ALLIED COMMERCIAL KGB092S4B Installation instructions

7.5 to 12.5 Tons

Net Cooling Capacity − 86,000 to 140,000 Btuh

Gas Input Heat Capacity − 130,000 to 240,000 Btuh

MODEL NUMBER IDENTIFICATION

ASHRAE 90.1

COMPLIANT

K G A 120 S 4 B S 1 Y

Brand/Family

K = K Series

Unit Type

G = Packaged Gas Heat w/ Electric Cooling

Major Design Sequence

A = 1st Generation

B = 2nd Generation

Nominal Cooling Capacity - Tons

092 = 7.5 Tons

102 = 8.5 Tons

120 = 10 Tons

150 = 12.5 Tons

Cooling Efciency

H = High Efciency

S = Standard Efciency

Refrigerant Type

4 = R-410A

Heating Type

S = Standard Gas Heat, 2 Stage

M = Medium Gas Heat, 2 Stage

H = High Gas Heat, 2 Stage

Minor Design Sequence

1 = 1st Revision

2 = 2nd Revision

3 = 3rd Revision

Voltage

Y = 208/230V-3 phase-60hz

G = 460V-3 phase-60hz

J = 575V-3 phase-60hz

Blower Type

B = Belt Drive, Constant Air Volume (CAV)

M = Single Zone VAV Supply Fan, Belt Drive

PACKAGED GAS ELECTRIC

Bulletin No. KGA/KGB-092-150 (10/2017)

KG

K-Series™ Rooftop Units

60 HZ

KG 7.5-12.5 TON ROOFTOP UNITS

PRODUCT SPECIFICATIONS

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 2

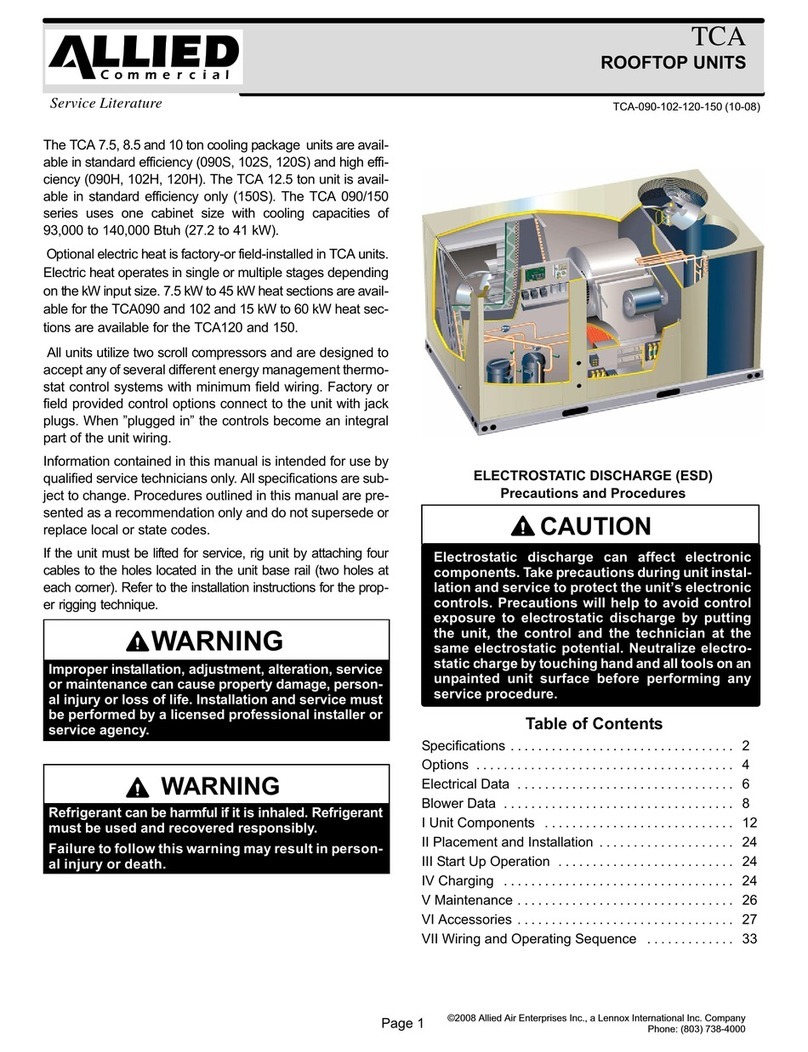

FEATURES AND BENEFITS

B

IJ

C

D

E

F

G

H

K

Unit shown with

optional

Economizer and

Outdoor Air Hoods

K-Series™ rooftop units from Allied are the new standard for reliable, efcient rooftop units built for long-lasting

performance that can signicantly improve indoor environments. K-Series™ rooftop units feature:

• Aluminized Steel Heat Exchanger With Inshot Burners - Life cycle tested.

• R-410A Refrigerant - Environmentally friendly.

• Scroll Compressors - Single speed scroll compressors are furnished on all models.

• Eco-Last™ Coil System (092-120 Models Only) - Smaller, lighter condenser coil.

• High Pressure Switches - Protect compressor.

• Isolated Compressor Compartment - Allows performance check during normal compressor operation without

disrupting airow.

• Independent Outdoor Fan Motor Mounts - Allows for easy and efcient service access without removing the top

panel.

• Constant Air Volume (CAV) or Single Zone VAV Supply Fan Blower Option - Allows constant or multi-staged

air delivery.

• Downow or Horizontal Airow - Easy eld conversion.

• Two Fork Lift Slots on Three Sides - Easy to pick up and transport units from almost any angle.

• Corrosion-Resistant Removable, Reversible Drain Pan - Provides application exibility, durability and improved

serviceability.

• Thermostatic Expansion Valves (High Efciency Models) - Provide peak cooling performance across the entire

application range.

• MERV 8 or MERV 13 Filters - Available as eld installed option, provide an enhanced level of indoor air quality, and

can help the building qualify for additional LEED credits.

• Common Components - Many maintenance items are standard throughout the entire product line, reducing the

need to carry different parts to the job or maintain in inventory.

L

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 3

FEATURES AND BENEFITS

APPROVALS

AHRI Certied to AHRI Standard

340/360-2007.

Units are ETL listed.

Units are certied by CSA.

Components bonded for grounding

to meet safety standards for

servicing required by UL, ULC and

National and Canadian Electrical

Codes.

All models are ASHRAE 90.1-2010

energy efciency compliant and

meet or exceed requirements of

Section 6.8.

Models equipped with the Single

Zone VAV Supply Fan option meet

California Code of Regulations,

Title 24 and ASHRAE 90.1-2010

Section 6.4.3.10 requirements for

staged airow.

ISO 9001 Registered

Manufacturing Quality System.

WARRANTY

Limited ten years aluminized

heat exchanger, limited fteen

years optional stainless steel heat

exchanger.

Limited ve years on compressors.

Limited three years on the

Eco-Last™ Coil System.

Limited ve years Optional High

Performance Economizers.

Limited one year all other covered

components.

A

HEATING SYSTEM

Aluminized steel inshot burners,

direct spark ignition, electronic

ame sensor, combustion air

inducer, redundant automatic dual

stage gas valve with manual shut-

off.

Heat Exchanger

Tubular construction, aluminized

steel, life cycle tested.

Optional Stainless Steel Heat

Exchanger is required if mixed air

temperature is below 45°F.

Electronic Pilot Ignition

Electronic spark igniter provides

positive direct ignition of burners

on each operating cycle. The

system permits main gas valve to

stay open only when the burners

are proven to be lit. Should a

loss of ame occur, the gas valve

closes, shutting off the gas to

the burners. Ignition module has

LED to indicate status and aid in

troubleshooting.

Watchguard circuit on module

automatically resets ignition

controls after one hour of

continuous thermostat demand

after unit lockout, eliminating

nuisance service calls.

Ignition control is factory installed

in the controls section.

B

Limit Control

Factory installed, limit control

with xed temperature setting.

Heat limit control protects heat

exchanger and other components

from overheating.

Safety Switches

Flame roll-out switch, ame sensor

and combustion air inducer proving

switch protect system operation.

Required Selections

Gas Input Choice - Order one:

Standard Gas Heat, 2 Stage

(84,500/130,000 Btuh)

Medium Gas Heat, 2 Stage

(117,000/180,000 Btuh)

High Gas Heat, 2 Stage

(156,000/240,000 Btuh)

Options/Accessories

Factory Installed

Stainless Steel Heat Exchanger

Required if mixed air temperature

is below 45°F.

Field Installed

Bottom Gas Piping Kit

Allows bottom gas entry.

Combustion Air Intake

Extensions

Recommended for use with

existing ue extension kits in areas

where high snow areas can block

intake air.

Low Temperature Vestibule

Heater

Electric heater automatically

controls minimum temperature in

gas burner compartment when

temperature is below -40°F. CSA

certied to allow operation of unit

down to -60°F.

LPG/Propane Kits

Conversion kit to eld change over

units from Natural Gas to LPG/

Propane.

CONTENTS

Blower Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Dimensions - Accessories - Inches . . . . . . . . . . . . . . . . . . . . .40

Dimensions - Unit - Inches . . . . . . . . . . . . . . . . . . . . . . . . .39

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Features And Benets . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model Number Identication . . . . . . . . . . . . . . . . . . . . . . . . 1

Options / Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Outdoor Sound Data . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Specications - Gas Heat . . . . . . . . . . . . . . . . . . . . . . . . . .17

Unit Clearances - Inches . . . . . . . . . . . . . . . . . . . . . . . . . .36

Weight Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 4

Filter/Driers

High capacity lter/drier protects

the system from dirt and moisture.

