ALLIED COMMERCIAL GCS16 Series Service manual

Service Literature

GCS16 series units in the 15 and 20 ton (52.8 and 70.3

kW) cooling sizes are packaged combination gas heat/

dx cool units designed for commercial applications. Gas

heat exchanger in 235,000 and 375,000 (68.9 and

109.9 kW) Btuh input sizes. Optional electric heat

sections with inputs of 15 to 75 kW are available in the

CHA16 series units and install inside the cabinet.

GCS/CHA16-180 units utilize reciprocating compres-

sors. Thse compressors are hermeticaly sealed for leak

free opration and long service life. A built in protection

device assures protection from excessive current and

temperatures.

GCS/CHA16-240 units utilize scroll compressors. The

scroll compressor offers high volumetric efficiency and

quiet operation. Continuous flank contact, maintained

by centrifugal force, minimizes gas leakage and maxi-

mizes efficiency. The motor is internally protected from

excessive current and temperature.

GCS/CHA16-180/240 units are designed for horizontal

or down flow discharge application and may be fitted

with RMF16 mounting frame, REMD16 economizer and

RTD11 ceiling diffuser.

GCS/CHA16-180/240 are designed to accept any of

several different thermostat control systems such as the

Honeywell T7300 or Honeywell T8621D with minimum

field wiring. Control options such as economizer and

warm up kit, connect to the unit with jack-plugs. When

plugged in the controls become an integral part of the

unit wiring. Units are also equipped with low voltage pig

tails to facilitate thermostat field wiring.

Information in this manual is for use by a qualified

service technician only. All specifications are subject to

change. Procedures outlined in this manual are repre-

sented as a recommendation only and do not super-

sede or replace local or state codes.

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, personal injury or loss of life. Installa-

tion and service must be performend by a

qualified installer or service agency.

WARNING

Refrigerant can be harmful if it is inhaled.

Refrigerant must be used and recovered re-

sponsibly.

Failure to follow this warning may result in

personal injury or death.

Page 1

GCS/CHA16

15 and 20 Ton

(52.8 and 70.3 kW)

Table of Contents

GENERAL .......................................................Page1

SPECIFICATIONS............................................Page2

HIGHALTITUDE...............................................Page3

ELECTRICALDATA........................................Page4

BLOWERDATA...............................................Page4

OPTIONALACCESSORIES............................Page10

PARTSARRANGEMENT.................................Page12

IAPPLICATION................................................Page14

IIUNITCOMPONENTS....................................Page14

III OPTIONAL ELECTRIC HEAT.......................Page 25

IV PLACEMENT AND INSTALLATION.............Page 30

VELECTRICAL CONNECTIONS.....................Page 30

VI INDOOR BLOWER OPERATION.................Page 30

VIISTARTUP....................................................Page31

VIII REFRIGERATION SERVICE CHECKS......Page 32

IX HEATING SERVICE CHECKS......................Page 33

XMAINTENANCE.............................................Page35

XIACCESSORIES.............................................Page37

XII WIRING AND OPERATION SEQUENCE....Page 41

Page 2

SPECIFICATIONS

Model No. GCS/CHA16-180 GCS/CHA16Ć240

Nominal Tonnage 15 20

Gross cooling capacity - Btuh (kW) 1 3,200 (53.7) 226,600 (66.4)

Cooling

LTotal cooling capacity - Btuh (kW) 176,000 (51.6) 216,000 (63.3)

Cooling

Ratings

LTotal unit kW 19.5 24.0

Ratings

LEER (Btuh/Watts) 9.0 9.0

LIntegrated Part Load Value 9.2 9.2

Refrigerant

Ch

Circuit 1 7 lbs. oz. (3.40 kg) lbs. oz. (3. 6 kg)

g

Charge

Furnished

Circuit 2 7 lbs. oz. (3.40 kg) lbs. oz. (3. 6 kg)

F

urn

i

s

h

e

d

(HCFCĆ22) Circuit 3 7 lbs. oz. (3.40 kg) lbs. oz. (3. 6 kg)

Blower wheel nominal diameter x width - in. (mm) 1 x 1 (457 x 457)

3 hp Nominal motor hp (kW) 3 (2.24) - - - -

3

hp

Motor and

Factory

Maximum usable hp (kW) 3.45 (2.57) - - - -

Factory

Installed Voltage & phase 20 /230/460v or 575vĆ3ph - - - -

Evaporator

Installed

Drives RPM range 645- 45 - - - -

Evaporator

Blower

5 hp Nominal motor hp (kW) 5 (3.73)

Blower

and

Di

5

hp

Motor and

Factory

Maximum usable hp (kW) 5.75 (4.29)

and

Drive

Selection

Factory

Installed Voltage & phase 20 /230/460v or 575vĆ3ph

S

e

l

ec

ti

on

Installed

Drives RPM range 765-965

7.5 h

p

Nominal motor hp (kW) - - - - 7.5 (5.60)

7

.

5

hp

Motor and

Factory

Maximum usable hp (kW) - - - - .6 (6.42)

Factory

Installed Voltage & phase - - - - 20 /230/460v or 575vĆ3ph

Installed

Drives RPM range - - - - 95-1120

Net face area - sq. ft. (m2)17.9 (1.66)

Evaporator

Tube diameter - in. (mm) & No. of rows 3/ (9.5) - 3 3/ (9.5) - 4

Evaporator

Coil

Fins per inch (m) 14 (551)

Coil

Expansion device type Thermostatic Expansion Valve

Drain connection size mpt - in. (mm) 1 (25.4)

Condenser

Net face area - sq. ft. (m2)29.5 (2.74)

Condenser

Coil

Tube diameter - in. (mm) & No. of rows 3/ (9.5) - 2

Coil

Fins per inch (m) 20 (7 7)

Diameter - in. (mm) & No. of blades (2) 24 (610) - 4 (2) 26 (660) - 4

Condenser

Air volume - cfm (L/s) 10,000 (4720) 13,500 (6370)

Condenser

Fans

Motor horsepower (W) 3/4 (560) 1 (746)

Fans

Motor rpm 1075 1140

Motor watts 1200 2050

Low fire input - Btuh (kW) Natural Gas / LPG/Propane 154,000 (45.1) Nat. / 170,000 (49. ) LPG/Propane

-235

Heat

Input - Btuh (kW) Natural Gas / LPG/Propane 235,000 (6 .9)

Heat

Models Output - Btuh (kW) Natural Gas / LPG/Propane 1 ,000 (55.1 ) Nat. / 191,000 (56.0) LPG/Propane

Models

CSA Thermal Efficiency Natural Gas / LPG/Propane 0.0% Nat. / 1.3% LPG/Propane

Low fire input - Btuh (kW) Natural Gas / LPG/Propane 246,000 (72.1) Nat. / 271,000 (79.4) LPG/Propane

-375

Heat

Input - Btuh (kW) Natural Gas / LPG/Propane 375,000 (109.9)

Heat

Models Output - Btuh (kW) Natural Gas / LPG/Propane 300,000 ( 7.9) Nat. / 305,000 ( 9.4) LPG/Propane

Models

CSA Thermal Efficiency Natural Gas / LPG/Propane 0.0% Nat. / 1.3% LPG/Propane

Gas Supply Connections fpt - in. (mm)Natural and LPG/Propane 3/4

Recommended Gas

Supply Pressure

Natural 7 (1.7)

Supply Pressure

- wc. in. (kPa) LPG/Propane 11 (2.7)

Filters Type of filter Disposable, pleated

Filters

(furnished) No. & size - in. (mm) (6) 1 x 24 x 2 (457 x 610 x 51)

Net weight of basic unit - lbs. (kg) 1700 (771) 1 25 ( 2 )

Shipping weight of basic unit - lbs. (kg) (1 Package) 1 70 ( 4 ) 1990 (903)

Electrical characteristics 20 /230v, 460v or 575v - 60 hertz - 3 phase

LRated in accordance with ARI Standard 340/360;

95_F (35_F) outdoor air temperature and 0_F (27_C) db/67_F (19_C) wb entering evaporator air.

NOTE - Integrated Part Load Value rated at 0_F (27_C) outdoor air temperature.

NOTE - ARI capacity is net and includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable output of motors

furnished by Lennox are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep within the service

factor limitations outlined on the motor nameplate.

Page 3

ELECTRICAL DATA

ModelĂNo. GCS16-180

LineĂvoltageĂdataĂ-Ă60ĂHzĂ-Ă3Ăphase 20 /230V 460V 575V

Compressors (3)

RatedĂloadĂampsĂ-Ăeach (total) 16.7 (50.1) .6 (25. ) 6.0 (1 .1)

C

ompressors

(3)

LockedĂrotorĂampsĂ-Ăeach (total) 110 (330) 55 (165) 44 (132)

Condenser FullĂloadĂamps (total) 7.4 (14. ) 3. (7.6) 3.2 (6.4)

Condenser

FanĂMotors (2) LockedĂrotorĂamps (total) 14.6 (29.2) 7.4 (14. ) 5. (11.6)

Motor Output

hp 3 5 3 5 3 5

Evaporator

Blower

M

otor

O

utput kW 2.2 3.7 2.2 3.7 2.2 3.7

Bl

ower

Motor FullĂloadĂampsĂ 10.6 16.7 4. 7.6 3.9 6.1

Motor

LockedĂrotorĂampsĂ 66 105 26. 45.6 23.4 36.6

"

RecommendedĂmaximum fuseĂor With Exhaust Fans 90 90 45 50 30 35

"Recommended

Ă

maximum

fuse

Ă

or

circuit breaker sizeĂ(am s) Less Exhaust Fans 80 90 45 45 30 35

{Minimum Circuit Am acity

With Exhaust Fans 78 84 40 42 29 31

{Mi

n

i

mumĂ

Ci

rcu

it

Ă

A

m ac

it

yLess Exhaust Fans 73 79 37 40 27 29

O

p

tional (No.) Motor Output - hp (kW) (2) - 1/3

Optional

Power Exhaust

F

FullĂloadĂampsĂ (total) 4. (9.6) 2.6 (5.2) 2 (4)

Fans LockedĂrotorĂamps (total) 9.4 (1 . ) 4. (9.6) 3. (7.6)

ModelĂNo. GCS16-240

LineĂvoltageĂdataĂ-Ă60ĂHzĂ-Ă3Ăphase 20 /230V 460V 575V

Compressors (3)

RatedĂloadĂampsĂ-Ăeach (total) 1 . (56.4) 9.1 (27.3) 7.5 (22.5)

C

ompressors

(3)

LockedĂrotorĂampsĂ-Ăeach (total) 156 (46 ) 70 (210) 54 (162)

Condenser FullĂloadĂamps (total) 9.6 (19.6) 4. (9.6) 4 ( )

Condenser

FanĂMotors (2) LockedĂrotorĂamps (total) 46 (92) 23 (46) 17. (35.6)

Motor Output

hp 5 7.5 5 7.5 5 7.5

Evaporator

Blower

M

otor

O

utput kW 3.7 5.6 3.7 5.6 3.7 5.6

Bl

ower

Motor FullĂloadĂampsĂ 16.7 24.2 7.6 11 6.1 9

Motor

LockedĂrotorĂampsĂ 105 152 45.6 66 36.6 54

"

RecommendedĂmaximum fuseĂor With Exhaust Fans 110 125 50 50 40 45

"Recommended

Ă

maximum

fuse

Ă

or

circuit breaker sizeĂ(am s) Less Exhaust Fans 100 110 50 50 40 45

{Minimum Circuit Am acity

With Exhaust Fans 93 100 45 48 37 40

{Mi

n

i

mumĂ

Ci

rcu

it

Ă

A

m ac

it

yLess Exhaust Fans 88 95 42 46 35 38

O

p

tional (No.) Motor Output - hp (W) (2) - 1/3 (250)

Optional

Power Exhaust

F

FullĂloadĂampsĂ (total) 4. (9.6) 2.6 (5.2) 2 (4)

Fans LockedĂrotorĂamps (total) 9.4 (1 . ) 4. (9.6) 3. (7.6)

{ReferĂtoĂNational or CanadianĂElectricalĂCodeĂmanualĂtoĂdetermineĂwire,ĂfuseĂandĂdisconnectĂsizeĂrequirements.

