Page 3 of 83

SK2018 PCG(H)-V/P-AECM-001

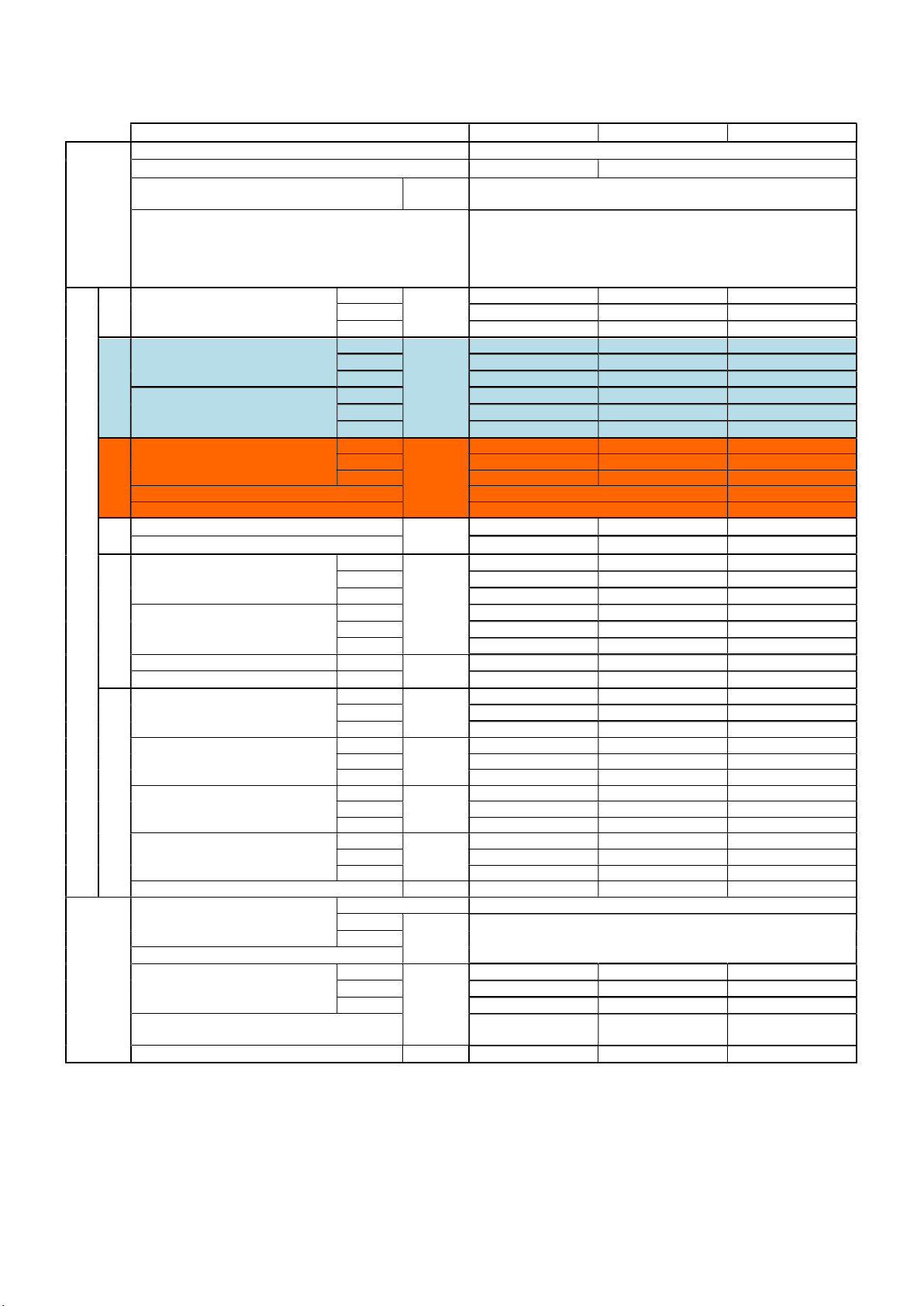

Wiring Diagram ......................................................................................................................................................... 46

Standard S Control PCB ....................................................................................................................................... 46

Master Slave Networking Wiring Diagram .......................................................................................................... 47

Configuration Settings ............................................................................................................................................... 48

Fan Coil Unit ON/OFF .......................................................................................................................................... 49

Auto Restart ........................................................................................................................................................ 49

Control Logic For 2-Pipe System ................................................................................................................................. 50

With Valve Configuration .................................................................................................................................... 50

Without Valve Configuration .............................................................................................................................. 54

Control Logic For 4-Pipe System ................................................................................................................................. 56

Sleep Mode ................................................................................................................................................................ 58

Auto Fan Speed .......................................................................................................................................................... 58

Modulating Valve Control Under Energy Saving Mode .............................................................................................. 59

Louver ........................................................................................................................................................................ 59

Buzzer....................................................................................................................................................................... 59

Auto Restart ............................................................................................................................................................. 59

On/Off Switch On LED Display Panel ........................................................................................................................ 59

Drain Pump .............................................................................................................................................................. 60

Float Switch .............................................................................................................................................................. 60

Electric Heater Safety Switch ................................................................................................................................... 60

Low Temperature Protection of Indoor Coil in Winter ............................................................................................. 60

LED Display and Error Description ........................................................................................................................... 62

