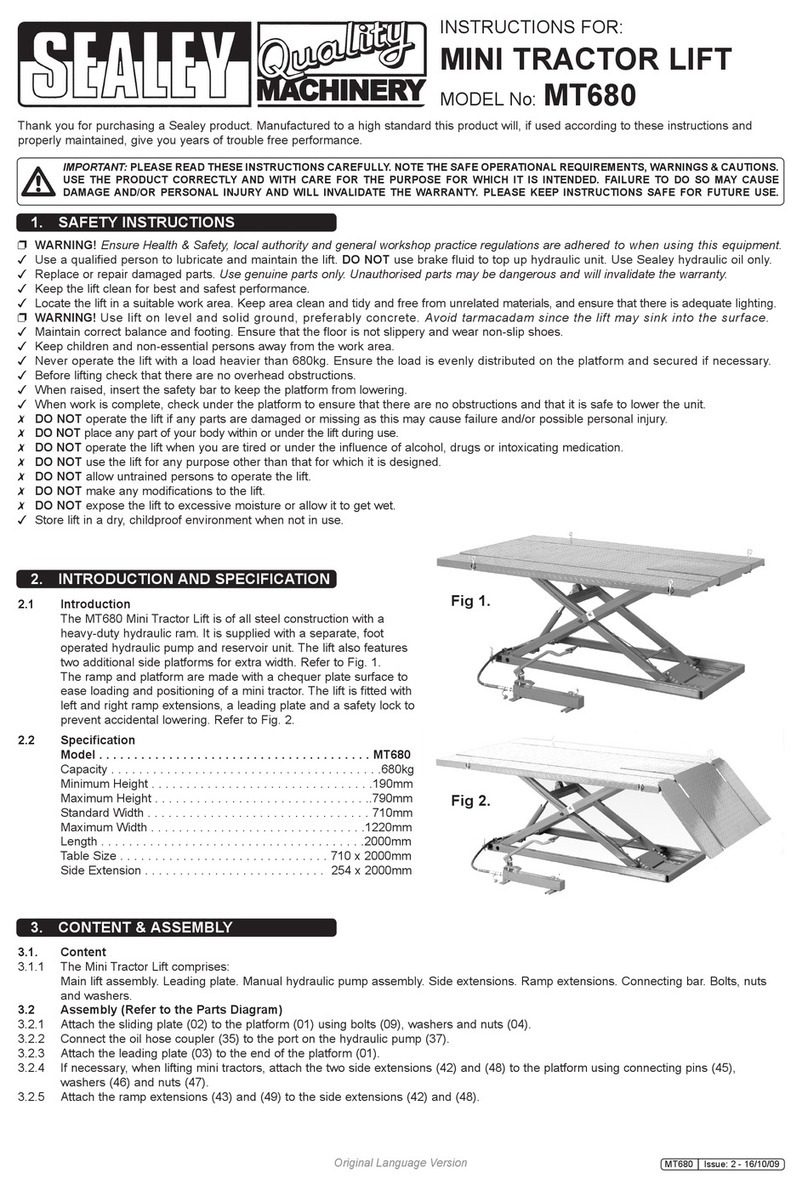

All steel construction with foot operated, integral hydraulic

pump and ram assembly. Fitted with platform safety lock device

to prevent accidental lowering. Bike fixed by front wheel clamp,

in addition, four eyelets allow tie downs to be used for added

stability. Fitted with tyre width loading ramp. Base assembly

fitted with transport wheels allowing lift to be moved in

horizontal or vertical position. Can be stored in an upright

position to save space when not in use.

4. INTRODUCTION

fig.2

fig.3

fig.4

5.3 Loading a motorcycle: Lay the lift on a smooth flat surface

such as concrete. Press and hold down the fast decent pedal

to ensure that the ram is fully retracted and the lift is therefore

in its lowest position.

5.3.1 Extend the rear section of the platform by removing the

locking pins from the middle of the platform and pulling the

extension out until the holes in the end of the extension piece

are in line with a second set of holes for locking in the

extended position. Insert the pins to lock the extension piece.

5.3.2 Hook the loading ramp into the two slots at the end of the

extension piece and allow the free end to rest on the ground.