"Where current does not exceed 100 amps, HACR type circuit breaker may be used in place of fuse (U.S. only).

NOTEĂ-ĂExtremesĂofĂoperatingĂrangeĂareĂplusĂandĂminusĂ10Ă%ĂofĂlineĂvoltage.

Model No. CHA16-180 CHA16-240

Line voltage data - 60 Hz - 3 phase 20 /230V 460V 575V 20 /230V 460V 575V

Compressors (3)

Rated load amps each (total) 16.7 (50.1) .6 (25. ) 6.0 (1 .1) 1 . (56.4) 9.1 (27.3) 7.5 (22.5)

C

ompressors

(3)

Locked rotor amps each (total) 110.0 (330.0) 55.0 (165.0) 44.0 (132.0) 156.0 (46 .0) 70.0 (210.0) 54.0 (162.0)

Condenser Fan Full load amps (total) 7.4 (14. ) 3. (7.6) 3.2 (6.4) 9.6 (19.6) 4. (9.6) 4.0 ( .0)

Condenser

Fan

Motor (2) Locked rotor amps (total) 14.6 (29.2) 7.4 (14. ) 5. (11.6) 46 (92) 23 (46) 17. (35.6)

Motor hp 3 5 3 5 3 5 5 7.5 5 7.5 5 7.5

Evaporator Blower

Motor

Output kW 2.2 3.7 2.2 3.7 2.2 3.7 3.7 5.6 3.7 5.6 3.7 5.6

Evaporator

Blower

Motor Full load amps 10.6 16.7 4. 7.6 3.9 6.1 16.7 24.2 7.6 11 6.1 9

Locked rotor amps 66 105 26. 45.6 23.4 36.6 105 152 45.6 66 36.6 54

Rec. max. fuse With Exhaust Fan 90 90 45 50 30 35 110 125 50 50 40 45

Rec.

max.

fuse

size (am s) Less Exhaust Fan 80 90 45 45 30 35 100 110 50 50 40 45

*Minimum Circuit With Exhaust Fan 78 84 40 42 29 31 93 100 45 48 37 40

Minimum

Circuit

Am acity Less Exhaust Fan 73 79 37 40 27 29 88 95 42 46 35 38

Optional Power

(No.) Horsepower (W) (2) - 1/3 (250)

Optional Power

Exhaust Fan

Full load amps (total) 4. (9.6) 2.6 (5.2) 2.0 (4.0) 4. (9.6) 2.6 (5.2) 2.0 (4.0)

Exhaust

Fan

Locked rotor amps (total) 9.4 (1 . ) 4. (9.6) 3. (7.6) 9.4 (1 . ) 4. (9.6) 3. (7.6)

Page 4

BLOWER DATA GCS16-180

GCS16-180 - DOWN-FLOW BLOWER PERFORMANCE (w/ 2 in. leated filters)

Air

STATIC PRESSURE EXTERNAL TO UNIT Ċ Inches Water Gauge (Pa)

Ai

r

Volume .20 (50) .40 (100) .60 (150) .80 (200) 1.00 (250) 1.20 (300) 1.40 (350) 1.60 (400) 1.80 (450) 2.00 (495)

Volume

cfm

(L/s) RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

4 00

(2265)

450 0.90

(0.67)

510 1.10

(0. 2)

575 1.35

(1.01)

630 1.55

(1.16)

6 0 1.75

(1.31)

730 2.00

(1.49)

775 2.25

(1.6 )

20 2.50

(1. 7)

60 2.75

(2.05)

900 3.05

(2.2 )

4900

(2310)

455 0.95

(0.71)

515 1.15

(0. 6)

5 0 1.40

(1.04)

635 1.60

(1.19)

6 5 1. 5

(1.3 )

735 2.10

(1.57)

7 0 2.35

(1.75)

20 2.55

(1.90)

65 2. 5

(2.13)

900 3.10

(2.31)

5000

(2360)

460 1.00

(0.75)

520 1.20

(0.90)

5 5 1.45

(1.0 )

640 1.70

(1.27)

690 1.90

(1.42)

735 2.15

(1.60)

7 0 2.40

(1.79)

25 2.65

(1.9 )

65 2.90

(2.16)

905 3.20

(2.39)

5100

(2405)

465 1.05

(0.7 )

530 1.30

(0.97)

590 1.50

(1.12)

645 1.75

(1.31)

695 2.00

(1.49)

740 2.20

(1.64)

7 5 2.45

(1. 3)

30 2.75

(2.05)

70 3.00

(2.24)

910 3.30

(2.46)

5200

(2455)

470 1.10

(0. 2)

535 1.35

(1.01)

595 1.55

(1.16)

645 1. 0

(1.34)

700 2.05

(1.53)

745 2.30

(1.72)

790 2.55

(1.90)

30 2. 0

(2.09)

70 3.05

(2.2 )

910 3.35

(2.50)

5300

(2500)

475 1.15

(0. 6)

540 1.40

(1.04)

600 1.65

(1.23)

650 1. 5

(1.3 )

700 2.10

(1.57)

750 2.40

(1.79)

795 2.65

(1.9 )

35 2.90

(2.16)

75 3.15

(2.35)

915 3.45

(2.57)

5400

(2550)

4 0 1.20

(0.90)

545 1.45

(1.0 )

605 1.70

(1.27)

655 1.95

(1.45)

705 2.20

(1.64)

755 2.45

(1. 3)

795 2.70

(2.01)

40 3.00

(2.24)

0 3.25

(2.42)

915 3.55

(2.65)

5500

(2595)

490 1.30

(0.97)

550 1.50

(1.12)

610 1.75

(1.31)

660 2.00

(1.49)

710 2.25

(1.6 )

755 2.50

(1. 7)

00 2. 0

(2.09)

40 3.05

(2.2 )

0 3.35

(2.50)

920 3.65

(2.72)

5600

(2645)

495 1.35

(1.01)

555 1.60

(1.19)

615 1. 5

(1.3 )

665 2.10

(1.57)

715 2.35

(1.75)

760 2.60

(1.94)

05 2.90

(2.16)

45 3.15

(2.35)

5 3.45

(2.57)

925 3.75

(2. 0)

5700

(2690)

500 1.40

(1.04)

560 1.65

(1.23)

620 1.90

(1.42)

670 2.15

(1.60)

720 2.45

(1. 3)

765 2.70

(2.01)

10 3.00

(2.24)

50 3.25

(2.42)

90 3.55

(2.65)

925 3. 0

(2. 3)

5 00

(2735)

505 1.45

(1.0 )

570 1.75

(1.31)

625 2.00

(1.49)

675 2.25

(1.6 )

725 2.50

(1. 7)

770 2. 0

(2.09)

10 3.05

(2.2 )

50 3.30

(2.46)

90 3.60

(2.69)

930 3.90

(2.91)

5900

(27 5)

515 1.55

(1.16)

575 1. 0

(1.34)

630 2.05

(1.53)

6 0 2.30

(1.72)

725 2.60

(1.94)

775 2.90

(2.16)

15 3.15

(2.35)

55 3.40

(2.54)

95 3.70

(2.76)

935 4.05

(3.02)

6000

(2 30)

520 1.60

(1.19)

5 0 1. 5

(1.3 )

635 2.15

(1.60)

6 5 2.40

(1.79)

730 2.65

(1.9 )

775 2.95

(2.20)

20 3.25

(2.42)

60 3.55

(2.65)

900 3. 5

(2. 7)

935 4.10

(3.06)

6100

(2 0)

525 1.65

(1.23)

5 5 1.95

(1.45)

640 2.20

(1.64)

690 2.50

(1. 7)

735 2.75

(2.05)

7 0 3.05

(2.2 )

25 3.35

(2.50)

65 3.65

(2.72)

900 3.90

(2.91)

940 4.25

(3.17)

6200

(2925)

530 1.75

(1.31)

590 2.00

(1.49)

645 2.30

(1.72)

695 2.60

(1.94)

740 2. 5

(2.13)

7 5 3.15

(2.35)

30 3.45

(2.57)

70 3.75

(2. 0)

905 4.00

(2.9 )

945 4.35

(3.25)

6300

(2975)

540 1. 5

(1.3 )

595 2.10

(1.57)

650 2.40

(1.79)

700 2.65

(1.9 )

745 2.95

(2.20)

790 3.25

(2.42)

30 3.50

(2.61)

70 3. 0

(2. 3)

910 4.15

(3.10)

945 4.45

(3.32)

6400

(3020)

545 1.90

(1.42)

605 2.20

(1.64)

655 2.45

(1. 3)

705 2.75

(2.05)

750 3.05

(2.2 )

795 3.35

(2.50)

35 3.65

(2.72)

75 3.95

(2.95)

915 4.25

(3.17)

950 4.55

(3.39)

6500

(3065)

550 2.00

(1.49)

610 2.30

(1.72)

660 2.55

(1.90)

710 2. 5

(2.13)

755 3.15

(2.35)

00 3.45

(2.57)

40 3.75

(2. 0)

0 4.05

(3.02)

915 4.35

(3.25)

955 4.70

(3.51)

6600

(3115)

560 2.10

(1.57)

615 2.35

(1.75)

665 2.65

(1.9 )

715 2.95

(2.20)

760 3.25

(2.42)

05 3.55

(2.65)

45 3. 5

(2. 7)

5 4.20

(3.13)

920 4.45

(3.32)

960 4. 0

(3.5 )

6700

(3160)

565 2.15

(1.60)

620 2.45

(1. 3)