High Pressure Switches

Protects the compressor from

overload conditions such as

dirty condenser coils, blocked

refrigerant ow, or loss of outdoor

fan operation. Auto reset.

Freezestats

Protects the evaporator coil from

damaging ice build-up due to

conditions such as low/no airow,

or low refrigerant charge.

Eco-Last™ Coil System (092

through 120

models

only)

Condenser

coil features

lightweight,

all aluminum

brazed n

construction.

Constructed

of three

components:

a at extrusion tube, ns in-

between the at extrusion tube and

two refrigerant manifolds.

Eco-Last™ Coil System Features:

• Improved heat transfer

performance due to high

primary surface area (flat

tubes) versus secondary

surface (fins).

• Smaller internal volume

(reduced refrigerant charge).

• High durability (all aluminum

construction).

• Fewer brazed joints.

• Compact design (reduces unit

weight).

• Easy maintenance/cleaning.

Face-split design.

Mounting brackets with rubber

inserts secure coil to unit providing

vibration dampening and corrosion

protection.

Conventional Fin/Tube

Condenser Coils

(150 models only)

Copper tube construction,

enhanced rippled-edge aluminum

ns, ared shoulder tubing

D

HEATING SYSTEM

(continued)

Options/Accessories

Field Installed

Vertical Vent Extension Kit

Use to exhaust ue gases

vertically above unit. Required

when unit vent is too close to fresh

air intakes per building codes. The

vent kit also prevents ice formation

on intake louvers.

Kit contains vent transition, vent

tee, drain cap and installation

hardware.

NOTE - Straight vent pipes (4 in.

B-Vent) and caps are not furnished

and must be eld supplied. Refer

to kit instructions for additional

information.

COOLING SYSTEM

Designed to maximize sensible

and latent cooling performance at

design conditions.

System can operate from 30°F

to 125°F without any additional

controls.

R-410A RefrigerantNon-chlorine

based, ozone friendly, R-410A.

Scroll Compressors

Scroll compressors on all models

for high performance, reliability and

quiet operation.

Resiliently mounted on rubber

grommets for quiet operation.

Compressor Crankcase Heaters

Protects against refrigerant

migration that can occur during low

ambient operation.

Thermal Expansion Valves

(High Efciency Models)

Assures optimal performance

throughout the application range.

Removable element head.

Refrigerant Metering Orice

(Standard Efciency Models)

Accurately meters refrigerant in

system.

Refrigerant control is accomplished

by exact sizing of refrigerant

metering orice.

C

connections, silver soldered

construction.

Evaporator Coil

Copper tube construction, enhanced

rippled-edge aluminum ns, ared

shoulder tubing connections, silver

soldered construction for improved

heat transfer.

Cross row circuiting with ried

copper tubing optimizes both

sensible and latent cooling

capacity.

Condensate Drain Pan

Plastic pan, sloped to meet

drainage requirements of ASHRAE

62.1.

Side or bottom drain connections.

Reversible to allow connection at

back of unit.

Outdoor Coil Fan Motors

Thermal overload protected, totally

enclosed, permanently lubricated

ball bearings, shaft up, wire basket

mount.

Outdoor Coil Fans

PVC coated fan guard furnished.

Required Selections

Cooling Capacity

Specify nominal cooling capacity of

the unit

Cooling Efciency

Specify either standard or high

efciency.

Options/Accessories

Field Installed

Condensate Drain Trap

Available in copper or PVC.

Drain Pan Overow Switch

Monitors condensate level in

drain pan, shuts down unit if drain

becomes clogged.

Low Ambient Kit

Cycles the outdoor fans while

allowing compressor operation in

the cooling cycle. This intermittent

fan operation allows the system

to operate without icing the

evaporator coil and losing capacity.

Designed for use in ambient

temperatures no lower than 0°F.

E

FEATURES AND BENEFITS

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 5

CONTROLS

Unit Control

All control voltage is provided via a

24V (secondary) transformer with

built-in circuit breaker protection.

Heat/Cool Staging - Capable of

up to 2 heat / 2 cool staging with a

third party DDC control system or

thermostat.

Low Voltage Terminal Block -

Provides screw terminal

connections for thermostat or

controller wiring.

Night Setback Mode - Saves

energy by closing outdoor air

dampers and operating supply fan

on thermostat demand only.

Options/Accessories

Field Installed

Smoke Detector

Photoelectric type, installed in

supply air section, return air

section or both sections. Available

with power board and single

sensor (supply or return) or power

board and two sensors (supply and

return).

F

CABINET

Construction

Heavy-gauge steel panels and full

perimeter heavy-gauge galvanized

steel base rail provides structural

integrity for transportation,

handling, and installation.

Base rails have rigging holes.

Three sides of the base rail have

forklift slots.

Raised edges around duct and

power entry openings in the bottom

of the unit provide additional

protection against water entering

the building.

Airow Choice

Units are shipped in downow

(vertical) conguration, can be eld

converted to horizontal airow with

optional Horizontal Discharge Kit.

Duct Flanges

Provided for horizontal duct

attachment.

Power/Gas Entry

Electrical and gas lines can be

brought through the unit base or

through horizontal access knock-

outs.

Exterior Panels

Constructed of heavy-gauge,

galvanized steel with a two-layer

enamel paint nish.

Insulation

All panels adjacent to conditioned

air are fully insulated with non-

hygroscopic berglass insulation.

Unit base is fully insulated. The

insulation also serves as an air

seal to the roof curb, eliminating

the need to add a seal during

installation.

Access Panels

Access panels are provided for

the lter section, heating/blower

section, and the compressor/

controls section.

G

Options/Accessories

Factory Installed

Corrosion Protection

A completely exible immersed

coating with an electrodeposited

dry lm process. (AST ElectroFin

E-Coat) Meets Mil Spec

MIL-P-53084, ASTM B117

Standard Method Salt Spray

Testing.

Indoor Corrosion Protection:

- Coated coil

- Painted blower housing

- Painted base

Outdoor Corrosion Protection:

- Coated coil

- Painted base

Hinged Access Panels

Large access panels are hinged

and have quarter-turn latches

for quick and easy access

to maintenance areas (lter,

compressor / controls, heating /

blower).

Field Installed

Combination Coil/Hail Guards

Heavy gauge steel frame painted

to match cabinet with expanded

metal mesh to protect the outdoor

coil from damage.

Horizontal Discharge Kit

Consists of duct covers to block

off downow supply and return

air openings for horizontal

applications.

Also includes return air duct

anges for end return air when

economizer is used in horizontal

applications.

NOTE - When conguring unit

for horizontal application with

economizer, a separate Horizontal

Barometric Relief Damper with

Hood must be ordered separately

for installation in the return air duct.

FEATURES AND BENEFITS

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 6

FEATURES AND BENEFITS

BLOWER

A wide selection of supply air

blower options are available to meet

a variety of airow requirements.

Motor

Overload protected, equipped with

ball bearings. Belt drive motors

are offered on all models and are

available in several different sizes

to maximize air performance.

Supply Air Blower

Forward curved blades, double

inlet, blower wheel is statically and

dynamically balanced. Equipped

with ball bearings and adjustable

pulley (allows speed change),.

Blower assembly slides out of unit

for servicing.

Required Selections

Select Constant Air Volume

(CAV) or Single Zone VAV

Supply Fan Supply Air Blower

Option

Order blower motor horsepower

and drive kit number required

when base unit is ordered, see

Drive Kit Specications Table.

CAV Operation

On units ordered with the Constant

Air volume (CAV) option, the

supply air blower will provide a

constant volume of air.

Single Zone VAV Supply Fan

Operation

Units ordered with the Single Zone

VAV Supply Fan option utilize a

Variable Frequency Drive (VFD) to

stage the supply air blower airow.

The VFD alters the frequency and

voltage of the power supply to the

blower to control blower speed.

The supply air blower has two

speeds:

1. Low speed for part-load

cooling operation. Note - Low

speed is 66% of high speed.

2. High speed for full load

cooling and all heat modes.

Full speed blower operation is

set by adjusting the motor pulley

to deliver the desired air volume.

The ventilation speed is selectable

between high and low speed.

HNOTE - Part load airow in cooling

mode on Single Zone VAV Supply

Fan units should not be set below

220 cfm/nominal full load ton to

reduce the risk of evaporator coil

freeze-up.

The VFD has an operational

range of -40 to 125° F outdoor air

ambient temperature.

Lower operating costs are obtained

when the blower is operated on

lower speeds.

Single Zone VAV Supply Fan

Sequence of Operation

Ventilation speed is determined by

the VENT SPEED switch setting

on VFD control board (LO or HI).

Blower operates in low speed for

mechanical cooling (Y1).

Blower operates in high speed

for any other mode (free cooling,

mechanical cooling Y1+Y2, and

heating).

Economizer damper minimum

position is fully closed in

unoccupied mode.

In occupied mode, the economizer

damper minimum position is

determined by the setting of the

two potentiometers on VFD control

board.

• LO SPD MIN POS

potentiometer sets the

minimum position when blower

is operating at low speed.

• HI SPD MIN POS

potentiometer sets the

minimum position when blower

is operating at high speed.

Options/Accessories

Field Installed

VFD Manual Bypass Kit

VFD Manual Bypass Control is

available as a kit for units equipped

with the Single Zone VAV Supply

Fan option.

The VFD Manual Bypass Control

is a manual bypass and is enabled

by re-conguring the wiring on the

unit.

ELECTRICAL

Marked & Color-Coded Wiring

All electrical wiring is color-coded

and marked to identify which

components it is connecting.

Electrical Plugs

Positive connection electrical plugs

are used to connect common

accessories or maintenance parts

for easy removal or installation.