LED Display on Master/Slave connection ................................................................................................................. 63

E. Networking System .................................................................................................................................................... 64

Master-Slave Network ................................................................................................................................................ 64

Master Control Unit Settings ............................................................................................................................... 64

Master – Slave Network Setup ............................................................................................................................ 65

Master – Slave Communication Method ............................................................................................................. 67

Open Modbus protocol ............................................................................................................................................... 68

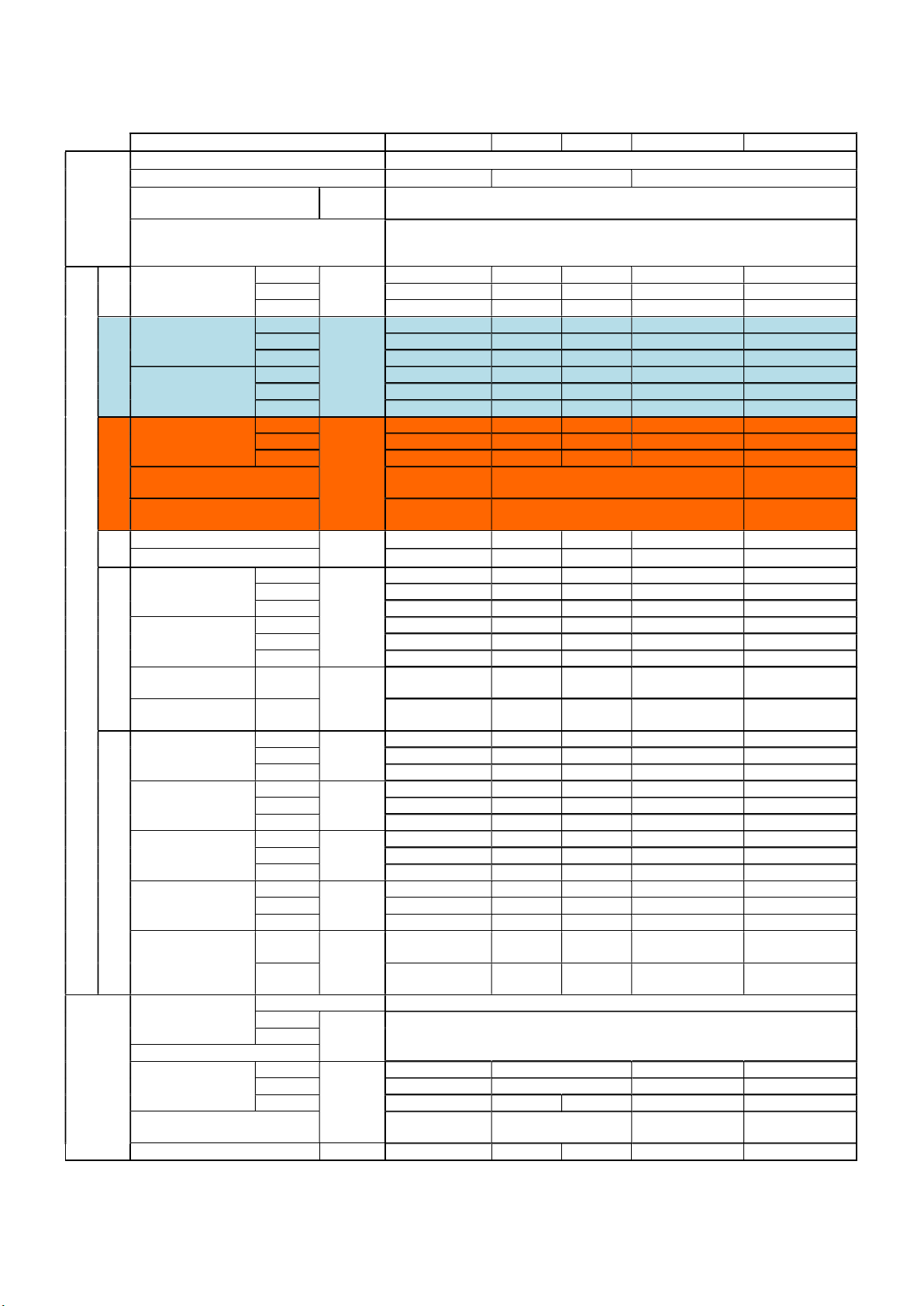

F. Control Specifications: Flexible Function PCB – NA-EC-W1 Control ............................................................................. 71

Features ...................................................................................................................................................................... 71

I/O Port Definitions ..................................................................................................................................................... 71

Onboard configuration ............................................................................................................................................... 71

Wiring Diagrams ......................................................................................................................................................... 72

Standard W Control PCB ...................................................................................................................................... 72

AECM-W1 unit with AC/EC thermostat wiring diagram ...................................................................................... 73

Control Logic Specification .......................................................................................................................................... 74

Unit Power ON/OFF ............................................................................................................................................. 74

Alarm Protection and Error Display ..................................................................................................................... 74

Drain-Pump Operation......................................................................................................................................... 74

Swing and Louver Control .................................................................................................................................... 74

Modulating Signal Input ...................................................................................................................................... 74

Electrical Heater Operation ................................................................................................................................. 74

Low Temperature Protection of Indoor Coil in Winter ........................................................................................ 74

LED Display and Error Description .............................................................................................................................. 75