670 2.75

(2.05)

720 3.05

(2.2 )

765 3.35

(2.50)

10 3.65

(2.72)

50 4.00

(2.9 )

90 4.30

(3.21)

925 4.60

(3.43)

960 4.90

(3.66)

6 00

(3210)

575 2.25

(1.6 )

625 2.55

(1.90)

6 0 2. 5

(2.13)

725 3.15

(2.35)

770 3.45

(2.57)

15 3. 0

(2. 3)

55 4.10

(3.06)

90 4.40

(3.2 )

930 4.75

(3.54)

965 5.05

(3.77)

6900

(3255)

5 0 2.35

(1.75)

635 2.65

(1.9 )

6 5 2.95

(2.20)

730 3.25

(2.42)

775 3.55

(2.65)

15 3. 5

(2. 7)

55 4.20

(3.13)

95 4.50

(3.36)

935 4. 5

(3.62)

970 5.20

(3. )

7000

(3305)

5 5 2.45

(1. 3)

640 2.75

(2.05)

690 3.05

(2.2 )

735 3.35

(2.50)

7 0 3.70

(2.76)

20 4.00

(2.9 )

60 4.30

(3.21)

900 4.65

(3.47)

935 4.95

(3.69)

975 5.35

(3.99)

7100

(3350)

590 2.50

(1. 7)

645 2. 5

(2.13)

695 3.15

(2.35)

740 3.45

(2.57)

7 5 3. 0

(2. 3)

25 4.10

(3.06)

65 4.45

(3.32)

905 4.75

(3.54)

940 5.10

(3. 0)

975 5.40

(4.03)

7200

(3400)

600 2.65

(1.9 )

650 2.95

(2.20)

700 3.25

(2.42)

745 3.60

(2.69)

790 3.90

(2.91)

30 4.20

(3.13)

70 4.55

(3.39)

910 4.90

(3.66)

945 5.25

(3.92)

9 0 5.55

(4.14)

Page 5

BLOWER DATA CHA16-180

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL & AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Wet indoor coil air resistance of selected unit.

2 - Any field installed accessories air resistance (electric heat, economizer, duct resistance, diffuser, etc.)

Then determine from blower table blower motor output.

MINIMUM AIR VOLUME REQUIRED FOR USE WITH OPTIONAL ELECTRIC HEAT

DUnits require 4900 cfm (2310 L/s) minimum air with electric heat.

BOLD ITALIC INDICATES FIELD FURNISHED DRIVE

Air

STATIC PRESSURE EXTERNAL TO UNIT Ċ Inches Water Gauge (Pa)

Air

Volume

f

.20 (50) .40 (100) .60 (150) .80 (200) 1.00 (250) 1.20 (300) 1.40 (350) 1.60 (400) 1.80 (450) 2.00 (495)

cfm

(L/s) RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

4 00

(2265)

455 0.90

(0. 7)

515 1.10

(0.82)

570 1.25

(0.93)

20 1.45

(1.08)

670 1.70

(1.27)

715 1.90

(1.42)

760 2.10

(1.57)

00 2.35

(1.75)

40 2.55

(1.90)

0 2. 0

(2.09)

4900

(2310)

4 0 0.95

(0.71)

520 1.10

(0.82)

575 1.30

(0.97)

25 1.55

(1.1 )

675 1.75

(1.31)

720 1.95

(1.45)

760 2.15

(1.60)

05 2.40

(1.79)

45 2.65

(1.9 )

0 2. 5

(2.13)

5000

(2360)

470 1.00

(0.75)

525 1.15

(0.8 )

580 1.40

(1.04)

30 1. 0

(1.19)

675 1. 0

(1.34)

720 2.00

(1.49)

765 2.25

(1.6 )

05 2.45

(1. 3)

45 2.70

(2.01)

5 2.95

(2.20)

5100

(2405)

475 1.05

(0.78)

530 1.25

(0.93)

585 1.45

(1.08)

35 1. 5

(1.23)

6 0 1. 5

(1.3 )

725 2.10

(1.57)

770 2.35

(1.75)

10 2.55

(1.90)

50 2. 0

(2.09)

5 3.05

(2.2 )

5200

(2455)

480 1.10

(0.82)

535 1.30

(0.97)

590 1.50

(1.12)

40 1.70

(1.27)

6 5 1.95

(1.45)

730 2.15

(1.60)

775 2.40

(1.79)

15 2.65

(1.9 )

50 2. 5

(2.13)

90 3.15

(2.35)

5300

(2500)

485 1.15

(0.8 )

545 1.35

(1.01)

595 1.55

(1.1 )

645 1. 0

(1.34)

690 2.00

(1.49)

735 2.25

(1.6 )

775 2.45

(1. 3)

15 2.70

(2.01)

55 2.95

(2.20)

90 3.20

(2.39)

5400

(2550)

495 1.20

(0.90)

550 1.40

(1.04)

00 1. 0

(1.19)

650 1. 5

(1.3 )

695 2.05

(1.53)

740 2.30

(1.72)

7 0 2.55

(1.90)

20 2. 0

(2.09)

60 3.05

(2.2 )

95 3.30

(2.46)

5500

(2595)

500 1.25

(0.93)

555 1.45

(1.08)

05 1.70

(1.27)

655 1.90

(1.42)

700 2.15

(1.60)

745 2.40

(1.79)

7 5 2.65

(1.9 )

25 2.90

(2.16)

60 3.10

(2.31)

900 3.40

(2.54)

5600

(2645)

505 1.30

(0.97)

5 0 1.55

(1.1 )

10 1.75

(1.31)

660 2.00

(1.49)

705 2.25

(1.6 )

745 2.45

(1. 3)

790 2.70

(2.01)

30 3.00

(2.24)

65 3.20

(2.39)

900 3.45

(2.57)

5700

(2690)

515 1.40

(1.04)

570 1. 0

(1.19)

20 1.85

(1.38)

665 2.05

(1.53)

710 2.30

(1.72)

750 2.55

(1.90)

790 2. 0

(2.09)

30 3.05

(2.2 )

70 3.30

(2.46)

905 3.55

(2.65)

5 00

(2735)

520 1.45

(1.08)

575 1. 5

(1.23)

25 1.90

(1.42)

670 2.15

(1.60)

715 2.40

(1.79)

755 2.60

(1.94)

795 2. 5

(2.13)

35 3.15

(2.35)

75 3.40

(2.54)

910 3.65

(2.72)

5900

(27 5)

530 1.50

(1.12)

580 1.75

(1.31)

30 2.00

(1.49)

675 2.20

(1.64)

720 2.45

(1. 3)

760 2.70

(2.01)

00 2.95

(2.20)

40 3.25

(2.42)

75 3.50

(2.61)

910 3.75

(2. 0)

6000

(2 30)

535 1. 0

(1.19)

585 1.80

(1.34)

35 2.05

(1.53)

6 0 2.30

(1.72)

725 2.55

(1.90)

765 2. 0

(2.09)

05 3.05

(2.2 )

45 3.35

(2.50)

0 3.60

(2.69)

915 3. 5

(2. 7)

6100

(2 0)

545 1. 5

(1.23)

595 1.90

(1.42)

40 2.15

(1. 0)

6 5 2.40

(1.79)

730 2.65

(1.9 )

770 2.90

(2.16)

10 3.15

(2.35)

45 3.40

(2.54)

5 3.70

(2.76)

920 3.95

(2.95)

6300

(2975)

5 0 1.80

(1.34)

05 2.05

(1.53)

655 2.30

(1.72)

695 2.55

(1.90)

740 2. 0

(2.09)

7 0 3.10

(2.31)

20 3.35

(2.50)

55 3.60

(2.69)

90 3.90

(2.91)

925 4.15

(3.10)

6200

(2925)

550 1.75

(1.31)

00 1.95

(1.45)

645 2.20

(1.64)

690 2.45

(1. 3)

735 2.75

(2.05)

775 3.00

(2.24)

15 3.25

(2.42)

50 3.50

(2.61)

90 3. 0

(2. 3)

925 4.10

(3.06)

6400

(3020)

5 5 1.90

(1.42)

15 2.15

(1. 0)

660 2.40

(1.79)

705 2.65

(1.9 )

745 2.90

(2.16)

7 5 3.20

(2.39)

25 3.45

(2.57)

60 3.70

(2.76)

95 4.00

(2.9 )

930 4.30

(3.21)

6500

(3065)

570 1.95

(1.45)

20 2.20

(1. 4)

665 2.50

(1. 7)

710 2.75

(2.05)

750 3.00

(2.24)

790 3.30

(2.46)

30 3.55

(2.65)

65 3. 5

(2. 7)

900 4.10

(3.06)

935 4.40

(3.2 )

6600

(3115)

580 2.05

(1.53)

25 2.30

(1.72)

670 2.55

(1.90)

715 2. 5

(2.13)

755 3.10

(2.31)

795 3.40

(2.54)

30 3.65

(2.72)

70 3.95

(2.95)

905 4.25

(3.17)

940 4.55

(3.39)

6700

(3160)

585 2.15

(1. 0)

35 2.40

(1.79)

6 0 2.70

(2.01)

720 2.95

(2.20)

760 3.20

(2.39)

00 3.50

(2.61)

35 3.75

(2. 0)

75 4.05

(3.02)

910 4.35

(3.25)

945 4.65

(3.47)

6 00

(3210)

595 2.25

(1. 8)

40 2.50

(1.87)

6 5 2.75

(2.05)

725 3.05

(2.2 )

765 3.30

(2.46)

05 3.60

(2.69)

40 3. 5

(2. 7)

0 4.20

(3.13)

915 4.50

(3.36)

945 4.75

(3.54)

6900

(3255)

00 2.30

(1.72)

645 2.55

(1.90)

690 2. 5

(2.13)

730 3.10

(2.31)

770 3.40

(2.54)

10 3.70

(2.76)

45 3.95

(2.95)

5 4.30

(3.21)

915 4.55

(3.39)

950 4. 5

(3.62)

7000

(3305)

10 2.40

(1.79)

655 2.70

(2.01)

695 2.95

(2.20)

740 3.25

(2.42)

775 3.50

(2.61)

15 3. 0

(2. 3)

50 4.10

(3.06)

5 4.40

(3.2 )

920 4.70

(3.51)

955 5.00

(3.73)

7100

(3350)

15 2.50

(1.87)

660 2. 0

(2.09)

705 3.10

(2.31)

745 3.35

(2.50)

7 5 3.65

(2.72)

20 3.95

(2.95)

55 4.20

(3.13)

90 4.50

(3.36)

925 4. 0

(3.5 )

960 5.15

(3. 4)

7200

(3400)

25 2. 0

(1.94)

665 2. 5

(2.13)

710 3.20

(2.39)

750 3.45

(2.57)

790 3.75

(2. 0)

25 4.05

(3.02)

60 4.35

(3.25)

95 4.65

(3.47)

930 4.95

(3.69)

965 5.30

(3.95)

Page 6

BLOWER DATA GCS16-240

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL & AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Wet indoor coil air resistance of selected unit.