Phase Monitor

(Factory Installed on Units

Equipped with the Single Zone

VAV Supply Fan)

Phase monitor located in the

control compartment detects the

phasing of incoming power. If the

incoming power is out of phase or

if any of the three phases are lost,

an indicator LED on the phase

monitor will turn red and the unit

will not start. In normal operation

with correct incoming power

phasing, the LED will be green.

Required Selections

Voltage Choice

Specify when ordering base unit.

Options/Accessories

Factory or Field Installed

Disconnect Switch

Accessible from outside of unit,

spring loaded weatherproof cover

furnished. Main power to the unit is

eld connected to the disconnect

which allows all power to be

shut off for service. See Options/

Accessories tables for ordering

information, page 10.

GFI Service Outlets (2)

115V ground fault circuit interrupter

(GFCI) type, non-powered, eld-

wired.

Field Installed

GFI Weatherproof Cover

Single-gang cover.

Heavy-duty UV-resistant

polycarbonate case construction.

Hinged base cover with gasket.

I

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 7

FEATURES AND BENEFITS

INDOOR AIR QUALITY

Air Filters

Disposable 2 inch lters furnished

as standard.

Options/Accessories

Field Installed

High Efciency Air Filters

Disposable MERV 8 or MERV 13

(Minimum Efciency Reporting

Value based on ASHRAE 52.2)

efciency 2 inch pleated lters.

Replacement Filter Media Kit

With Frame

Replaces existing pleated lter

media. Includes washable metal

mesh screen and metal frame with

clip for holding replaceable non-

pleated lter.

J

UVC Germicidal Lamps

Germicidal lamps emit ultra-violet

(UV-C) energy, which has been

proven to be effective in reducing

microbes such as viruses, bacteria,

yeasts, and molds. This process

either destroys the organism or

controls its ability to reproduce.

UV-C energy greatly reduces the

growth and proliferation of mold

and other bioaerosols (bacteria

and viruses) on illuminated

surfaces (particularly coil and drain

pan).

Lamps are eld installed in the

blower/evaporator coil section.

All necessary hardware for

installation is included.

Lamps operate on 208/230V power

supply. Step-down transformer

must be eld supplied when used

with 460V and 575V rooftop units.

Magnetic safety interlock

terminates power when access

panels are removed.

Approved by ETL.

Indoor Air Quality (CO2) Sensors

Monitors CO2levels, reports to

the Unit Controller which adjusts

economizer dampers as needed.

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 8

ECONOMIZER OPTIONS

Factory or Field Installed

Economizer

(Standard and High Performance

Common Features)

Downow or Horizontal with

Outdoor Air Hood and Barometric

Relief Dampers with Exhaust

Hood.

Barometric Relief Dampers allow

relief of excess air, aluminum blade

dampers prevent blow back and

outdoor air inltration during off

cycle, bird screen furnished.

NOTE - Optional Horizontal Low

Prole Barometric Relief Dampers

with Exhaust Hood are available

for eld installation in a reduced

space.

Occupied/Unoccupied mode with

eld furnished setback thermostat.

Demand Control Ventilation (DCV)

ready using optional CO2sensors.

Mixed Air Sensor is furnished for

eld installation in the rooftop unit.

Sensor is factory installed when

Economizers are factory installed.

Single sensible sensor is furnished

with Economizer and enables

economizer operation if the

outdoor temperature is less than

the setpoint of the control.

Standard Economizer Features

(Not for Title 24)

Gear-driven action, return air

and outdoor air dampers, plug-

in connections to unit, nylon

bearings, neoprene seals, 24-volt,

fully-modulating spring return

motor.

Standard Economizer

Control Module

The Standard

Economizer

Control Module

can be adjusted

to operate based

on outdoor air

temperatures.

K

L

Economizer Controls:

• Damper Minimum Position

- Can be set lower than

traditional minimum air

requirements resulting in cost

savings.

• IAQ Sensor - Signals

dampers to modulate and

maintain 55°F when CO2is

higher than the CO2setpoint.

• Demand Control Ventilation

(DCV) LED - A steady green

Demand Control Ventilation

LED indicates the IAQ reading

is higher than setpoint and

requires more fresh air.

• Free Cool LED - A steady

green LED indicates outdoor

air is suitable for free cooling.

Free Cooling runs when outdoor

air temperature is lower than

the set temperature on the

economizer control.

NOTE: The Free Cooling

default setting for outdoor air

temperature sensor is 55°F.

High Performance

Economizer Features

Approved for California Title 24

building standards.

Low leakage dampers are Air

Movement and Control Association

International (AMCA) Class 1A

Certied - Maximum 3 CFM per sq.

ft. leakage at 1 in. w.g.

ASHRAE 90.1-2010 compliant

Gear-driven action, high torque

24-volt fully-modulating spring

return damper motor, return air

and outdoor air dampers, plug-in

connections to unit, stainless steel

bearings, enhanced neoprene

blade edge seals and exible

stainless steel jamb seals to

minimize air leakage.

NOTE - High Performance

Economizers are not approved for

use with enthalpy controls in Title

24 applications.

High Performance

Economizer Control Module

Module

provides inputs

and outputs

to control

economizer

based on

parameter settings. Module

automatically detects sensors by

polling to determine which sensors

are installed in system.

Module displays any alarm messages

(fault detection and diagnostics) as

an aid in troubleshooting.

Non-volatile memory retains

parameter settings in case of

power failure.

Keypad with four navigation

buttons and LCD screen is

furnished for setting economizer

parameters.

• Menu Up/Exit button

returns to the main menu.

• Arrow Up button moves

to the previous or next

parameter within the selected

menu.

• Arrow Down button moves

to the next parameter within

the selected menu.

• Select (enter) button

conrms parameter selection.

Main Menu Structure:

• STATUS (economizer and

system operation status)

• SETPOINTS (settings for

various setpoint parameters)

• SYSTEM SETUP (settings/

information about the system)

• ADVANCED SETUP (freeze

protection, CO2settings,

stage 3 delay and additional

calibration settings)

• CHECKOUT (damper

positions)

• ALARMS (output signal that

can be congured for remote

alarm monitoring)

OPTIONS / ACCESSORIES

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 9

OPTIONS / ACCESSORIES

ROOF CURBS

Nailer strip furnished, mates to unit,

US National Roong Contractors

Approved, shipped knocked down.

Hybrid Roof Curbs, Downow

Roof curb can be assembled using

interlocking tabs to fasten corners

together. No tools required.

Curb can also be fastened together

with furnished hardware.

Available in 8, 14, 18, and 24 inch

heights.

Adjustable Pitch Curb

Fully adjustable pitch curbs (3/4 in.

per foot in any direction) provide

a level platform for rooftop units

allowing exible installations on

roofs with uneven or sloped angles.

Uses interlocking tabs to fasten

corners together. No tools required.

Hardware is furnished to connect

upper curb with lower curb.

Available in 14 inch height

Adaptor Curbs (not shown)

Curbs are regionally sourced.

Dimensions will vary based

upon the source. Contact your

local sales representative for a

detailed cut sheet with applicable

dimensions.

CEILING DIFFUSERS

Ceiling Diffusers

(Flush or Step-Down)

Diffuser face and grilles with white

powder coat nish, insulated (UL

listed duct liner), diffuser box

with collars for duct connection,

xed blades (ush diffusers) and

double deection blades (step-

down diffusers), provisions for

suspending, internally sealed

(prevents recirculation), removable

return air grille, adapts to T-bar

ceiling grids or plaster ceilings.

Transitions (Supply and Return)

Used with diffusers, installs

in roof curb, galvanized steel

construction, anges furnished for

duct connection to diffusers, fully

insulated.

ECONOMIZER OPTIONS

(continued)

NOTE - The Free Cooling

setpoint for Title 24 applications

must be set based on the

Climate Zone where the system

is installed. See Section 140.4

“Prescriptive Requirements for

Space Conditioning Systems”

of the California Energy

Commission’s 2013 Building

Energy Efciency Standards.

Refer to Installation Instructions

for complete setup information

and menu parameters available.

Factory or Field Installed

Single Enthalpy Temperature

Control

(Not for Title 24)

Outdoor air enthalpy sensor

enables Economizer if the outdoor

enthalpy is less than the setpoint of

the control.

Field Installed

Differential Enthalpy Control

(Not for Title 24)

Order two Single Enthalpy

Controls. One is eld installed in

the return air section, the other in

the outdoor air section. Allows the

economizer control board to select

between outdoor air or return air,

whichever has lower enthalpy.

EXHAUST OPTIONS

Field Installed

Horizontal Low Prole

Barometric Relief Dampers

Replaces barometric relief

dampers furnished with

Economizer.

For use when unit is congured for

horizontal applications in a reduced

space requiring an economizer.

Allows relief of excess air.

Aluminum blade dampers prevent

blow back and outdoor air

inltration during off cycle.

Field installed in return air duct.

Exhaust hood with bird screen

furnished.

Requires Horizontal Discharge Kit.

Power Exhaust Fan

Installs internal to unit for downow

applications only with economizer

option. Provides exhaust air

pressure relief. Interlocked to

run when supply air blower is

operating, fan runs when outdoor

air dampers are 50% open

(adjustable), motor is overload

protected. Requires Economizer

with Outdoor Air Hood and

Barometric Relief Dampers. Fan

is 20 in. diameter with 5 blades

(K1PWRE10B) WITH 1/3 hp motor.

OUTDOOR AIR OPTIONS

Factory or Field Installed

Outdoor Air Damper - Downow

or Horizontal With Air Hood

Linked mechanical dampers, 0 to

25% (xed) outdoor air adjustable,

installs in unit. Includes outdoor air

hood.

Automatic model features fully

modulating spring return damper

motor with plug-in connection.

Manual model features a slide

damper.

Maximum mixed air temperature in

cooling mode: 100°F.