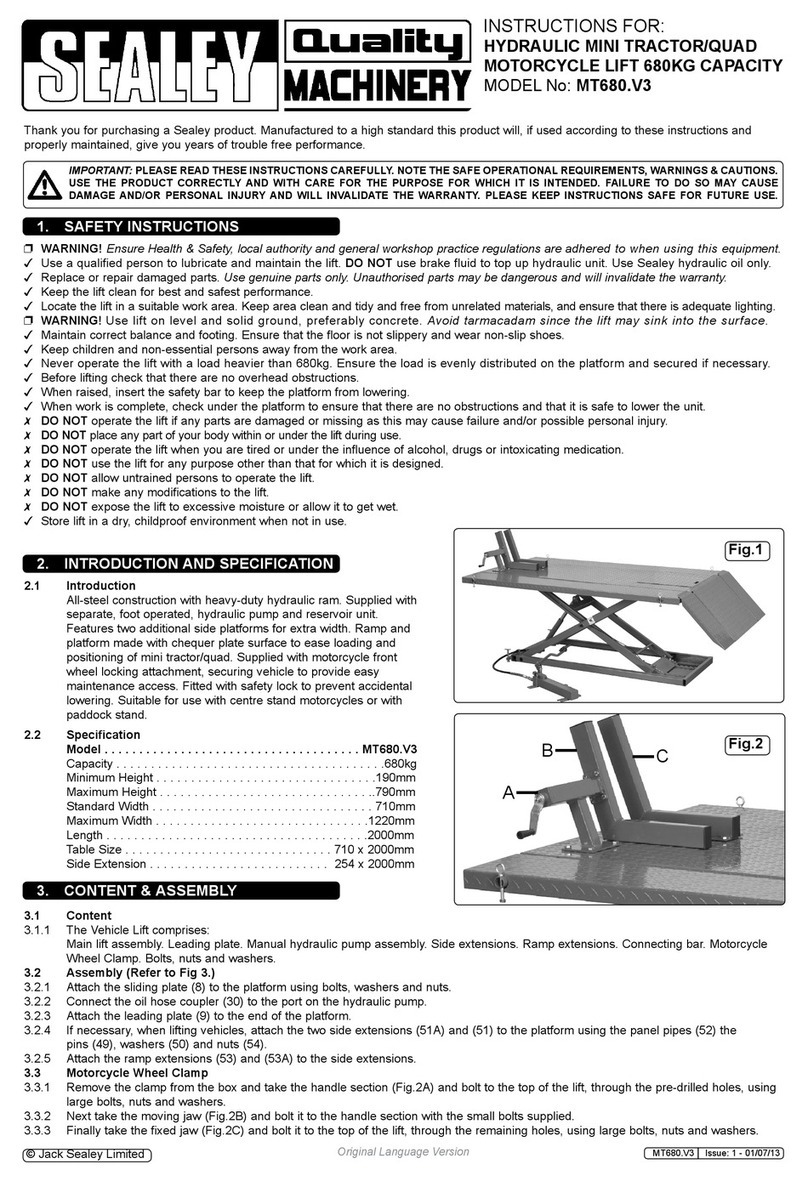

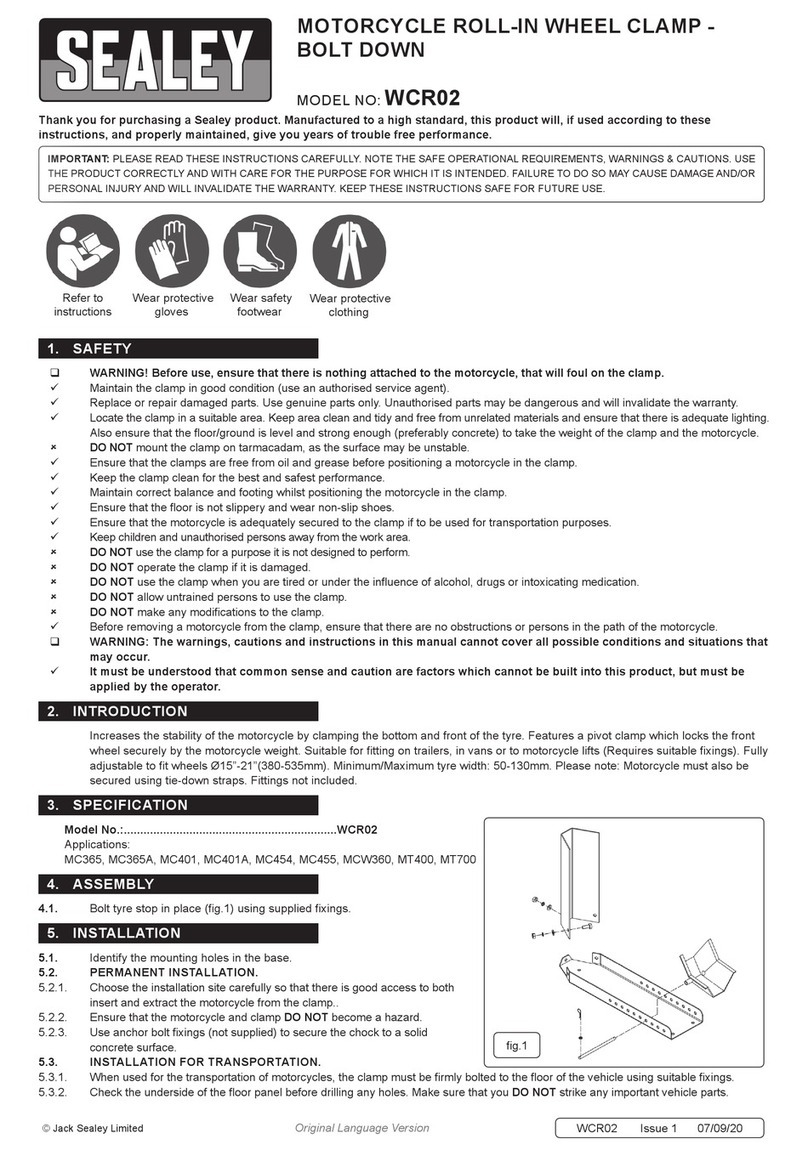

5.3.3 When the bike is fully on the ramp the front wheel will be

retained between the front wheel attachment (C) and the

closed wheel chock (A) as shown in fig.4. The position of the

wheel chock can be altered to cater for different diameter

wheels by placing the pivot bolt in one of four positions as

shown in fig.3. If the front wheel is not held firmly between

the wheel chock and the front wheel attachment remove the

motorcycle from the ramp and move the chock closer to the

front wheel attachment.

5.3.4 The motorcycle must be loaded onto the centre of the loading

ramp. Failure to do this could result in the motorcycle falling

from the ramp resulting in serious injury to the operator and/

or damage to the ramp or motorcycle.

5.3.5 Ensure the wheel chock is in the ready position to receive

the motorcycle front wheel as shown in fig.3A.

5.3.6 Standing beside the motorcycle, push it up the ramp and

all the way up onto the platform. As the front wheel on the

motorcycle passes over the open wheel chock, the wheel

chock will rotate forwards. The front tyre of the motorcycle

will now be pushing down on the wheel chock, which will

rotate it into the closed position. This causes the wheel chock

to clasp the front wheel of your motorcycle in place, holding

the motorcycle upright. This is NOT a substitute for securely

tying the motorcycle onto the Lift using LOCKING RATCHET

STYLE TIE DOWN STRAPS. Please ensure that the tie

down straps are locked in place and hold the motorcycle

safely on the Lift. Failure to correctly and safely tie the

motorcycle in place will invalidate the warranty and may

cause injury or death in the event that the motorcycle was to

become dislodged from the lift.

5.4 Correct Tie-down Procedure:

5.4.1 Attach one end of the ratchet tie downs to the handlebars or

fork area. Connect the other end of the straps to the forward

outrigger tie-down rings. Ratchet the tie-down straps to

compress the motorcycle suspension until the motorcycle is

secure. This will typically require that you compress the front

suspension on your motorcycle to approximately 75% of its

full travel.

5.4.2 Secure the rear of the motorcycle in a similar manner using

an attachment point such as the frame, swing arm, passenger

foot rests e.t.c. Attach the other end of the straps to the rear

outrigger tie-down rings, and ratchet until motorcycle is

secure. Again, this will require you to compress the rear

suspension on the motorcycle until there is no possibility that

the motorcycle could become dislodged.

Original Language Version MC450 Issue: 2 - 15/10/09