2 - Any field installed accessories air resistance (economizer, duct resistance, diffuser, etc.)

Then determine from blower table blower motor output.

BOLD ITALIC INDICATES FIELD FURNISHED DRIVE

Air STATIC PRESSURE EXTERNAL TO UNIT Ċ Inches Water Gauge (Pa)

Air

Volume

f

.20 (50) .40 (100) .60 (150) .80 (200) 1.00 (250) 1.20 (300) 1.40 (350) 1.60 (400) 1.80 (450) 2.00 (495)

Volume

cfm

(L/s) RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

6000

(2 30)

5 5 1. 5

(1.23)

20 1.95

(1.45)

70 2.20

(1. 4)

720 2.50

(1.87)

765 2.75

(2.05)

10 3.05

(2.2 )

50 3.35

(2.50)

90 3.65

(2.72)

930 3.95

(2.95)

965 4.25

(3.17)

6100

(2 0)

575 1.75

(1.31)

25 2.00

(1.49)

75 2.25

(1. 8)

725 2.55

(1.90)

770 2. 5

(2.13)

15 3.15

(2.35)

55 3.45

(2.57)

95 3.75

(2. 0)

930 4.05

(3.02)

970 4.40

(3.2 )

6200

(2925)

580 1.80

(1.34)

35 2.10

(1.57)

85 2.40

(1.79)

730 2. 5

(1.98)

775 2.95

(2.20)

20 3.25

(2.42)

60 3.55

(2.65)

900 3. 5

(2. 7)

935 4.15

(3.10)

975 4.50

(3.36)

6300

(2975)

590 1.90

(1.42)

40 2.20

(1. 4)

90 2.45

(1.83)

735 2.75

(2.05)

7 0 3.05

(2.2 )

25 3.35

(2.50)

65 3.65

(2.72)

900 3.95

(2.95)

940 4.25

(3.17)

975 4.60

(3.43)

6400

(3020)

595 2.00

(1.49)

50 2.30

(1.72)

95 2.55

(1.90)

740 2.85

(2.13)

7 5 3.15

(2.35)

30 3.45

(2.57)

70 3.75

(2. 0)

905 4.05

(3.02)

945 4.40

(3.2 )

9 0 4.70

(3.51)

6500

(3065)

05 2.10

(1.57)

55 2.35

(1.75)

700 2. 5

(1.98)

750 2.95

(2.20)

790 3.25

(2.42)

35 3.55

(2.65)

75 3. 5

(2. 7)

910 4.15

(3.10)

950 4.50

(3.36)

9 5 4. 5

(3.62)

6600

(3115)

10 2.15

(1. 0)

0 2.45

(1.83)

710 2.75

(2.05)

755 3.05

(2.28)

795 3.35

(2.50)

40 3.65

(2.72)

0 4.00

(2.9 )

915 4.30

(3.21)

955 4.65

(3.47)

990 4.95

(3.69)

6700

(3160)

20 2.25

(1. 8)

70 2.55

(1.90)

715 2.85

(2.13)

7 0 3.15

(2.35)

05 3.45

(2.57)

45 3.75

(2. 0)

5 4.10

(3.06)

920 4.40

(3.2 )

960 4.75

(3.54)

995 5.10

(3. 0)

6 00

(3210)

30 2.35

(1.75)

75 2. 5

(1.98)

720 2.95

(2.20)

765 3.25

(2.42)

10 3.55

(2.65)

50 3.90

(2.91)

90 4.20

(3.13)

925 4.50

(3.36)

965 4.90

(3.66)

1000 5.25

(3.92)

6900

(3255)

35 2.45

(1.83)

85 2.75

(2.05)

730 3.05

(2.28)

770 3.35

(2.50)

15 3.70

(2.76)

55 4.00

(2.9 )

95 4.35

(3.25)

930 4.65

(3.47)

965 4.95

(3.69)

1005 5.35

(3.99)

7000

(3305)

45 2.55

(1.90)

90 2.85

(2.13)

735 3.15

(2.35)

7 0 3.50

(2.61)

20 3. 0

(2. 3)

60 4.10

(3.06)

900 4.45

(3.32)

935 4.75

(3.54)

970 5.10

(3. 0)

1005 5.45

(4.07)

7100

(3350)

50 2. 5

(1.98)

700 2.95

(2.20)

740 3.25

(2.42)

7 5 3.60

(2.69)

25 3.90

(2.91)

65 4.25

(3.17)

905 4.60

(3.43)

940 4.90

(3.66)

975 5.25

(3.92)

1010 5.60

(4.1 )

7200

(3400)

0 2.75

(2.05)

705 3.05

(2.28)

750 3.40

(2.54)

790 3.70

(2.76)

30 4.00

(2.9 )

70 4.35

(3.25)

910 4.70

(3.51)

945 5.05

(3.77)

9 0 5.35

(3.99)

1015 5.75

(4.29)

7300

(3445)

5 2.85

(2.13)

710 3.15

(2.35)

755 3.50

(2. 1)

00 3. 5

(2. 7)

40 4.15

(3.10)

75 4.45

(3.32)

915 4. 5

(3.62)

950 5.15

(3. 4)

9 5 5.50

(4.10)

1020 5.90

(4.40)

7400

(3490)

75 3.00

(2.24)

720 3.30

(2.4 )

765 3.65

(2.72)

05 3.95

(2.95)

45 4.30

(3.21)

5 4.65

(3.47)

920 4.95

(3.69)

955 5.30

(3.95)

990 5.65

(4.21)

1025 6.00

(4.4 )

7500

(3540)

80 3.05

(2.28)

725 3.40

(2.54)

770 3.75

(2. 0)

10 4.05

(3.02)

50 4.40

(3.2 )

90 4.75

(3.54)

925 5.10

(3. 0)

960 5.45

(4.07)

995 5. 0

(4.33)

1030 6.15

(4.59)

7600

(35 5)

90 3.20

(2.39)

735 3.55

(2. 5)

775 3. 5

(2. 7)

20 4.20

(3.13)

55 4.50

(3.36)

95 4.90

(3.66)

930 5.20

(3. )

965 5.55

(4.14)

1000 5.95

(4.44)

1035 6.35

(4.74)

7700

(3635)

700 3.35

(2.50)

740 3. 5

(2.72)

7 5 4.00

(2.9 )

25 4.35

(3.25)

65 4.70

(3.51)

900 5.00

(3.73)

935 5.35

(3.99)

970 5.70

(4.25)

1005 6.10

(4.55)

1040 6.50

(4. 5)

7 00

(36 0)

705 3.45

(2.57)

750 3.80

(2.83)

790 4.10

(3.06)

30 4.45

(3.32)

70 4. 0

(3.5 )

905 5.15

(3. 4)

945 5.55

(4.14)

9 0 5.90

(4.40)

1010 6.25

(4.66)

1045 6.65

(4.96)

7900

(3730)

715 3. 0

(2. 9)

755 3.90

(2.91)

00 4.25

(3.17)

35 4.60

(3.43)

75 4.95

(3.69)

910 5.30

(3.95)

950 5.70

(4.25)

9 5 6.05

(4.51)

1015 6.40

(4.77)

1050 6. 0

(5.07)

000

(3775)

720 3.70

(2.7 )

765 4.05

(3.02)

05 4.40

(3.2 )

45 4.75

(3.54)

0 5.10

(3. 0)

920 5.45

(4.07)

955 5. 5

(4.36)

990 6.20

(4.63)

1020 6.55

(4. 9)

1055 6.95

(5.1 )

100

(3 20)

730 3.85

(2.87)

770 4.15

(3.10)

10 4.50

(3.36)

50 4.90

(3.66)

90 5.25

(3.92)

925 5.60

(4.1 )

960 6.00

(4.4 )

995 6.35

(4.74)

1030 6.75

(5.04)

1060 7.10

(5.30)

200

(3 70)

740 4.00

(2.98)

7 0 4.30

(3.21)

20 4.70

(3.51)

55 5.00

(3.73)

95 5.40

(4.03)

930 5.75

(4.29)

965 6.15

(4.59)

1000 6.50

(4. 5)

1035 6.95

(5.1 )

1065 7.30

(5.45)

300

(3915)

745 4.10

(3.0 )

7 5 4.45

(3.32)

25 4. 0

(3.5 )

65 5.20

(3. )

900 5.55

(4.14)

935 5.90

(4.40)

970 6.30

(4.70)

1005 6.70

(5.00)

1040 7.10

(5.30)

1070 7.45

(5.56)

400

(3965)

755 4.25

(3.17)

795 4.60

(3.43)

35 5.00

(3.73)

70 5.30

(3.95)

910 5.75

(4.29)

945 6.10

(4.55)

9 0 6.50

(4. 5)

1010 6. 5

(5.11)

1045 7.25

(5.41)

1075 7.65

(5.71)

500

(4010)

7 0 4.40

(3.28)

00 4.75

(3.54)

40 5.10

(3. 0)

0 5.50

(4.10)

915 5.90

(4.40)

950 6.25

(4.66)

9 5 6.65

(4.96)

1015 7.00

(5.22)

1050 7.45

(5.56)

10 0 7. 0

(5. 2)

600

(4060)

770 4.55

(3.39)

10 4.90

(3.66)

50 5.30

(3.95)

5 5.65

(4.21)

920 6.00

(4.4 )

955 6.40

(4.77)

990 6. 0

(5.07)

1025 7.25

(5.41)

1055 7.60

(5.67)

10 5 .00

(5.97)

700

(4105)

780 4.70

(3.51)

15 5.05

(3.77)

55 5.45

(4.07)

90 5. 0

(4.33)

925 6.15

(4.59)

960 6.55

(4. 9)

995 6.95

(5.1 )

1030 7.40

(5.52)

1060 7. 0

(5. 2)

1090 .15

(6.0 )

00

(4155)

785 4.85

(3. 2)

25 5.20

(3. )

60 5.60

(4.1 )

900 6.00

(4.4 )

935 6.40

(4.77)

970 6. 0

(5.07)

1000 7.15

(5.33)

1035 7.55

(5.63)

1065 7.95

(5.93)

1095 .35

(6.23)

900

(4200)

795 5.00

(3.73)

30 5.35

(3.99)

70 5.75

(4.29)

905 6.15

(4.59)

940 6.55

(4. 9)

975 6.95

(5.1 )

1010 7.35

(5.4 )

1040 7.75

(5.7 )

1070 .15

(6.0 )

1105 .60

(6.42)

9000

(4245)

800 5.15

(3.84)

40 5.55

(4.14)

75 5.90

(4.40)

910 6.30

(4.70)

950 6.75

(5.04)

9 0 7.10

(5.30)

1015 7.55

(5.63)

1045 7.90

(5. 9)

10 0 .40

(6.27)

1110 8.80

( .5 )

Page 7

BLOWER DATA CHA16-240

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY WITH DRY INDOOR COIL & AIR FILTERS IN PLACE.