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 10

OPTIONS / ACCESSORIES

Item Description Model

Number

Catalog

Number

Unit Model No

092 102 120 150

COOLING SYSTEM

Condensate Drain Trap PVC - C1TRAP20AD2 76W26 X X X X

Copper - C1TRAP10AD2 76W27 X X X X

Corrosion Protection Factory O O O O

Drain Pan Overow Switch K1SNSR71AB1- 74W42 X X X X

Efciency High O O O O

Standard O O O O

Low Ambient Kit K1SNSR33B-1 54W16 X X X X

Refrigerant Type R-410A O O O O

HEATING SYSTEM

Bottom Gas Piping Kit C1GPKT01B-01 54W95 X X X X

Combustion Air Intake Extensions T1EXTN10AN1 19W51 X X X X

Gas Heat Input 130,000 Btuh Factory O O O O

180,000 Btuh Factory O O O O

240,000 Btuh Factory O O O O

Low Temperature Vestibule Heater 208/230V-3ph - C1LTVH10B-2Y 13X63 X X X X

460V - C1LTVH10B-2G 13X64 X X X X

575V - C1LTVH10B-2J 13X65 X X X X

LPG/Propane Conversion Kits Standard Heat - C1PROP23BS1 14N22 X X X X

Medium Heat - C1PROP22BS1 14N23 X X X X

High Heat - C1PROP21BS1 14N25 X X X X

Stainless Steel Heat Exchanger Factory O O O O

Vertical Vent Extension C1EXTN2021 42W16 X X X X

BLOWER - SUPPLY AIR

Blower Option CAV (Constant Air Volume) Factory O O O O

Single Zone VAV Supply Fan Factory O O O O

Blower Motors Belt Drive - 2 hp Factory O O O O

Belt Drive - 3 hp Factory O O O O

Belt Drive - 5 hp Factory O O O O

VFD Manual Bypass Kit (for Single Zone VAV Supply Fan equipped units

only) KVFDB12C-1 90W53 X X X X

Drive Kits

See Blower Data Tables for selection

Kit #1 590-890 rpm Factory O O O O

Kit #2 800-1105 rpm Factory O O O O

Kit #3 795-1195 rpm Factory O O O O

Kit #4 730-970 rpm Factory O O O O

Kit #5 940-1200 rpm Factory O O O O

Kit #6 1015-1300 rpm Factory O O O O

Kit #10 900-1135 rpm Factory O O O O

Kit #11 1040-1315 rpm Factory O O O O

Kit #12 1125-1425 rpm Factory O O O O

CABINET

Combination Coil/Hail Guards C1GARD52B-1 13T05 X X X X

Hinged Access Panels Factory O O O O

Horizontal Discharge Kit K1HECK00B-1 51W25 X X X X

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 11

OPTIONS / ACCESSORIES

Item Description Model

Number

Catalog

Number

Unit Model No

092 102 120 150

CONTROLS

Commercial Controls

BACnet®K0CTRL31B-1 96W15 OX OX OX OX

BACnet® Sensor with Display K0SNSR01FF1 97W23 X X X X

BACnet® Sensor without Display K0SNSR00FF1 97W24 X X X X

Novar® 2051 K0CTRL30B-1 96W12 OX OX OX OX

Plenum Cable (75 ft.) K0MISC00FF1 97W25 X X X X

Smoke Detector - Supply or Return (Power board and one sensor) C1SNSR44B-2 11K76 X X X X

Smoke Detector - Supply and Return (Power board and two sensors) C1SNSR43B-2 11K80 X X X X

INDOOR AIR QUALITY

Air Filters

High Efciency Air Filters

20 x 25 x 2 (Order 4 per unit)

MERV 8 - C1FLTR15B-1 50W61 X X X X

MERV 13 - C1FLTR40B-1 52W41 X X X X

Replacement Media Filter With Metal Mesh Frame

(includes non-pleated lter media)

C1FLTR30B-1- Y3063 X X X X

Indoor Air Quality (CO2) Sensors

Sensor - Wall-mount, off-white plastic cover with LCD display C0SNSR50AE1L 77N39 X X X X

Sensor - Wall-mount, off-white plastic cover, no display C0SNSR52AE1L 87N53 X X X X

Sensor - Black plastic case with LCD display, rated for

plenum mounting

C0SNSR51AE1L 87N52 X X X X

Sensor - Wall-mount, black plastic case, no display, rated for

plenum mounting

C0MISC19AE1 87N54 X X X X

CO2 Sensor Duct Mounting Kit - for downow applications C0MISC19AE1- 85L43 X X X X

Aspiration Box - for duct mounting non-plenum rated CO2sensors

(87N53 or 77N39)C0MISC16AE1- 90N43 X X X X

UVC Germicidal Lamps

1UVC Light Kit (208/230v-1ph) C1UVCL10B-1 54W62 X X X X

ELECTRICAL

Voltage 60 hz 208/230V - 3 phase Factory O O O O

460V - 3 phase Factory O O O O

575V - 3 phase Factory O O O O

Disconnect Switch - See Electrical/Electric Heat tables for selection 80 amp - C1DISC080B-1 54W56 OX OX OX OX

150 amp - C1DISC150B-1 54W57 OX OX OX OX

GFI Service Outlets 15 amp non-powered, eld-wired (208/230V, 460V only) LTAGFIK10/15 74M70 OX OX OX OX

20 amp non-powered, eld-wired (575V only) C1GFCI20FF1 67E01 X X X X

Weatherproof Cover for GFI C1GFCI99FF1 10C89 X X X X

1 Lamps operate on 110-230V single-phase power supply. Step-down transformer may be ordered separately for 460V and 575V units. Alternately, 110V power supply

may be used to directly power the UVC ballast(s)

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 12

OPTIONS / ACCESSORIES

Item Description Model

Number

Catalog

Number

Unit Model No

092 102 120 150

ECONOMIZER

Standard Economizer (Not for Title 24)

Standard Economizer with Single Temperature Control

Downow or Horizontal Applications - Includes Barometric Relief

Dampers and Air Hoods

K1ECON20B-2 13U45 OX OX OX OX

Standard Economizer Controls (Not for Title 24)

Single Enthalpy Control C1SNSR64FF1 53W64 OX OX OX OX

Differential Enthalpy Control (order 2) C1SNSR64FF1 53W64 X X X X

High Performance Economizer (Approved for California Title 24 Building Standards / AMCA Class 1A Certied)

High Performance Economizer with Single Temperature Control

Downow or Horizontal Applications - Includes Barometric Relief

Dampers and Air Hoods

K1ECON22B-1 10U58 OX OX OX OX

High Performance Economizer Controls (Not for Title 24)

Single Enthalpy Control C1SNSR60FF1 10Z75 OX OX OX OX

Differential Enthalpy Control (order 2) C1SNSR60FF1 10Z75 X X X X

Horizontal Low Prole Barometric Relief Dampers With Exhaust Hood

Horizontal Low Prole Barometric Relief Dampers With Exhaust Hood LAGEDH03/15 53K04 X X X X

OUTDOOR AIR

Outdoor Air Dampers With Outdoor Air Hood

Motorized C1DAMP20B-1 14G28 OX OX OX OX

Manual C1DAMP10B-1 14G29 OX OX OX OX

POWER EXHAUST

Standard Static 208/230V-3ph - K1PWRE10B-1Y 53W44 X X X X

460V-3ph - K1PWRE10B-1G 53W45 X X X X

575V-3ph - K1PWRE10B-1J 53W46 X X X X

ROOF CURBS

Hybrid Roof Curbs, Downow

8 in. height C1CURB70B-1 11F54 X X X X

14 in. height C1CURB71B-1 11F55 X X X X

18 in. height C1CURB72B-1 11F56 X X X X

24 in. height C1CURB73B-1 11F57 X X X X

Adjustable Pitch Curb

14 in. height C1CURB55B-1 54W50 X X X X

CEILING DIFFUSERS

Step-Down - Order one RTD11-95S 13K61 X

RTD11-135S 13K62 X X

RTD11-185S 13K63 X

Flush - Order one FD11-95S 13K56 X

FD11-135S 13K57 X X

FD11-185S 13K58 X

Transitions (Supply and Return) - Order one C1DIFF30B-1 12X65 X

C1DIFF31B-1 12X66 X X

C1DIFF32B-1 12X67 X

NOTE - Catalog and model numbers shown are for ordering eld installed accessories.

OX - Congure To Order (Factory Installed) or Field Installed

O = Congure To Order (Factory Installed)

X = Field Installed

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 13

SPECIFICATIONS 7.5 TON

General Data Nominal Tonnage 7.5 Ton 7.5 Ton 7.5 Ton 7.5 Ton

Model Number KGB092S4B KGA092S4M KGA092H4B KGA092H4M

Efciency Type Standard Standard High High

Blower Type Constant Air

Volume (CAV)

Single Zone VAV

Supply Fan

Constant Air

Volume (CAV)

Single Zone VAV

Supply Fan

Cooling

Performance

Gross Cooling Capacity - Btuh 87,800 88,200 93,000 93,000

1 Net Cooling Capacity - Btuh 86,000 86,000 90,000 90,000

AHRI Rated Air Flow - cfm 2400 3000 3000 2800

Total Unit Power - kW 7.8 7.8 7.2 7.2

1EER (Btuh/Watt) 11.0 11.0 12.5 12.5

1IEER (Btuh/Watt) 12.7 13.0 13.0 14.0

Refrigerant Type R-410A R-410A R-410A R-410A

Refrigerant Charge Furnished Circuit 1 4 lbs. 0 oz. 4 lbs. 0 oz. 6 lbs. 13 oz. 6 lbs. 13 oz.