FOR ALL UNITS ADD:

1 - Wet indoor coil air resistance of selected unit. 2 - Any field installed accessories air resistance (electric heat, economizer, duct resistance, diffuser, etc.)

Then determine from blower table blower motor output.

MINIMUM AIR VOLUME REQUIRED FOR USE WITH OPTIONAL ELECTRIC HEAT

DUnits require 4900 cfm (2310 L/s) minimum air with electric heat.

BOLD ITALIC INDICATES FIELD FURNISHED DRIVE

Air STATIC PRESSURE EXTERNAL TO UNIT Ċ Inches Water Gauge (Pa)

Air

Volume

f

.20 (50) .40 (100) .60 (150) .80 (200) 1.00 (250) 1.20 (300) 1.40 (350) 1.60 (400) 1.80 (450) 2.00 (495)

Volume

cfm

(L/s) RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

RPM BHP

(kW)

6000

(2 30)

5 0 1.70

(1.27)

10 1.95

(1.45)

0 2.20

(1. 4)

710 2.45

(1.83)

755 2.75

(2.05)

795 3.00

(2.24)

40 3.30

(2.46)

0 3.60

(2.69)

915 3. 5

(2. 7)

955 4.20

(3.13)

6100

(2 0)

5 5 1.75

(1.31)

20 2.05

(1.53)

70 2.30

(1.72)

715 2.55

(1.90)

7 0 2.85

(2.13)

00 3.10

(2.31)

45 3.40

(2.54)

5 3.70

(2.76)

920 3.95

(2.95)

955 4.25

(3.17)

6200

(2925)

575 1.85

(1.38)

25 2.10

(1.57)

75 2.35

(1.75)

720 2. 5

(1.98)

765 2.90

(2.16)

05 3.20

(2.39)

50 3.50

(2.61)

5 3.75

(2. 0)

925 4.10

(3.06)

960 4.40

(3.2 )

6300

(2975)

580 1.90

(1.42)

35 2.20

(1. 4)

80 2.45

(1.83)

725 2.75

(2.05)

770 3.00

(2.24)

15 3.30

(2.46)

50 3.60

(2.69)

90 3.90

(2.91)

930 4.20

(3.13)

965 4.50

(3.36)

6400

(3020)

590 2.00

(1.49)

40 2.30

(1.72)

85 2.55

(1.90)

735 2.85

(2.13)

775 3.10

(2.31)

20 3.45

(2.57)

55 3.70

(2.76)

95 4.00

(2.9 )

935 4.35

(3.25)

970 4.65

(3.47)

6500

(3065)

595 2.10

(1.57)

45 2.35

(1.75)

95 2. 5

(1.98)

740 2.95

(2.20)

7 0 3.20

(2.39)

25 3.55

(2.65)

60 3. 0

(2. 3)

900 4.10

(3.06)

940 4.45

(3.32)

975 4.75

(3.54)

6600

(3115)

05 2.20

(1. 4)

55 2.45

(1.83)

700 2.75

(2.05)

745 3.05

(2.28)

7 5 3.30

(2.46)

30 3.65

(2.72)

65 3.90

(2.91)

905 4.25

(3.17)

940 4.55

(3.39)

975 4. 5

(3.62)

6700

(3160)

10 2.25

(1. 8)

0 2.55

(1.90)

705 2.85

(2.13)

750 3.15

(2.35)

795 3.45

(2.57)

35 3.75

(2. 0)

70 4.00

(2.9 )

910 4.35

(3.25)

945 4.65

(3.47)

9 0 4.95

(3.69)

6 00

(3210)

20 2.35

(1.75)

5 2. 5

(1.98)

715 2.95

(2.20)

755 3.25

(2.42)

00 3.55

(2.65)

40 3. 5

(2. 7)

0 4.20

(3.13)

915 4.50

(3.36)

950 4. 0

(3.5 )

9 5 5.10

(3. 0)

6900

(3255)

25 2.45

(1.83)

75 2.75

(2.05)

720 3.05

(2.28)

765 3.35

(2.50)

05 3.65

(2.72)

45 3.95

(2.95)

5 4.30

(3.21)

920 4.60

(3.43)

955 4.90

(3.66)

990 5.25

(3.92)

7000

(3305)

35 2.55

(1.90)

80 2.85

(2.13)

725 3.15

(2.35)

770 3.45

(2.57)

10 3.75

(2. 0)

50 4.10

(3.06)

90 4.40

(3.2 )

925 4.75

(3.54)

960 5.05

(3.77)

995 5.40

(4.03)

7100

(3350)

40 2. 5

(1.98)

90 3.00

(2.24)

735 3.30

(2.4 )

775 3.60

(2.69)

15 3.90

(2.91)

55 4.20

(3.13)

95 4.55

(3.39)

930 4. 5

(3.62)

965 5.20

(3. )

1000 5.55

(4.14)

7200

(3400)

50 2.80

(2.09)

95 3.05

(2.28)

740 3.40

(2.54)

7 0 3.70

(2.76)

20 4.00

(2.9 )

60 4.35

(3.25)

900 4.70

(3.51)

935 5.00

(3.73)

970 5.35

(3.99)

1005 5.65

(4.21)

7300

(3445)

55 2.85

(2.13)

705 3.20

(2.39)

745 3.50

(2. 1)

790 3. 5

(2. 7)

30 4.15

(3.10)

65 4.45

(3.32)

905 4. 0

(3.5 )

940 5.15

(3. 4)

975 5.45

(4.07)

1010 5. 0

(4.33)

7400

(3490)

5 3.00

(2.24)

710 3.30

(2.4 )

755 3. 5

(2.72)

795 3.95

(2.95)

35 4.30

(3.21)

70 4.60

(3.43)

910 4.95

(3.69)

945 5.25

(3.92)

9 0 5.60

(4.1 )

1015 5.95

(4.44)

7500

(3540)

75 3.10

(2.31)

715 3.40

(2.54)

7 0 3.75

(2.80)

00 4.05

(3.02)

40 4.40

(3.2 )

0 4.75

(3.54)

915 5.05

(3.77)

950 5.40

(4.03)

9 5 5.75

(4.29)

1020 6.10

(4.55)

7600

(35 5)

80 3.20

(2.39)

725 3.55

(2. 5)

765 3. 5

(2. 7)

05 4.20

(3.13)

45 4.50

(3.36)

5 4.90

(3.66)

920 5.20

(3. )

955 5.55

(4.14)

990 5.90

(4.40)

1020 6.20

(4.63)

7700

(3635)

90 3.35

(2.50)

730 3. 5

(2.72)

775 4.00

(2.9 )

15 4.35

(3.25)

50 4.65

(3.47)

90 5.00

(3.73)

925 5.35

(3.99)

960 5.70

(4.25)

995 6.05

(4.51)

1025 6.40

(4.77)

7 00

(36 0)

95 3.45

(2.57)

740 3.80

(2.83)

7 0 4.15

(3.10)

20 4.45

(3.32)

60 4. 0

(3.5 )

95 5.15

(3. 4)

930 5.50

(4.10)

965 5. 5

(4.36)

1000 6.20

(4.63)

1030 6.55

(4. 9)

7900

(3730)

705 3. 0

(2. 9)

745 3.90

(2.91)

7 5 4.25

(3.17)

25 4.60

(3.43)

65 4.95

(3.69)

900 5.30

(3.95)

935 5.65

(4.21)

970 6.00

(4.4 )

1005 6.35

(4.74)

1035 6.70

(5.00)

000

(3775)

710 3.70

(2.7 )

755 4.05

(3.02)

795 4.40

(3.2 )

35 4.75

(3.54)

70 5.10

(3. 0)

905 5.45

(4.07)

940 5. 0

(4.33)

975 6.15

(4.59)

1010 6.50

(4. 5)

1040 6. 5

(5.11)

100

(3 20)

720 3.85

(2.87)

7 0 4.20

(3.13)

00 4.55

(3.39)

40 4.90

(3.66)

75 5.25

(3.92)

915 5.60

(4.1 )

950 6.00

(4.4 )

9 0 6.30

(4.70)

1015 6.70

(5.00)

1045 7.05

(5.26)

200

(3 70)

730 4.00

(2.98)

770 4.35

(3.25)

10 4.70

(3.51)

45 5.05

(3.77)

5 5.40

(4.03)

920 5.75

(4.29)

955 6.15

(4.59)

9 5 6.45

(4. 1)

1020 6. 5

(5.11)

1050 7.20

(5.37)

300

(3915)

735 4.15

(3.10)

775 4.45

(3.32)

15 4. 5

(3.62)

55 5.20

(3. )

90 5.55

(4.14)

925 5.90

(4.40)

960 6.30

(4.70)

995 6.65

(4.96)

1025 7.00

(5.22)

1055 7.35

(5.4 )

400

(3965)

745 4.30

(3.21)

7 5 4.65

(3.47)

25 5.00

(3.73)

60 5.35

(3.99)

95 5.70

(4.25)

930 6.05

(4.51)

965 6.45

(4. 1)

1000 6. 5

(5.11)

1030 7.20

(5.37)

1065 7.60

(5.67)

500

(4010)

750 4.40

(3.28)

790 4.75

(3.54)

30 5.15

(3. 4)

65 5.50

(4.10)

900 5. 5

(4.36)

940 6.25

(4.66)

970 6.60

(4.92)

1005 7.00

(5.22)

1035 7.35

(5.4 )

1070 7. 0

(5. 2)

600

(4060)

7 0 4. 0

(3.43)

00 4.95

(3.69)

35 5.30

(3.95)

75 5.70

(4.25)

910 6.05

(4.51)

945 6.45

(4. 1)

975 6.75

(5.04)

1010 7.15

(5.33)

1040 7.55

(5.63)

1075 7.95

(5.93)

700

(4105)

7 5 4.70

(3.51)

05 5.10

(3. 0)

45 5.45

(4.07)

0 5. 5

(4.36)

915 6.20

(4.63)

950 6.60

(4.92)

9 5 7.00

(5.22)

1015 7.35

(5.4 )

1045 7.70

(5.74)

10 0 .15

(6.0 )

00

(4155)

775 4.90

(3.66)

15 5.25

(3.92)

50 5.60

(4.1 )

5 6.00

(4.4 )

920 6.35

(4.74)

955 6.75

(5.04)

990 7.15

(5.33)

1020 7.50

(5.60)

1055 7.95

(5.93)

10 5 .35

(6.23)

900

(4200)

7 5 5.05

(3.77)

20 5.40

(4.03)

60 5. 0

(4.33)

95 6.20

(4.63)

930 6.55

(4. 9)

960 6.90

(5.15)