Circuit 2 3 lbs. 6 oz. 3 lbs. 6 oz. 7 lbs. 2 oz. 7 lbs. 2 oz.

Gas Heating Options Available - See page 17 Standard (2 stage), Medium (2 Stage), High (2 Stage)

Compressor Type (number) Scroll (2) Scroll (2) Scroll (2) Scroll (2)

Outdoor

Coils

(Fin/Tube)

Net face area (total) - sq. ft. 20.9 20.9 28.0 28.0

Number of rows 1 1 1 1

Fins per inch 23 23 20 20

Outdoor

Coil Fans

Motor - (No.) hp (2) 1/3 (2) 1/3 (2) 1/3 (2) 1/3

Motor rpm 1075 1075 1075 1075

Total Motor watts 740 740 800 800

Diameter - (No.) in. (2) 24 (2) 24 (2) 24 (2) 24

Number of blades 3 3 3 3

Total Air volume - cfm 8800 8800 8800 8800

Indoor

Coils

Net face area (total) - sq. ft. 12.78 12.78 12.78 12.78

Tube diameter - in. 3/8 3/8 3/8 3/8

Number of rows 2 2 4 4

Fins per inch 14 14 14 14

Drain connection - Number and size (2) 1 in. NPT coupling

Expansion device type Refrigerant Metering Orice (RFC) Balance port TXV, removable head

2Indoor

Blower and

Drive

Selection

Nominal motor output 2 hp, 3 hp, 5 hp

Maximum usable motor output

(US Only)

2.3 hp, 3.45 hp, 5.75 hp

Motor - Drive kit number 2 hp

Kit 1 590-890 rpm

Kit 2 800-1105 rpm

Kit 3 795-1195 rpm

3 hp

Kit 4 730-970 rpm

Kit 5 940-1200 rpm

Kit 6 1015-1300 rpm

5 hp

Kit 10 900-1135 rpm

Kit 11 1040-1315 rpm

Kit 12 1125-1425 rpm

Blower wheel nominal diameter x width - in. (1) 15 X 15 (1) 15 X 15 (1) 15 X 15 (1) 15 X 15

Filters Type of lter Disposable

Number and size - in. (4) 20 x 25 x 2

Electrical characteristics 208/230V, 460V or 575V - 60 hertz - 3 phase

NOTE - Net capacity includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

1 AHRI Certied to AHRI Standard 340/360; 95°F outdoor air temperature and 80°F db/67°F wb entering evaporator air; minimum external duct static pressure.

2 Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable output of

motors furnished are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep within

the service factor limitations outlined on the motor nameplate.

NOTE – Units equipped with Single Zone VAV Supply Fan option are limited to a motor service factor of 1.0.

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 14

SPECIFICATIONS 8.5 TON

General Data Nominal Tonnage 8.5 Ton 8.5 Ton 8.5 Ton 8.5 Ton

Model Number KGB102S4B KGA102S4M KGA102H4B KGA102H4M

Efciency Type Standard Standard High High

Blower Type Constant Air

Volume (CAV)

Single Zone VAV

Supply Fan

Constant Air

Volume (CAV)

Single Zone VAV

Supply Fan

Cooling

Performance

Gross Cooling Capacity - Btuh 99,600 99,600 103,800 103,800

1 Net Cooling Capacity - Btuh 97,000 97,000 100,000 100,000

AHRI Rated Air Flow - cfm 2800 3400 3400 3400

Total Unit Power - kW 8.8 8.8 8.2 8.2

1EER (Btuh/Watt) 11.0 11.0 12.2 12.2

1IEER (Btuh/Watt) 12.7 13.0 12.9 14.0

Refrigerant Type R-410A R-410A R-410A R-410A

Refrigerant Charge Furnished Circuit 1 4 lbs. 5 oz. 3 lbs. 12 oz. 6 lbs. 8 oz. 6 lbs. 8 oz.

Circuit 2 4 lbs. 3 oz. 3 lbs. 12 oz. 6 lbs. 15 oz. 6 lbs. 15 oz.

Gas Heating Options Available - See page 17 Standard (2 stage), Medium (2 Stage), High (2 Stage)

Compressor Type (number) Scroll (2) Scroll (2) Scroll (2) Scroll (2)

Outdoor

Coils

(Fin/Tube)

Net face area (total) - sq. ft. 20.9 20.9 28.0 28.0

Number of rows 1 1 1 1

Fins per inch 23 23 20 20

Outdoor

Coil Fans

Motor - (No.) hp (2) 1/3 (2) 1/3 (2) 1/3 (2) 1/3

Motor rpm 1075 1075 1075 1075

Total Motor watts 740 740 800 800

Diameter - (No.) in. (2) 24 (2) 24 (2) 24 (2) 24

Number of blades 3 3 3 3

Total Air volume - cfm 8800 8800 8800 8800

Indoor

Coils

Net face area (total) - sq. ft. 12.78 12.78 12.78 12.78

Tube diameter - in. 3/8 3/8 3/8 3/8

Number of rows 3 3 4 4

Fins per inch 14 14 14 14

Drain connection - Number and size (2) 1 in. NPT coupling

Expansion device type Refrigerant Metering Orice (RFC) Balance port TXV, removable head

2Indoor

Blower and

Drive

Selection

Nominal motor output 2 hp, 3 hp, 5 hp

Maximum usable motor output

(US Only)

2.3 hp, 3.45 hp, 5.75 hp

Motor - Drive kit number 2 hp

Kit 1 590-890 rpm

Kit 2 800-1105 rpm

Kit 3 795-1195 rpm

3 hp

Kit 4 730-970 rpm

Kit 5 940-1200 rpm

Kit 6 1015-1300 rpm

5 hp

Kit 10 900-1135 rpm

Kit 11 1040-1315 rpm

Kit 12 1125-1425 rpm

Blower wheel nominal diameter x width - in. (1) 15 X 15 (1) 15 X 15 (1) 15 X 15 (1) 15 X 15

Filters Type of lter Disposable

Number and size - in. (4) 20 x 25 x 2

Electrical characteristics 208/230V, 460V or 575V - 60 hertz - 3 phase

NOTE - Net capacity includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

1 AHRI Certied to AHRI Standard 340/360; 95°F outdoor air temperature and 80°F db/67°F wb entering evaporator air; minimum external duct static pressure.

2 Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable output of

motors furnished are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep within

the service factor limitations outlined on the motor nameplate.

NOTE – Units equipped with Single Zone VAV Supply Fan option are limited to a motor service factor of 1.0.

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 15

SPECIFICATIONS 10 TON

General Data Nominal Tonnage 10 Ton 10 Ton 10 Ton 10 Ton

Model Number KGB120S4B KGA120S4M KGA120H4B KGA120H4M

Efciency Type Standard Standard High High

Blower Type Constant Air

Volume (CAV)

Single Zone VAV

Supply Fan

Constant Air

Volume (CAV)

Single Zone VAV

Supply Fan

Cooling

Performance

Gross Cooling Capacity - Btuh 118,000 118,400 122,000 122,000

1 Net Cooling Capacity - Btuh 115,000 115,000 118,000 118,000

AHRI Rated Air Flow - cfm 3000 3800 3600 3300

Total Unit Power - kW 10.5 10.5 9.8 9.8

1EER (Btuh/Watt) 11.0 11.0 12 12

1IEER (Btuh/Watt) 12.7 13.0 13 13.8

Refrigerant Type R-410A R-410A R-410A R-410A

Refrigerant Charge Furnished Circuit 1 5 lbs. 11 oz. 4 lbs. 12 oz. 7 lbs. 4 oz. 7 lbs. 4 oz.

Circuit 2 5 lbs. 6 oz. 4 lbs. 10 oz. 7 lbs. 8 oz. 7 lbs. 8 oz.

Gas Heating Options Available - See page 17 Standard (2 stage), Medium (2 Stage), High (2 Stage)

Compressor Type (number) Scroll (2) Scroll (2) Scroll (2) Scroll (2)

Outdoor

Coils

(Fin/Tube)

Net face area (total) - sq. ft. 28.0 28.0 28.0 28.0

Number of rows 1 1 1 1

Fins per inch 23 23 20 20

Outdoor

Coil Fans

Motor - (No.) hp (2) 1/3 (2) 1/3 (2) 1/3 (2) 1/3

Motor rpm 1075 1075 1075 1075

Total Motor watts 690 690 800 800

Diameter - (No.) in. (2) 24 (2) 24 (2) 24 (2) 24

Number of blades 3 3 3 3

Total Air volume - cfm 9300 9300 8800 8800

Indoor

Coils

Net face area (total) - sq. ft. 12.78 12.78 13.54 13.54

Tube diameter - in. 3/8 3/8 3/8 3/8

Number of rows 4 3 4 4

Fins per inch 14 14 14 14

Drain connection - Number and size (2) 1 in. NPT coupling

Expansion device type Refrigerant Metering Orice (RFC) Balance port TXV, removable head

2Indoor

Blower and

Drive

Selection

Nominal motor output 2 hp, 3 hp, 5 hp

Maximum usable motor output

(US Only)

2.3 hp, 3.45 hp, 5.75 hp

Motor - Drive kit number 2 hp

Kit 1 590-890 rpm

Kit 2 800-1105 rpm

Kit 3 795-1195 rpm

3 hp

Kit 4 730-970 rpm

Kit 5 940-1200 rpm

Kit 6 1015-1300 rpm

5 hp

Kit 10 900-1135 rpm

Kit 11 1040-1315 rpm

Kit 12 1125-1425 rpm

Blower wheel nominal diameter x width - in. (1) 15 X 15 (1) 15 X 15 (1) 15 X 15 (1) 15 X 15

Filters Type of lter Disposable

Number and size - in. (4) 20 x 25 x 2

Electrical characteristics 208/230V, 460V or 575V - 60 hertz - 3 phase

NOTE - Net capacity includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

1 AHRI Certied to AHRI Standard 340/360; 95°F outdoor air temperature and 80°F db/67°F wb entering evaporator air; minimum external duct static pressure.

2 Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable output of

motors furnished are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep within

the service factor limitations outlined on the motor nameplate.

NOTE – Units equipped with Single Zone VAV Supply Fan option are limited to a motor service factor of 1.0.

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 16

SPECIFICATIONS 12.5 TON

General Data Nominal Tonnage 12.5 Ton 12.5 Ton

Model Number KGB150S4B KGB150S4M

Efciency Type Standard Standard

Blower Type Constant Air

Volume (CAV)

Single Zone VAV

Supply Fan

Cooling

Performance

Gross Cooling Capacity - Btuh 146,000 146,000

1 Net Cooling Capacity - Btuh 140,000 140,000

AHRI Rated Air Flow - cfm 3950 3950

Total Unit Power - kW 13.0 13.0

1EER (Btuh/Watt) 10.8 10.8

1IEER (Btuh/Watt) 12.2 13.5

Refrigerant Type R-410A R-410A

Refrigerant Charge Furnished Circuit 1 12 lbs. 3 oz. 12 lbs. 3 oz.

Circuit 2 11 lbs. 15 oz. 11 lbs. 15 oz.

Gas Heating Options Available - See page 17 Standard (2 stage), Medium (2 Stage), High (2 Stage)

Compressor Type (number) Scroll (2) Scroll (2)

Outdoor

Coils

(Fin/Tube)

Net face area (total) - sq. ft. 25.9 25.9

Number of rows 3 3

Fins per inch 20 20

Outdoor

Coil Fans

Motor - (No.) hp (2) 1/2 (2) 1/2

Motor rpm 1075 1075

Total Motor watts 1050 1050

Diameter - (No.) in. (2) 24 (2) 24

Number of blades 3 3

Total Air volume - cfm 9700 9700

Indoor

Coils

Net face area (total) - sq. ft. 13.54 13.54

Tube diameter - in. 3/8 3/8

Number of rows 4 4

Fins per inch 14 14

Drain connection - Number and size (2) 1 in. NPT coupling

Expansion device type Refrigerant Metering Orice (RFC)

2Indoor

Blower and

Drive

Selection

Nominal motor output 2 hp, 3 hp, 5 hp

Maximum usable motor output

(US Only)

2.3 hp, 3.45 hp, 5.75 hp

Motor - Drive kit number 2 hp

Kit 1 590-890 rpm

Kit 2 800-1105 rpm

Kit 3 795-1195 rpm

3 hp

Kit 4 730-970 rpm

Kit 5 940-1200 rpm

Kit 6 1015-1300 rpm

5 hp

Kit 10 900-1135 rpm

Kit 11 1040-1315 rpm

Kit 12 1125-1425 rpm

Blower wheel nominal diameter x width - in. (1) 15 X 15 (1) 15 X 15

Filters Type of lter Disposable

Number and size - in. (4) 20 x 25 x 2

Electrical characteristics 208/230V, 460V or 575V - 60 hertz - 3 phase

NOTE - Net capacity includes evaporator blower motor heat deduction. Gross capacity does not include evaporator blower motor heat deduction.

1 AHRI Certied to AHRI Standard 340/360; 95°F outdoor air temperature and 80°F db/67°F wb entering evaporator air; minimum external duct static pressure.

2 Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable output of

motors furnished are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep within

the service factor limitations outlined on the motor nameplate.

NOTE – Units equipped with Single Zone VAV Supply Fan option are limited to a motor service factor of 1.0.

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 17

SPECIFICATIONS - GAS HEAT

Heat Input Type Standard Medium High

Number of Gas Heat Stages 2 2 2

Gas Heating

Performance

Input - Btuh First Stage 84,500 117,000 156,000

Second Stage 130,000 180,000 240,000

Output - Btuh Second Stage 104,000 144,000 192000

Temperature Rise Range - °F 15-45 30-60 40-70

Thermal Efciency 80% 80% 80%

Gas Supply Connections 3/4 in NPT 3/4 in NPT 3/4 in NPT

Recommended Gas Supply

Pressure - in. w.g.

Natural 7 7 7

LPG/Propane 11 11 11

HIGH ALTITUDE DERATE

Units may be installed at altitudes up to 2000 feet above sea level without any modication.

At altitudes above 2000 feet, units must be derated to match gas manifold pressures shown in table below.

At altitudes above 4500 feet unit must be derated 2% for each 1000 feet above sea level.

NOTE − This is the only permissible derate for these units.

Gas Heat

Type

Altitude Gas Manifold Pressure Input Rate

Natural Gas or LPG/Propane

Natural Gas LPG/Propane Gas First Stage Second Stage

ft. In. w.g. In. w.g. Btuh Btuh

Standard 2001-4500 3.4 9.6 84,500 124,000

Medium 2001-4500 3.4 9.6 117,000 172,000

High 2001-4500 3.4 9.6 156,000 230,000

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 18

RATINGS

NOTE − For Temperatures and Capacities not shown in tables, see bulletin − Cooling Unit Rating Table Correction Factor Data in Miscellaneous Engineering Data section.

7.5 TON STANDARD EFFICIENCY KGB092S4B (1ST STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

65°F 75°F 85°F 95°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

2400 63.6 2.73 0.66 0.77 0.90 60.9 3.06 0.66 0.78 0.91 57.8 3.43 0.67 0.80 0.93 54.5 3.86 0.68 0.82 0.96

3000 67.1 2.76 0.69 0.83 0.96 64.3 3.08 0.70 0.84 0.98 61.1 3.45 0.71 0.86 0.99 57.6 3.88 0.72 0.88 1.00

3600 70.2 2.78 0.72 0.88 1.00 67.1 3.10 0.73 0.89 1.00 63.7 3.47 0.74 0.91 1.00 60.0 3.90 0.76 0.94 1.00

67°F

2400 66.8 2.76 0.53 0.64 0.74 64.0 3.08 0.54 0.64 0.75 60.9 3.45 0.54 0.65 0.76 57.4 3.88 0.54 0.66 0.78

3000 70.7 2.79 0.55 0.67 0.79 67.5 3.10 0.56 0.67 0.81 64.1 3.47 0.56 0.68 0.82 60.5 3.91 0.56 0.70 0.85

3600 73.5 2.80 0.57 0.70 0.84 70.2 3.12 0.57 0.71 0.86 66.6 3.49 0.58 0.72 0.88 62.6 3.92 0.58 0.74 0.90

71°F

2400 69.7 2.78 0.42 0.52 0.61 66.8 3.10 0.42 0.52 0.62 63.6 3.47 0.41 0.52 0.63 60.1 3.90 0.40 0.53 0.64

3000 73.9 2.81 0.43 0.54 0.65 70.6 3.12 0.43 0.54 0.65 67.1 3.50 0.42 0.55 0.66 63.3 3.93 0.41 0.55 0.68

3600 77.0 2.83 0.44 0.56 0.68 73.5 3.14 0.44 0.56 0.69 69.6 3.51 0.41 0.57 0.70 65.6 3.95 0.42 0.57 0.72

7.5 TON STANDARD EFFICIENCY KGB092S4B (2ND STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

85°F 95°F 105°F 115°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

2400 86.0 5.76 0.68 0.82 0.96 80.6 6.50 0.69 0.84 0.98 74.8 7.36 0.71 0.87 1.00 68.6 8.33 0.73 0.90 1.00

3000 90.8 5.80 0.73 0.89 1.00 85.0 6.54 0.74 0.92 1.00 78.8 7.40 0.76 0.95 1.00 72.2 8.38 0.79 0.98 1.00

3600 94.4 5.82 0.77 0.95 1.00 88.3 6.57 0.79 0.98 1.00 82.0 7.43 0.82 0.99 1.00 75.5 8.42 0.85 1.00 1.00

67°F

2400 90.7 5.79 0.54 0.66 0.78 85.2 6.54 0.54 0.67 0.80 79.3 7.40 0.55 0.69 0.83 72.7 8.38 0.56 0.70 0.86

3000 96.0 5.83 0.57 0.70 0.85 89.9 6.58 0.57 0.72 0.88 83.5 7.45 0.58 0.74 0.91 76.7 8.43 0.59 0.77 0.95

3600 99.7 5.85 0.59 0.75 0.92 93.4 6.61 0.60 0.77 0.95 86.6 7.48 0.61 0.79 0.98 79.3 8.47 0.63 0.83 1.00

71°F

2400 95.0 5.82 0.41 0.53 0.64 89.5 6.58 0.41 0.53 0.65 83.3 7.44 0.4 0.54 0.66 76.7 8.43 0.40 0.55 0.68

3000 100.7 5.86 0.43 0.56 0.68 94.5 6.62 0.42 0.56 0.70 87.9 7.49 0.41 0.57 0.72 80.8 8.48 0.41 0.58 0.74

3600 104.7 5.89 0.43 0.58 0.72 98.1 6.65 0.43 0.59 0.74 91.2 7.52 0.43 0.60 0.77 83.8 8.52 0.43 0.62 0.80

7.5 TON HIGH EFFICIENCY KGA092H4B (1ST STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

65°F 75°F 85°F 95°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

2400 48.2 1.95 0.67 0.80 0.95 46.2 2.21 0.67 0.81 0.97 43.9 2.49 0.68 0.83 0.99 41.7 2.81 0.69 0.85 1.00

3000 50.8 1.96 0.71 0.88 1.00 48.6 2.21 0.72 0.90 1.00 46.2 2.49 0.74 0.92 1.00 43.7 2.81 0.76 0.96 1.00