995 7.35

(5.4 )

1025 7.70

(5.74)

1060 .15

(6.0 )

1090 .55

(6.3 )

9000

(4245)

790 5.20

(3. )

30 5.60

(4.1 )

65 5.95

(4.44)

900 6.35

(4.74)

935 6.75

(5.04)

970 7.15

(5.33)

1000 7.50

(5.60)

1035 7.95

(5.93)

1065 .30

(6.19)

1095 8.70

( .49)

Page 8

BLOWER DATA GCS/CHA16

ACCESSORY AIR RESISTANCE

Total Resistance - inches water gauge (Pa)

Unit

Mdl

Air Volume

Wet

REMD16M

RTD11 Ste ĆDown Diffuser

FD11

Model

No

W

e

t

Eva orator

Electric Heat

REMD16M

Down

Ć

Flow

2 Ends

1 Side All Ends

FD11

Flush

No.

cfm L/s

Eva orator

Coil

El

ec

t

r

i

c

H

ea

t

Down

Ć

Flow

Economizer 2 Ends

O en

1

Side

2 Ends

O en

All

Ends

& Sides

O en

Flush

Diffuser

4 00 2265 .14 (35) .15 (37) .03 (7) .46 (114) .40 (99) .36 (90) .24 (60)

5000 2360 .14 (35) .17 (42) .03 (7) .51 (127) .44 (109) .39 (97) .27 (67)

5200 2455 .15 (37) .20 (50) .03 (7) .56 (139) .4 (119) .42 (104) .30 (75)

5400 2550 .16 (40) .22 (55) .04 (10) .61 (152) .52 (129) .45 (112) .33 ( 2)

5600 2645 .17 (42) .22 (55) .04 (10) .66 (164) .56 (139) .4 (119) .36 (90)

5 00 2735 .1 (45) .25 (62) .05 (12) .71 (177) .59 (147) .51 (127) .39 (97)

GCS/

CHA16-1 0 6000 2 30 .19 (47) .26 (64) .05 (12) .76 (1 9) .63 (157) .55 (137) .42 (104)

CHA16-1 0

6200 2925 .20 (50) .29 (72) .05 (12) . 0 (199) .6 (169) .59 (147) .46 (114)

6400 3020 .21 (52) .31 (77) .06 (15) . 6 (214) .72 (179) .63 (157) .50 (124)

6600 3115 .22 (55) .32 ( 0) .06 (15) .92 (229) .77 (191) .67 (167) .54 (134)

6 00 3210 .23 (57) .33 ( 2) .07 (17) .99 (246) . 3 (206) .72 (174) .5 (144)

7000 3305 .24 (60) .33 ( 2) .07 (17) 1.03 (256) . 7 (216) .76 (1 9) .62 (154)

7200 3400 .25 (62) .34 ( 5) .0 (20) 1.09 (271) .92 (229) . 0 (199) .66 (164)

6000 2 30 .24 (60) .26 (64) .05 (12) .36 (90) .31 (77) .27 (67) .29 (72)

6500 3065 .2 (70) .32 ( 0) .06 (15) .42 (104) .36 (90) .31 (77) .34 ( 5)

7000 3305 .31 (77) .33 ( 2) .07 (17) .49 (122) .41 (102) .36 (90) .40 (99)

GCS/

CHA16-240 7500 3540 .34 ( 5) .40 (99) .09 (22) .51 (127) .46 (114) .41 (102) .45 (112)

CHA16

-

240

000 3775 .3 (94) .42 (104) .10 (25) .59 (147) .49 (122) .43 (107) .50 (124)

500 4010 .42 (104) .50 (124) .11 (27) .69 (172) .5 (144) .50 (124) .57 (142)

9000 4245 .46 (114) .5 (144) .13 (32) .79 (196) .67 (167) .5 (144) .66 (164)

CEILING DIFFUSER AIR THROW DATA

Model

Air Volume

Effective Throw Range

Model

No.

Air Volume RTD11 Ste ĆDown FD11 Flush

No

.

cfm L/s ft. m ft. m

5600 2645 39 - 49 12 - 15 2 - 37 9 - 11

5 00 2740 42 - 51 13 - 16 29 - 3 9 - 12

GCS/CHA 6000 2 30 44 - 54 13 - 17 40 - 50 12 - 15

GCS/CHA

16-1 0 6200 2925 45 - 55 14 - 17 42 - 51 13 - 16

6400 3020 46 - 55 14 - 17 43 - 52 13 - 16

6600 3115 47 - 56 14 - 17 45 - 56 14 - 17

7200 3400 33 - 3 10 - 12 26 - 35 - 11

7400 3490 35 - 40 11 - 12 2 - 37 9 - 11

7600 35 5 36- 41 11 - 13 29 - 3 9 - 12

GCS/CHA

7 00 36 0 3 - 43 11 - 13 40 - 50 12 - 15

GCS/CHA

16

-

240

000 3775 39 - 44 12 - 13 42 - 51 13 - 16

16

-

240

200 3 70 41 - 46 12 - 14 43 - 52 13 - 16

400 3965 43 - 49 13 - 15 44 - 54 13 - 17

600 4060 44 - 50 13 - 15 46 - 57 14 - 17

00 4155 47 - 55 14 - 17 4 - 59 15 - 1

Throw is the horizontal or vertical distance an airstream travels on leaving the outĆ

letĂor diffuser before the maximum velocity is reduced to 50 ft. (15 m) per minute. Four

sides open.

PED16-18/24 POWER EXHAUST FANS PERFORMANCE

Model No. Air Volume Return Air System

Static Pressure

Model

No

.

cfm L/s In. w.g. Pa

6000 2 30 0 0

5700 2690 .05 12

5300 2500 .10 25

PED16-1 /24 5000 2360 .15 37

4700 2210 .20 50

4200 19 0 .25 62

3600 1700 .30 75

Page 9

OPTIONAL ACCESSORIES

Item GCS/CHA16Ć180 GCS/CHA16-240

Coil Guard - PVC coated steel wire guards to protect outdoor coil. Not used with Hail Guards. 78L49

Control Systems See Engineering Handbook

Differential Enthal y Control - For use with economizer dampers, solidĆstate return air sensor alĆ

lows selection between outdoor air and return air (whichever has lowest enthalpy). 54G44

Diffusers (Ste ĆDown) - Aluminum grilles, double deflection louvers, large center grille, insulated difĆ

fuser box with flanges, hanging rings furnished, interior transition (even air flow), internally sealed

(prevents recirculation), adapts to TĆbar ceiling grids or plaster ceilings.

RTD11Ć1 5

392 lbs. (17 kg)

RTD11Ć275

403 lbs. (1 3 kg)

Diffusers (Flush) - Aluminum grilles, fixed blade louvers, large center grille, insulated diffuser box

with flanges, hanging rings furnished, interior transition (even air flow), internally sealed (prevents

recirculation), adapts to TĆbar ceiling grids or plaster ceilings.

FD11Ć1 5

2 9 lbs. (131 kg)

FD11Ć275

363 lbs. (165 kg)

Transitions (Su ly and Return) - Used with diffusers, installs in roof mounting frame, galvanized

steel construction, flanges furnished for duct connection, fully insulated.

SRT16Ć1

75 lbs. (34 kg)

SRT16Ć24

120 lbs. (54 kg)

Economizer Dam ers (DownĆFlow or Horizontal) - Mechanically

linked recirculated air and outdoor air dampers, plugĆin connecĆ

tions to unit, nylon bearings, stainless steel seals (outdoor dampĆ

ers), 24 volt fully modulating spring return damper motor, adjustĆ

able minimum damper position switch, mixed air sensor, solidĆ

state adjustable outdoor air enthalpy control, 0 to 100% outdoor

air adjustable, powdered enamel paint finish.

Model No. - Net Wt.

REMD16MĆ1 /24

95 lbs. (43 kg)

(order Economizer Damper Hood

for complete assembly)

air

adjustable

,

powdered

enamel

paint

finish

.

NOTE - Economizer Damper Hood is required and must be ordered

separately (see below).

NOTE - Gravity Exhaust Dampers are required for down-flow apĆ

plications and must be ordered separately (see below).

Net face area 5.3 sq. ft. (0.49 m2)

Economizer Dam er Hood - Required with REMD16M economizer

dampers (see above) Installs over outdoor air dampers Includes

Order No. 81L45

36 lbs. (16 kg)

d

ampers

(

see a

b

ove

)

.

I

ns

t

a

ll

s over ou

td

oor a

i

r

d

ampers.

I

nc

l

u

d

es

cleanable aluminum mesh frame filters. No. & Size of Filters - in.

(mm)

(2) 25 x 25 x 1

(635 x 635 x 25)

Economizer Gravity Exhaust Dam ers - Required with REMD16 economizer dampers in down-

flow applications. Optional for horizontal applications. Neoprene coated fiberglass dampers. InĆ

cludes rain hood. Field installs on economizer for down-flow applications. Field installs on return air

duct for horizontal applications. See dimension drawings.

GED16-1 /24

23 lbs. (10 kg)

Economizer Power Exhaust Fans - For use with REMD16M econoĆ Model No. - Net Wt. PED16-1 /24

0 lbs. (36 kg)

Economizer

Power

Exhaust

Fans

-

For

use

with

REMD16M

econoĆ

mizer dampers (see above). Provides pressure relief. Installed beĆ

tween economizer and gravity exhaust dampers (required) Inter

Dia. - in. (mm) No. blades 20 (50 ) - 5

p( ) p

tween economizer and gravity exhaust dampers (required). InterĆ

locked to run when return air dampers are closed and supply air blow

ĆTotal air volume - cfm (L/s) 6000 (2 30)

locked

to

run

when

return

air

dampers

are

closed

and

supply

air

blow

Ć

ers are operating. Overload protected. Must be ordered separately. Motor horsepower (W) (2) - 1/3 (250)

ers

are

operating.

Overload

protected.

Must

be

ordered

separately.

Total Watts input 50

Hail Guards - Heavy duty field installed coil guard protects coils from damage. Not used with Coil

Guards. 78L48

Horizontal Su ly and Return Air Kit - Provides duct connection to unit, flanges furnished, hardĆ

ware furnished, two filler panels furnished for unused air openings in unit base.

HDK16-1 /24

55 lbs. (25 kg)

Low Ambient Controls - Allows unit operation down to 0_F (-17.7_C). LBĆ57113BY (85L42)

LPG/Pro ane Kits GCS MODELS ONLY 81L86

Outdoor Air Dam er Section (Down-Flow A lications Only) -

Linked mechanical dampers, 0 to 25% (fixed) outdoor air adjustĆ

able, installs on unit for downĆflow applications, outdoor air hood

and panel kit must be ordered separately (see below)

Minimum mixed air temperature:

Heat mode (aluminized heat exchanger) - 45°F (7°C)

Maximum mixed air temperature:

Cool mode - 90°F (32°C),

Model No.