3600 52.8 1.96 0.76 0.96 1.00 50.4 2.22 0.78 0.98 1.00 48.0 2.50 0.80 1.00 1.00 45.6 2.81 0.82 1.00 1.00

67°F

2400 51.1 1.96 0.53 0.65 0.76 48.9 2.21 0.53 0.65 0.78 46.6 2.49 0.54 0.66 0.79 44.1 2.81 0.54 0.67 0.81

3000 53.8 1.97 0.55 0.69 0.84 51.4 2.22 0.56 0.70 0.86 48.9 2.50 0.57 0.71 0.88 46.4 2.82 0.58 0.73 0.92

3600 55.7 1.97 0.59 0.74 0.91 53.3 2.22 0.60 0.76 0.95 50.6 2.50 0.61 0.78 0.97 47.7 2.82 0.61 0.80 1.00

71°F

2400 54.2 1.97 0.41 0.52 0.62 51.9 2.22 0.41 0.52 0.63 49.5 2.50 0.41 0.52 0.64 47.1 2.82 0.41 0.53 0.65

3000 56.7 1.98 0.41 0.54 0.67 54.3 2.23 0.42 0.55 0.68 51.7 2.51 0.42 0.56 0.69 48.9 2.82 0.42 0.57 0.71

3600 58.6 1.98 0.43 0.57 0.71 56.1 2.23 0.44 0.58 0.73 53.4 2.51 0.43 0.60 0.75 50.6 2.83 0.43 0.61 0.78

7.5 TON HIGH EFFICIENCY KGA092H4B (2ND STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

85°F 95°F 105°F 115°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

2400 87.9 4.98 0.68 0.83 0.99 83.4 5.62 0.69 0.85 1.00 78.4 6.36 0.71 0.88 1.00 73.1 7.23 0.73 0.92 1.00

3000 92.4 4.99 0.74 0.92 1.00 87.6 5.63 0.76 0.96 1.00 82.3 6.37 0.78 0.98 1.00 76.8 7.22 0.80 1.00 1.00

3600 96.0 5.00 0.80 1.00 1.00 91.2 5.64 0.82 1.00 1.00 86.4 6.37 0.85 1.00 1.00 81.2 7.22 0.88 1.00 1.00

67°F

2400 93.3 4.99 0.54 0.66 0.79 88.4 5.63 0.54 0.67 0.81 83.3 6.37 0.55 0.68 0.84 78.0 7.23 0.56 0.71 0.88

3000 97.9 5.00 0.57 0.71 0.88 93.0 5.64 0.58 0.73 0.91 87.2 6.37 0.59 0.75 0.95 81.1 7.22 0.59 0.78 0.99

3600 101.4 5.01 0.61 0.77 0.97 95.6 5.64 0.61 0.79 1.00 90.0 6.38 0.62 0.82 1.00 83.6 7.22 0.64 0.86 1.00

71°F

2400 99.1 5.00 0.41 0.52 0.64 94.0 5.64 0.41 0.53 0.65 88.6 6.37 0.4 0.54 0.66 82.7 7.22 0.41 0.55 0.68

3000 103.3 5.01 0.42 0.56 0.69 98.0 5.65 0.42 0.57 0.71 92.2 6.38 0.42 0.58 0.73 86.0 7.23 0.43 0.59 0.75

3600 106.9 5.02 0.44 0.60 0.75 101.2 5.66 0.43 0.60 0.77 95.0 6.38 0.44 0.61 0.8 88.3 7.22 0.44 0.63 0.84

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 19

RATINGS

NOTE − For Temperatures and Capacities not shown in tables, see bulletin − Cooling Unit Rating Table Correction Factor Data in Miscellaneous Engineering Data section.

8.5 TON STANDARD EFFICIENCY KGB102S4B (1ST STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

65°F 75°F 85°F 95°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

2720 57.3 2.49 0.63 0.76 0.91 53.8 2.78 0.63 0.77 0.93 50.0 3.10 0.63 0.79 0.96 46.1 3.49 0.63 0.81 0.99

3400 61.1 2.51 0.67 0.83 0.99 57.4 2.79 0.67 0.85 1.00 53.3 3.11 0.68 0.87 1.00 49.0 3.49 0.69 0.90 1.00

4080 63.9 2.51 0.71 0.90 1.00 59.9 2.79 0.72 0.92 1.00 55.7 3.12 0.73 0.95 1.00 51.1 3.50 0.75 0.98 1.00

67°F

2720 60.9 2.50 0.50 0.61 0.73 57.2 2.79 0.50 0.61 0.73 53.4 3.11 0.49 0.61 0.75 49.3 3.49 0.49 0.62 0.76

3400 64.9 2.50 0.53 0.65 0.79 61.0 2.79 0.52 0.65 0.81 56.8 3.12 0.52 0.66 0.83 52.4 3.50 0.52 0.67 0.86

4080 67.8 2.52 0.55 0.69 0.86 63.7 2.81 0.55 0.69 0.88 59.4 3.13 0.55 0.71 0.91 54.7 3.51 0.55 0.73 0.94

71°F

2720 64.2 2.51 0.39 0.49 0.59 60.5 2.80 0.38 0.49 0.59 56.5 3.12 0.37 0.48 0.59 52.4 3.51 0.35 0.48 0.60

3400 68.4 2.52 0.40 0.52 0.63 64.4 2.80 0.39 0.52 0.63 60.1 3.13 0.38 0.51 0.64 55.6 3.52 0.37 0.51 0.65

4080 71.4 2.53 0.41 0.54 0.66 67.3 2.82 0.41 0.54 0.67 62.8 3.14 0.40 0.54 0.69 58.0 3.52 0.39 0.54 0.70

8.5 TON STANDARD EFFICIENCY KGB102S4B (2ND STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

85°F 95°F 105°F 115°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

2720 95.0 6.52 0.67 0.82 0.96 87.4 7.34 0.67 0.83 0.99 79.3 8.28 0.68 0.85 1.00 70.8 9.42 0.69 0.88 1.00

3400 101.3 6.54 0.72 0.89 1.00 93.1 7.35 0.73 0.91 1.00 84.6 8.30 0.74 0.94 1.00 75.4 9.43 0.76 0.98 1.00

4080 105.8 6.55 0.77 0.96 1.00 97.1 7.37 0.78 0.98 1.00 88.4 8.31 0.80 1.00 1.00 79.8 9.44 0.83 1.00 1.00

67°F

2720 101.4 6.54 0.52 0.65 0.78 93.5 7.34 0.52 0.66 0.80 85.3 8.30 0.50 0.66 0.82 76.5 9.43 0.50 0.67 0.84

3400 108.0 6.56 0.55 0.70 0.85 99.6 7.37 0.55 0.71 0.87 90.8 8.31 0.55 0.72 0.90 81.5 9.43 0.54 0.74 0.94

4080 112.7 6.57 0.58 0.75 0.92 103.9 7.37 0.58 0.76 0.95 94.8 8.33 0.58 0.78 0.98 85.1 9.46 0.59 0.81 1.00

71°F

2720 107.3 6.56 0.38 0.52 0.63 99.5 7.37 0.37 0.51 0.64 91.0 8.31 0.35 0.50 0.64 82.1 9.45 0.33 0.49 0.65

3400 114.3 6.58 0.40 0.54 0.68 105.7 7.39 0.39 0.54 0.69 96.6 8.34 0.37 0.54 0.70 87.2 9.46 0.35 0.54 0.72

4080 119.3 6.60 0.41 0.58 0.73 110.2 7.40 0.40 0.58 0.74 100.8 8.36 0.39 0.58 0.76 90.9 9.49 0.38 0.59 0.78

8.5 TON HIGH EFFICIENCY KGA102H4B (1ST STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

65°F 75°F 85°F 95°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

2720 53.6 2.17 0.61 0.76 0.95 50.7 2.45 0.62 0.78 0.98 47.7 2.77 0.62 0.8 1.00 44.6 3.13 0.63 0.83 1.00

3400 56.5 2.18 0.66 0.87 1.00 53.5 2.46 0.66 0.89 1.00 50.3 2.78 0.68 0.93 1.00 47.1 3.13 0.70 0.97 1.00

4080 58.7 2.18 0.72 0.97 1.00 55.6 2.47 0.74 1.00 1.00 52.4 2.78 0.76 1.00 1.00 49.4 3.14 0.78 1.00 1.00

67°F

2720 57.0 2.18 0.48 0.59 0.71 54.1 2.46 0.49 0.60 0.73 51.0 2.78 0.48 0.61 0.75 47.7 3.14 0.48 0.61 0.78

3400 60.0 2.19 0.51 0.64 0.82 56.8 2.47 0.51 0.64 0.84 53.6 2.78 0.52 0.66 0.88 50.1 3.14 0.52 0.67 0.92

4080 62.2 2.19 0.54 0.69 0.93 58.9 2.48 0.55 0.71 0.96 55.5 2.79 0.55 0.73 0.99 51.8 3.14 0.55 0.76 1.00

71°F

2720 60.4 2.19 0.37 0.47 0.57 57.5 2.47 0.37 0.48 0.58 54.2 2.78 0.36 0.47 0.59 50.8 3.14 0.35 0.47 0.59

3400 63.5 2.20 0.38 0.50 0.62 60.2 2.48 0.38 0.51 0.63 56.8 2.79 0.37 0.51 0.64 53.3 3.15 0.37 0.52 0.65

4080 65.6 2.20 0.39 0.53 0.67 62.3 2.49 0.40 0.54 0.68 58.9 2.80 0.39 0.54 0.70 55.0 3.15 0.39 0.55 0.73