OAD16Ć1 /24

(Order Air Damper Hood and Damper Panel Kit

for complete assembly)

Outdoor Air Dam er/Hood - Cleanable aluminum mesh frame t

yp

eCatalog No. - Net Wt. 81L38

52 lbs. (24 kg)

Outdoor

Air

Dam er/Hood

-

Cleanable

aluminum

mesh

frame

type

filter furnished, installs over outdoor air damper section. No. & Size of Filters (1) 26 x 2 x 1 in.

(660 x 711 x 25 mm)

Electric Heat - Factory or field installed, helix wound nichrome elements, time delay for element staging.

individual element limit controls, may be twoĆstage controlled, requires optional Fuse Block

CHA16 MODELS ONLY

ECH16Ć1 5-15

15 kW (all voltages)

ECH16-1 5/300

30Ć45-60 kW

(all voltages)

75 kW (460/575v)

ECH16Ć1 5/300

30Ć45-60 kW

(all voltages)

75 kW (460/575v)

3 hp (2.2 kW) 84L19 (90 amp) - - - -

20 /230v -3 phase 5 hp (3.7 kW) 84L19 (90 amp) 84L24 (110 amp)

20 /230v

3

phase

7.5 hp (5.7 kW) - - - - 89L37 (125 amp)

Unit Fuse Block - Required for electric heat installaĆ 3 hp (2.2 kW) 84L20 (45 amp) - - - -

Unit

Fuse

Block

Required

for

electric

heat

installa

tion, wiring harness and mounting screws furnished 460v - 3 phase 5 hp (3.7 kW) 84L22 (50 amp) 84L22 (50 amp)

tion,

wiring

harness

and

mounting

screws

furnished

CHA16 MODELS ONLY

460v

3

phase

7.5 hp (5.7 kW) - - - - 84L22 (50 amp)

CHA16

MODELS

ONLY

3 hp (2.2 kW) 84L21 (30 amp) - - - -

575v - 3 phase 5 hp (3.7 kW) 84L23 (35 amp) 84L25 (40 amp)

575v

3

phase

7.5 hp (5.7 kW) - - - - 84L24 (45 amp)

Page 10

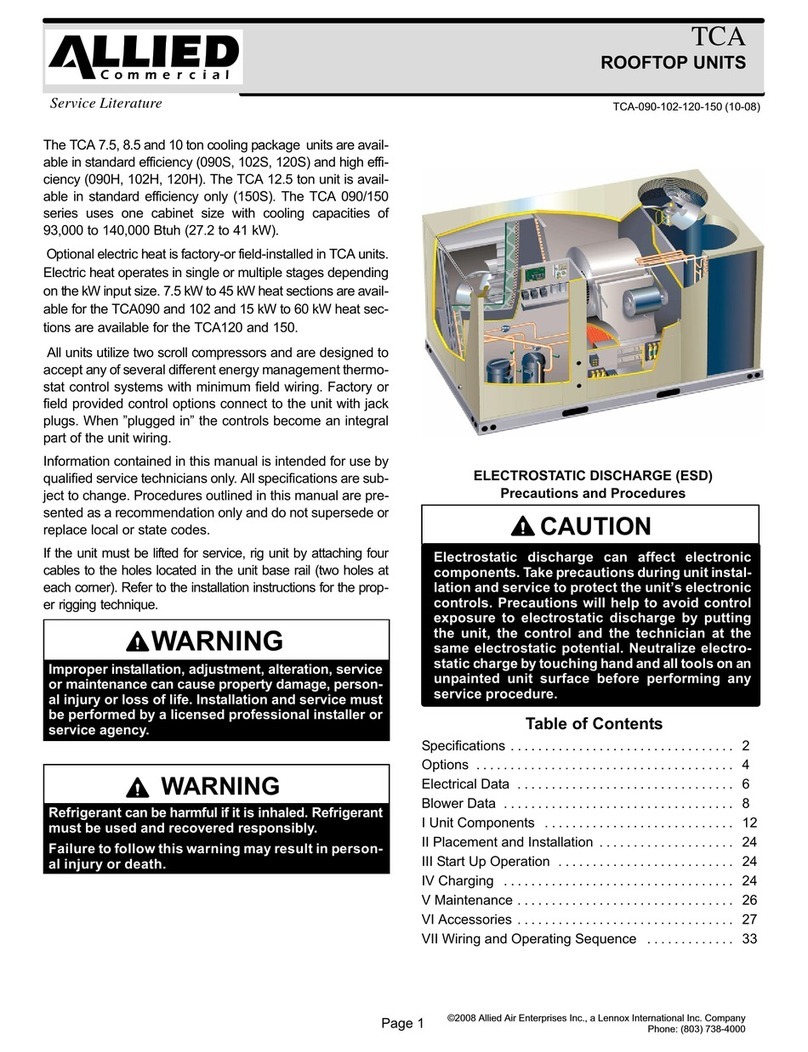

FIGURE 1

GCS16-180/240 PARTS ARRANGEMENT

EVAPORATOR

COIL

BLOWER MOTOR

BOTTOM POWER ENTRY

CONDENSER FAN

CONDENSER

COIL

CONTROL BOX

COMPRESSOR (3)

MANIFOLD

ASSEMBLY

GAS VALVE

COMBUSTION

AIR INDUCER

HEAT EXCHANGER TUBES

FILTERS (4)

16 X 20 X 2"

BURNER

CONTROL

BOX

FLUE BOX

COVER

FIGURE 2

CHA16-180/240 PARTS ARRANGEMENT

EVAPORATOR

COIL

BLOWER MOTOR

BOTTOM POWER

ENTRY

CONDENSER FAN (2)

CONDENSER

COIL

CONTROL BOX

COMPRESSOR (3)

FILTERS (6)

18 X 24 X 2"

ELECTRIC HEAT

COMPARTMENT

ELECTRIC HEAT MAKE

UP BOX

I-APPLICATION

GCSCHA 15 and 20 ton units are available in one

cabinet size. All models are applicable for commercial

three phase installations. GCS/CHA16 models are

factory equipped with the hardware required for install-

ing optional thermostat control systems.

II-UNIT COMPONENTS

See figures 1 and 2 for GCS16 or CHA16-180/240 parts

arrangement.

A-Control Box Components

The GCS/CHA16 control box is shown in figure 3. The

control box is located in the upper portion of the com-

pressor compartment behind the compressor compart-

ment access panel. Note that the burner ignition control

and other components are located in the burner control

box, above the manifold assembly.

The condenser fans can be accessed by removing the

fan grills located on top of the unit.

The indoor blower access panel (all units) is located to

the left side of the heating compartment access.

1 - Transformer T1

All GCS16/CHA-180/240 units use a line voltage to

24VAC transformer mounted in the control box. The

transformer supplies power to control circuits in the unit.

Transformers are rated at 70VA and is protected by a

3.5 amp circuit breaker (CB). CB8 is internal to the

transformer. Transformers use two primary voltage taps

as shown in figure 6.

Page 11

DANGER

Remove all power to disconnect before

servicing.

Electrical shock resulting in death or injury

may result if power is not disconnected.

CAUTION

Label all wires prior to disconnection when

servicing control box. Wiring errors can

cause improper and dangerous operation.

Verify proper operation after servicing.

Page 12

2 - Cooling Contactor K1, K2 & K14

K1, K2 and K14, are 24V coil contactors used to energize

the compressors in response to thermostat demand. K1

and K2 energize compressors B1 and B2 in response to Y1

first stage cooling demand. K14 energizes compressor B13

in response to Y2 second stage cooling demand. All units

use three-pole-double-break contactors.

3 - Com ressor Run Time Delay DL15 & DL9

All GCS16 units are equipped with compressor run time

delay DL15 (1st stage cool) and DL9 (2nd stage cool). The

delay time (approximately 2 seconds) prevents compresĆ

sors B1, B2 and B13 from energizing simultaneously during

a demand for 1st or 2nd stage cool.

4 - Indoor Blower Contactor K3

All GCS16/CHA-1 0/240 units use a three-pole double

break contactor to energize the indoor blower and optional

economizer. The coil is energized by blower demand from

indoor thermostat terminal G" (cooling demand or fan

switch in ON" position).

5 - Condenser Fan Contactor K10

K10 is a single pole contactor in -1 0 units and three pole

contactor in -240 units, used to energize condenser fans B4

and B5 in response to thermostat demand.

6 - Condenser Fan Motor Ca acitors C1 &C2

Fan capacitors C1 and C2 (GCS16-1 0 only) are used to

assist in start up of condenser fans B4 and B5 respectively.

See condenser fan motor nameplate for capacitor ratings.

7 - Condenser Fan Motor Fuse F10

Three line voltage fuses F10 provide overcurrent protection

to condenser fans B4 and B5 (and optional power exhaust

fans ) in all Y voltage GCS16 units. The fuses are rated at

30A.

8 - Terminal Stri s TB2, TB13 and TB34

Terminal strips TB13 and TB2 distribute line voltage power

to line voltage components in the unit. TB34 distributes 24V

power from transformer T1 to the control box components.

TB13 is located in the bottom power entry section for GCS

units and in the electric heat make up box for CHA units.

9 - Power Exhaust Relay K65

K65 is a N.O. DPDT relay with a 24Vcoil. K65 is used with all

units with the optional power exhaust fans. K65 is energized

by a mercury switch S39, which is mounted on the econoĆ

mizer intake blades. S39 closes when the damper reaches

50% open. When K65 closes exhaust fans B10 and B11 are

energized. K65 is located behind the filter access panel.

10 - Blower Motor Overload Relay S42

The motor relay is used on all M voltage GCS16 units. The

relay is connected in line with the blower motor to monitor

the current flow to the motor. When the relay senses an

overload condition, a set of normally closed contacts open

to de-energize the blower motor and terminate 24V supply

to TB34.

Relay Panel A11

A11 is a pilot duty relay board that reduces load on the therĆ

mostat circuit. Installations with extended thermostat wiring

without A11 will have excessive voltage drop affecting start

up operation. The following relays: K46, K77, K49,K66 and

K67 are a part of this board. If any of these relays fail reĆ

place the entire board.

11 - Blower Relay K46

Blower relay K46 is located on relay panel (A11) in the main

control box. K46 is energized in response to G" demand

from the indoor thermostat. K46 contacts close energizing

indoor blower relay K3.

12 - Heat Relay K77 (1st Stage)

Heat relay K77 is located on the relay panel (A11) in the

main control box. K77 is energized in response to 1st stage

heat demand W1. K77 contacts close energizing combusĆ

tion air inducer relay K13 to begin heat operation.

13 - Heat Relay K49 (2nd Stage)

Heat relay K49 is located on the relay panel (A11) in the

main control box. K49 is energized in response to 2nd stage

heat W2. K49 contacts close energizing DL3 heat delay

timer. After 1 0 seconds DL3 energizes the gas valve on

2nd stage heat.

14 - Cool Relay K66 (1st Stage)

Cool relay K66 is located on the relay panel (A11) in the

main control box. K66 is energized in response to 1st stage

cool demand Y1. K66 contacts close energizing compresĆ

sor contactor K1 which in turn energizes compressor B1. SiĆ

multaneously, compressor delay DL15 is energized, startĆ

ing a two second delay. After the delay, compressor contacĆ

tor K2 is energized which in turn energizes compressor B2.

15 - Cool Relay K67 (2nd Stage)

Cool relay K67 is located on the relay panel (A11) in the

main control box. K67 is energized in response to 2nd stage

cool demand Y2. K67 contacts close energizing compresĆ

sor delay DL9. After a two second delay, compressor conĆ

tactor K14 is energized which in turn energizes compressor

B13.

Page 13

B-Burner Control Box Figure 5

GCS models only

Figure 1 shows the location of the burner control box just

above the manifold assembly.

FIGURE 5

IGNITION CONTROL A3

TRANSFORMER

T3 (G, J & M VOLTAGE)

TIMER DL3 C.A.I. RELAY

K13

LIMIT RELAY

K20

BLOWER DELAY

RELAY K25

BURNER CONTROL BOX

1 - Indoor Blower Delay Relay K25

Relay K25 is a printed circuit board located in the burner

control box wired in series with the gas valve. K25 is deĆ

signed to provide an indoor blower delay of 45 seconds on

time and 150 seconds off time during a heat demand. When

there is a demand for heat, the gas valve will open and the

on time delay will begin. When heat demand is satisfied the

gas valve will close and the off time will begin.

2 - Combustion Air Inducer Relay K13

Relay K13 is a DPDT relay located inside the control box.

K13 is energized by heating demand from the thermostat

and is energized throughout the heating demand. When

energized, K13 normally open contacts close to energize

the combustion air inducer and begin a heating sequence.

3 - Indoor Blower Limit Relay K20

Relay K20 is a DPDT relay located in the burner control box.

Relay K20 is wired in series with limit S10 and S21. If either

limit opens, K20-1 contacts close energizing blower contacĆ

tor K3. Simultaneously, K20-2 contacts open de-energizing

the gas valve on second stage heat.

4 - Gas Delay DL3

DL3 is a SPST time delay located in the burner control box.

Upon receiving increased heat demand, DL3 initiates a 1 0

second time delay before closing its N.O. contacts. After the

delay, DL3 energizes W2 on the gas valve bringing on 2nd.

stage heat. DL3 is wired in series with the gas valve and inĆ

door blower limit relay K20.

5 - Transformer T3 (G, J & M Voltage Only)

All GCS16/CHA-1 0/240 G and J units use one 230VAC

transformer mounted in the control box. The transformer

has an output rating of 0.5A. T3 transformer supplies

230VAC power to combustion air inducer motor B6.

6 - Ignition Control A3

DANGER

Shock Hazard.

S ark related com onents contain

high voltage. Disconnect ower

before servicing unit.Ă The ignition

control is not field re airable.

Can cause unsafe o eration, injury

or death.

CAUTION

Electrostatic discharge can affect electronic

com onents. Take recautions during unit

installation and service to rotect the electronic

controls. Precautions will hel to avoid control

ex osure to electrostatic discharge by utting

the unit, the control and the technician at the

same electrostatic otential. Neutralize electroĆ

static charge by touching hand and all tools on

an un ainted unit surface, such as the gas

valve or blower deck, before erforming any

service rocedure.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

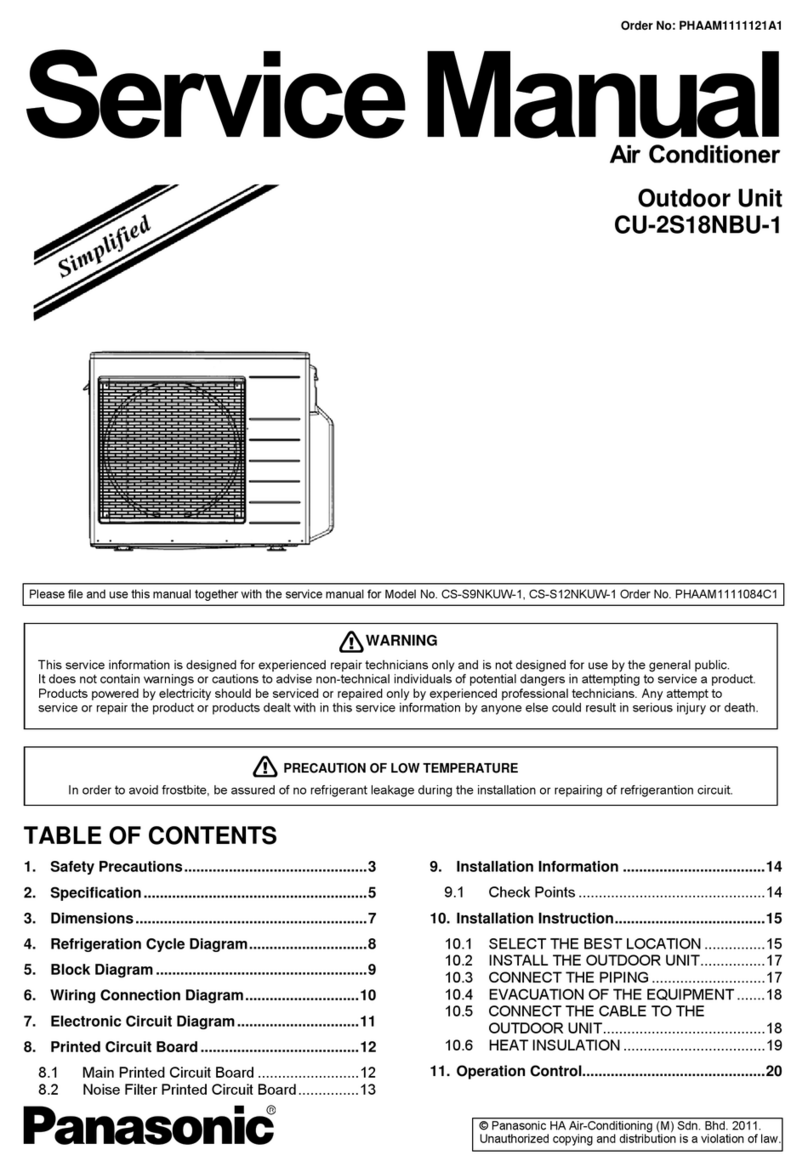

ALL GCS16 units are equipped with a Johnson control.

See figure 6. The ignition control provides three main funcĆ

tions: gas valve control, ignition, and flame sensing. The

unit will usually ignite on the first attempt; however, the

ignition attempt sequence provides three trials for ignition

before locking out. After one hour, the ignition control automatiĆ

cally resets and provides three more attempts at ignition.

Manual reset after lockout requires breaking and remaking

power to the ignition control. See figure 7 for ignition seĆ

quence with retrials timings.

Flame rectification sensing is used on all GCS16 units.

Loss of flame during a heating cycle is indicated by an abĆ

sence of flame signal. If this happens, the control will immediĆ

ately restart the ignition sequence and then lock out if ignition is

not gained after the third trial. Normal flame signal is 0.5 - 1.0

micro amps with a drop out signal of .09.

The ignition control shuts off gas flow immediately in the event

of a power failure. Upon restoration of gas and power, the conĆ

trol will restart the ignition sequence and continue until flame is

established or system locks out.

On a heating demand, the combustion air blower is energized.

As the combustion air blower nears full speed, the combustion

air prove switch S1 closes energizing ignition control A3.

The ignition control then has a 30 to 40 second delay to allow

the combustion air blower to purge exhaust gases from the

Page 14

combustion chamber and introduce fresh air. After the delay,

the ignition control then activates gas valve, the spark elecĆ

trode and the flame sensing electrode.

Sparking stops immediately after flame is sensed. The comĆ

bustion air blower continues to operate throughout the heating

demand. If the flame fails or if the burners do not ignite, the igniĆ

tion control will attempt to ignite the burners up to two more

times. If ignition cannot be obtained after the third attempt, the

control will lock out. The ignition control is not adjustable.

Spade connections are used to connect the control to the

unit. Each of the spade terminals are identified by function.

The spark electrode wire connects to the sparkĆplugĆtype

connector on top of the control.

JOHNSON IGNITION CONTROL

FIGURE 6

FIGURE 7

ÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉ

ÉÉÉ

ÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉ

ÉÉ

ÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉ

JOHNSON NORMAL IGNITION SEQUENCE

TIMINGS NOMINAL

THERMOSTAT DEMAND

combustion air BLOWER

GAS VALVE

IGNITION SPARK

BLOWER

IGNITION TRIAL

SECONDS 0 30 35 0 110

ON / CLOSED

OFF / OPEN END OF

DEMAND

1

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

combustion air PROVE SWITCH

5 570

RETRIALS - IGNITION ATTEMPT SEQUENCE - TIMINGS NOMINAL

ÉÉÉ

ÉÉÉ

ÉÉ

ÉÉ

ÉÉ

THERMOSTAT DEMAND

combustion air BLOWER

GAS VALVE

IGNITION SPARK

BLOWER

IGNITION TRIAL

SECONDS 0 30 35 70

ON

OFF

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉ

É

É

É

ÉÉ

ÉÉ

65 100 105

WATCHGUARD

LOCKOUT

combustion air PROVE SWITCH

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

5

ÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉ

ÉÉÉÉÉÉ

ÉÉÉ

ÉÉÉ

THERMOSTAT DEMAND

combustion air BLOWER

GAS VALVE

IGNITION SPARK

BLOWER

IGNITION TRIAL

SECONDS 0 30

ON

OFF

IGNITION CONTROL TIMING

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉÉ

ÉÉÉ

30 30 HEATING

CYCLE

6 (+3.4, -2.0) SEC. END OF

THERMOSTAT

DEMAND

123

42 SEC. 122 SEC.

Page 15

FIGURE 8

GCS16-180/240 HEAT EXCHANGER ASSEMBLY

HIGH INPUT ASSEMBLY SHOWN

MANIFOLD/BURNER ASSEMBLY

(LOW INPUT MANIFOLD WILL HAVE 5 BURNERS)

DIVISION PANEL

BLOWER

COMPARTMENT

SECONDARY LIMIT

S21

PRIMARY LIMIT

S10

HEAT EXCHANGER

(LOW INPUT HEAT EXCHANGER WILL HAVE 5 TUBES)

COMBUSTION

AIR INDUCER

GAS VALVE

BURNERS

ROLLOUT SWITCH

S47 (HIGH INPUT)

ROLLOUT SWITCH

S47 (LOW INPUT)

IGNITOR

SENSOR

(HIGH INPUT)

SENSOR

(LOW INPUT)

C-Gas Heat Components