8.5 TON HIGH EFFICIENCY KGA102H4B (2ND STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

85°F 95°F 105°F 115°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

2720 98.9 5.54 0.70 0.85 1.00 92.5 6.27 0.71 0.87 1.00 85.7 7.10 0.71 0.90 1.00 78.6 8.09 0.73 0.94 1.00

3400 104.2 5.56 0.76 0.95 1.00 97.5 6.27 0.77 0.98 1.00 90.4 7.11 0.79 1.00 1.00 83.6 8.08 0.82 1.00 1.00

4080 108.6 5.56 0.82 1.00 1.00 102.3 6.28 0.84 1.00 1.00 95.9 7.12 0.87 1.00 1.00 88.9 8.08 0.91 1.00 1.00

67°F

2720 105.6 5.56 0.53 0.67 0.81 98.9 6.28 0.53 0.68 0.83 91.8 7.11 0.54 0.69 0.87 84.4 8.08 0.55 0.71 0.90

3400 110.9 5.57 0.58 0.74 0.91 103.8 6.29 0.59 0.75 0.94 96.4 7.12 0.59 0.77 0.97 88.5 8.08 0.59 0.79 1.00

4080 114.8 5.58 0.61 0.80 0.99 107.2 6.30 0.62 0.82 1.00 99.6 7.12 0.63 0.85 1.00 91.5 8.08 0.63 0.88 1.00

71°F

2720 112.1 5.57 0.40 0.53 0.65 105.2 6.29 0.39 0.53 0.66 98.1 7.12 0.38 0.53 0.67 90.3 8.08 0.38 0.54 0.69

3400 117.6 5.59 0.42 0.57 0.72 110.4 6.30 0.41 0.58 0.73 102.7 7.12 0.41 0.58 0.75 94.3 8.08 0.40 0.59 0.77

4080 121.7 5.60 0.44 0.61 0.77 113.9 6.31 0.43 0.61 0.79 105.9 7.13 0.42 0.62 0.83 97.4 8.08 0.43 0.63 0.86

K-Series Packaged Gas / Electric 7.5 to 12.5 Ton / Page 20

RATINGS

NOTE − For Temperatures and Capacities not shown in tables, see bulletin − Cooling Unit Rating Table Correction Factor Data in Miscellaneous Engineering Data section.

10 TON STANDARD EFFICIENCY KGB120S4B (1ST STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

65°F 75°F 85°F 95°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

3200 62.2 2.85 0.66 0.80 0.94 58.1 3.21 0.66 0.81 0.96 53.6 3.62 0.66 0.82 0.98 49.0 4.09 0.66 0.84 1.00

4000 66.2 2.86 0.71 0.87 1.00 61.8 3.23 0.71 0.88 1.00 57.2 3.65 0.71 0.90 1.00 52.4 4.11 0.73 0.93 1.00

4800 69.2 2.89 0.75 0.94 1.00 64.7 3.24 0.76 0.96 1.00 59.9 3.66 0.78 0.98 1.00 54.9 4.14 0.79 1.00 1.00

67°F

3200 66.8 2.87 0.53 0.64 0.76 62.4 3.23 0.52 0.64 0.77 57.9 3.65 0.51 0.64 0.78 53.1 4.12 0.50 0.64 0.80

4000 70.8 2.88 0.55 0.69 0.83 66.2 3.25 0.55 0.69 0.85 61.3 3.67 0.54 0.69 0.86 56.3 4.15 0.54 0.70 0.89

4800 73.7 2.89 0.58 0.73 0.90 68.8 3.27 0.57 0.74 0.92 63.9 3.69 0.58 0.75 0.94 58.7 4.17 0.57 0.77 0.97

71°F

3200 71.3 2.89 0.41 0.52 0.62 66.9 3.26 0.39 0.51 0.62 62.1 3.68 0.37 0.50 0.62 57.1 4.16 0.36 0.49 0.63

4000 75.4 2.90 0.42 0.55 0.67 70.7 3.28 0.40 0.54 0.67 65.7 3.70 0.39 0.54 0.68 60.3 4.18 0.38 0.53 0.68

4800 78.4 2.92 0.43 0.58 0.71 73.4 3.29 0.42 0.57 0.72 68.2 3.72 0.41 0.57 0.73 62.8 4.20 0.40 0.57 0.75

10 TON STANDARD EFFICIENCY KGB120S4B (2ND STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

85°F 95°F 105°F 115°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

3200 114.0 7.38 0.68 0.83 0.98 104.2 8.32 0.68 0.85 1.00 93.9 9.38 0.68 0.87 1.00 83.2 10.57 0.69 0.91 1.00

4000 121.0 7.42 0.73 0.92 1.00 111.1 8.38 0.74 0.94 1.00 100.5 9.44 0.76 0.97 1.00 89.4 10.64 0.78 1.00 1.00

4800 126.9 7.46 0.79 0.99 1.00 116.4 8.42 0.81 1.00 1.00 106.5 9.50 0.83 1.00 1.00 96.0 10.71 0.86 1.00 1.00

67°F

3200 123.1 7.43 0.52 0.66 0.79 113.0 8.39 0.51 0.66 0.81 102.5 9.46 0.50 0.67 0.83 91.5 10.66 0.49 0.67 0.87

4000 130.6 7.48 0.55 0.71 0.88 120.0 8.44 0.55 0.72 0.90 108.8 9.52 0.55 0.74 0.93 97.0 10.73 0.55 0.76 0.98

4800 136.0 7.51 0.59 0.77 0.95 124.9 8.48 0.59 0.78 0.98 113.3 9.56 0.59 0.81 1.00 101.2 10.77 0.60 0.84 1.00

71°F

3200 131.9 7.49 0.38 0.51 0.64 121.7 8.45 0.36 0.50 0.64 110.7 9.53 0.34 0.50 0.65 99.4 10.75 0.32 0.49 0.65

4000 139.7 7.54 0.40 0.55 0.69 128.7 8.50 0.39 0.55 0.70 117.5 9.60 0.37 0.55 0.72 105.4 10.82 0.35 0.55 0.74

4800 145.4 7.58 0.42 0.58 0.75 134.0 8.56 0.41 0.59 0.76 122.3 9.65 0.39 0.59 0.78 109.7 10.88 0.38 0.60 0.82

10 TON HIGH EFFICIENCY KGA120H4B (1ST STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

65°F 75°F 85°F 95°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

3200 67.0 2.76 0.66 0.80 0.95 64.0 3.14 0.67 0.81 0.97 60.6 3.55 0.68 0.83 0.99 57.1 4.01 0.68 0.85 1.00

4000 70.5 2.80 0.71 0.88 1.00 67.2 3.17 0.72 0.90 1.00 63.7 3.58 0.73 0.93 1.00 60.1 4.05 0.75 0.96 1.00

4800 73.1 2.82 0.77 0.96 1.00 69.8 3.19 0.78 0.98 1.00 66.1 3.60 0.80 1.00 1.00 62.6 4.07 0.82 1.00 1.00

67°F

3200 71.0 2.80 0.53 0.64 0.76 67.8 3.17 0.53 0.65 0.78 64.3 3.59 0.53 0.66 0.79 60.8 4.05 0.53 0.66 0.81

4000 74.7 2.83 0.56 0.69 0.84 71.2 3.21 0.56 0.70 0.86 67.5 3.62 0.57 0.71 0.89 63.8 4.08 0.57 0.73 0.91

4800 77.3 2.86 0.58 0.74 0.92 73.8 3.23 0.59 0.76 0.95 69.9 3.64 0.6 0.77 0.98 65.9 4.11 0.61 0.80 1.00

71°F

3200 75.3 2.84 0.41 0.52 0.62 71.9 3.21 0.40 0.52 0.63 68.3 3.63 0.40 0.51 0.64 64.6 4.09 0.39 0.52 0.65

4000 78.7 2.87 0.42 0.54 0.67 75.2 3.25 0.41 0.55 0.68 71.3 3.66 0.42 0.54 0.69 67.5 4.13 0.41 0.56 0.70

4800 81.3 2.90 0.43 0.57 0.71 77.6 3.28 0.43 0.58 0.73 73.8 3.69 0.43 0.59 0.75 69.6 4.15 0.43 0.60 0.77

10 TON HIGH EFFICIENCY KGA120H4B (2ND STAGE) - CONSTANT AIR VOLUME

Entering

Wet

Bulb

Temper-

ature

Total

Air

Volume

Outdoor Air Temperature Entering Outdoor Coil

85°F 95°F 105°F 115°F

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Total

Cool

Cap.

Comp.

Motor

Input

Sensible To Total

Ratio (S/T)

Dry Bulb Dry Bulb Dry Bulb Dry Bulb

cfm kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F kBtuh kW 75°F 80°F 85°F

63°F

3200 118.9 7.05 0.68 0.84 1.00 112.1 7.96 0.69 0.86 1.00 104.6 9.00 0.71 0.89 1.00 96.6 10.17 0.72 0.93 1.00

4000 124.9 7.11 0.74 0.94 1.00 117.7 8.03 0.76 0.97 1.00 110.0 9.05 0.78 1.00 1.00 102.2 10.23 0.80 1.00 1.00

4800 129.9 7.17 0.80 1.00 1.00 123.0 8.08 0.83 1.00 1.00 115.7 9.12 0.86 1.00 1.00 108.0 10.30 0.90 1.00 1.00

67°F

3200 126.5 7.12 0.53 0.66 0.80 119.2 8.03 0.53 0.67 0.82 111.4 9.07 0.53 0.68 0.85 103.4 10.25 0.54 0.70 0.89

4000 132.6 7.19 0.57 0.72 0.90 124.8 8.10 0.57 0.73 0.93 116.7 9.13 0.58 0.75 0.97 108.0 10.30 0.59 0.78 1.00